Addressable RGB COB LED Strip

Addressable COB LED strip lights represent a major leap forward in LED strip technology, with the unique ability to independently control each LED unit or group of LEDs, creating unlimited possibilities for customization and creativity.

- High-density chip linear arrangement, integrated package, uniform light color, no spots

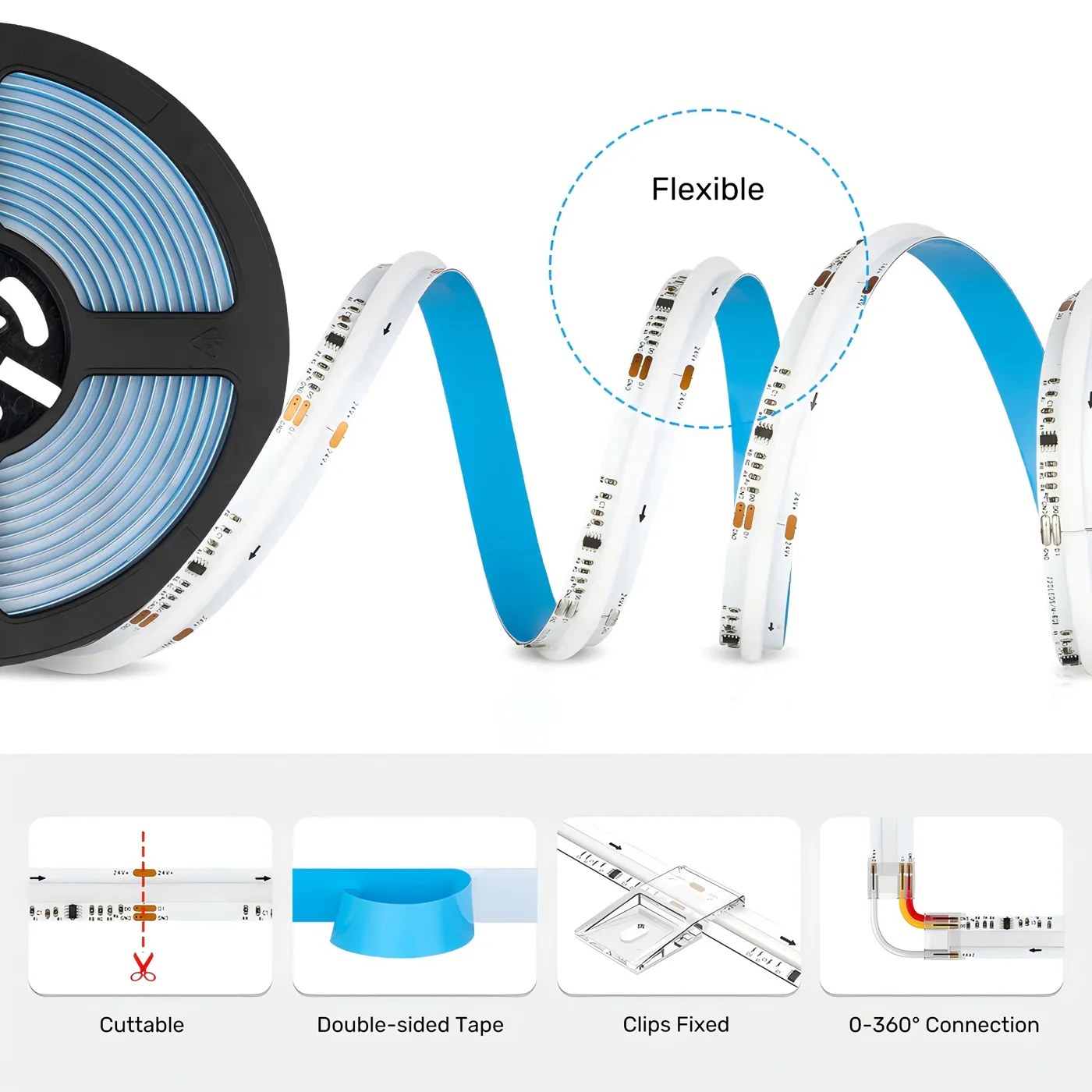

- High thermal conductivity, flexible circuit board design, bendable, easy to install

- LED chip directly mounted on FPC, addressable LED strip’s light angle up to 180 degrees

- DC12V/24V constant voltage design, safe low voltage, small voltage drop, standard cascade length of 5 meters

- Highly adhesive, thermally conductive double-sided adhesive backing for easy installation and long-lasting adhesion

- LED sources are energy-saving and environmentally friendly and meet ROHS environmental standards

- Can to be OEM/ODM and customizable

Addressable RGB COB LED Strip

- High-density chip linear arrangement, integrated package, uniform light color, no spots

- High thermal conductivity, flexible circuit board design, bendable, easy to install

- LED chip directly mounted on FPC, light angle up to 180 degrees

- DC12V/24V constant voltage design, safe low voltage, small voltage drop, standard cascade length of 5 meters

- Highly adhesive, thermally conductive double-sided adhesive backing for easy installation and long-lasting adhesion

- LED sources are energy-saving and environmentally friendly and meet ROHS environmental standards

Addressable RGB RGBW COB LED Strip Specifications

RGB RGBW RGBCCT COB LED Strip Specifications

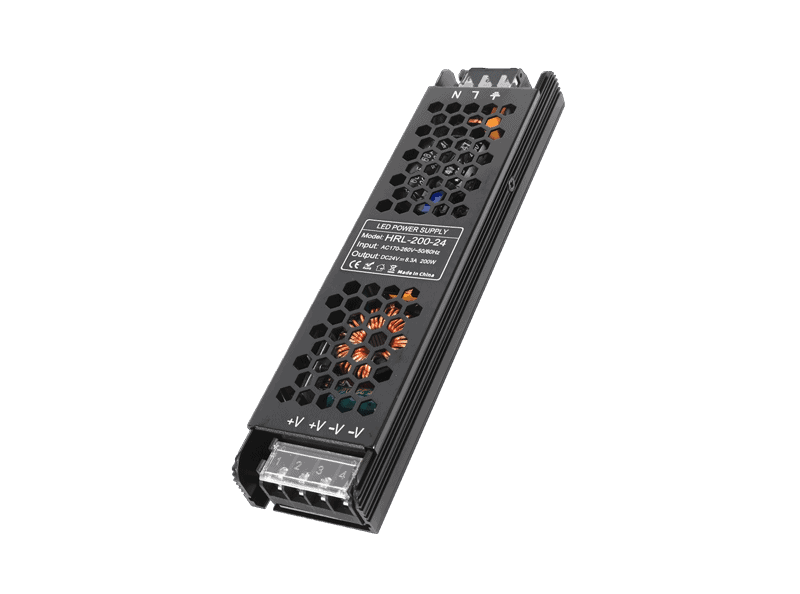

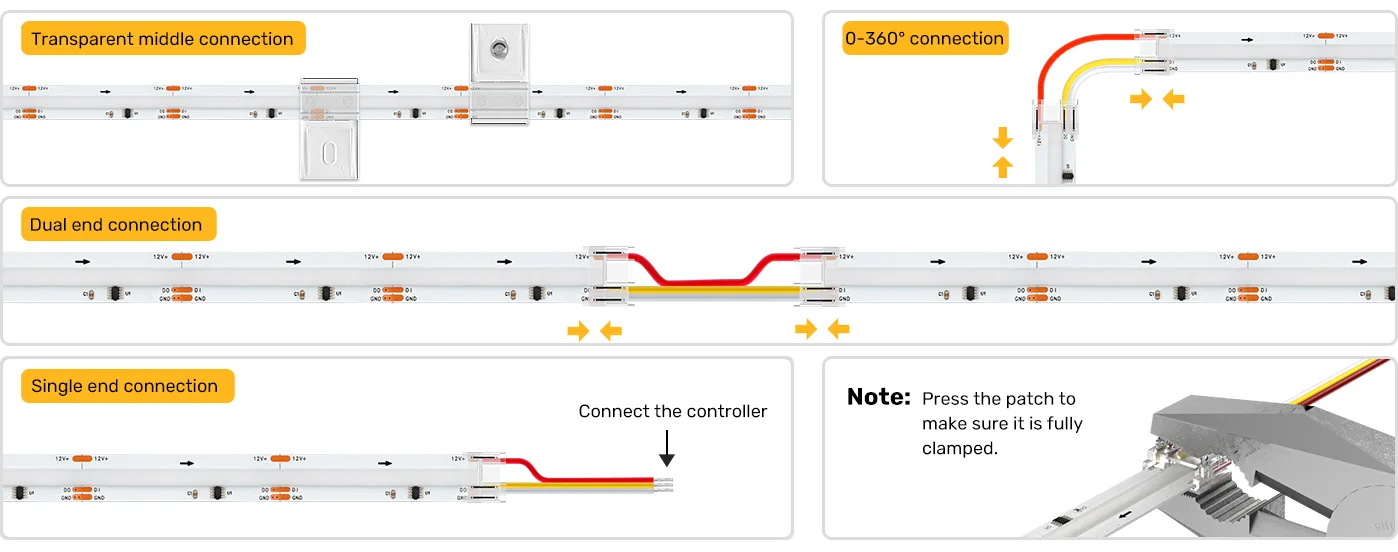

Related Addressable COB LED Strip Accessories

Dot-Free Dynamic RGB COB Light Strip

Features

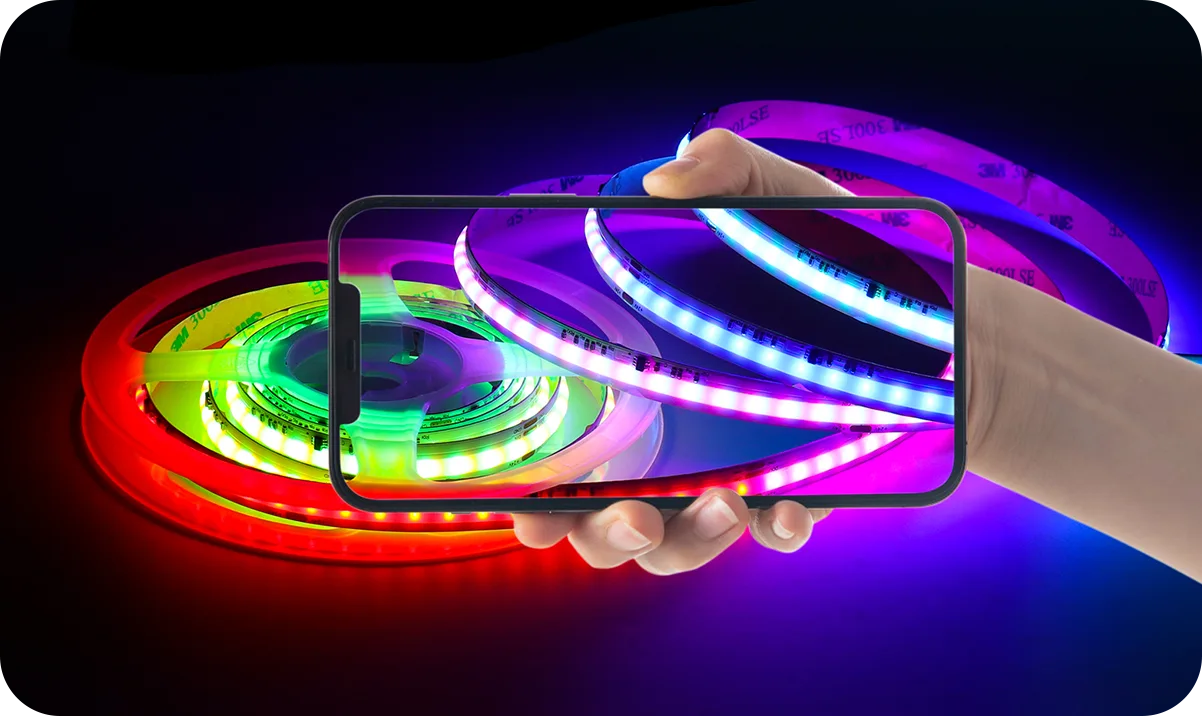

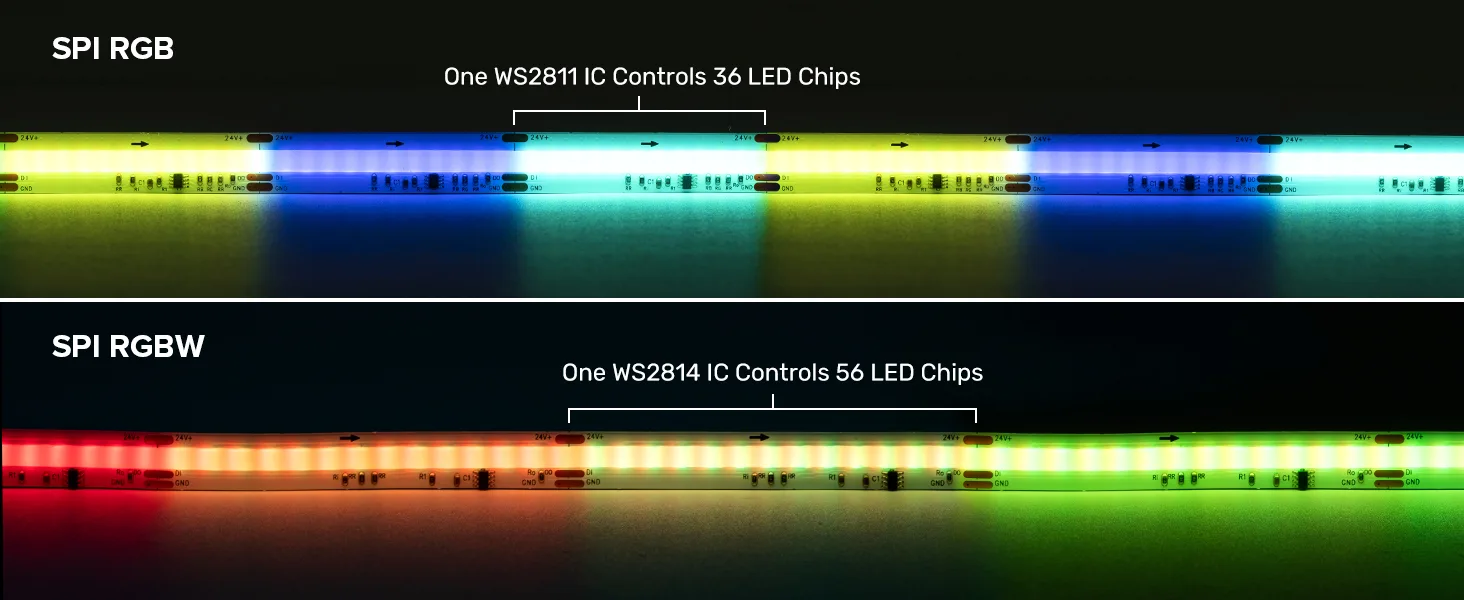

Multiple Colors Smart RGBIC COB LED Strip Available for Selection:

RGBIC COB LED strip light is a higher level of RGB COB strip by adding external ICs WS2811, WS2814, and WS2818 to achieve magic dream colors. Like the RGB and RGBW strips, it also has over 16 million colors to choose from. This addressable RGB COB LED strip is the same as the RGB and RGBW strips, with over 16 million colors controlled by an SPI controller. The RGBIC COB LED strip with an external SPI IC chip can control each group of COB LEDs individually and display light effects such as rainbows, running water, hoses, and more.

180° Wide-angle Irradiation:

180° wide-angle irradiation, more uniform and softer light.

No Dark Spots Uniform Linear Lighting:

Dotless/no spot/uniform linear lighting.

COB VS SMD:

RGBIC COB Strip Light Details:

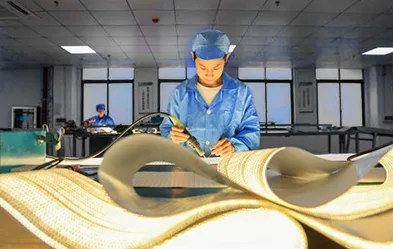

Our Factory

- Factory located in smart manufacturing industry city, Shenzhen.

- A team deeply involved in the industry since year 2010.

- Equipped with complete optical testing instruments.

- Products are UL listed, 100% aged and tested.

- Proficient in OEM & ODM products design, develop and support.

- Deeply cultivate signage and linear led light products more than 10 years.

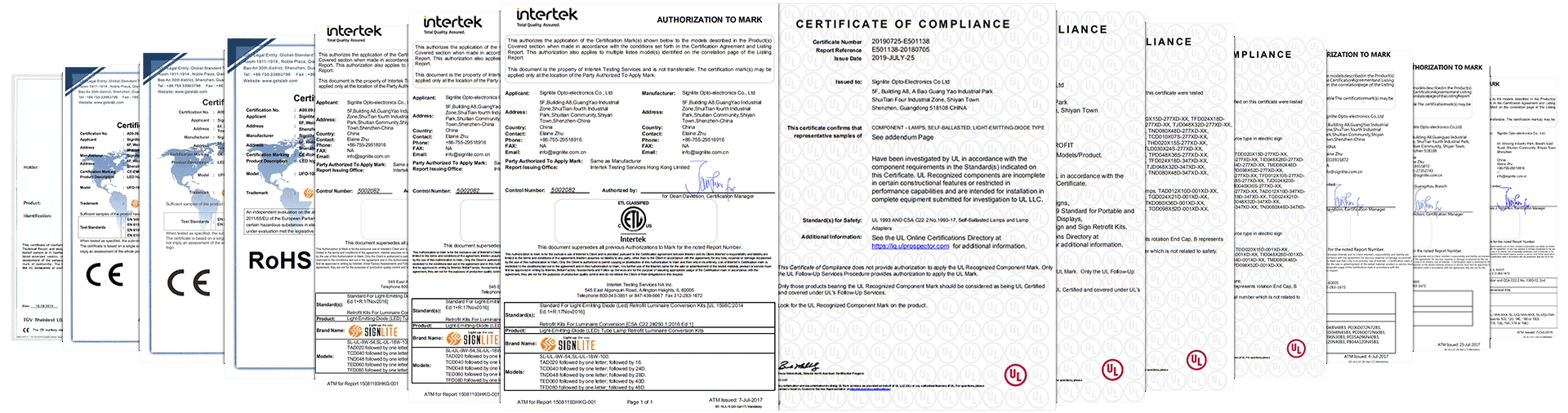

Product Certificates

We got UL, ETL, CE, ROHS certifiacted to meet different region standards.

Production Quality Control Process

We have developed a complete set of production quality control systems, from raw materials to SMT, and even the subsequent assembly, testing, packaging, and shipment of each link are the implementation of strict quality control processes to ensure that our colors COB LED strip can be perfectly delivered to customers.

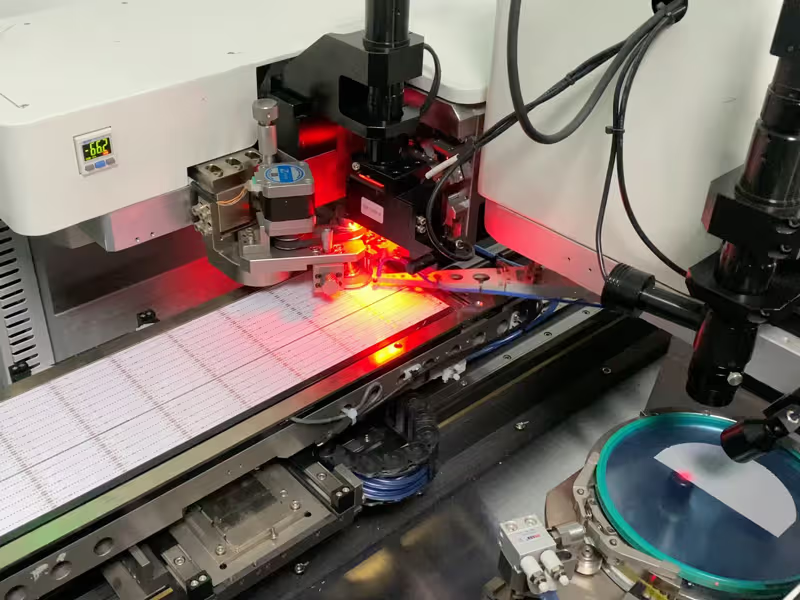

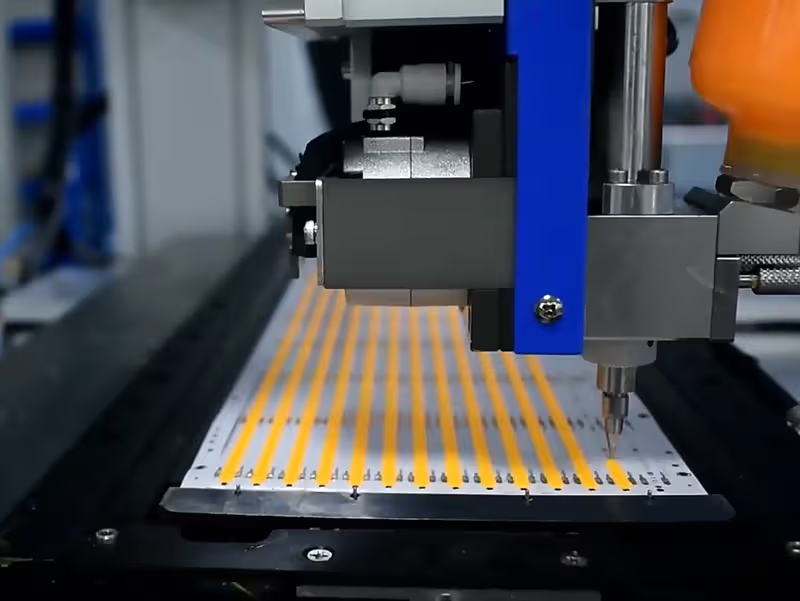

SMT Process

Use high speed automated SMT machine to paste LED chips, IC chips, resistors to make sure all components are in the right place.

Automated Dispensing

Use multi-nozzle automated dispensing equipment to evenly coat the formulated phosphor on the COB tape light.

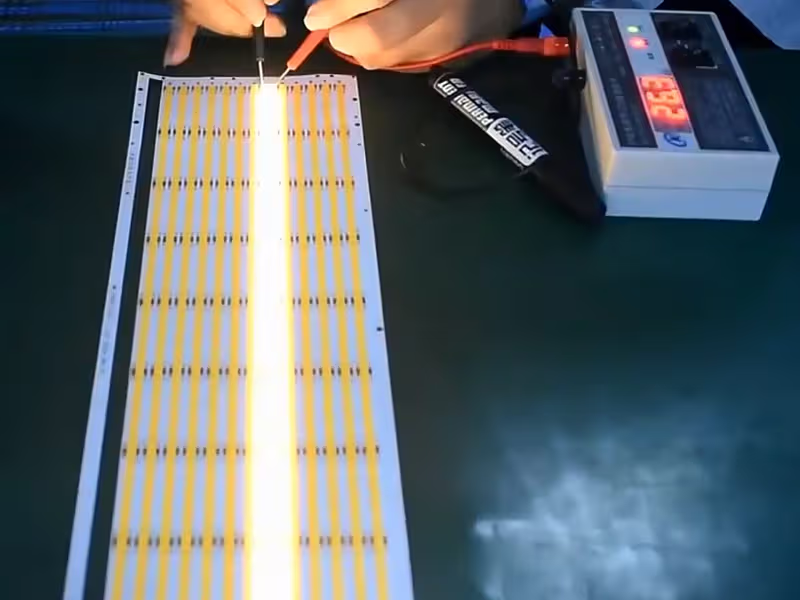

100% QC Inspection

After reflow soldering and high-temperature ovens, the COB strip needs to be tested again at 100% to ensure no defective LEDs.

Bending Test

The purpose of the bend test is to test whether the strip light can withstand a certain amount of bending without affecting its performance or life.

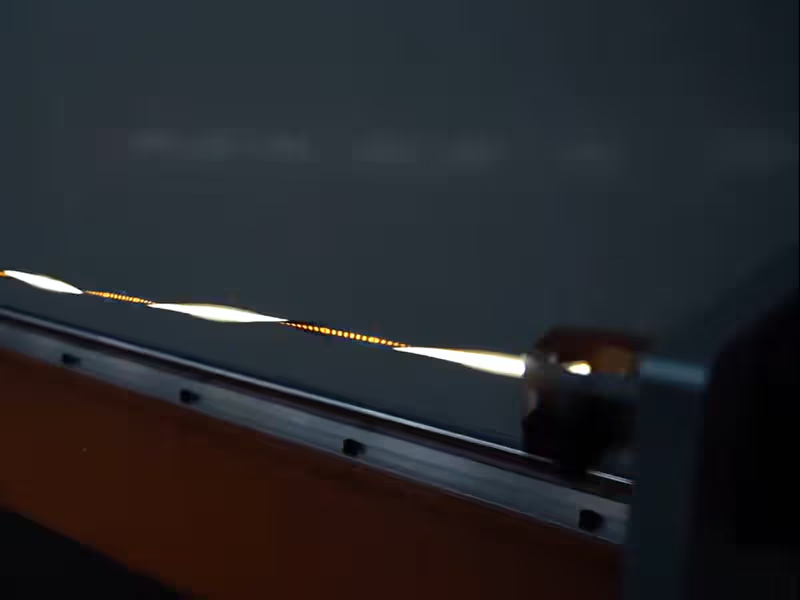

Twist Test

The LED strip twist test is mainly used to test the bending resistance and life span of LED strip lights by simulating the deformation of light strips in long-term use.

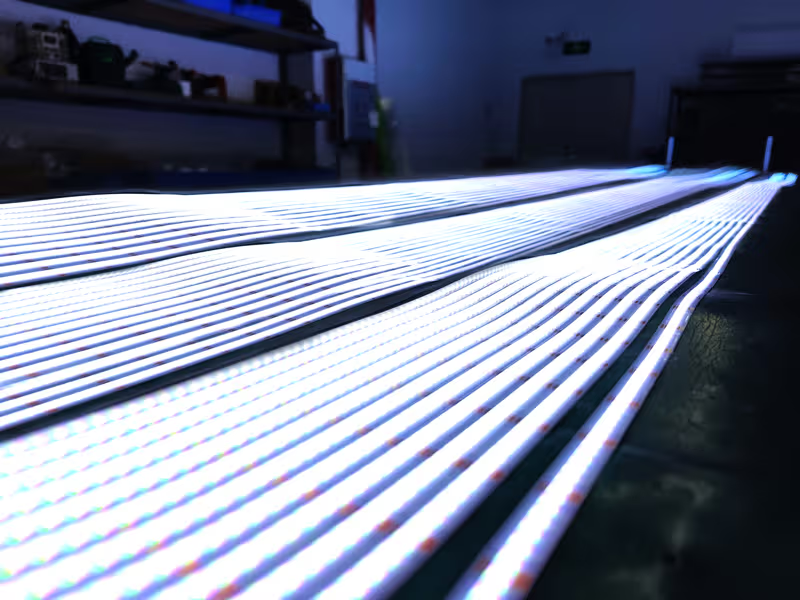

Aging Test

Aging for 8 hours, ensure each LED runs in good condition. And for the COB LED strip, there will be a slap test to check the stability.

Pasted With 3M Tape

All LED strips pasted with 3M adhesive tape and rolled reels to ensure easy transportation and installation.

Final Product Test

Our quality inspectors conduct a final inspection of each roll of LED strip to ensure the consistency of the light color and the good appearance of the strip.

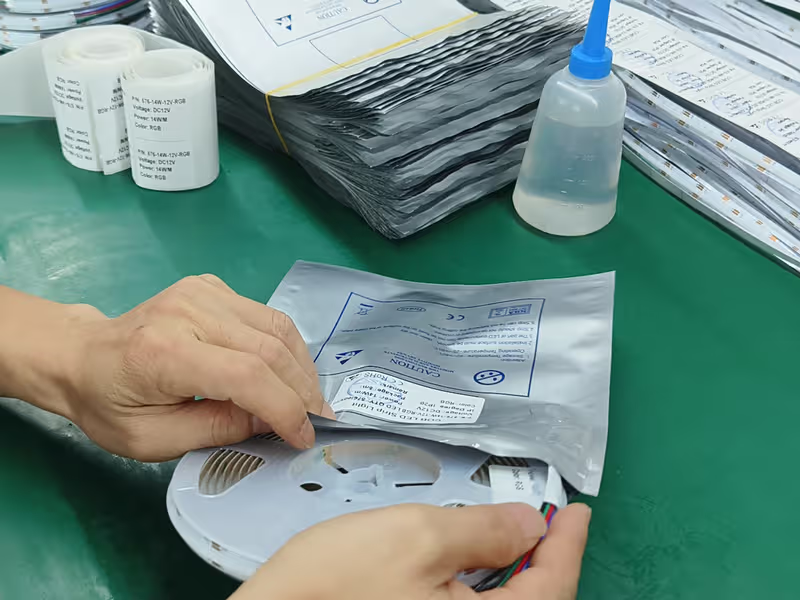

Packaging

Finally, the labels are pasted on the reels and anti-static aluminum foil bags, and the COB strip lights are ready to be boxed and shipped.

IP65 Waterproof Drop Process

This type of waterproof COB strip light add a silicone layer on top of the LEDs basically fully sealing off the top end of the LED

strip, including all the solder joints and contact points. It can provide protection from water, humidity, and dust.

Before

Dropping gel

After

Applications