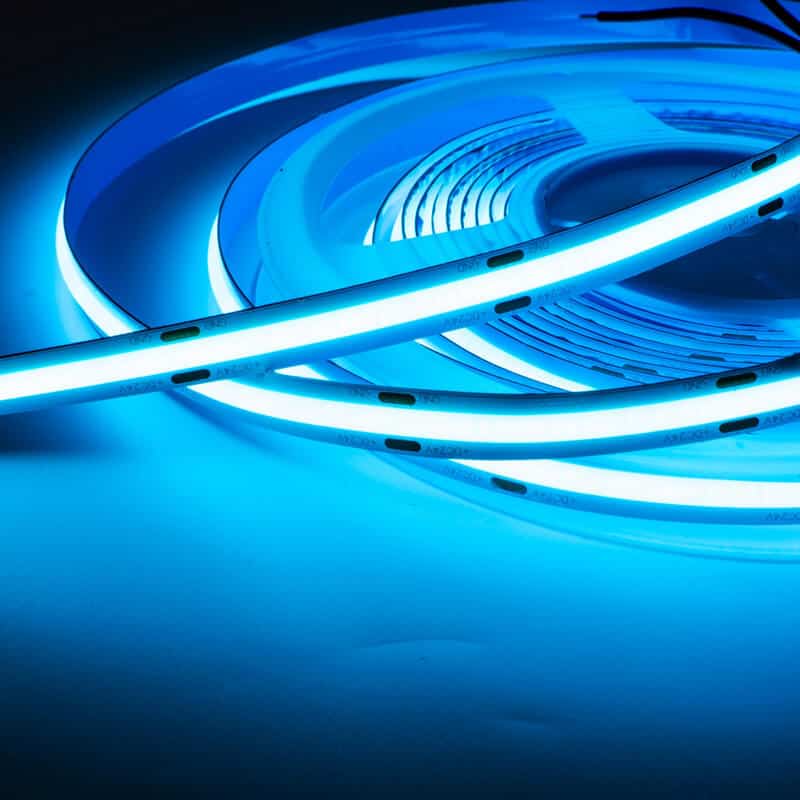

In recent years, COB (Chip On Board) lighting technology has become more well-known as a high-performance and energy-efficient lighting option. COB strips have a high output density because they are constructed of numerous small LED chips organized in a matrix on a single board.

However, it is vital to determine whether COB strips are secure. We will examine COB strip safety in this article and give you all the relevant details.

What is COB strip lighting?

As was already said, COB strip lighting is a lighting solution that makes use of the most recent LED technology. COB strips are more compact than conventional LED strip lighting, yet they are more potent.

Each COB strip, in contrast to conventional LED strips, has several tiny LED chips installed directly on a circuit board. COB strip lights are perfect for a variety of applications since they are compact, create a focused beam of light, and require less installation space.

COB Strips Safety Concerns

The fact that COB strips use low DC voltage, frequently 12V or 24V, as opposed to the high-voltage AC sources used by traditional lighting, is one of the biggest safety concerns with them. Although DC voltage is thought to be safer than AC voltage, improper installation and use can still provide significant safety risks.

First and foremost, it’s crucial to confirm that COB strips are rated at the appropriate voltage for the application. The LEDs could burn out or even catch fire if the strip is overloaded with voltage.

Second, it’s crucial to use the COB strip with the proper wiring and connectors installed. Electrical risks, including fires, electric shocks, or damage to the light strips, might result from unintentional short circuits or improperly installed wiring.

Third, even though COB strip lighting produces less heat than conventional lighting options, it is still important to take into account the cooling options available.

To avoid the LED chip overheating and shortening the strip lighting’s overall lifespan, the proper heat dissipation technique must be used. The LED chips may malfunction as a result of insufficient heat dissipation, which exposes the circuit board to dangers and risks.

How to securely utilize COB strip lighting

There are certain crucial steps to take in order to ensure the safe and successful use of COB strip lighting:

1. Consistently utilize power supplies or transformers that have the recommended voltage rating from the manufacturer.

2. When connecting your COB strip to preexisting electrical systems, use the correct wire, connectors, and cable covers.

3. Make sure the system is properly grounded by attaching a grounding wire or utilizing a grounded outlet to get rid of any electrical interference or static electricity.

4. To guarantee safe operating temperatures and prevent overheating, select the proper heat dissipation strategies.

3. Ascertain that the installation site is appropriate and free from any potential dangers, such as water, moisture, or vibrations.

Conclusion

COB strip lighting solutions are secure to use when handled and placed properly. Understanding and adhering to the manufacturer’s instructions for suitable voltage, wiring, grounding, and heat dissipation techniques is crucial.

In conclusion, COB strip lighting, which offers both energy efficiency and concentrated light output, is a great investment for many lighting applications. It is an excellent complement to your home or office lighting system when used carefully and responsibly.