Why use double-sided tape to secure LED strips?

LED strip light is a common decorative fixture that has soft light and a variety of color options to add to the ambiance of a room. When installing the lamp belt, it is very important to choose the right adhesive fixation, so as to ensure that the lamp belt is firmly stuck to the target surface and avoid falling or loosening.

Now LED strip with installation is very easy, only need to tear lamp tape behind the tape, bring sticky surface can be installed in the lamp. This process does not need to be fixed again, convenient and fast, and can quickly install this to the effect of decoration.

Low-quality tape can’t firmly grip the strips, causing them to fall off after working for a short time. This can be very frustrating for you, as you have to keep re-passing LED strips at a high cost. If the product affects the use of the product because of the quality of the tape, this is not worth the loss. The falling off of the tape caused customers to lose confidence in the product. I believe this blow to the product is very big.

Why choose 3M double-sided tape?

The 3M mounting tape is a premium product for all kinds of projects, and a product we love recommending for LED strip light installations. The 3M tape performs especially well under harsh or changing temperatures, so if you have environmental concerns for your LED strip light project, the 3M tape might be the better choice.

The consequences of using inferior tape:

The lower cost of the lamp belt on the market hides the potential risks and dangers that are ignored. Due to the use of inferior double-sided tape and manufacturing process, the lamp belt has a short service life and needs to be replaced frequently. This not only reduces the cost effectiveness of the initial purchase, but also increases the cost after sale over time.

1. The adhesive force is insufficient, and the adhesive properties of the lamp belt cannot be effectively maintained.

2. The adhesive material is poor, and the high temperature when the lamp belt is working causes the adhesive to melt, resulting in the lamp belt falling off.

3. The installation is not firm, the shock-proof dynamic effect is poor, resulting in the lamp strip falling off.

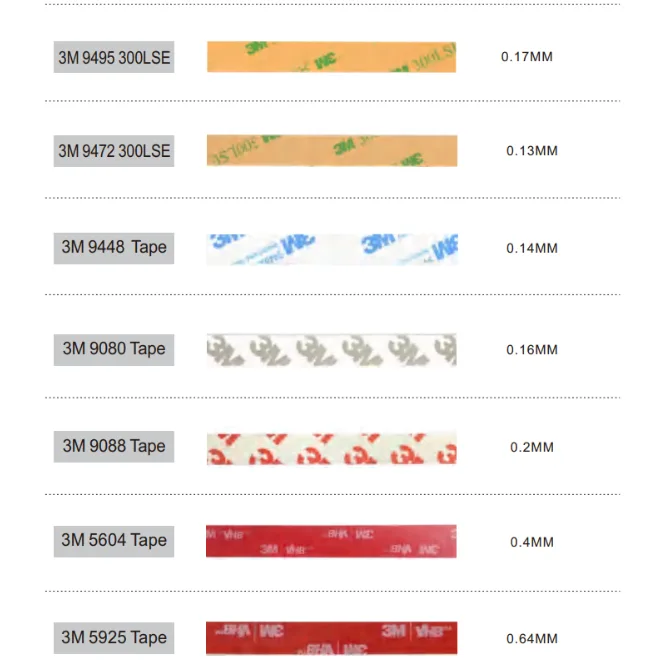

What types of double-sided tape are there?

LED strips have become an increasingly popular lighting solution for both commercial and residential applications due to their energy efficiency and versatility. However, to ensure their proper functioning, it is essential to choose the right adhesive tapes to attach them to the desired surface. With the multitude of adhesive tapes available on the market, it can be overwhelming to determine which one is suitable for your project. In this article, we will discuss some of the most popular adhesive tapes used for LED strips and their specific features to help you make an informed decision.

Let’s take a look at what types of adhesive paper are there? How do we choose the right adhesive paper when designing the led strip products.

3M 200MP

3M™ Adhesive 200MP is a popular choice for graphic attachment and membrane switch applications because it has excellent quality, consistency and durability. In addition, as a result of 3M’s innovative, proprietary process, 3M adhesive 200MP also offers the following excellent performance characteristics.

Clarity (virtually free of vapor inclusions that are commonly found in adhesives produced by the traditional solvent coating technique).

Excellent high temperature performance as well as excellent shear strength (that minimizes edge lifting and slippage of parts).

Excellent resistance to harsh environments; this adhesive can withstand splashes of organic solvents, weak acids and bases and salt water, cleaning solutions, germicidals, disinfectants, oils, etc. In addition, it performs well after exposure to humidity and hot/cold cycles.

Provides some initial repositionability when bonding to plastic parts (not metal) which allows graphic parts to be lifted and repositioned if initial alignment is incorrect.

Finally, this adhesive family is provided with a variety of liner configurations to help ensure excellent process flexibility.

3M 300MP

3M™ Double Coated Tapes with 3M™ Adhesive 300MP provide high adhesion to a wide variety of materials, including plastics and foams and has a thin nonwoven carrier for dimensional stability and improved handling.

- Excellent adhesion to open cell foams.

- Consistent adhesive performance to many plastics.

- Polycoated liner for ease of handling.

More information, you can download this PDF.

3M 9080

3M™ Double Coated Tape 9080HL is a Double Coated Non-woven Tape with Polycoated Paper Liner. High tack adhesive suitable for high temperature and bonding to LSE materials.

3M™ Double Coated Tape 9080HL is specially formulated for low- and high-speed splicing applications, followed if required by heat-setting or other oven-based processing conditions. The tape makes an excellent bond to paper and board, and many plastic film substrates including Polyethylene, Polypropylene and PVC.

- General purpose, double sided tissue tape

- High tack, high initial adhesion

- Pressure sensitive adhesive

- Easy to remove liner

- Economy tape

More information, you can visit this web page.

3M VHB5608

3M™ 5608 Acrylic Foam Tape is a high performance tape made of grey acrylic foam. The tape is especially qualified for attaching elastomeric parts such as seals to car bodies and doors. 5608 is characterised by its high adhesion to a variety of automobile surfaces. One side of the tape is attached to the painted surface or the respective substrate by a pressure sensitive adhesive. The other side is bonded to the elastomeric part through heat-activation.

The heat-activated adhesive guarantees a durable bond, especially to seals made of EPDM and TPE Rubber.

A good inner strength, brilliant long-term stability as well as very good conformability to the bonded surfaces are characteristic attributes of 5608

More information, you can download this PDF

Tesa 4965

Tesa® 4965 Original is a transparent, double-sided self-adhesive tape consisting of a PET backing and a tackified acrylic adhesive. Its adhesive technology is based on a patented and protected product formulation. Several products are equipped with this unique and high performing product design and together these products make up Team 4965.

This double-sided film tape assortment helps to easily select the most efficient tape based on customer demands, products, and processes.

More information, you can visit this web page.

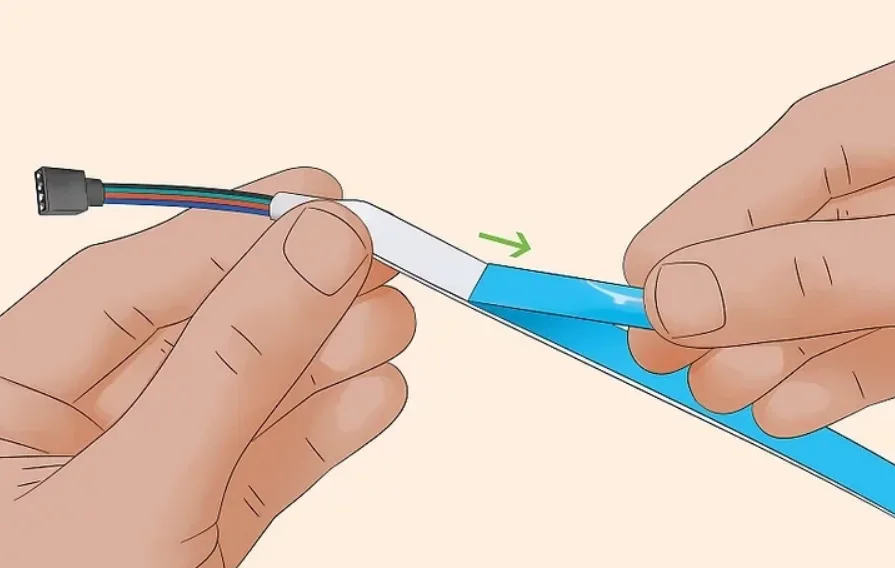

Blue Thernal Tape

Blue Thermal Tape is designed to provide a preferential heat-transfer path between heat generating components and heat sinks or other cooling devices (e.g., fans, heat spreaders or heat pipes).

It is generally attached to a high-power LED strip, and then the LED strip is attached to the aluminum profile. In this way, the heat of the LED strip can be quickly transferred to the aluminum profile so that the LED strip can be kept at a suitable working temperature.

What does VHB mean?

Very High Bond. This is a grade of tape that can be used for mounting and supporting heavier items. For example, our clear VHB tape supports up to 2.2lbs per square inch. The 3M VHB mounting tape is an excellent choice for mounting LED strip lights. It is waterproof (after curing for 72 hours and while applied in dry conditions.) You get a choice of black or clear mounting tape. The black tape can hoist a hefty 3lbs per square inch!

How to choose double-sided tape?

1.The surface you want to glue: Depending on the surface, you must choose different double-sided tape. For example, the flatter the surface (glass, aluminum, PVC), the thinner the tape. On the other hand, the rougher the surface (wood, cement, brick, stucco), the thicker the tape

2.Consider the degree of attraction or repulsion of the material you want to attach to: for example, glass, glazed tiles and bare metal make a very good bonding surface;

3.When using double-sided tape, you should consider your environment and choose heat-resistant tape. If you must work in low temperatures, then use double-sided tape specifically designed for cold climates. The same applies to extremely hot or humid environments.

The service life of 3M double-sided tape?

He acrylic adhesive used in the 3M™ Extreme Sealing Tape is manufactured from the same technology platform as the 3M™ VHB™ Tapes. When properly applied, 3M™ Extreme Sealing Tape is expected to be durable for 3-5 years in harsh UV climates and 4-9 years in mild UV climates. Gray and black colors last 25% longer

How to install LED strips on a flat surface?

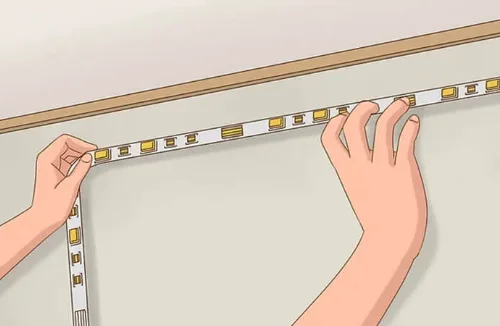

Applying double-sided tape on a surface might seem easy at first, but it’s a job that requires extreme precision. The following are the things to pay attention to when installing the led strip>

1. Make sure the tape and surface are warm enough. Make sure to avoid cold temperatures when installing the tape in mild weather and follow specific instructions to get the best adhesive results

2. Clean the pasted surface with alcohol before adhesive tape.Avoid debris and other items on the colloid pollution, resulting in decreased adhesion.

3. Apply enough pressure to make the strip stick to the surface.in order to make them perfectly coincide. You might need to press for a few seconds to ensure the best tape adhesion

4. Avoid sun exposure, heat expands and cold shrinks.

5. Please store the tape properly before use and try to seal and dry.

Tape Selection: Choose the appropriate 3M VHB Tape for the application based on the surface type, the weight of the LED strip light, and the environmental conditions

What are the factors that affect the use of tape?

1.Whether the temperature of the tape and the surface is reasonable, the colder the environment, the weaker the viscosity of the tape. On the other hand, extremely high temperatures can cause the adhesive to melt and lose strength.

2.Traces of dust, dirt, grease, and even the slightest moisture before bonding can contaminate the adhesive surface and act as a barrier between the two.

3. Long-term exposure to ultraviolet light will cause the tape to become hard and brittle.

4. Liquids such as oils, plasticizers and dyes contaminate the tape,the adsorption force decreases.

Conclusion: Choose the appropriate 3M VHB Tape for the application based on the surface type, the weight of the LED strip light, and the environmental conditions.For indoor LED strips,Signlite LED strips are typically affixed with 300LSE double-sided tape. For stronger adhesion and outdoor use, we recommend 3M VHB double-sided tape. For cost-sensitive LED strips to aid heat dissipation, we suggest using blue thermal tape for rapid heat transfer.