Nowadays, with the development of science and technology, the concept of LED is getting deeper and deeper. Abandoning high-pollution, high-energy-consuming materials and pursuing high-energy-saving LEDs has become what everyone wants. LED injection molding modules are one of the products, which have been used in daily life. Many areas in the field may have been very common in life but are not well known. In fact, people are familiar with the actual objects it is applied to, but they are still completely unfamiliar with the concept of LED injection molding modules.

1. What is LED injection molding module?

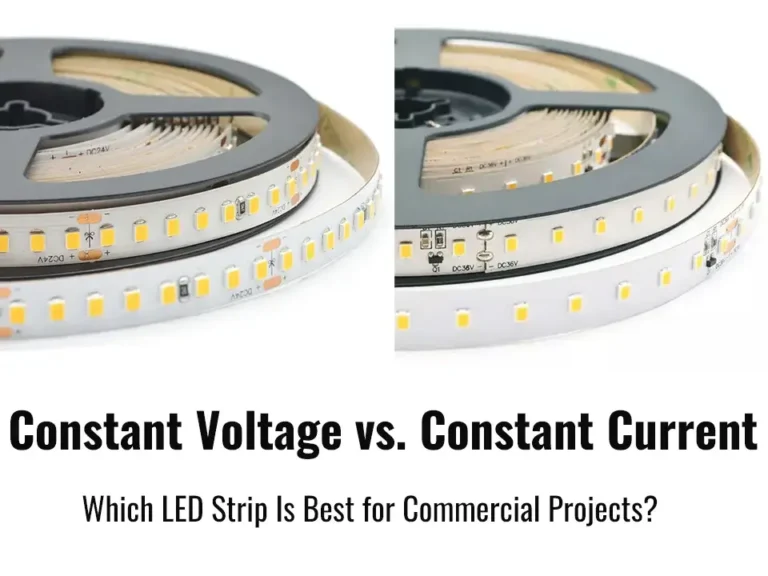

In fact, the LED injection molding module is a component composed of wires that is pasted with LED light beads on the PCB, and then pressed out by the gravity pressure of the injection molding machine. There are currently three main models on the market, they are 5050, 3030 and 2835 respectively, and these three are the most widely circulated in the market. The LED injection molding module is not only beautiful and unique in appearance design, but also has a relatively high waterproof level, which has reached above IP65 at present.

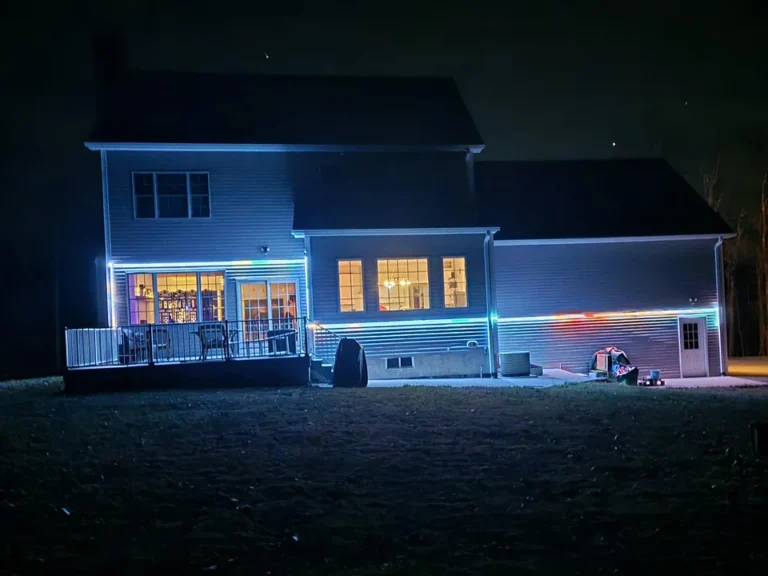

At present, the scope of application of LED injection molding modules is also very wide. In fact, objects using LED injection molding modules are ubiquitous in our lives, and these objects are also very eye-catching. For example, the large advertising display screen used outside the supermarket uses LED injection molding modules inside.

When you see this, you will definitely think of hotels and bars, and LED injection modules are also used in them. In addition, LED injection molding modules are also widely used in stage decoration and three-dimensional luminous characters. These are relatively common in our lives.

2. Product Features of LED Injection Molding Module

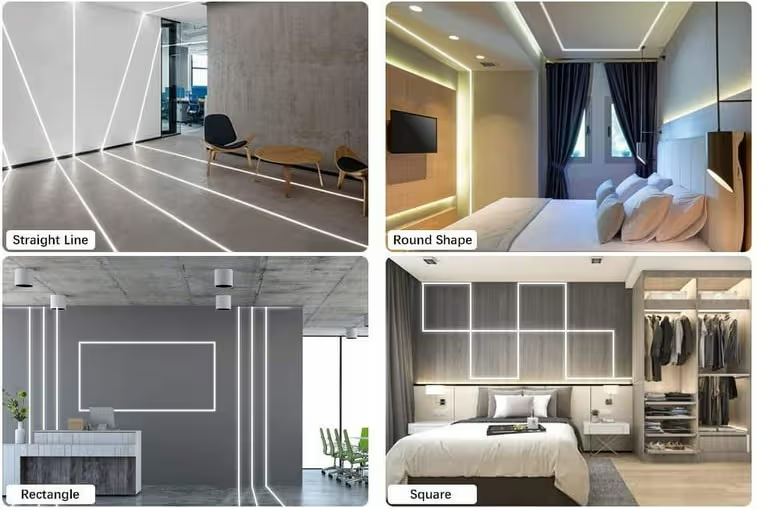

1. The LED injection molding module can present seven common colors, and can also complete the seven-color jump and gradient in these seven colors, and can also complete the colorful jump and gradient at the same time. When the LED injection molding module When applied to the display screen, it can make the picture displayed on the display screen achieve a dazzling effect and attract people’s attention more. This is why LED injection molding modules are widely used in advertising display screens.

2. The light source of the LED injection molding module is TOP5050led light source, which also shows its high-quality features such as no light spot, good consistency and low light decay.

3. The energy consumption of the LED injection molding module is also greatly reduced. The low energy consumption it produces increases its service life. At the same time, it also has the characteristics of high brightness. It is used on the display screen even in sunlight The bright sunny day will not affect the display of the screen on the screen at all.

4. The installation and disassembly of the LED injection molding module is also relatively convenient, and it will not cause too much trouble in the reassembly and installation. For example, in the application of stage decoration, it can provide greater convenience for the construction of stage decoration, and it can be disassembled immediately after the stage performance is over, and it will not cause waste of resources.

These are the overall introduction to LED injection molding modules. Now that you have read these introductions, do you have a better understanding of LED injection molding modules? In fact, LED injection molding modules are already very common in our lives, but we only see the finished products using them and forget the silent contribution behind these finished products.