In today’s colorful world, LED strip lights are widely used in various scenarios for their flexibility, high energy efficiency, and rich colors. In the family of LED strip lights, 110V/220V LED strip lights are becoming the new favorite in the market with their unique advantages. In this article, we will bring you an in-depth understanding of high voltage LED strip lights, discuss their application in different fields, and their future development.

What is a 110V/220V LED Strip Light?

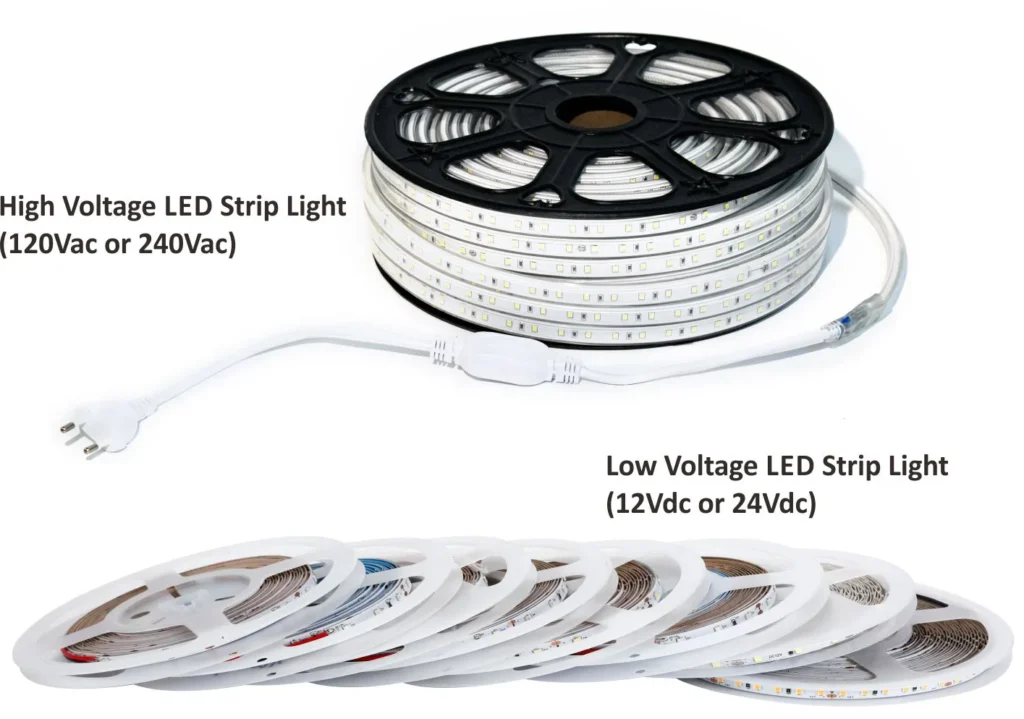

110V/220V LED strip lights are also called driverless LED strip lights, high voltage LED strip lights or AC LED strip lights because they are powered by AC electricity. They are a kind of LED lighting product with an integrated high-power LED chip and special driving circuit. High voltage LED strips can withstand higher voltages, such as 220V (the same voltage as domestic electricity), than ordinary low voltage LED strips, which usually use 12V or 24V. This is the direct difference between low voltage LED strips and 110V/220V LED strips: the operating voltage is different.

We should know that high voltage is very dangerous to the human body, so AC 110V/220V light strips are waterproof IP67 grade, and they are all wrapped with glue. In terms of the safety of use, high voltage light strips are indeed a greater safety hazard than low voltage light strips, which is where we must pay full attention to the use of dangerous high voltage 110V/220V LED light strips.

The traditional high voltage 110V/220V LED light strips on the market have power plugs at the beginning of the strip to convert AC power to DC power. SignliteLED’s high voltage 110V/220V LED strip, on the other hand, puts the diode rectifier on the PCB and does not require a power plug at all, which is why it is sometimes referred to as a driverless LED strip. The core components include high-quality LED light beads, a flexible circuit board (FPC), and the necessary electronics. The LED light beads, as the key components of light-emitting, are responsible for converting electrical energy into light energy to illuminate the surrounding space. The FPC offers sturdy support for the lamp beads, allowing for effortless bending and folding to accommodate various complex installation scenarios. The electronic components, such as resistors and capacitors, precisely regulate the current and voltage to ensure stable and efficient operation and prolong the service life of the strip.

What Are The Types of 110V/220V LED Light Strips?

110V/220V high voltage LED light strips are widely used in various scenarios with their unique advantages. Among them, 110V/220V driverless SMD LED strips and high voltage driverless COB LED strips are two common types with different characteristics.

110V/220V SMD LED Strip Light

- LED Type: SMD2835/SMD5050

- LED QTY per Meter: 60/80/120@SMD2835, 60@SMD5050

- PCB Width: 10mm/12mm

- Length: 50m

- Input Voltage: AC110V/AC220V

- Power per Meter: 10W/7W

- Color Temperature: 2700K/3000K/4000K/5000K/6500K/RGB

- IP Grade: IP67/IP68

- Warranty: 3 years

- Above the function supports customization

110V/220V COB LED Strip Light

- LED Chip QTY per Meter: 320chips (Sanan)

- CRI: >80

- PCB Width: 12mm

- Color Temperature: 3000K/4000K/6000K

- Input Voltage: AC110V/AC220V

- Power per Meter: 8W

- Cuttable Length: 500mm

- Waterproof Version: IP67

- Warranty: 2 years

Advantages of 110V/220V LED Strips

The main advantage of high voltage 110V/220V LED strips is that they are able to cover longer distances without a significant voltage drop, making them suitable for larger installations.

AC Voltage Operation: The main feature of high voltage 110V/220V LED strips is that they do not require any transformer or driver. These strips are compatible with AC voltage; this is what distinguishes them from low voltage strips.

Long Distance Operation: 110V/220V high voltage LED strips can be operated over long distances without any voltage drop. This makes them suitable for large installations in commercial areas. Due to their long length, they do not require multiple strip connections.

High Brightness: Due to the 220V AC power supply, the individual LEDs of high voltage LED strips are much brighter than those of low voltage strips, which can meet the needs of high-brightness applications such as outdoor advertising signs and building outline lighting.

Easy to Install: 110V/220V LED Strip does not require an additional driver; the installation process is simple and fast, ideal for commercial applications and outdoor lighting or places where quick installation is required.

Durable: High Voltage 110V/220V LED Strips are designed for commercial use, resulting in rugged construction. Most strips have standard IK and IP ratings to withstand physical contact or natural disasters. In addition, they last much longer than traditional lighting.

Despite the many advantages of 110V/220V LED light strips, there are a few things to keep in mind when using them:

Safety Hazards: Due to the high operating voltage of high voltage 110V/220V LED light strips, special attention should be paid to safety when using them. If prolonged contact with the strip occurs or the strip is damaged, there may be a risk of electric shock.

Scope of Application: The length of 110V/220V LED strip light is usually fixed, generally 50 meters, not conducive to special occasions of contour lighting. At the same time, a high voltage LED strip is not suitable for environments that require frequent disassembly, and once damaged, the entire strip needs to be replaced.

Price and Quality: The price of 110V/220V high voltage LED strips is higher than that of low voltage strips, and the quality of different brands varies greatly. When choosing, you need to choose according to the actual needs and choose durable, high-quality products.

High Voltage 110V/220V LED Strips vs. Low Voltage LED Strips

When choosing between 110V/220V high voltage LED strips or low voltage LED strips, check out the differences between low voltage and high voltage LED strips to determine which is best for your project.

Safety

High voltage LED strips usually operate at 110V or 220V, which corresponds to the voltage we use in our daily lives, and can be connected directly to the mains without the need for an additional transformer. However, because of this, there is a certain safety risk in the process of using them; once the insulation layer of the strip is broken or improperly installed, the user accidentally touches them, which will easily cause electric shock accidents, especially in humid environments or outdoor installation scenarios; the risk factor is higher.

In contrast, low voltage LED strips generally use 12V or 24V DC voltage, which belongs to the category of safe voltage; even if the human body is in direct contact, it will hardly cause electric shock hazards, so the safety is extremely high.

Run Length

110V/220V high voltage LED strips benefit from higher operating voltages and can be run up to 50 or 100 meters in a single strip. Therefore, high voltage 110V/220V LED strips usually do not experience voltage drops, and the brightness remains constant over the entire length. In large-scale installation scenarios, such as outlining the contours of large buildings, lighting very long corridors, and lighting large outdoor billboards, it is possible to achieve continuous lighting, reduce the number of power supply connectors, reduce the complexity of the line, and ensure a uniform and smooth light, avoiding uneven brightness or failure potential caused by too many connectors.

Low voltage LED light strips are limited by the characteristics of low voltage power supplies; the voltage drop problem is more prominent, and the general length of a single recommended operation is 5-10 meters; more than the length of the light, brightness will be significantly attenuated. Even with thicker wires, optimized circuit design, and special constant current drive power supplies, the maximum access length is usually only 15-30 meters. This means that in a large area of lighting needs, there is the need to frequently arrange multiple power connectors, increasing the installation cost and difficulty and subsequent maintenance workload. However, in small, delicate lighting areas, such as small display cases and delicate bookshelves, shorter run lengths allow for flexible layout and precise illumination of the target area.

Energy Efficiency

High voltage AC110V/220V LED light strips have internal circuits such as buck and rectifier, and these circuits will have a certain amount of energy loss in the process of converting voltage. Typically, the power factor of a 110V/220V LED strip may be in the range of 0.5-0.7, which means that in the process of converting AC to DC, about 30%-50% of the electrical energy may not be effectively utilized due to power factor issues.

Generally speaking, the power factor of low voltage light strips is usually high, reaching 0.95 or even higher, due to the relative simplicity of the circuitry and the low energy loss during the conversion process of low voltage power supplies. Low voltage LED strips require less power and generate less heat. Low voltage LED strips are also more adaptable to a wider range of dimming and control options, which can further reduce energy consumption. High voltage LED strips are less adaptable and may not work with certain types of dimmers or controllers.

Flicker Issues

High voltage LED strips are connected directly to a 110V/220V AC power supply, which can be affected by fluctuations in grid voltage. If the power supply is of poor quality or does not have a good voltage regulator circuit, the DC output of the AC power after step-down and rectification may be unstable, causing the strip to flicker. For example, during the peak period of power grid consumption, the voltage may drop or fluctuate to a certain extent, and such fluctuations, if they are beyond the adjustment range of the voltage regulator circuit inside the strip, will lead to changes in the brightness of the strip and the flickering phenomenon.

The use of low voltage LED strips is a relative advantage. These strips are powered by a stable direct current (DC) voltage. They provide a constant lighting output and do not fluctuate like alternating current (AC) voltage.

Cut Lengths

High voltage 110V-220V LED strips are usually available in cut lengths of 10 cm, 50 cm, or 100 cm. The scissor marks must be strictly followed when cutting; otherwise, the internal circuitry may be damaged, rendering the entire strip inoperable. This cutting method is relatively fixed and less flexible, but in long-distance, regular installation scenarios, it can ensure the electrical performance of the strip is stable and reduce the risk of failure.

Low voltage LED strips are cut more flexibly; generally, every 10-100 mm on the strip (depending on different voltages and bead specifications) there is a scissor marking, which corresponds to the position of the safe cutting. Taking the common 120 LED per meter 12V low voltage strip as an example, most of them are cut with 3 lamp beads at 25 mm intervals, which allows users to cut accurately according to the actual needs and easily adapt to a variety of irregularly shaped installation areas.

Waterproof IP Rating

Both high voltage and low voltage LED strips can achieve the same waterproof IP ratings, such as IP65, IP67, and IP68. With the same waterproof rating, they are virtually identical in terms of waterproof performance and are able to withstand dust and water ingress according to the standards of the respective rating.

High voltage 110V/220V LED strips are mainly used outdoors. As such, they are subject to extreme weather conditions such as rain, wind, dust, storms, etc. A higher IP rating is essential to ensure that LED strips can withstand such weather conditions. High voltage LED strips have IP ratings of IP65, IP67, and even IP68, making them ideal for harsh outdoor environments.

Low voltage LED strips are mainly used for indoor applications and have a lower IP rating. Lower IP ratings, such as IP20, may be sufficient for residential lighting. Low voltage IP65-rated strips can be used in indoor and outdoor scenarios where there is a small amount of water contact, such as indoor bathroom mirror headlamps (if low voltage powered) or outdoor corridor lighting with awnings. Due to its lower operating voltage, it is more advantageous in some wet environments where safety is important.

Packaging

High voltage LED strips are available in reels of 50 to 100 meters. This makes them ideal for large installations where continuous lighting is required.

Low voltage LED strips are available in 5 to 10 meter lengths per roll, making them ideal for smaller projects. However, for longer installations, it is important to consider that going beyond 10 meters may cause voltage drop issues. In this case, you will need to add additional wiring to maintain light output.

Install

Although 110V/220V LED strips are relatively easy to install, simply connecting the strip to the mains and lighting it up with simple wiring, I would recommend that you seek professional help to install high voltage LED strips. However, I still recommend you seek professional help to install the high voltage LED strip. For some large-scale applications, such as large-scale commercial venues, outdoor lighting projects, etc., it can significantly save installation time and labor costs.

Due to the low operating voltage of low voltage LED strips, an additional DC power supply (transformer) is required to convert the utility power into low voltage DC power suitable for the strips. This not only increases the number of installation steps but also requires consideration of the location of the power supply, heat dissipation, and the stability of the connection to the strip. In some environments with limited space and complex wiring, such as the interiors of narrow cabinets and delicate display cases, the installation difficulty will be further enhanced. However, for those who pursue personalization and flexible installation, low voltage LED strips can easily achieve a variety of creative shapes with their safe and low voltage characteristics, such as meandering in the interior of bookshelves and bedside backdrop decorations to create a unique atmosphere.

Cost and Longevity

In terms of purchasing cost, the price difference between a single high voltage 110V/220V LED strip and a low voltage LED strip is very small. However, when considering the cost of the power supply, the difference becomes apparent. 110V/220V LED strips are equipped with a high voltage power supply; usually, a power supply can drive 30-50 meters of light strip, and the cost is relatively low after sharing.

Low voltage LED light strips need to be equipped with an independent DC power supply for each meter or every few meters of the strip; for example, 1 meter of 60LEDs 5050 strips, the power is about 12-14W, which means that each meter needs to be paired with a DC power supply of 15W or so; the overall cost has increased dramatically, especially in the long distance. Especially in the long-distance and large-area use, the cost disadvantage is more prominent. However, when it comes to energy consumption, high voltage 110V/220V LED strips consume more energy, so you will have to spend more on electricity. In this case, using low voltage LED strips is cost-effective in the long run.

In terms of lifetime, low voltage LED strips have a technical lifetime of 50,000 – 100,000 hours and in practice usually last 30,000 – 50,000 hours due to their lower operating voltage, low heat generation, and slow light decay. 110V/220V High voltage LED strips, due to high voltage, heat per unit length, and internal components to withstand the pressure, are far greater than the low voltage strip, accelerating the aging of the LEDs and light failure, with a general service life of about 10,000 hours.

Long-term, frequent use of places, such as shopping malls, hotels, etc., and low-voltage LED light belt replacement frequency is low, which can reduce maintenance costs and risk of operational disruption; if the frequency of use of the light belt is not high, or budgetary constraints and the pursuit of short-term high-brightness lighting effect, high voltage LED light belt upfront cost advantage is more obvious.

When and Why Use High Voltage LED Strip Lights or Low Voltage LED Strip Lights?

High voltage 110V/220V LED strip lights are installed in areas where constant bright light is needed and are ideal for commercial and industrial areas. The most common applications for high voltage LED strips are as follows:

Hotels and Restaurants: Active and crowded areas such as restaurants and hotels require bright fixtures with sufficient brightness. For these reasons, 110V/220V LED strips are used in these areas. In addition to outdoor lighting, these strips are also used in indoor lobbies, corridors, and hallways.

Outdoor Signage: Brightness is the most important factor to consider when selecting fixtures for outdoor signage. Because high-voltage 110V/220V LED strips produce brighter illumination than low-voltage LED strips, they are ideal for signage. In addition, high voltage LED strips, LED retrofit tubes, and LED neon strips are popular choices for outdoor signage. For more on outdoor signage LED lighting, read the article: Cabinet Sign LED Retrofit: Fluorescent to LED Replacement.

Industrial Lighting: 110V/220V High voltage LED strips are ideal for large-scale industrial lighting. With higher IP and IK ratings, these strips can withstand the unforgiving environments of manufacturing plants.

Commercial Spaces: Locations such as museums, hospitals, offices, and other commercial spaces use high voltage 110V/220V LED strips outdoors. In addition, these strips are used in other public spaces such as parks, facades, pathways, and landscaping.

Low voltage LED strips are the best choice when you need energy-efficient and safe indoor lighting. They can be used for a variety of purposes. The most common use for these strips is in residential areas. They are also used in automobiles, decorative environments, and more. Here are some of the uses of low voltage LED strips:

Vehicle Lighting: The low energy consumption of LED strips makes them ideal for vehicle lighting. In addition, these LED strips have a lifespan of about 50,000 hours, so you don’t have to worry about the durability of your automotive lighting. Low voltage LED strips are mainly used under the seats and under the car to create a mesmerizing floating effect.

Stairway Lighting: Because low voltage LED strips don’t get hot, you can use them on stair railings. You’ll see them on stair lighting in modern duplexes or other interior staircases, and the flexibility and cutting capabilities of LED strips make it easy to install these fixtures around stair corners.

Under Cabinet Lighting: Whether it’s a bedroom, closet, or kitchen cabinet, low voltage LED strips are best suited for installation under cabinets. However, you must consider color temperature, color rendering index (CRI), and cabinet material before choosing the right strip. For more information, read the article: Kitchen cabinet lighting: how to choose and install LED strip lights.

Bedroom and Bathroom Lighting: As I already mentioned, low voltage LED strip lights are a popular choice for residential lighting. You can use them in your bedroom, bathroom, living room, or kitchen. They are great for general lighting and accent lighting.

DIY Projects: Low voltage LED strips are safe for experimenting or doing DIY lighting projects. They are flexible and resizable. Therefore, you can use scissors to cut them to the desired size. In addition, LED strips are very easy to install. Simply remove the adhesive backing and press it to the surface. So you can try out creative lighting ideas; check out how to DIY mirror lighting: A Guide for Mirror LED Strip!

Conclusion

As a key force in the field of LED lighting and decoration, high voltage 110V/220V LED strips, with their excellent brightness, easy installation, long-distance illumination ability, and good cost-effectiveness, shine in many scenarios such as architectural exterior lighting, commercial space creation, outdoor landscape embellishment, and so on. Compared with low voltage LED strips, it provides accurate adaptation for diversified needs under different voltages, installation difficulties, costs, and life span characteristics. When choosing and using them, it is important to grasp the key points of brightness, protection, color temperature, and brand, and strictly abide by the installation, use, and maintenance specifications in order to enjoy their advantages to the fullest.

Low voltage and high voltage LED strips are available from SignliteLED. Our range of high voltage 110V/220V LED strips is available in 50-meter rolls. We also have 48V ultra long LED strips available in 50-meter rolls. So, if you need LED strips for large installations, please contact us.