Although we have previously introduced a large number of LED light strips, we examined a number of potential causes when we discovered that some LED lamp beads were not lighting up. A thorough explanation of these elements and their accompanying fixes is provided below:

1. Inadvertent connection to high-voltage power supply: Due to carelessness during installation, workers may inadvertently connect LED light strips intended for low voltage (such as 12V or 24V) directly to 200V, 220V, and above mains power systems. The LED lamp beads and their circuits cannot withstand this abrupt spike in voltage, which either causes the lamp beads to burn out quickly or triggers the circuit’s protection components, rendering the entire light strip inoperable.

Solution: Make sure that customers can comprehend the rated voltage and proper wiring method of the LED light strip when using it for the first time by strengthening the creation and advertising of product manuals and making clear marks. Simultaneously, to lessen the harm caused by malfunction, an overvoltage protection system might be incorporated into the product design.

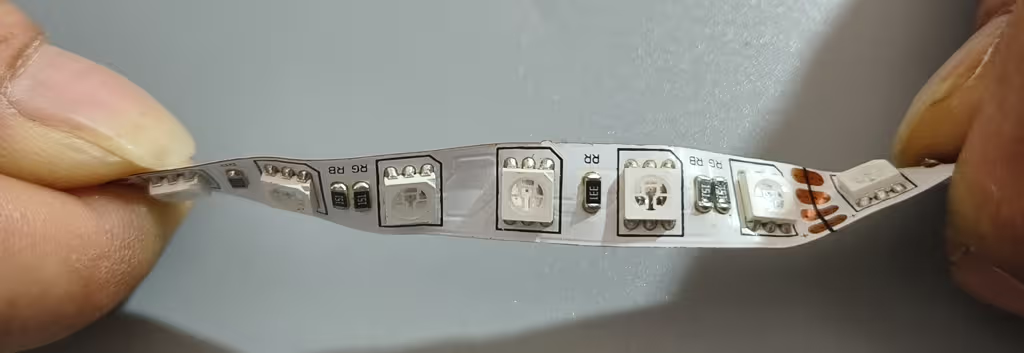

2. Causes of inappropriate use during installation:Distortion-induced welding point detachment: If the LED light strip is overly bent or twisted during installation or operation, the internal welding points may become loose or perhaps break off, disrupting the circuit. Structural damage resulting from squeezing the exterior packaging: Excessive external pressure can harm the LED lamp beads’ packaging structure, impairing their luminous performance or causing damage directly.

Resolution: To keep the LED light strip in its naturally curled or straight state, do not apply undue external force to it during installation, use, packaging, or transit. Select LED light strip goods that are flexible and resistant to bending at the same time.

3. Issue with heat dissipation Reason: When LED light beads are operating, they will produce some heat. The internal temperature of the lamp beads will rise if there is insufficient heat dissipation, which will reduce the lamp’s luminous efficiency and lifespan. The lamp beads may potentially be directly harmed by prolonged high-temperature use.

Solution: Enhance the LED light strip’s heat dissipation design by adding heat sinks, utilizing materials with high thermal conductivity, or rearranging the light strip’s structure to increase the effectiveness of heat dissipation. In addition, make sure the area is well-ventilated for the installation and steer clear of placing the light strip in a closed or warm space.

4. The place where the light strip is mounted is prone to dampness Reason: Moisture may infiltrate the circuit of an LED light strip placed in a humid or wet location, leading to short circuits, corrosion, and other issues that could ultimately result in the failure of the lamp beads.

Solution: Select waterproof IP65, IP67, and IP68 LED light strips, and make sure they remain watertight throughout installation. To prevent moisture entry, installed light strips should have their seals examined on a regular basis.