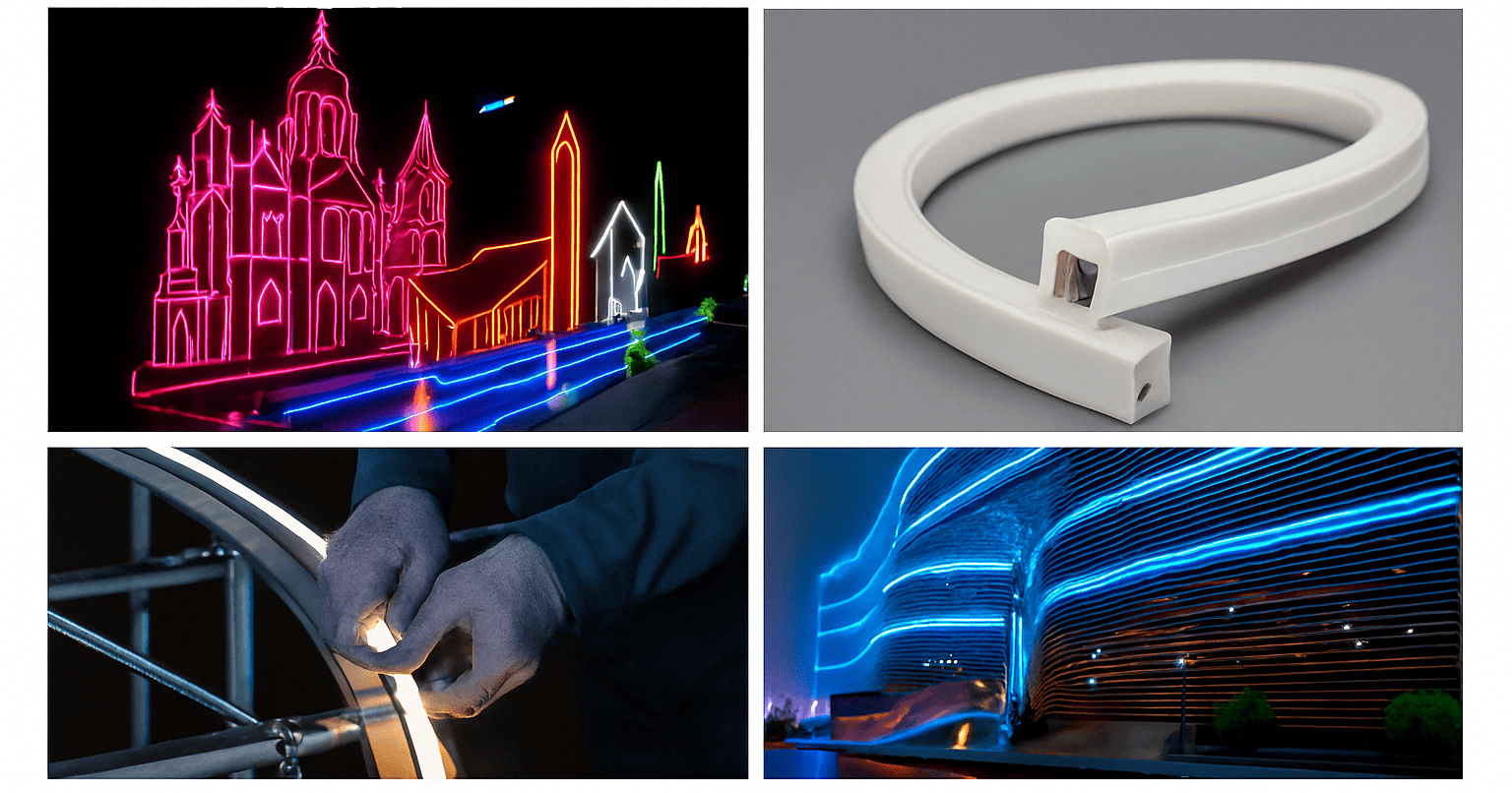

LED Aluminum Channels, also referred to as LED profiles or housings, are specially designed extrusions that give your LED strip lighting installations a sleek and polished appearance. These channels allow for the easy creation of customized fixtures tailored to your preferred style of LED Channel and LED Strip Light. We offer an extensive range of high-quality and innovative LED Aluminum Channels for your lighting needs.

Our collection encompasses various shapes and styles, many of which can be cut to the desired length. Whether you need ultra-wide or ultra-thin options, as well as specialized extrusions for corners and curves, you will find the ideal LED Aluminum Channels to suit your project. You can enhance these channels with end caps, lenses, and mounting clips. They are perfect for diverse applications, including cabinet lighting, under-cabinet illumination, display shelf lighting, cupboard lights, cove lighting, stair lighting, and more.

Additionally, LED Aluminum Mounting Channels are excellent for facilitating heat dissipation, which is crucial as LED strip lights can heat up during operation. These channels also offer a perfectly flat surface, ensuring that LED strips are mounted securely and aligned in a straight groove.

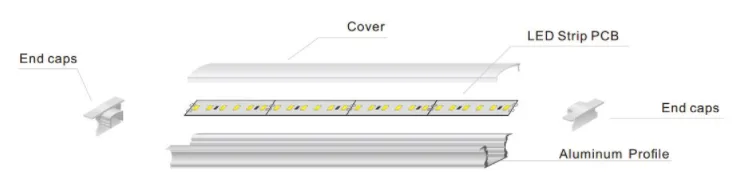

A Complete LED Channel Lighting System Includes:

- LED channel diffuser

- LED aluminum channel

- Aluminum Channel Color: sliver, white, and black aluminum.

- Aluminum Profile Shape: U shape, circle, corner, and other special shapes.

- Aluminum Channel Sizes: Aluminum channel dimensions include height, width, and length.

- End Caps

- Mounting clips

- Accessories

Why Choose LED Aluminum Extrusion Profile?

The design and characteristics of the aluminum channel for your LED strips play a crucial role in their overall performance. Various aluminum alloys can be used to manufacture these extrusions. Choosing the appropriate aluminum type can help ensure your LED lighting meets desired standards. For instance, 6061 aluminum provides a smooth finish and is easy to work with, making it a versatile choice for both indoor and outdoor lighting applications.

When selecting an LED channel, your decision should primarily be guided by your specific lighting needs and design preferences. No single profile or shape of LED channel is universally superior; rather, the ideal choice will depend on the particular requirements of your lighting fixtures or installation setup.

Aluminum Channels Serve Multiple Key Functions:

- Housing and mounting for LED strips – The channel protects the strip and provides an easy installation method.

- Heat dissipation – The aluminum material pulls heat away from the LEDs, preventing overheating.

- Diffuser mounting – The channel securely holds diffusers/lenses to soften and spread the LED light.

- Decorative appearance – Channels look more finished versus an exposed strip.

- Physical protection – Channels protect the LED strip from damage.

- Safety – Channels prevent direct contact with the powered LED strip.

With built-in mounting, heat sinking capabilities, and compatibility with lenses and diffusers, aluminum channels can transform LED strips into durable linear lighting fixtures. But there are some key considerations when deciding whether channels are needed for your unique project.

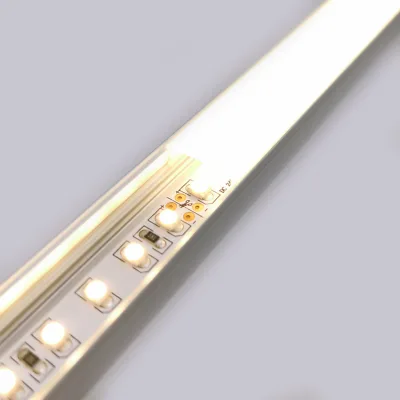

LED Diffusers & Light Distribution

Although aluminum is not necessary for heat dissipation, its compatibility with LED strips and diffusers makes aluminum channels incredibly beneficial. Diffuser lenses made of acrylic or polycarbonate can be securely fitted into these channels, transforming the quality of light emitted by the LED strips.

In the absence of a diffuser, LED strips produce a concentrated beam of light, akin to that of spotlights. This direct light can be harsh on the eyes. By utilizing diffusers, the light is evenly distributed and blended, which effectively softens shadows and reduces glare.

Glare refers to the discomfort caused by excessive brightness entering the eyes. Direct glare happens when intense light directly shines into one’s line of sight from the light source itself, often an issue with compact light sources. Diffusers work by enlarging and scattering the area of the light source, thereby mitigating direct glare.

In addition, indirect glare arises when bright light reflects off shiny surfaces, such as polished floors or glossy tabletops, creating distracting reflections. Diffusers are effective in alleviating both types of glare, enhancing overall visual comfort.

Moreover, the diffused lighting creates a more uniform look, which is often sought after in various lighting designs.

Aesthetic Value and Functional Advantages

In addition to their technical attributes, aluminum channels offer both functional and visual benefits for LED strip lights.

Firstly, these channels enhance the overall appearance of LED strips by providing a sleek and cohesive look. The aluminum encasement conceals the yellow circuit boards, wires, and connectors that can disrupt a clean and contemporary aesthetic. Additionally, the housing allows for the installation of LED strips to be flush with various surfaces, contributing to a more polished finish.

Secondly, aluminum channels serve as a protective barrier for the LED strips, shielding them from physical damage as well as dust and dirt accumulation. The enclosed design minimizes the risk of debris settling on the LEDs, which can cause heat sinks to clog and lead to early burnout. The sturdy aluminum material also offers impact resistance for the LED strips.

Lastly, using channels adds an extra measure of safety, particularly when LED strips are mounted at lower heights. Though these strips operate on low-voltage 12V or 24V DC power, the channels help prevent accidental contact with live components, which is especially crucial for ensuring child safety.

In scenarios where visual appeal, protection, and safety are priorities, aluminum channels effectively address several concerns. However, are there any potential drawbacks to using aluminum for LED strip lighting?

Drawbacks of Aluminum Channels

Although aluminum channels offer numerous advantages, there are a few disadvantages that should be taken into account:

1. Increased Cost: Extruded aluminum channels typically range from $5 to $10 per foot, depending on their dimensions. Additionally, the required acrylic or polycarbonate diffusors can add between $1.20 and $5.50 per foot to the overall cost.

2. Light Loss: The use of diffusors can absorb or reflect up to 12% of the emitted light, leading to a reduction in brightness compared to an exposed LED strip.

3. Limited Flexibility: Once formed, aluminum channels do not have the ability to bend or flex, which can restrict the options for mounting.

4. Glare Issues: While diffusors help in reducing glare, they may not completely eliminate reflective glare on glossy surfaces.

5. Extended Installation Time: Installing aluminum channels can be more time-consuming and complex than simply mounting an LED strip.

6. Shifts in Color Temperature: The presence of diffusors can cause a slight decrease in color temperature, resulting in a shift of about 150-300K in cool white LEDs.

7. Maintenance Accessibility: If repairs are needed, the channels must be taken apart to access the LED strips, which can be inconvenient.

In many lighting applications, the significant advantages of using aluminum channels far outweigh these costs and limitations. However, for straightforward hidden installations, the extra time and expense of aluminum channels may not be justified.

When to Go Without Aluminum Channels

Not every lighting application requires aluminum channels to realize the benefits of LED strips. In general, channels are unnecessary when:

- LEDs are fully hidden from view and glare is not an issue

- Diffused lighting is not important

- Physical protection is not needed

- Easy bending and shaping of the strips is required

- A common example is using LED strips to uplight a ceiling or wall

Considerations When Choosing an Aluminum Profile

It’s important to understand the difference between surface-mounted and recessed LED profiles, as well as the difference between through-hole and blind-hole profiles – we explain these differences below.

SURFACE-MOUNTED LED PROFILES

These profiles are mounted directly on the surface without requiring any grooves. They can be attached with included 3M tape, screws, or smart clips, depending on the chosen LED profile. Some examples of our surface-mounted profiles are LD8104, Twig XA, and Blade.

RECESSED LED PROFILES

These profiles are intended for installation in specially routed grooves on the chosen surface. The advantage of recessed profiles is that they seamlessly blend into the material they are mounted on. Most recessed profiles have an easy click-mounting feature that allows them to be placed in the groove without the need for screws or adhesive. Examples of our recessed profiles include LD8104, Apex and Miss.

THROUGH-HOLE GROOVES

These grooves extend from one side of the material to the other without interruption. Through-hole grooves do not require end caps to finish the profile’s rounded ends, which often occurs when using blind-hole grooves.

BLIND-HOLE GROOVES

Blind-hole grooves do not extend across the entire material but can start and finish at desired positions. For example, 50 mm from the bottom and 50 mm from the top of a cabinet. When using blind-hole grooves, it may be appropriate to use end caps to create a neat finish on the profile and conceal the rounded ends of the routed groove.

To ensure accurate routing of the grooves, we recommend using a router or similar tool to achieve a precise and tidy groove. This step is especially important to ensure that the profile is securely and neatly attached.

STRAIGHT OR ANGLED PROFILE

When choosing an aluminum profile, it’s also important to consider how you want the light to be directed. If you want the light to be directed towards a specific area, such as a kitchen cabinet or clothing in the wardrobe, we recommend choosing an angled LED profile. Examples of angled profiles include Blade and 8112. If, on the other hand, you prefer a straight light source, there are several options to choose from, such as Apex and Miss.

In applications where protection, heat dissipation, and glare control are critical, aluminum channels paired with diffusers are a worthwhile investment to create durable, professional LED lighting. For more hidden and basic lighting needs, stripped-down LED strips often suffice. If you have any needs, please contact us.