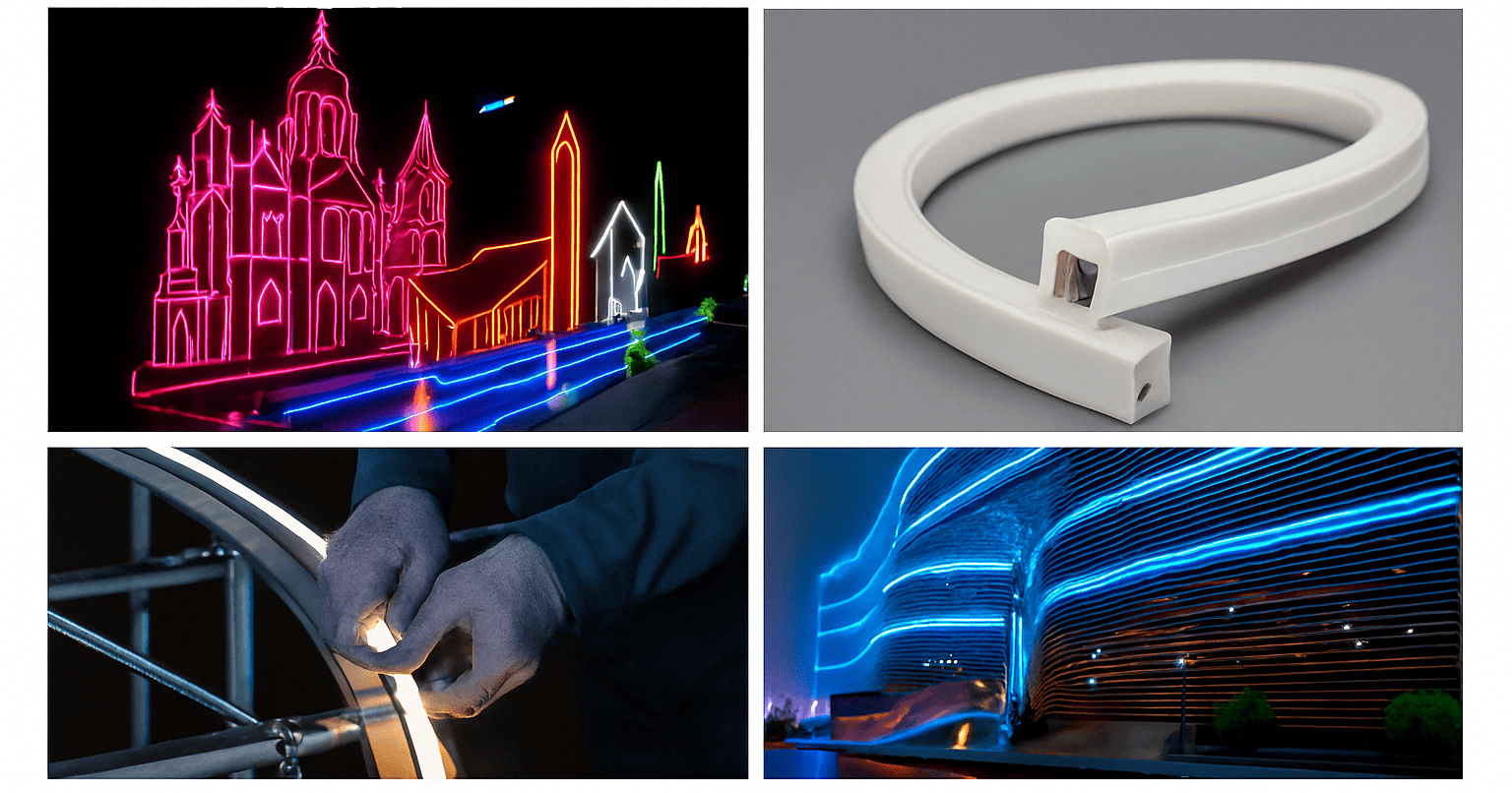

When it comes to large-scale projects, the decision to choose the right LED Neon Flex lighting is one of the most critical and impactful choices you’ll make. Whether you’re tasked with illuminating a high-traffic city billboard, creating a stunning lighting display for an event venue, or designing the lighting for a sprawling shopping mall or commercial building, the quality, specifications, and features of the LED Neon Flex you select will directly influence both the visual appeal and functionality of the entire installation.

The aesthetic impact of the lighting is immediately noticeable, but the long-term performance, energy efficiency, and maintenance of the lighting system are equally important considerations. From drawing in consumers and passing foot traffic to setting the right ambiance for your brand or event, choosing the right lighting can elevate the project to a new level of professionalism and attractiveness. The success of your LED Neon Flex installation depends on factors such as brightness, color consistency, durability, and ease of installation—each of which can make or break the final effect.

In this detailed and comprehensive guide, we’ll walk you through the critical factors you need to evaluate when sourcing LED Neon Flex for your large-scale project. By understanding what to look for and asking the right questions, you’ll be empowered to make informed decisions that align with your budget, project timeline, and long-term goals. We’ll cover everything from customization options to quality control standards, ensuring you choose a product that not only meets your immediate needs but also enhances the overall success of the project for years to come.

How Brightness and Color Consistency Impact Large-Scale LED Neon Projects

1. The Role of Brightness in Large-Scale Visual Impact

When it comes to large-scale LED Neon Flex installations, brightness is more than just a visual feature — it’s a core performance metric that directly affects the visibility, effectiveness, and appeal of the lighting project. Whether it’s a high-rise building facade, a city landmark, or a commercial billboard, the level of brightness determines how well the installation stands out, especially in areas with heavy ambient lighting or direct sunlight exposure. In outdoor applications, where natural lighting conditions change dramatically throughout the day, using high-lumen output LED Neon Flex ensures that signage or architectural accents maintain optimal visibility. For example, installations in urban cityscapes often compete with streetlights, commercial displays, and vehicle headlights. In these cases, low-brightness solutions may simply be lost in the background noise. When selecting LED Neon Flex for such demanding environments, look for products offering adjustable brightness levels, high-intensity SMD LEDs, and optimized beam angles to enhance illumination across wide surfaces.

2. Why Color Consistency Is Critical for Brand and Design Integrity

Equally important as brightness is color consistency, especially in large-scale and brand-sensitive projects. When multiple LED Neon Flex runs are installed across expansive surfaces or over long distances, even slight color variations can become highly noticeable. This affects not only the aesthetic harmony of the installation but also the credibility of the brand being represented.

Imagine a national retail chain installing colored neon outlines around its storefronts — if one section appears bluish while another is more purple, the brand’s visual identity is compromised. That’s why color uniformity, both within a single batch and across multiple production runs, must be guaranteed.

To ensure top-tier color consistency:

Choose LED Neon products with tight binning of LEDs (e.g., 3-step or 2-step MacAdam ellipse).

Verify that your supplier follows rigorous quality control standards during manufacturing.

Work with manufacturers that offer full OEM/ODM services, ensuring the color temperature and brightness meet project-specific needs.

High-end manufacturers typically offer color calibration systems, in-line testing, and batch traceability, helping eliminate inconsistencies and ensuring perfect color rendering throughout the entire installation.

3. Choosing the Right Partner for Brightness and Color Performance

Achieving both brightness and color consistency requires more than just good hardware — it requires the right manufacturing partner. Suppliers offering full OEM/ODM customization, engineering support, and strict QC protocols are better equipped to deliver consistent quality across large orders.

Other factors to consider include:

Flexible MOQ (Minimum Order Quantity), especially for custom colors or brightness levels

Reliable lead times, ensuring project deadlines are met

Component sourcing transparency, for better control over product quality

By selecting a trusted partner with advanced manufacturing capabilities, project managers and lighting designers can reduce risk, ensure visual cohesion, and create impactful installations that meet both technical and branding requirements.

Weatherproof and Durable LED Neon Flex: Key to Reliable Outdoor Performance

1. Why Durability Matters for Large-Scale Installations

In large-scale LED neon projects—such as architectural outlines, building facades, bridges, or commercial signage—long-term durability isn’t just a preference, it’s a necessity. When choosing LED Neon Flex for expansive or permanent installations, durability directly affects both maintenance costs and visual consistency over time. Inferior materials may degrade, yellow, or crack under stress, leading to uneven brightness, safety hazards, and expensive replacements.

Premium LED Neon Flex uses materials like UV-resistant silicone or high-grade PVC, which provide superior flexibility, impact resistance, and chemical stability. These materials not only protect the internal LEDs and circuitry but also extend the overall product lifespan—an essential factor for long-term ROI in commercial and public lighting projects.

2. Weather Resistance: Built for Harsh Outdoor Environments

Outdoor LED neon lighting is subject to environmental extremes—intense sunlight, heavy rain, snow, wind, salt air, and fluctuating temperatures. High-quality LED Neon Flex should come with at least an IP65 rating or higher (e.g., IP67 or IP68) to ensure full protection against dust, water jets, and even temporary immersion.

To boost UV stability, advanced coatings are applied to prevent discoloration, yellowing, or cracking from prolonged exposure to sunlight. In coastal or highly humid areas, corrosion-resistant designs are especially valuable for avoiding early degradation. Whether used in tropical heat or icy climates, weather-resistant LED Neon Flex ensures consistent performance without frequent servicing.

3. Choosing Products with Industrial-Grade Testing

For critical applications, always look for products that have undergone accelerated aging tests, salt spray testing, thermal cycling, and vibration testing. These certifications demonstrate that the product is truly industrial-grade and suitable for high-end architectural lighting.

Additionally, ensure your supplier offers:

Full OEM/ODM services for customized durability solutions.

Strict quality control protocols during production.

Engineering support to help plan for challenging site conditions.

Reliable lead times to avoid project delays.

Flexible MOQ (Minimum Order Quantity) to match project scale.

How LED Neon Flex Boosts Energy Efficiency and Cuts Operational Costs

| LED Neon Flex Performance Comparison: Durability and Installation Efficiency | ||

| Kriterler | Standard-Grade LED Neon Flex | Project-Grade LED Neon Flex |

| Su geçirmezlik derecesi | IP65 – Basic water resistance | IP67/IP68 – Fully submersible or heavy-duty outdoor use |

| UV Resistance | Limited – May yellow or crack over time | High – Maintains clarity and flexibility for years |

| Operating Temperature | 0°C to 40°C – Not ideal for extreme environments | -25°C to 60°C – Wide climate compatibility |

| Ease of Installation | Rigid structure, limited bending radius | Flexible body with optimized mounting accessories |

| Installation Time | Slower – Requires more labor to adapt to curves | Faster – Designed for seamless architectural integration |

| Maintenance Needs | Frequent – Prone to degradation and inconsistent lighting | Minimal – Long lifespan with low failure rates |

Reduced Power Consumption

Energy efficiency is another critical consideration, especially for large-scale projects with long-term operational costs. LED Neon Flex consumes significantly less energy compared to traditional neon or incandescent lighting, often reducing energy consumption by up to 80%. Over time, this leads to substantial savings on electricity bills, which is a significant factor for large commercial projects, public installations, or event venues that operate for long hours.

In addition to cutting electricity costs, LED Neon Flex typically has a longer lifespan than traditional neon, reducing the need for frequent replacements. This contributes to long-term sustainability and reduces the carbon footprint of the project.

Eco-Friendly Benefits

With increasing attention on sustainability, using LED Neon Flex aligns with eco-friendly goals. Since it’s energy-efficient and has a long lifespan, fewer replacements and less waste are generated. Many LED Neon Flex products are also made from recyclable materials, making them an environmentally responsible choice for large projects.

By choosing LED Neon Flex for your installation, you’re not only reducing operational costs but also ensuring that your project is in line with sustainability efforts. This can enhance the reputation of your project, particularly in cities or regions where green initiatives are a major consideration.

Flexible Installation: Bending Radius, Mounting Methods & Time Savings

When planning large-scale LED neon projects, installation flexibility plays a vital role in both visual design and project efficiency. LED Neon Flex is engineered to adapt to various architectural surfaces and shapes, offering significant advantages in installation layout, time-saving, and creative execution.

1. Horizontal & Vertical Bending Options

LED Neon Flex is available in side-bend and top-bend models to support different directional requirements. Side-bend (horizontal bending): Ideal for creating curved letters, signs, and logos along a flat surface. Top-bend (vertical bending): Suitable for outlining ceilings, columns, and wall edges with vertical contours.

Its small minimum bending radius, often between 30mm and 100mm (depending on model), ensures tight curves and clean angles, allowing seamless outlines even in complex layouts.

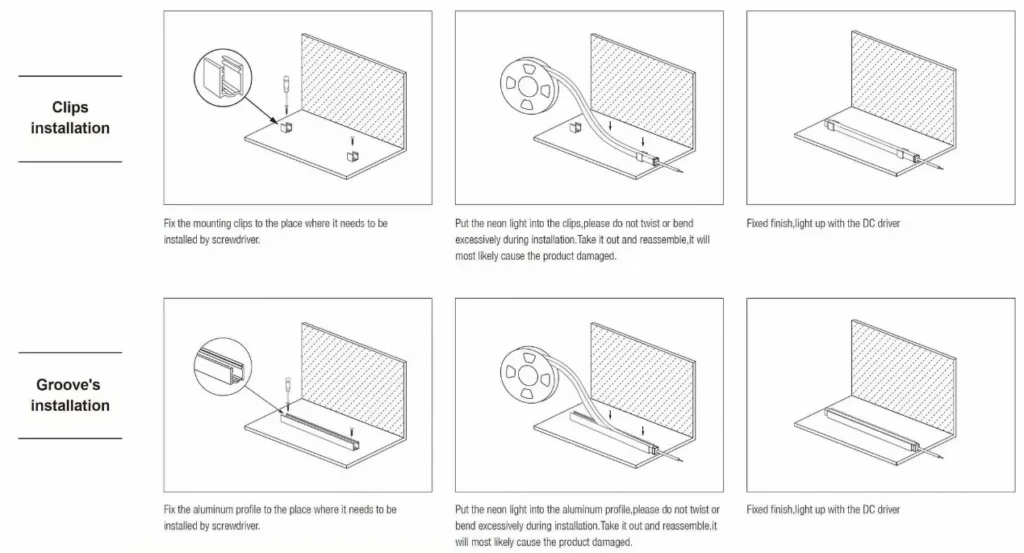

2. Multiple Mounting Methods for Different Surfaces

LED Neon Flex offers a variety of mounting accessories that make installation simple, secure, and clean:

Mounting Clips: Easy-to-use stainless steel or aluminum clips that snap the strip securely to most flat or curved surfaces.

Aluminum Profiles: Provide better heat dissipation and recessed mounting options for ultra-clean integration.

Corner & Ceiling Brackets: Allow mounting at 90° angles or upside down, ideal for seamless architectural transitions.

Suspension Kits: Enable hanging neon flex from ceilings in creative or commercial spaces.

3. Simplified Installation Saves Time & Labor

Compared with traditional glass neon or rigid LED tubes, LED Neon Flex is lightweight, cuttable, and bendable—reducing installation time by up to 50%.

Pre-marked cutting points allow easy customization on-site.

Waterproof connectors and ready-to-use accessories help speed up wiring.

Flexible structures minimize the need for extra joints or heat-bending.

4. Professional Support for Complex Installations

We provide engineering support, layout planning, and customized mounting solutions for projects that involve curves, multilevel buildings, or high installation heights. Whether it’s façade outlining, signage illumination, or cove lighting, our team ensures your layout is optimized for aesthetics, safety, and performance.

Tips: Example of ceiling and curved wall installation using flexible LED Neon Flex with aluminum profiles and surface clips.

LED Neon Flex vs Traditional Neon: A Practical Comparison

When planning a large-scale lighting installation, it’s essential to understand how modern LED Neon Flex stacks up against traditional glass neon lighting. While both may appear visually similar from a distance, they differ significantly in terms of performance, cost, maintenance, and sustainability.

LED Neon Flex offers superior energy efficiency, consuming up to 80% less power than traditional neon tubes while delivering comparable or brighter illumination. This leads to lower electricity bills and a reduced carbon footprint—especially important in long-term architectural or commercial projects.

In terms of installation, LED Neon Flex is lightweight, flexible, and can be installed with simple mounting clips or aluminum channels. In contrast, traditional neon requires delicate handling, high-voltage transformers, and professional glass bending, which increases both installation time and labor costs.

Durability is another key differentiator. LED Neon Flex is made from silicone or PVC, making it shatter-resistant and waterproof (typically rated IP65 to IP68), while glass neon is fragile and prone to breakage during transport or installation.

Additionally, LED Neon Flex has a significantly longer lifespan, typically 50,000+ hours, with minimal maintenance. Traditional neon, on the other hand, requires more frequent repairs and component replacements, adding to the lifetime cost of ownership.

From an environmental standpoint, LED Neon Flex uses recyclable materials and does not contain hazardous gases such as mercury or argon, unlike glass neon, making it a safer and greener solution for modern lighting applications.

| LED Neon Flex vs Traditional Glass Neon – Practical Comparison Table | ||

| Feature / Aspect | LED Neon Flex | Geleneksel Cam Neon |

| Güç Tüketimi | 70–80% less energy usage | High power consumption due to older tech and inefficient gas discharge |

| Kurulum | Flexible, lightweight, easy to cut & mount with clips or tracks | Rigid, fragile glass requires custom bending, high-voltage transformers, pro handling |

| Dayanıklılık | Impact-resistant, waterproof (IP65–IP68), UV stable | Fragile, prone to breakage, not suitable for outdoor exposure without protection |

| Maintenance | Low maintenance, long lifespan (50,000+ hours) | Frequent maintenance, gas leakage, shorter lifespan |

| Güvenlik | Low voltage (12V/24V), no toxic materials | High voltage (3,000–15,000V), may contain argon/mercury gas |

| Design Flexibility | Can bend vertically or horizontally, suits curves, text, art | Limited to linear glass tubes, poor fit for compact or complex designs |

| Environmental Impact | RoHS-compliant, recyclable materials, energy-efficient | Glass waste, gas disposal issues, higher carbon footprint |

| Cost of Ownership | Lower total cost due to energy savings and minimal repairs | Higher total cost due to electricity and maintenance |

Customization & Control: Designing LED Neon Flex to Fit Your Project

1. Voltage, Power, IP Rating & Controls

When selecting LED Neon Flex for large-scale lighting projects, it is crucial to understand the core technical specifications to ensure proper system performance, safety, and integration. Key factors include the operating voltage—typically 12V, 24V, or 48V—with higher voltages preferred for long runs to minimize voltage drop. Power consumption, measured in watts per meter, affects both energy use and power supply planning. Lumen output, which can range from 300 to over 1000 lumens per meter, determines the brightness and visibility of the installation, particularly in outdoor or high-ambient-light environments. The product’s IP (Ingress Protection) rating is vital for outdoor applications, with IP65 suitable for general weather resistance and IP67 or IP68 required for water-prone or submerged areas. Additionally, understanding the minimum bending radius is essential for creative flexibility, as side-bend and top-bend variants differ in curvature compatibility. Finally, verifying control compatibility—such as DMX512, DALI, SPI, or 0-10V—is key to integrating the neon flex into broader smart lighting systems.

2. Tailored Lengths, Shapes & Configurations

For large-scale LED neon installations, standard sizes often don’t meet the unique requirements of complex architectural or branding designs. Whether the project involves tracing curved building facades, creating intricate logos, or integrating lighting into custom signage or furniture, precise customization of LED neon flex lengths and shapes is critical. To achieve a perfect fit and seamless visual flow, it’s essential to work with a manufacturer that offers tailored solutions such as custom cutting based on detailed architectural drawings or CAD files, pre-molded corners, and curved sections that eliminate light gaps or uneven illumination. Additionally, choosing suppliers that provide factory pre-wiring and pre-assembly can significantly reduce on-site installation time and labor costs, especially for time-sensitive commercial or municipal projects. For best results, always request layout previews or mockups before production begins to ensure accuracy and alignment with your design goals.

3. Lighting Effects for Visual Impact

To create an unforgettable visual impact in large-scale lighting projects, LED Neon Flex offers far more than just static illumination. By incorporating dynamic lighting effects such as RGB or RGBW color-changing modes, dimming controls for mood transitions, and animated sequences like color-chasing, wave patterns, or fade in/out effects, designers can achieve immersive, attention-grabbing results. These lighting effects can also be synchronized with music, seasonal events, or brand-specific themes, making LED Neon Flex an ideal solution for high-impact architectural facades, commercial displays, and interactive environments.

4. Smart & DMX Lighting Control Integration

Modern LED Neon Flex systems are designed for seamless integration with smart lighting controls, offering exceptional flexibility and functionality in large-scale architectural and commercial projects. Whether utilizing DMX512 for precise, professional lighting effects, DALI or 0-10V for smart building automation, or wireless technologies like Wi-Fi, Bluetooth, or mobile app-based controllers, these systems enable dynamic, responsive lighting control. Features such as scene-based zoning, time scheduling, and instant color adjustments enhance both visual impact and energy efficiency. For a deeper understanding of how DMX512 operates within pixel-controlled LED Neon applications, refer to our guide: DMX512 Pixel LED Neon Şeritleri Nasıl Kontrol Eder? For complex installations like commercial showrooms, building facades, or public art displays, choosing a supplier that offers OEM/ODM customization, technical engineering support, and full system integration services ensures compatibility, performance, and long-term reliability.

For a real-world example of dynamic DMX512 lighting effects using pixel LED Neon Flex, watch this video demonstration

Why Choose Signliteled as Your LED Neon Flex Manufacturer

Selecting the right manufacturer is crucial for the success of your project. Look for manufacturers with a proven track record in large-scale installations. Research customer reviews, project portfolios, and client testimonials to gauge the reputation and reliability of the manufacturer. A well-established supplier with experience in commercial or industrial lighting will be better equipped to meet your specific needs and handle the challenges of large projects.

Top-tier manufacturers should offer Full OEM/ODM Services, allowing you to tailor products to your exact specifications. Whether you need custom lengths, special colors, or unique shapes, the right manufacturer should provide the flexibility to create a solution that aligns perfectly with your vision.

Additionally, ensure that the manufacturer follows strict quality control processes to maintain high standards in product performance and reliability. Rigorous testing and quality checks should be part of the manufacturing process to ensure that each unit performs to its full potential, reducing the likelihood of issues during installation or long-term operation.

Another key factor to consider is engineering support. A reliable manufacturer should offer ongoing support for product design, installation, and any technical challenges you may face. Whether it’s adjusting to specific installation requirements or troubleshooting, engineering assistance ensures that your project goes smoothly from start to finish.

Reliable lead times are essential for large projects, as tight deadlines and the need for large quantities mean delays can be costly. Make sure the manufacturer has a history of meeting deadlines consistently and offers transparent communication about delivery times.

Finally, flexible MOQ (Minimum Order Quantity) can be a deciding factor. Some manufacturers may offer lower MOQs for large projects, which can help streamline the process and reduce upfront costs while still accommodating your specific requirements.

Comprehensive Support and Warranty

Ensure the manufacturer offers robust after-sales support and warranties. Even the best products can occasionally experience issues during installation or after use. A good warranty will cover defective components, and comprehensive customer support ensures any technical problems are quickly addressed, minimizing downtime.

Environmental Considerations: Embracing Sustainability with LED Neon Flex

Incorporating LED Neon Flex lighting into large-scale projects supports not only visual impact and performance but also aligns with today’s growing emphasis on eco-friendly and sustainable construction practices. Unlike traditional neon or halogen lights, LED Neon Flex consumes significantly less energy, reducing carbon emissions and long-term energy costs.

LED Neon Flex Cost Savings

One of the most compelling advantages of LED Neon Flex in large-scale lighting projects is its ability to significantly reduce long-term operational costs. Compared to traditional glass neon or fluorescent lighting, LED Neon Flex consumes far less electricity—up to 70–80% less—while delivering equal or superior brightness. This translates into substantial energy savings over the lifespan of the installation. Additionally, with a typical rated lifespan of over 50,000 hours, LED Neon Flex minimizes the need for frequent replacements and routine maintenance, which is especially valuable for hard-to-reach installations such as building facades, ceilings, or signage mounted at height. Fewer service calls mean reduced labor costs, less downtime, and a more reliable lighting system overall. When evaluating total cost of ownership, LED Neon Flex provides not only upfront flexibility and visual impact but also consistent financial savings throughout the product’s operational lifecycle.

Many LED Neon Flex products—such as those available from Signliteled are crafted using non-toxic, recyclable materials, minimizing their environmental footprint. With an average lifespan exceeding 50,000 hours, these flexible lighting solutions require fewer replacements and less frequent maintenance, helping reduce waste and conserve resources throughout the lifecycle of a project. Additionally, most LED Neon Flex operates on low-voltage DC power, which enhances energy efficiency and safety in both indoor and outdoor environments. This is especially valuable in large architectural installations where energy savings are critical. Integrating sustainable lighting choices like LED Neon Flex can also contribute to green building certifications such as LEED, boosting the overall environmental value of your project. By choosing eco-conscious lighting options, you’re not just meeting aesthetic and functional goals—you’re actively participating in global sustainability efforts.

Want to see LED Neon Flex in action? Watch this video below!

SSS About LED Neon Flex for Large Projects

1. Can I cut LED Neon Flex to custom lengths?

Yes, LED Neon Flex can be cut at specific marked intervals, usually every 2.5cm to 10cm, depending on the model. Always follow the manufacturer’s guidelines and use the appropriate tools to ensure a clean, safe cut.

2. Is LED Neon Flex suitable for outdoor use?

Absolutely. Many LED Neon Flex products are rated IP65, IP67, or even IP68, making them resistant to dust, rain, and moisture. For permanently wet or submerged environments, IP68-rated products are recommended.

3. What is the typical lifespan of LED Neon Flex?

Most high-quality LED Neon Flex has a rated lifespan of over 50,000 hours, provided it is installed and powered correctly. This makes it ideal for long-term architectural and commercial applications.

4. Does LED Neon Flex require special power supplies?

Yes. LED Neon Flex typically runs on 12V, 24V, or 48V DC power and requires a compatible LED driver. Choosing the correct power supply based on voltage, wattage, and control system is essential for safe operation.

5. Can LED Neon Flex be controlled with DMX or other lighting systems?

Yes. Many models are compatible with DMX512, DALI, SPI, or 0-10V protocols. If dynamic lighting effects are needed (like color chasing or dimming), ensure you select a DMX-ready model and pair it with the correct controller.

6. Is LED Neon Flex safe to touch and install?

Yes. It operates on low voltage and is designed to be safe to touch when properly installed. Unlike glass neon, it contains no high-voltage elements or toxic gases, making it safer for public and interactive environments.

7. What are the advantages over traditional neon lights?

LED Neon Flex is more energy-efficient, durable, easier to install, and environmentally friendly. It offers flexible design options and lower maintenance costs over time. See our comparison section above for full details.