LED şerit ışıklarla ilk kez karşılaşıldığında ve bunların düzgün çalışması beklendiğinde, önemli bir adım LED şeridin düzgün şekilde yanması için uygun güç girişinin nasıl sağlanacağını belirlemektir. LED şerit ışıklar ve LED güç kaynakları farklı kaynaklardan satın alındığından, nasıl kuruldukları konusunda farklılıklar vardır. Bu makale en yaygın kurulum yöntemlerini detaylandıracaktır.

LED şerit ışık bağlantıları hakkında daha fazla bilgi için lütfen aşağıdaki ilgili blogları okuyun:

LED Şerit Işıkların Nasıl Kablolanacağına Dair Eksiksiz Bir Kılavuz

LED Şerit Işıkları Kablolamak Mümkün mü?

LED Şeritleri Fişsiz Kullanabilir miyim?

Birden Fazla LED Şerit Işığı Bağlayabilir misiniz?

LED Şerit ve Güç Kaynağının Elektriksel Uyumluluğunun Kontrol Edilmesi

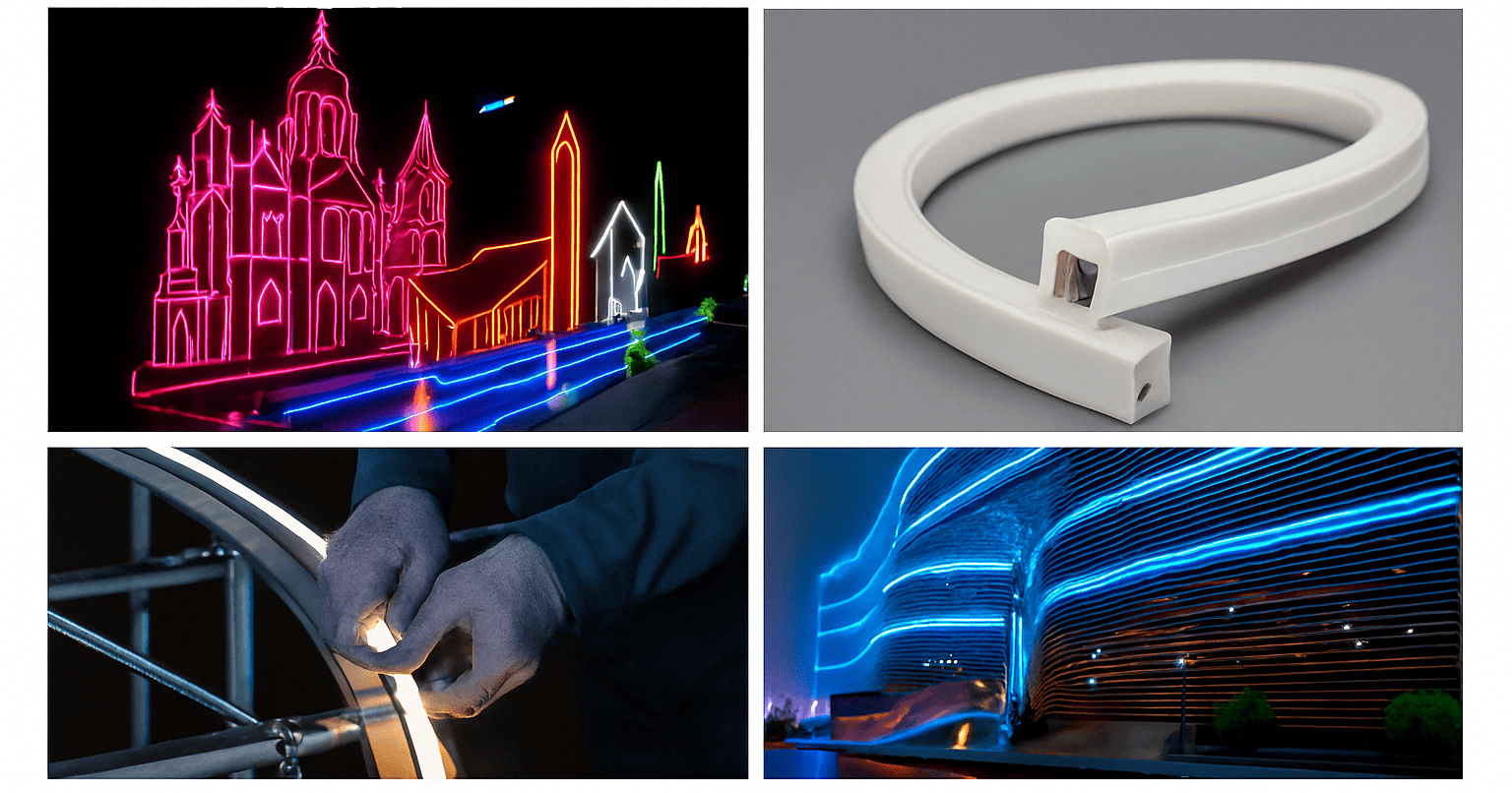

Çoğu LED şerit ışıklar düşük voltajlı DC kullanır; yaygın DC voltajları DC12V ve DC24V'dir. Örneğin, ev dekorasyon sahnelerindeki küçük LED şeritler genellikle DC12V kullanırken, ticari ekranlar için kullanılan bazı büyük LED şeritler DC24V kullanabilir.

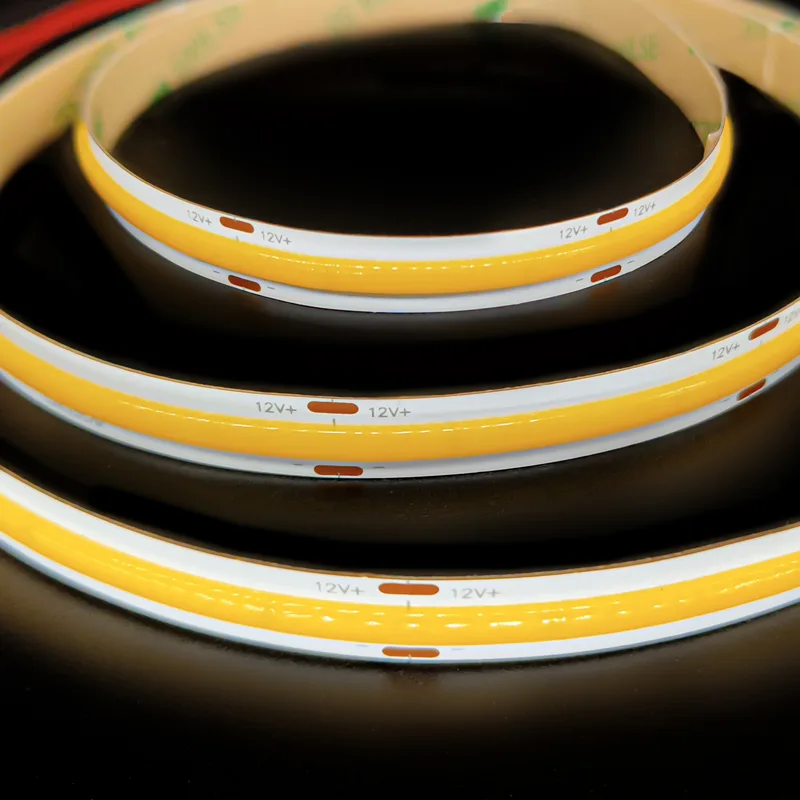

DC12V

Metre başına LED Çip Miktarı: 320/384/480/528chips

CRI: >90

PCB Genişliği: 8mm/10mm

Renk Sıcaklığı: 2700K/3000K/4000K/6500K

Giriş Voltajı: DC12V

Metre başına güç: 8-14W/m

Verimlilik: 90-105lm/w

IP Sınıfı: IP20/IP65/IP67/IP68

Garanti: 3 yıl

DC24V

Metre başına LED Çip Miktarı: 320/384/480/528chips

CRI: >90

PCB Genişliği: 8mm/10mm

Renk Sıcaklığı: 2700K/3000K/4000K/6500K

Giriş Voltajı: DC24V

Metre başına güç: 8-14W/m

Verimlilik: 90-105lm/w

IP Sınıfı: IP20/IP65/IP67/IP68

Garanti: 3 yıl

Daha Fazla Bilgi Edinmek İster misiniz?

Bu LED şerit ışıklar hakkında fiyat, özelleştirilebilir olup olmadıkları, kısılabilir olup olmadıkları vb. gibi daha fazla bilgi edinmek isterseniz, lütfen bugün bizimle iletişime geçin!

1. Gerilim eşleşmesini kontrol edin: Her şeyden önce, güç kaynağının nominal voltajının LED şerit ışığının voltajıyla eşleşip eşleşmediğini kontrol etmeniz gerekir. LED güç kaynağı voltajı çok düşükse, LED şeridin parlaklığının azalmasına veya hatta hiç ışık çıkışının olmamasına neden olur.

LED şerit nominal voltajı 12V olduğunda ancak 9V güç kaynağına erişildiğinde, parlaklığın yaklaşık 30% azalacağını ve güç kaynağı voltajının çok yüksek olduğunu ve bu da LED'in yanmasına neden olacağını gösteren pratik testler vardır. Voltaj nominal voltajı 20% aştığında, LED'in yanma riski büyük olacaktır.

2. Güç kaynağı kapasitesini kontrol edin: İkinci olarak, aşağıdakilerden emin olun GÜÇ KAYNAĞI kapasitesi, kullanılan LED şerit uzunluğunun gereksinimlerini karşılayabilir. Bu, genellikle her uzunluk için akım veya güç tüketimini listeleyen LED şerit ışık teknik özellik sayfasına bakılarak hesaplanabilir.

DC12V Güç Kaynağı

Giriş Voltajı: AC100-240V

Çıkış Gerilimi: DC12V

Çıkış Akımı: 3A-10A

Güç: 35W-150W

Etkililik: 83%-87%

PF: >0.8

Karartma: N/A

IP Derecesi: IP67

Sertifika: UL, CE, ROHS

Garanti: 2 yıl

DC24V Güç Kaynağı

Giriş Voltajı: AC90-305V

Çıkış Gerilimi: DC24V

Çıkış Akımı: 1.5A-22A

Güç: 80W-320W

Etkililik: 88%-95%

PF: >0.95

Karartma: 3'ü 1 arada kısılabilir, DALI (ELG serisi)

IP Derecesi: IP67

Sertifika: UL, CE, ROHS

Garanti: 7 yıl

Daha Fazla Bilgi Edinmek İster misiniz?

LED güç kaynakları hakkında fiyatlar, daha fazla model vb. gibi daha fazla bilgi edinmek istiyorsanız, lütfen şimdi bizimle iletişime geçin!

10W LED şerit ışık için metre başına ortak bir güce, örneğin, 5 metre uzunluğundaki şeridi bağlamak istiyorsanız, toplam güç 50W'tır; P = UI (güç = voltaj × akım) formülüne göre, 12V voltajda, gereken akım yaklaşık 4.2A'dır ve daha sonra güç kaynağının 4.2A'dan daha büyük çıkış akımını seçmeniz gerekir.

Elektriksel açıdan bu iki koşul karşılandığında, kullanıma alınabilirler.

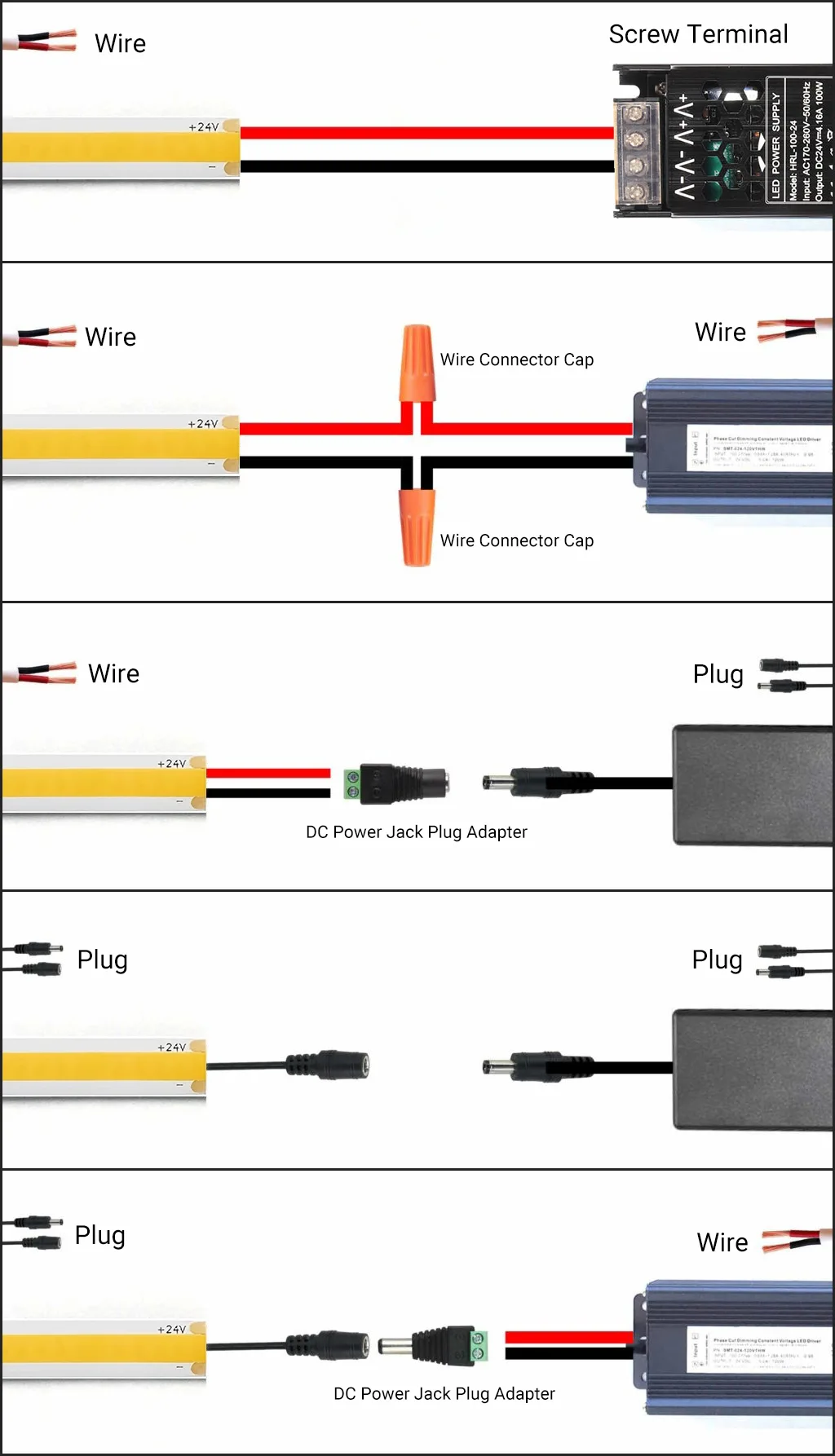

Güç Kaynağını LED Şerit Işığa Bağlama Kılavuzu

LED şerit ışık ile güç kaynağı arasındaki elektriksel uyumluluğu belirledikten sonra, güç kaynağı ile LED şerit arasındaki konektörler ve fişler açısından fiziksel uyumluluğu da göz önünde bulundurmanız gerekir. LED şerit ışıklar ve güç kaynakları arasındaki bağlantı türlerinin çeşitliliği nedeniyle bu durum kafa karıştırıcı olabilir. Anlaşılmasına yardımcı olmak için, aşağıdaki diyagramlar LED şeritlerin güç kaynaklarına bağlanmasına rehberlik edecek şekilde düzenlenmiştir.

Yukarıdaki Bağlantı Kılavuzu Diyagramı Nasıl Anlaşılır?

İlk olarak, "güç kaynağı tarafında" kullanılan bağlantı türünü belirleyin; ardından, "LED şerit tarafında" kullanılan bağlantı türünü belirleyin.

Güç kaynağı tarafındaki yaygın bağlantı türleri yalnızca DC erkek fişler ve açık kablolar değil, aynı zamanda veri aktarım işlevlerine sahip çok işlevli arabirimlerle donatılmış bazı üst düzey akıllı güç kaynakları gibi bazı özel özelleştirilmiş arabirimlerdir, bu yalnızca gücü iletmekle kalmaz, aynı zamanda LED şerit ışık parlaklığı, rengi ve diğer parametrelerin kontrolünü de gerçekleştirebilir.

LED şerit tarafında, yukarıda bahsedilen açık kablolara ve DC soketlerine ek olarak, kurulumu daha kolay ve hızlı olan ancak nispeten daha az çok yönlü olan bazı entegre kalıp hızlı bağlantı arayüzleri de vardır.

Daha sonra, kendi kurulumunuz için geçerli olan bağlantı yöntemini bulun. Örneğin, güç kaynağı "açık kablo" üzerindeyse ve LED şerit "DC fişi" üzerindeyse, diyagramdaki üçüncü kutuya bakın.

Güç Kaynağının DC Çıkış Konektörünün Belirlenmesi

İlk olarak, güç kaynağının DC çıkışındaki konektör tipini kontrol edin. En yaygın konektör, piyasada daha yaygın olan ve çoğu geleneksel LED şerit ışığa uyum sağlayan DC erkek fiştir.

Meanwell güç kaynakları gibi diğer durumlarda fiş olmayabilir, sadece kırmızı ve siyah etiketli iki kablo olabilir. Kırmızı kablo genellikle pozitif terminali ve siyah kablo negatif terminali temsil eder ve kutupların ters çevrilmemesi için bunları bağlarken özel dikkat gösterilmesi gerekir.

Her iki güç kaynağı türü de LED şerit ışıklarla kullanılabilir ancak farklı şekilde bağlanır, bu nedenle kullanmadan önce bu konuda net olmak önemlidir.

LED Şerit Işıktaki Bağlantı Türünü Kontrol Edin

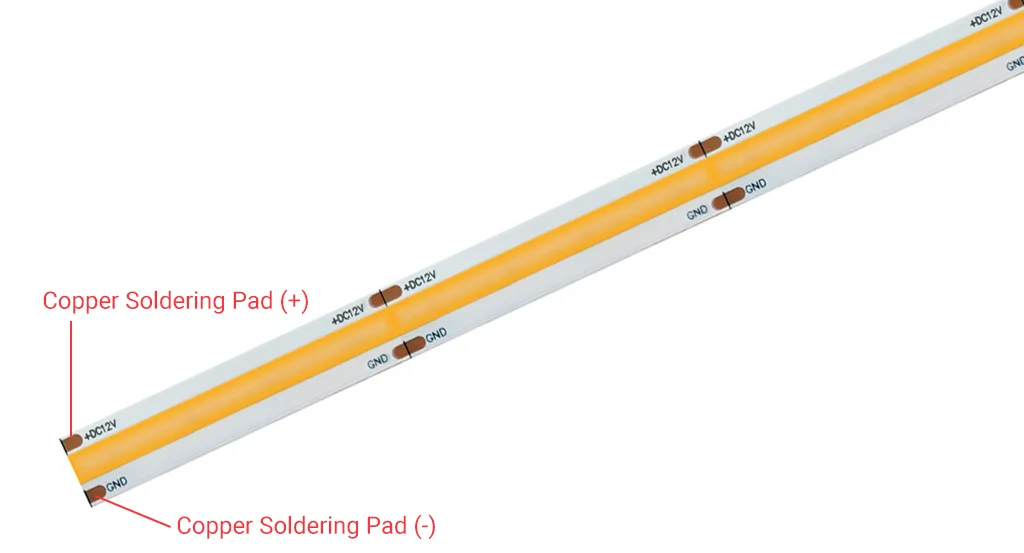

Neredeyse tüm LED şerit ışıklarda, elektrik girişinin sonunda yönlendirileceği "+" ve "-" etiketli pedler bulunur. Duruma bağlı olarak üç farklı senaryo ortaya çıkabilir.

İlk senaryoda, LED şerit makarasının herhangi bir bölümünü kesip açarsanız, her bölümün sonunda yarı dairesel pedler bulacaksınız. Bu pedler elektrik bağlantısının temelini oluşturur ve bağlantı yaparken kabloların pedlerle iyi temas ettiğinden emin olmanız gerekir.

Bütün bir LED şerit ışık rulosu satın alıyorsanız, LED şerit ışık üreticisi şeridin her bir ucuna bir dizi kablo takmıştır. Bu teller çıplak açık teller veya DC soketleri olabilir. LED şeridi daha kısa segmentler halinde keserseniz, ilk senaryoya giren en az bir segment elde edersiniz.

Akılda tutulması gereken bazı temel elektronik ilkeler vardır: nihai hedef, güç kaynağının DC çıkışından gelen pozitif (genellikle kırmızı) kabloyu "+" bakır pede ve güç kaynağının DC çıkışından gelen negatif veya toprak (genellikle siyah veya beyaz) kabloyu "-" bakır pede bağlamaktır. Kablolar ters çevrilirse, LED şerit düzgün çalışmayacağı gibi güç kaynağı veya şerit de zarar görebilir.

Pedleri Kablolara Dönüştürme

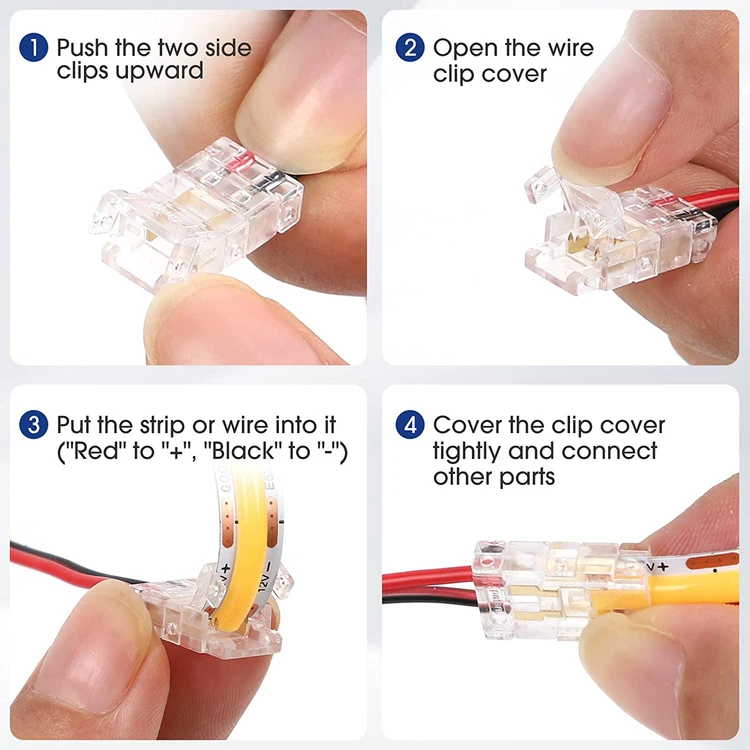

LED şerit ışıkları daha kısa uzunluklarda kesmek için bakır lehimleme pedlerinde kablo olmayacaktır. Birçok öğretici ve eğitici video, elektrik bağlantısı yapmak için bu bakır pedlere kablo lehimlenmesini önerecektir.

Ancak lehimleme herkes için uygun değildir ve lehim havyası, lehim teli, akı gibi aletler ve ustalaşmak için biraz pratik gerektiren sıkıcı bir süreç olabilir. Sıcaklık doğru şekilde kontrol edilmezse lehimleme LED şeride de zarar verebilir.

Onun yerine, lehimsiz konnektörler tavsiye edilir. Bu konektörler, teller ve bakır lehim diski arasında güvenli temas sağlamak için LED şerit ışığın uçlarına klipslenir. Örneğin, piyasada yaygın olarak bulunan yaylı lehimsiz konektörler, bakır pedleri dahili bir yay yapısıyla sıkıca sıkıştırarak sabit bir bağlantı sağlar.

Sonuç olarak, LED şeridin ucundaki bakır pedler sadece birkaç saniye içinde kablolara dönüştürülebilir. En önemlisi, LED şerit sadece mandalını açarak serbest bırakılabilir ve konektörden çıkarılabilir.

LED Şerit Işıklar Paralel mi Seri mi Bağlanmalıdır?

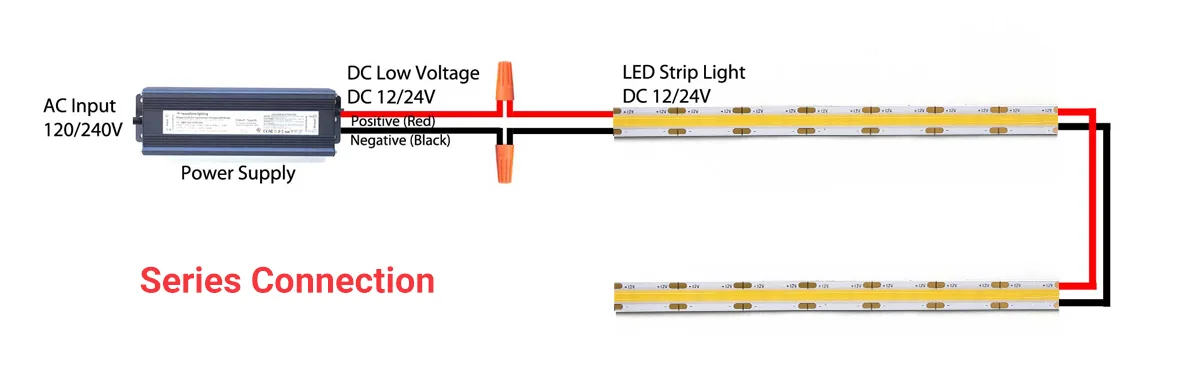

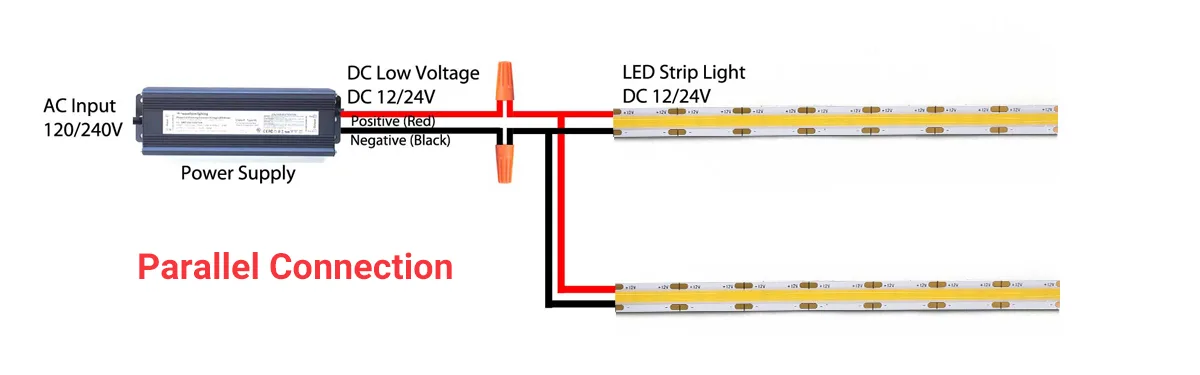

Aynı güç kaynağına birden fazla LED şerit ışık bağlamak için, ilk şeridi ikinci şeride "seri" olarak bağlamayı veya iki şeridi bağımsız olarak aynı güç kaynağına, yani "paralel" olarak bağlamayı yararlı bulabilirsiniz.

Genel olarak, seri bağlantının kullanımı daha kolaydır, sadece ışık şeritlerinin sırayla ilk ve son olarak bağlanmasını gerektirir. Ancak, seri bağlandığında akım her bir şeritten sırayla geçer ve bu da bazı voltaj düşüşü sorunlarına neden olabilir.

Örneğin, her biri 1 ohm dirençli üç adet 1 metrelik LED şeridin seri bağlantısı kullanıldığında akım 1A olur. Ohm yasasına göre (U = IR, voltaj = akım × direnç), ilk şerit 1V'luk bir voltaj düşüşü üretecektir. Şerit sayısı arttıkça, voltaj düşüşü kademeli olarak birikecek ve şeridin arkasının parlaklığının önemli ölçüde azalmasına neden olacaktır.

Paralel bağlantı, her LED şerit voltajı, her şeridin parlaklığının aynı olmasını sağlamak için eşittir, ancak daha fazla kablo ve bağlantı gerektirir, maliyet nispeten yüksektir ve kurulum nispeten karmaşıktır.

Özet olarak

LED şerit ışıkların güç kaynağına bağlanması hem basit hem de karmaşıktır. Elektrik uyumluluğunun önceden dikkatli bir şekilde kontrol edilmesi, bağlantı işlemi sırasında fiziksel arayüz türünün doğru bir şekilde belirlenmesi, bağlantı yönteminin doğru seçilmesi veya bağlantı parçalarının uygun kullanımı olsun, her adım kritik öneme sahiptir.

Gerçek kullanımda herhangi bir sorunla karşılaşırsanız, lütfen bizimle iletişime geçmekten çekinmeyin; profesyonel ekibimiz, cihazın işlevini tam olarak yerine getirmenize yardımcı olmak için size tam destek ve yardım sağlayacaktır. LED şerit ışık ideal aydınlatma efektini yaratmak için.