LED strip lights have become increasingly popular for both decorative and functional lighting due to their flexibility, energy efficiency, and ease of installation. However, to get them up and running, it’s essential to know how to properly connect them to a power supply. Whether you’re a DIY enthusiast or new to LED lighting, understanding this process is crucial for safe and effective use. In this article, we’ll share you the connection methods, cautions and important tips to ensure a successful and reliable connection between your LED strip and power source.

How to Connect LED Strip to Power Supply?

When connecting LED strips to a power supply, it’s important to understand the different wiring and connector types available. LED strips typically come with either open wires or DC connectors. On the power supply side, there are also several options: some, like the Meanwell LPV series, come with open wire outputs; others, like the LRS series, require wiring directly to terminals; and some use plug-and-play adapters with DC female plug. Choosing the right connection method depends on the types of strip and power supply you’re using. In this guide, we’ll break down the most common connection scenarios and show you how to safely and effectively connect your LED strip to the power supply.

LED Strip with Open Wire to Power Supply without Any Open Wire or Plug

Super easy, just connect the LED wires directly to the power supply’s output terminals by a screwdriver, matching polarity (+ to +, – to -). Ensure voltage compatibility, secure the connections tightly, and insulate exposed wires to prevent short circuits.

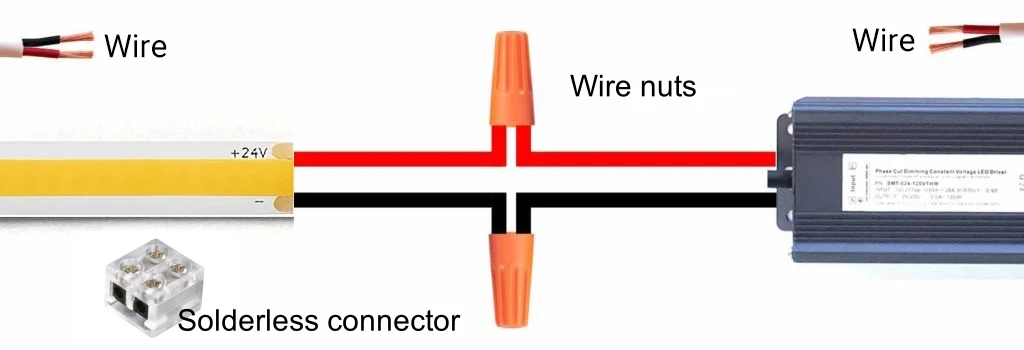

LED Strip with Open Wire to Power Supply with Open Wire

Twist “+” of LED Strip and “+” of LED driver together, fasten them by wire nuts or wirelss connectors tightly, check more connector options here.

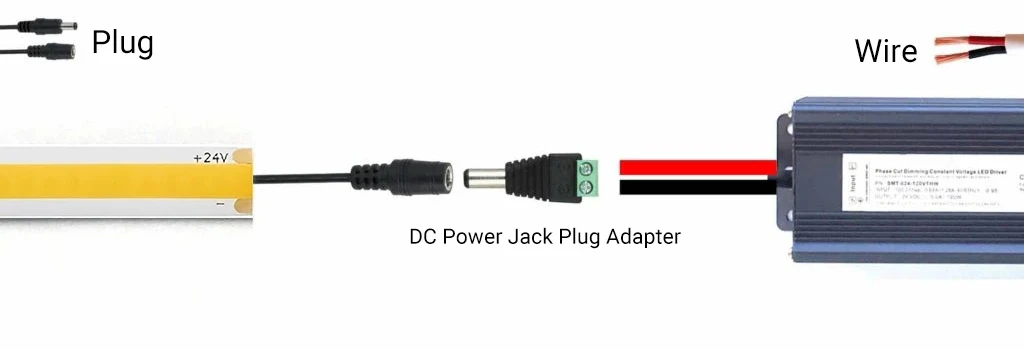

LED Strip with Open Wire to LED adapter

LED adapters typically have a DC female plug as the output. If the LED strip is with open wires, a screw-in male terminal connector is needed. Simply insert the LED wires into the connector, match the polarity (+ to +, – to -), tighten the screws, and plug it into the adapter securely.

LED Strip with DC Plug to Power Supply without Any Open Wire or Plug

If your LED strip comes with a DC male plug, which is standard since most adapters have a DC female plug. But you’re using a power supply without any output wires, there are three ways to connect them:

- Use a cable with a DC female plug.

- Use a screw-in female terminal connector and any wires.

- Cut off the DC plug and connect the wires from the strip directly to the power supply.

LED Strip with DC Plug to Power Supply with Open Wire

In this case, if you want a cleaner and more secure connection, using screw-in female terminal connectors is a great option. However, if you don’t have any connectors on hand and want a quick solution, you can cut off the DC male plug from the LED strip and connect the exposed wires to the power supply using wire nuts or solderless connectors. Just make sure to match the polarity correctly and insulate the connection to ensure safety and durability.

LED Strip with DC Plug to Power Supply with DC Plug

This is the simplest method—just plug the DC male connector from the LED strip directly into the DC female connector on the power supply. No tools or wiring needed, as long as the voltage and polarity match.

LED Strip without Any Wires or Plug to Power Supply

Most LED strips come with DC plugs or wires, but when you cut the strip to a shorter length, the new section won’t have input wires. This is important to consider when connecting to a power supply. To solve this, you can use solderless connectors for a quick and clean connection. Alternatively, if you have a soldering iron, you can solder two wires onto the copper pads of the cut strip, then connect them to the power supply refer to the methods mentioned above.

The Other Situations

If your LED strip uses a custom connector, always ask the supplier to provide a matching one for better connection.

Additionally, if you’re using a multi-color strip—such as a CCT tunable, RGB, or addressable LED strip—a controller is required between the strip and the power supply. The controller manages color, brightness, and effects, and must be correctly selected and connected based on your strip type. For detailed guidance on how to choose and connect the right controller, please refer to our dedicated article on this topic.

Important Tips for Connecting LED Strips to LED Drivers

When installing LED strips, ensuring a safe and stable connection to the LED driver is crucial for performance and longevity. Below are key points to consider during installation:

Voltage Matching

Always make sure the output voltage of the LED driver matches the working voltage of the LED strip. For example, use a 12V driver for 12V LED strips, or 24V for 24V strips. A mismatch can damage the LEDs or cause them not to work.

Power Rating

The driver’s power output should be at least 20% higher than the total wattage of the LED strip. This reserve capacity prevents overloading and extends the lifespan of the driver.

Correct Polarity

Never connect the positive and negative wires incorrectly. Reverse polarity can cause the strip to fail or even lead to short circuits.

Short Cable Runs & Thick Wires

Install the driver close to the LED strip. Use thick, high-quality wires and keep the cable length short to minimize voltage drop, especially for long or high-power installations.

Proper Insulation

Ensure all connections are well insulated using heat shrink tubing or electrical tape. Poor insulation can lead to short circuits or electric shock.

Waterproofing for Outdoor Use

If the setup is outdoors, waterproof all connections. Use waterproof connectors and enclosures, and seal any exposed wires to prevent water damage.

Power Supply for Long Strips

For LED strips longer than 5 meters, power them in sections to avoid voltage drop at the far end. This ensures even brightness across the entire strip.

Grounding Metal Drivers

If your LED driver has a metal housing, make sure it is properly grounded. This helps prevent electric shocks and reduces the risk of electrical leakage.

Troubleshooting Carefully

If the LED strip doesn’t light up after connection, turn off the power immediately and double-check wiring, voltage, and polarity before trying again.

Seek Professional Help

If you’re unsure or dealing with a complex setup, it’s always best to consult a qualified electrician to avoid risks and ensure a reliable installation.

Can I Connect Multiple LED Strips to One Power Supply?

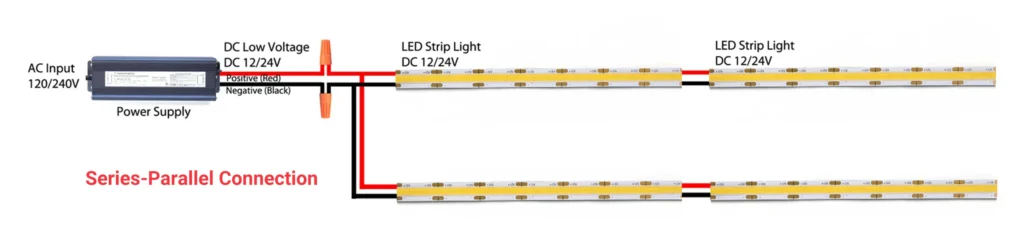

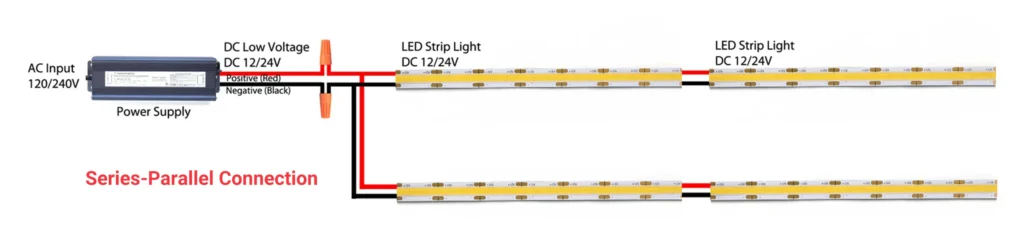

Yes, you can connect multiple LED strips to a single power supply, but the method you choose—series or parallel—matters greatly in terms of performance and safety. Below are two common approaches:

Series Connection (Not Recommended in Most Cases)

Most manufacturers do not recommend connecting LED strips in series, especially for standard 5-meter strips. The reason is voltage drop: the further the electricity travels along the strip, the more voltage is lost, which can result in visible brightness differences between the beginning and end of the strip.

However, in some custom projects—such as installations where each LED strip is only 1.2 meters—series connection may be considered for convenience. In such cases, it’s important to ensure that the total length of the connected strips does not exceed 5 meters. Additionally, voltage drop should be tested after installation, and the difference between the power input end and the far end should not exceed 1.5V to maintain uniform brightness.

Parallel Connection (Recommended)

Parallel wiring is the most commonly used and recommended method for connecting multiple LED strips to a single power supply. In a parallel setup, each strip receives the same voltage directly from the power source, ensuring consistent brightness across all strips. This method also minimizes voltage drop and allows easier maintenance. Just make sure the total current draw of all the strips combined does not exceed the rated output of the power supply.

Can I Use Multiple Power Supplies to Drive One LED Strip?

In theory, it is possible to use multiple power supplies to power a single LED strip. For example, if your LED strip requires 100W but you only have two 60W power supplies, you might consider using both to meet the power requirement. However, this setup requires strict conditions to ensure safety and performance.

First, both power supplies must be from the same manufacturer and the same product series to ensure their output characteristics (such as voltage regulation and current response) are matched. They must be connected in parallel to the LED strip—not in series—so that they share the load evenly.

However, due to potential risks in real-world applications, such as electrical surges, short circuits, or slight performance differences between the power supplies, we strongly recommend splitting the LED strip into two sections. Cut the strip in the middle and power each section with a separate power supply. This approach reduces the chance of instability and ensures more reliable operation.

If one power supply fails or becomes unstable over time, it could cause fluctuations in voltage or insufficient current to the strip, negatively impacting performance and reducing the overall lifespan of the LEDs. To avoid such issues, always plan for stable, well-matched power sources, or consider using a single higher-wattage power supply when possible.

Where to Buy Reliable LED Strip and Power Supply

If you are looking for supplier for LED strip and LED power supply, Signlite is a supplier you can trust. With over 15 years of professional manufacturing experience, we carefully select only premium raw materials and strictly follow industry standards throughout our production processes. Our skilled and responsible workers ensure consistent product quality, and every LED strip undergoes rigorous testing—including integration sphere tests, IES reports, and aging tests—with full records for traceability. We also offer customized solutions based on your specific needs.

We have experienced power supply engineers who can assist with the development of new drivers. As authorized distributors of well-known brands such as Meanwell, Osram, and Lifud, we are able to offer highly competitive pricing—often better than overseas sources. If you’re looking for reliable, factory-direct products and expert support, contact us for good price.

LED Chip QTY per Meter: 320/384/480/528chips

CRI: >90

PCB Width: 8mm/10mm

Color Temperature: 2700K/3000K/4000K/6500K

Input Voltage: DC12V/24V

Power per meter: 8-14W/m

Efficiency: 90-105lm/w

IP Grade: IP20/IP65/IP67/IP68

Warranty: 3 years

Input Voltage: AC220-240V

Output Voltage: DC24V

Output Current: 1.875A-10A

Power: 45W-240W

Efficicency: 87%-93%

PF: >0.95

Dimming: N/A

IP Rating: IP20

Certification: ENEC, CE, CB, RCM, UKCA, MM, CCC, RoHS

Warranty: 5 years