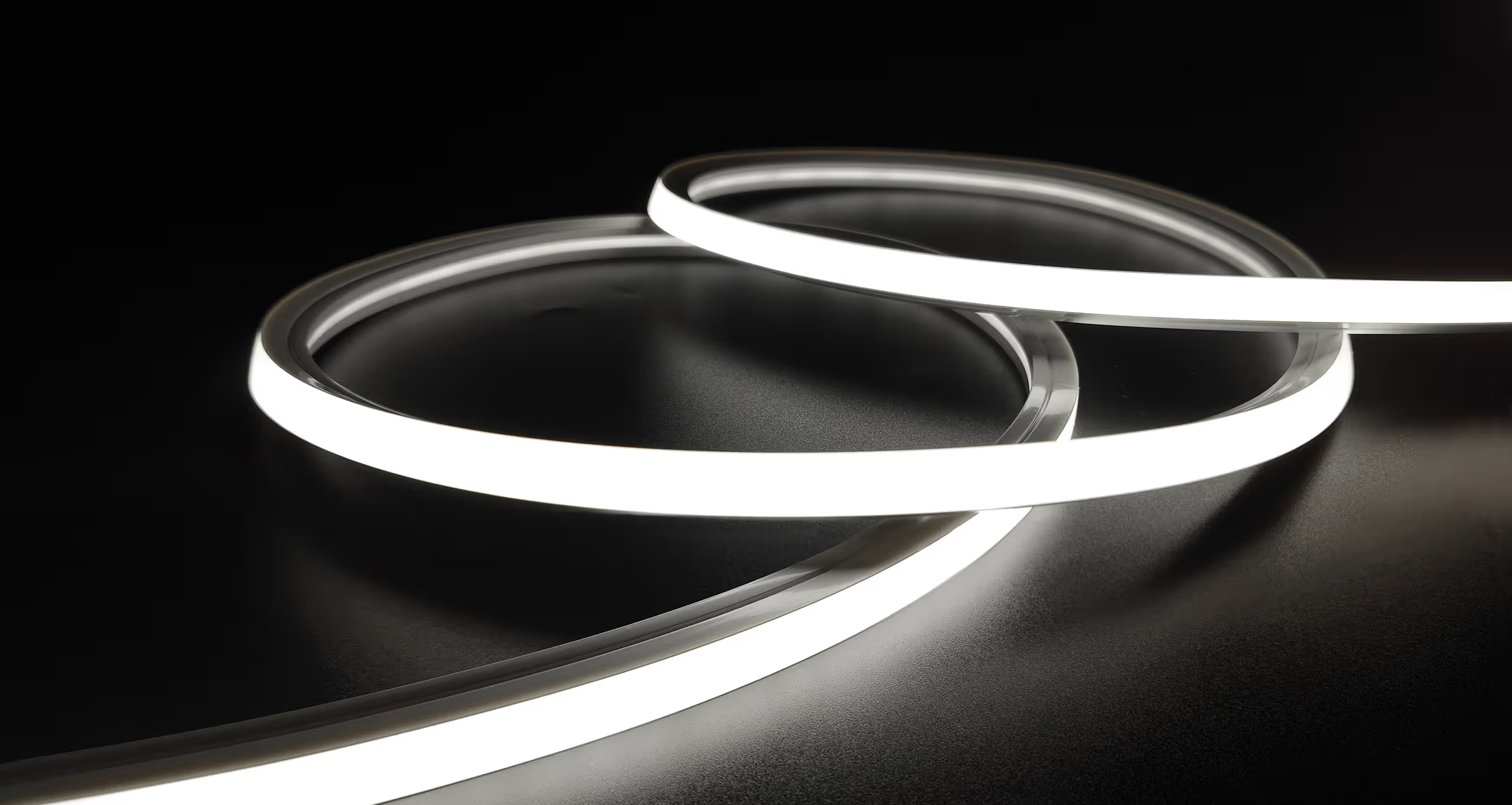

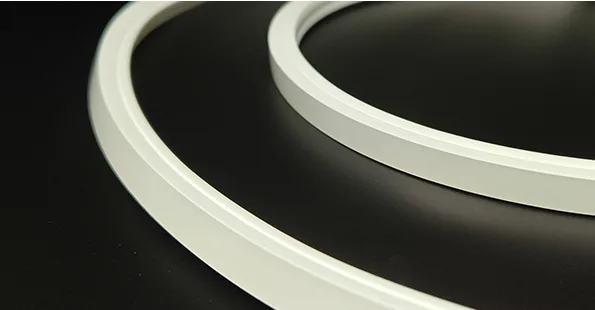

Top Bendable 10x10mm LED Neon Flex Light

The T1010 LED neon flex strip light is a dimmable low-voltage lighting fixture made of high-quality silicone tubing and LED strips. This LED neon strip light is top-bendable, UV, yellowing, and salt-resistant, making it an excellent choice for indoor and outdoor lighting. They can be used for decorative gas station lighting, perimeter lighting, outlining, building boundary lighting, and other applications.

- Flexible and cuttable LED neon strip, cut points every 50mm

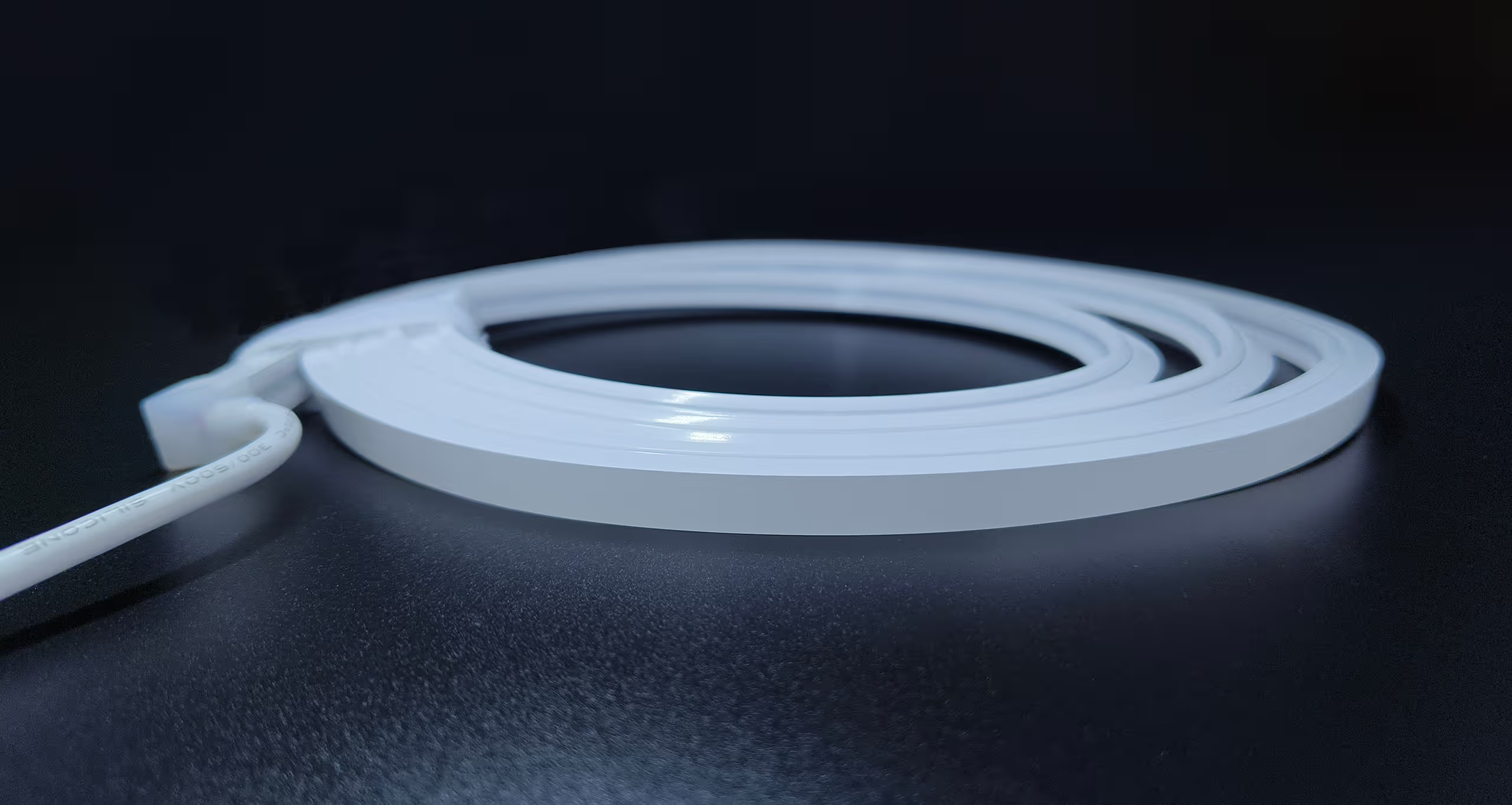

- 5m per spool, 480lm/m, single color 2700K – 6500K optional

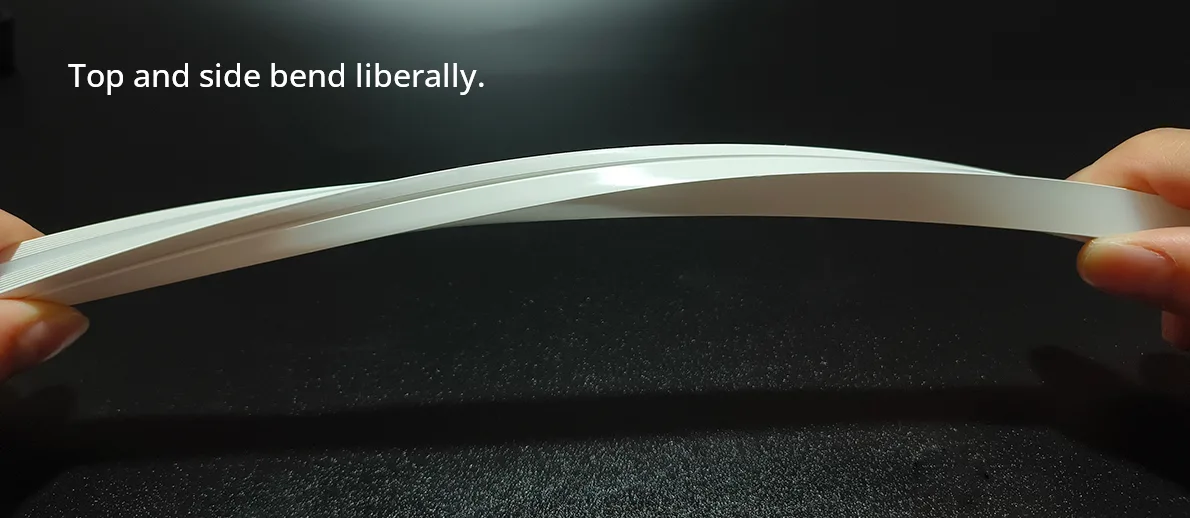

- Vertical bending, min bending diameter 100mm

- High density SMD2835 strip(120LEDs/m), customizable

- Low Voltage Product at 24V – 40W Per Spool

- Waterproof rated at IP65, indoor or outdoor application

- Product comes ready to plug and play

- NQX1010TC Specification Download

T1010 Neon Flex Specifications:

Model No.

NQX1010TC

Lumen

>480lm/m

Input Voltage

DC24V

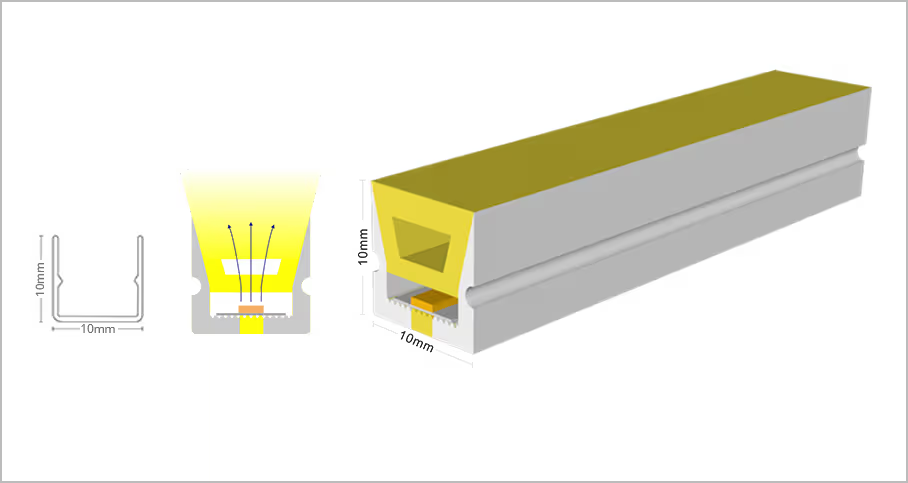

Beam Angle

120°

Power

8W/m

Cut Section

50mm

LED QTY

120LEDs/m

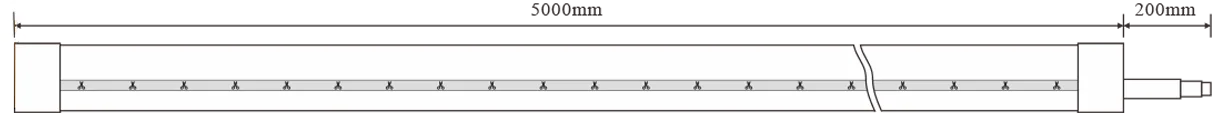

Dimension

5000*10*10mm

CCT

2700K - 6500K

IP Rating

IP65/IP67

SDCM

≤5

Warranty

3 Years

CRI

>80

Package Info

L460*W250*H256mm(300m/Box)

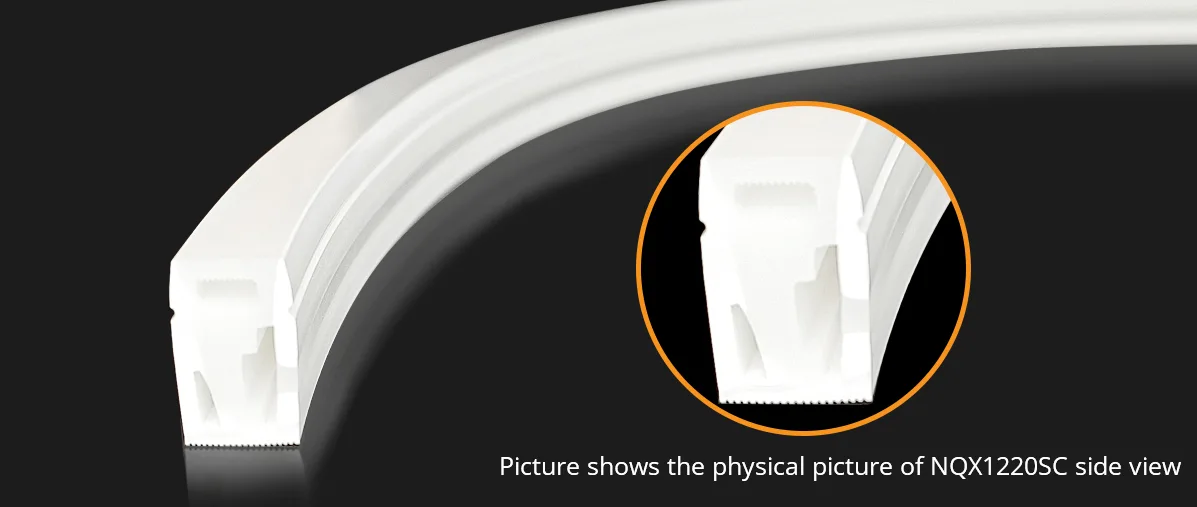

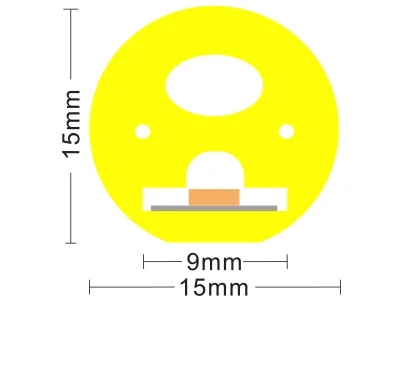

T1010 Neon Dimensions:

NQX1010TC

The Neon Strip Advantages:

Customizable: The T1010 LED neon flex can be customized according to your specific requirements, including size, color, power, voltage, terminals, and so on, to ensure that it perfectly meets your project needs.

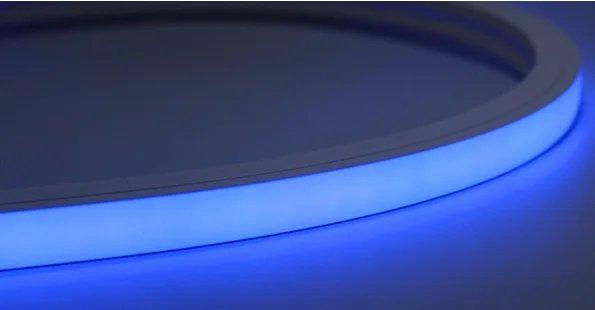

The LED neon light with a high color rendering index (CRI>80/90) and brightness (≥480 lm/m), bright and vivid colors.

All neon LED strip lights have high transmittance semi-transparent optical silicone, which is diffused to achieve dotless illumination.

These LED neon silicone tubes use environmentally friendly silicone material that is soft and resilient, not easy to break, not easy to turn yellow, and has a longer service life.

UV-resistant, yellowing-resistant, and salt-resistant, the operating temperature is -25°C to 100°C.

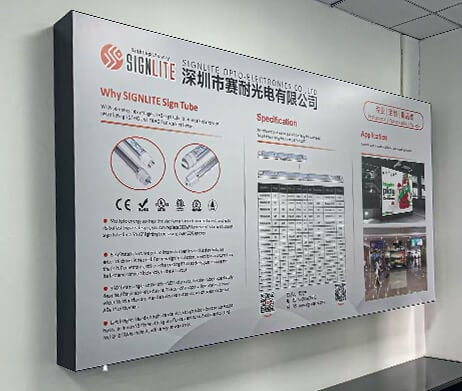

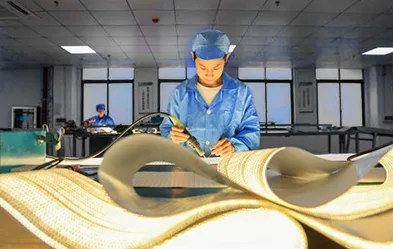

Our Factory

- Factory located in smart manufacturing industry city, Shenzhen.

- A team deeply involved in the industry since year 2010.

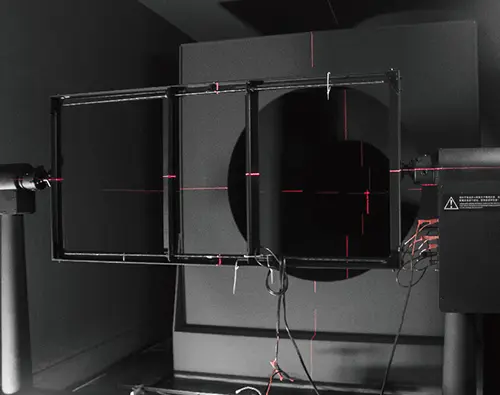

- Equipped with complete optical testing instruments.

- Products are UL listed, 100% aged and tested.

- Proficient in OEM & ODM products design, develop and support.

- Deeply cultivate signage and linear led light products more than 10 years.

Product Certificates

We got UL, ETL, CE, ROHS certifiacted to meet different region standards.

Why Choose Us?

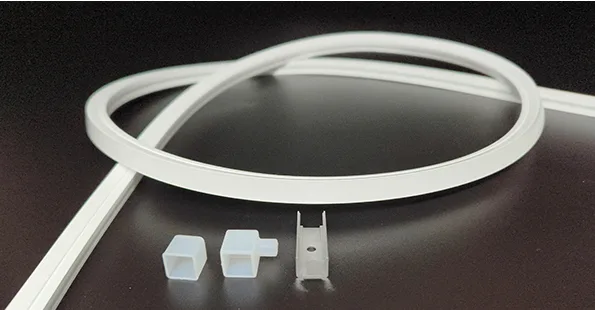

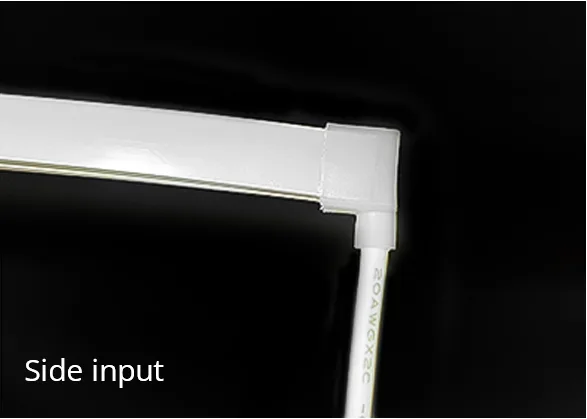

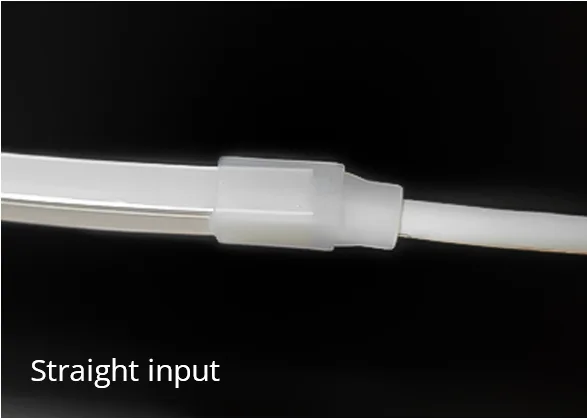

Cable Input Direction

To meet different installation and application, we have developed a variety of outlet plugs for these neon LED strips, namely side, bottom, and front types.

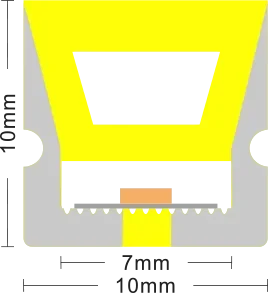

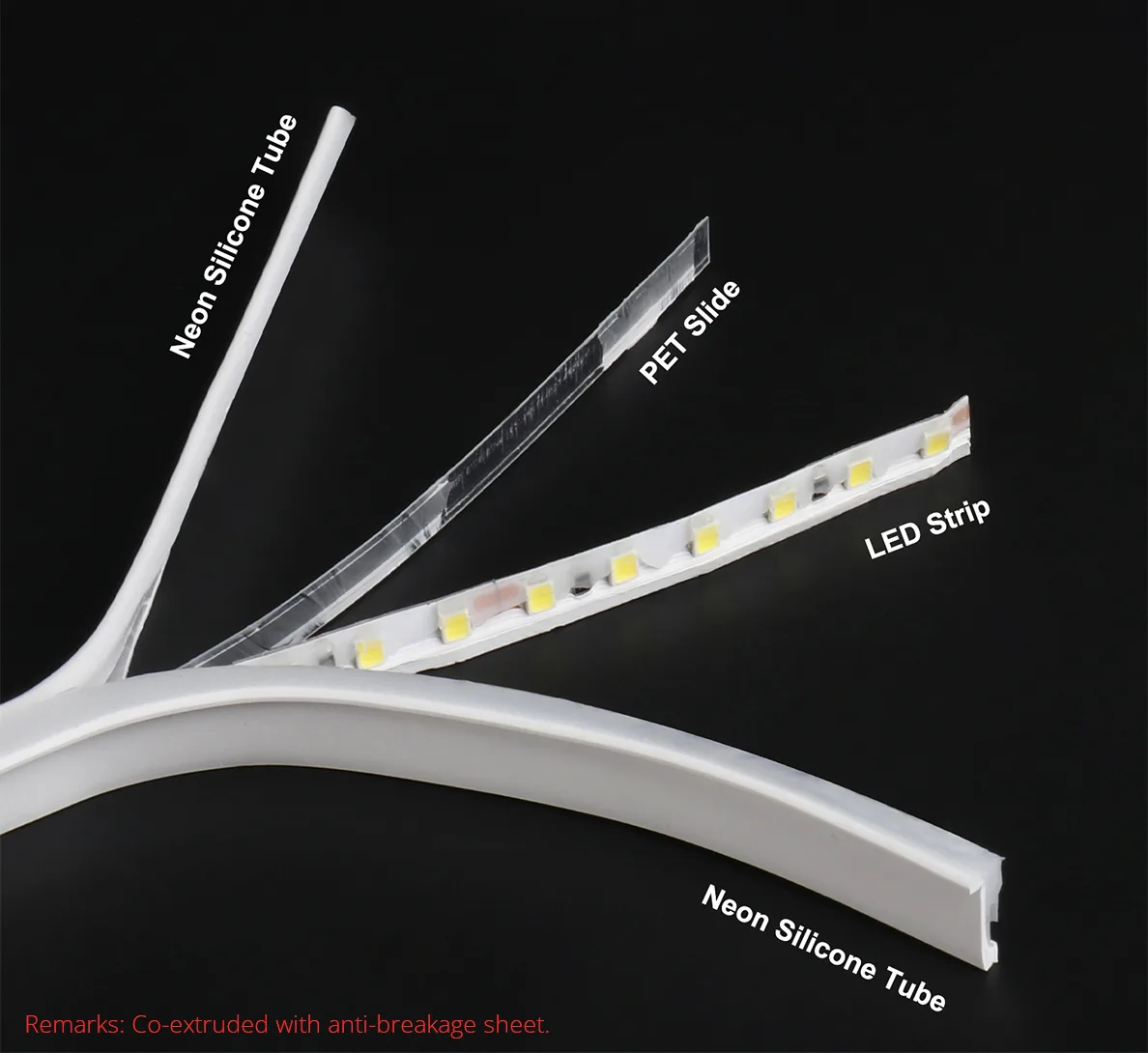

LED Neon Inner Structure

LED neon light consists of a silicone tube, an LED strip, and a transparent PET anti-break sheet. Among them, the neon silicone tube is formed by co-extruding white silicone and translucent silicone.

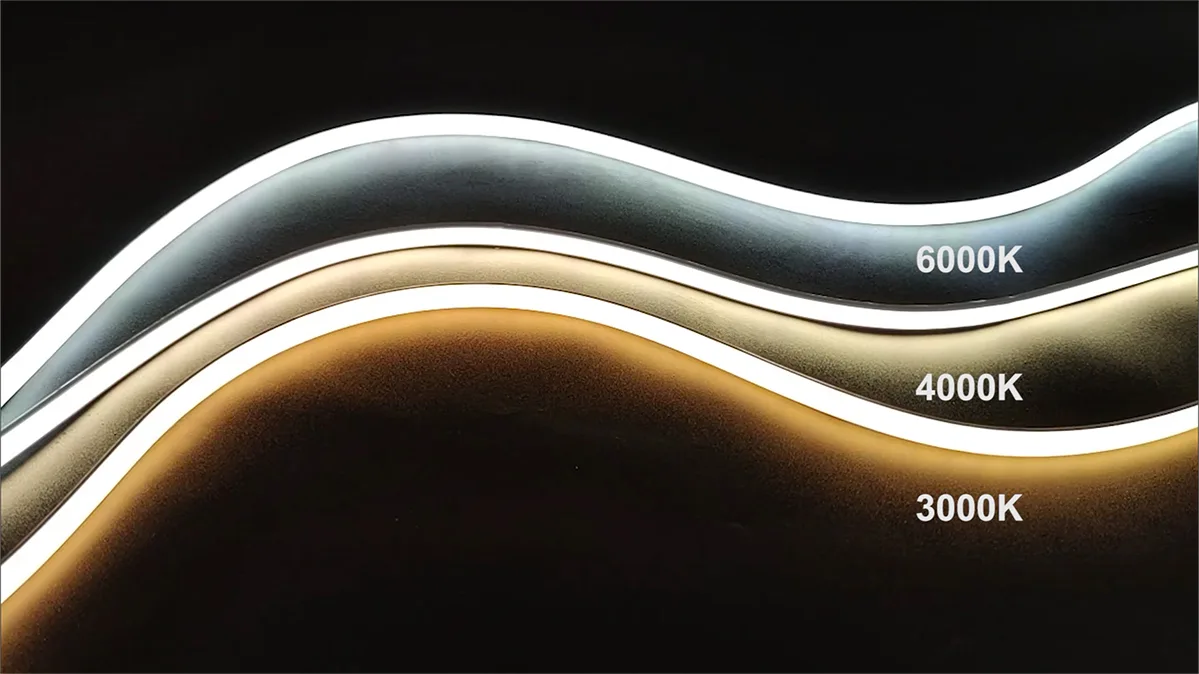

Color Temperature Optional

Bendable, Fireproof, Waterproof

Color Rendering Index

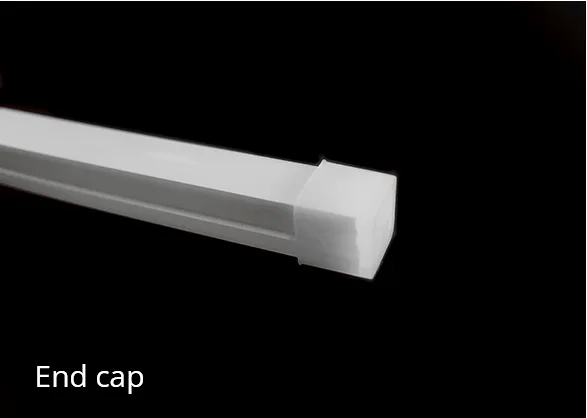

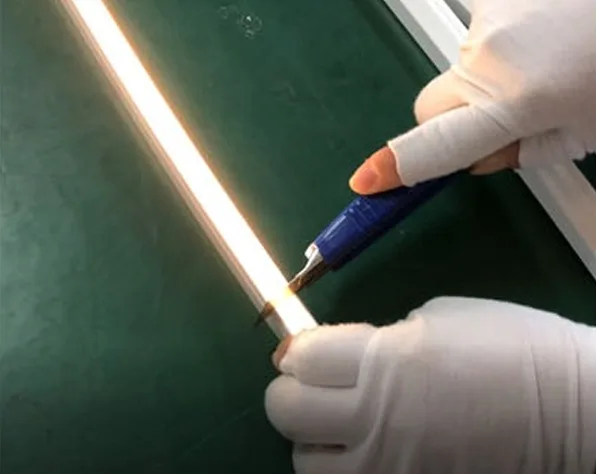

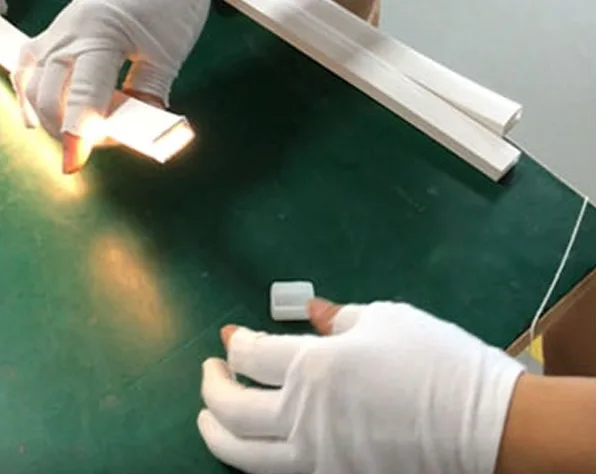

Neon Cutting Process

Step 1: Cut according to your needs.

Step 2: Apply silicone glue at the end.

Step 3: Put the end cap on to firmly fit the light.

Step 4: Wipe off redundant glue with a rag.

Applications

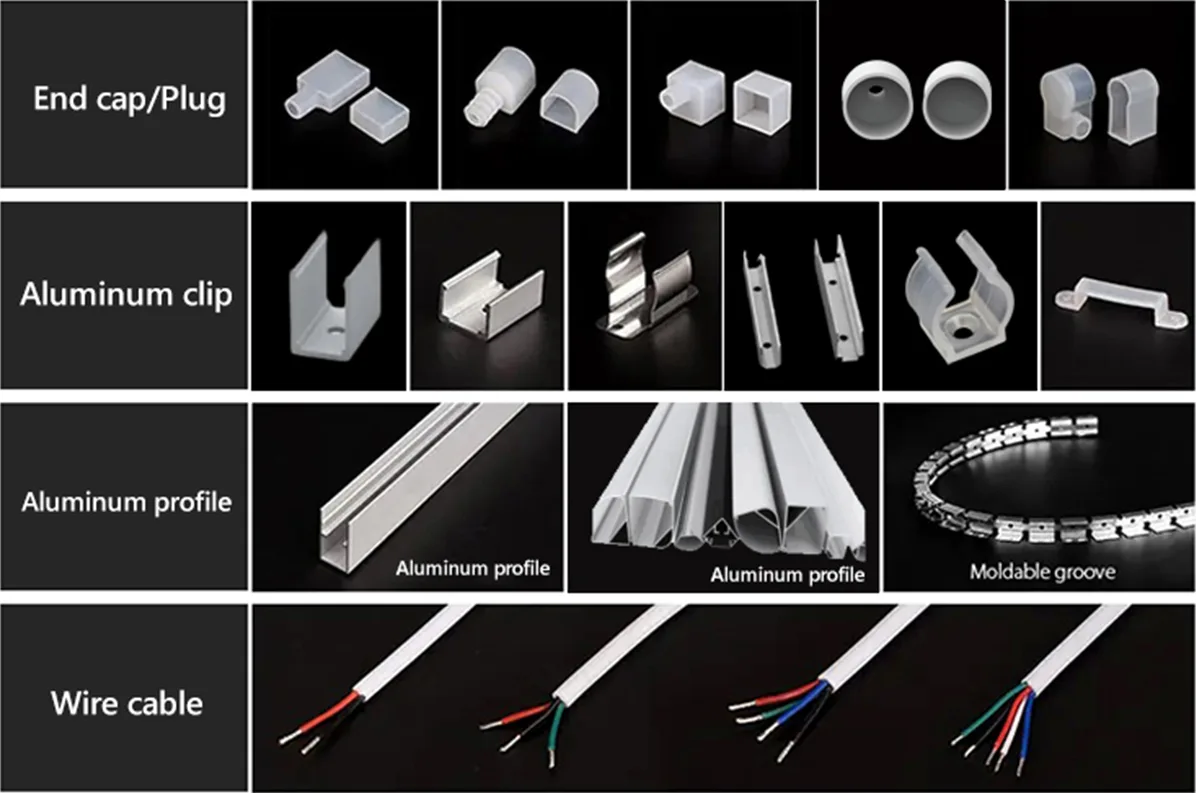

Optional Accessories

Optional More Sizes

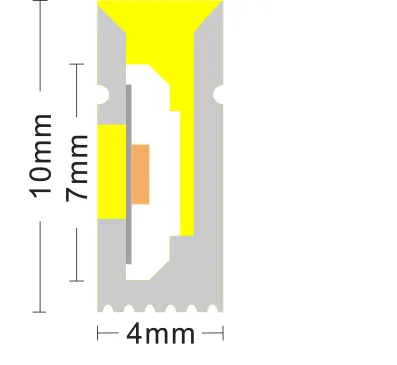

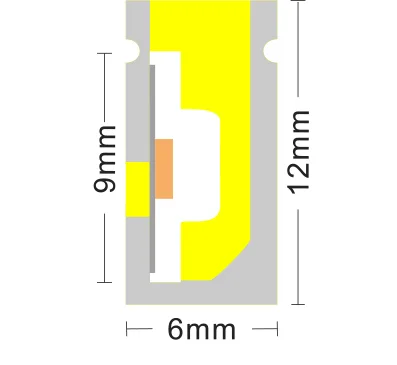

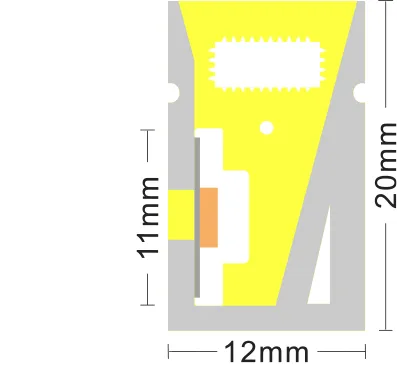

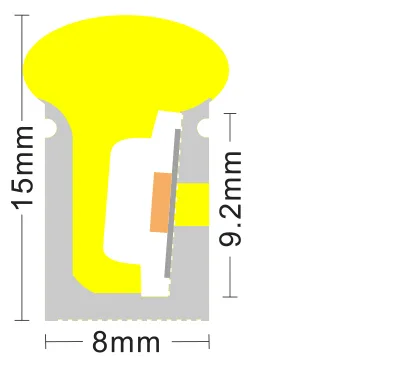

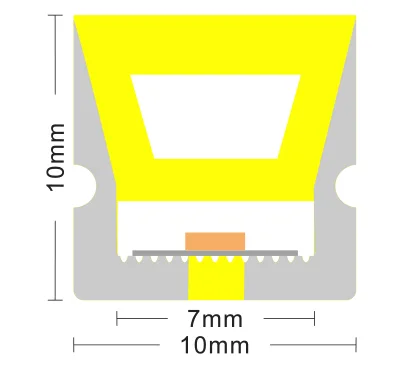

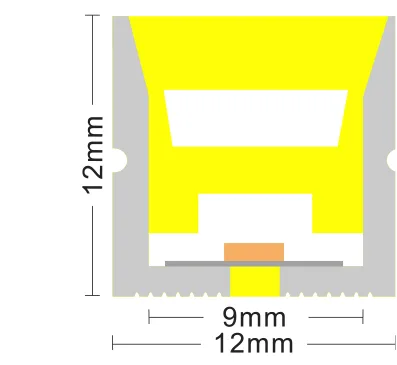

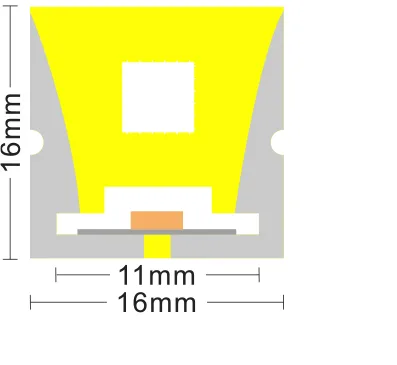

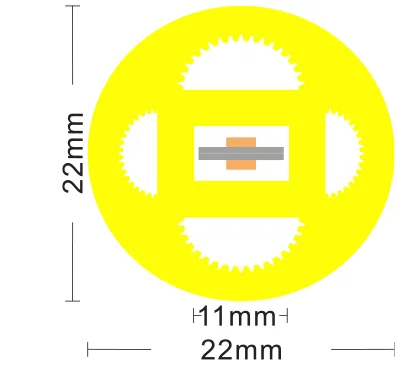

The following is a cross-section of the LED neon strip:

NQX0410SC

NQX0612SC

NAQ1220SC

NQX0815TC

NQX1010TC

NQX1212TC

NQX1616TC

NQX15DC

NQX22CC

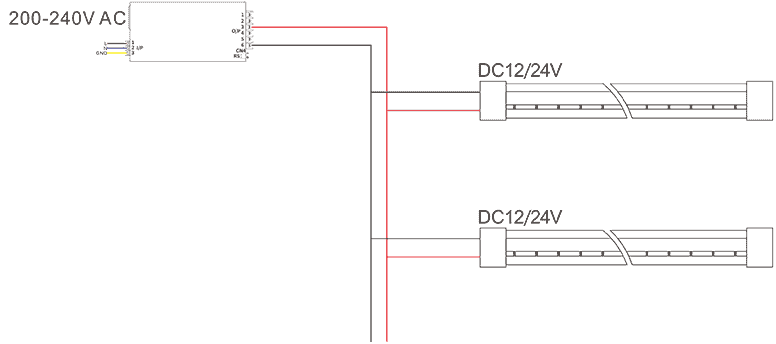

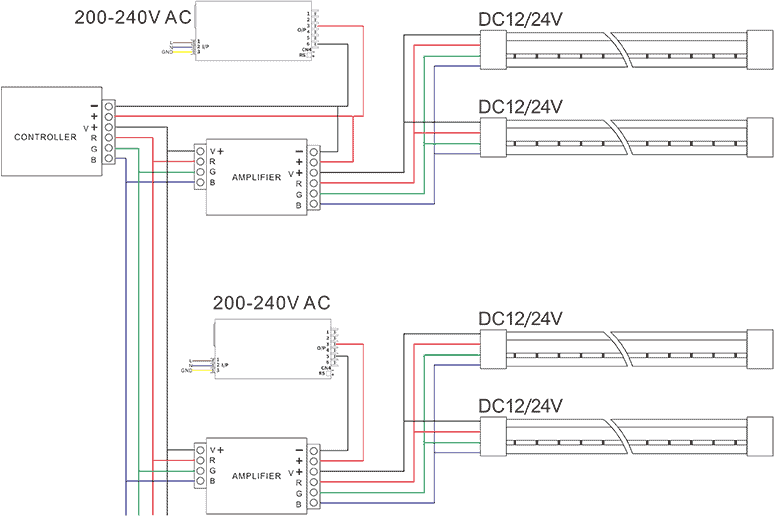

Wiring Installation Diagram

Single Color Wiring Diagram

RGB Wiring Diagram

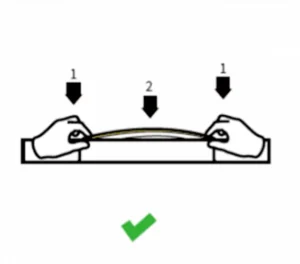

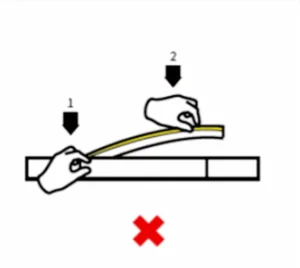

1. When installing the LED neon strip, install it from both ends at the same time; installation from one direction is prohibited.

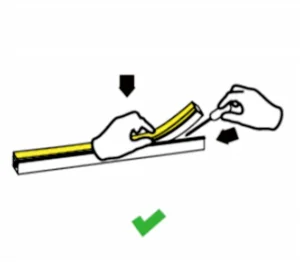

2. Use the tool to disassemble carefully, and do not pull the LED neon strip directly.

Packaging

5meter/reel

Inner anti static bag