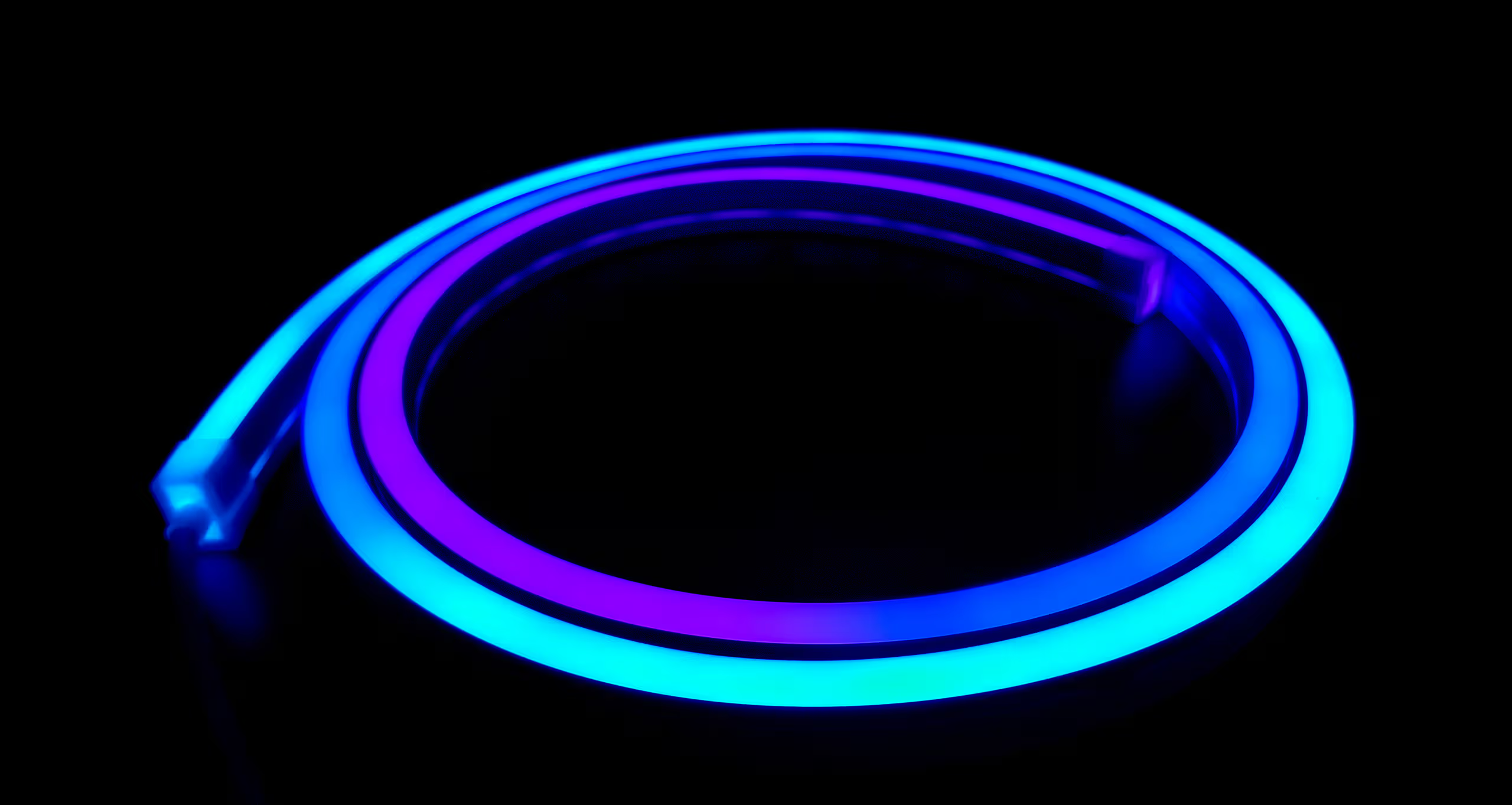

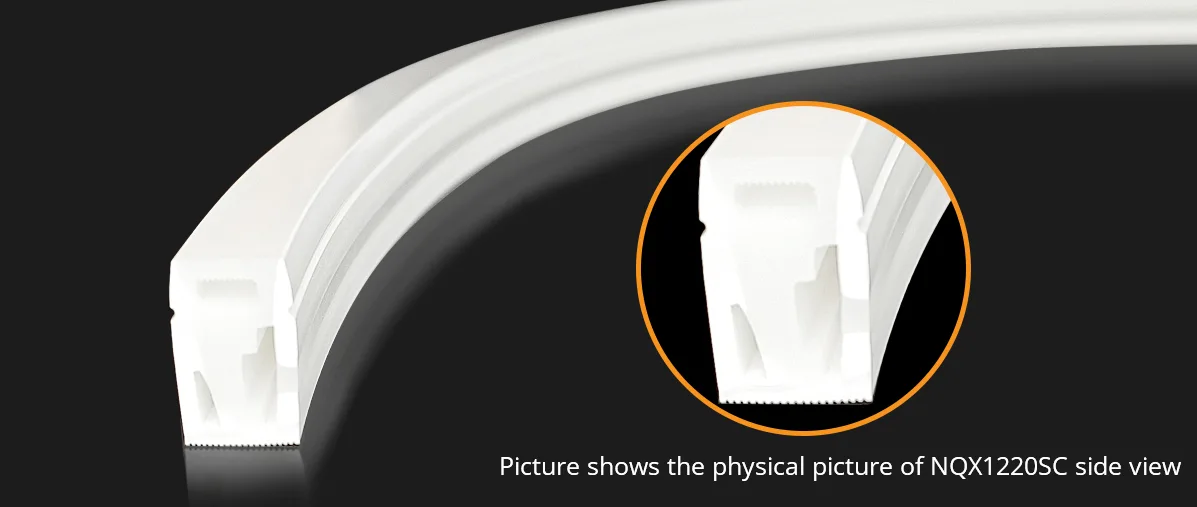

Horizontal Bend Neon Flex RGB Strip Light

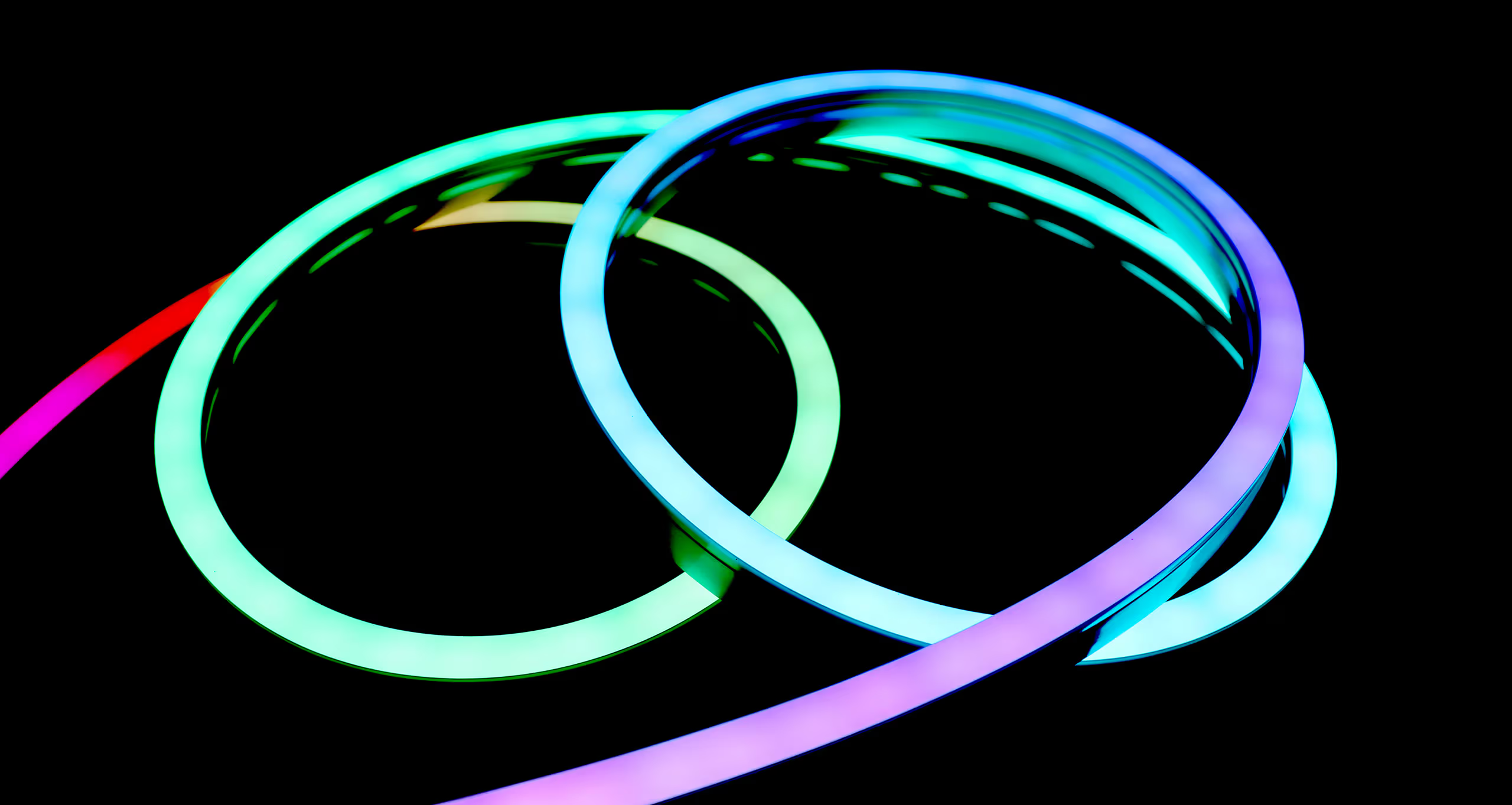

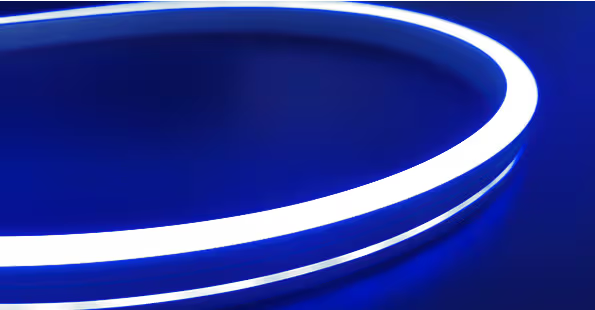

The LED Neon Flex RGB strip light is a color-changing neon LED strip replacement for traditional neon lights. This S1220 RGB Flex Neon is made from 5 meters of RGB strip through a silicone sleeve, is side-illuminated, can be horizontal bent, and requires an RGB color controller and a low-voltage 24DC power supply to operate. This RGB neon can also be used with a DMX decoder to provide continuous smooth lighting effects and very smooth color transitions for architectural decorations, commercial displays, nightclubs, interior design, or any application that requires spotless color-changing lighting.

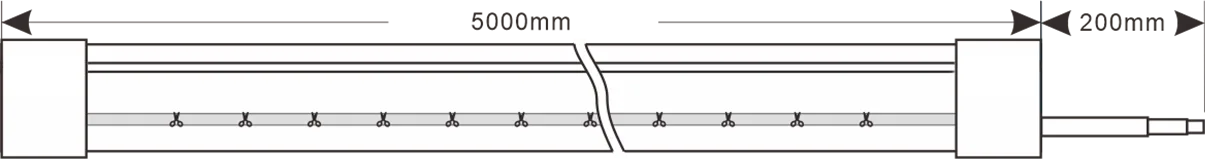

- Flexible and cuttable LED neon strip, cut points every 100mm

- RGB color changing, used with DMX decoder or RGB controller

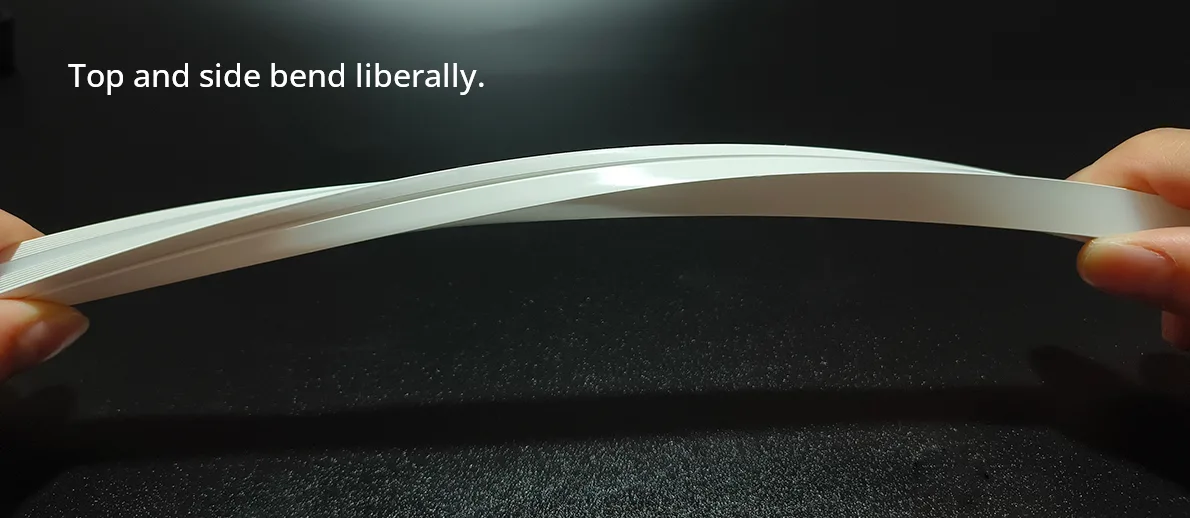

- Horizontal bending, min bending diameter 100mm

- Built-in SMD5050 RGB strip(60LEDs/m), customizable

- Low Voltage Product at 24V – 60W Per Spool

- Waterproof rated at IP65, indoor or outdoor application

- Product comes ready to plug and play

- NQX1010TC Specification Download

Specifications:

Model No.

NAQ1220SC

Lumen

N/A

Input Voltage

DC24V

Beam Angle

120°

Power

12W/m

Cut Section

100mm

LED QTY

60LEDs/m

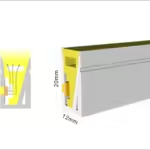

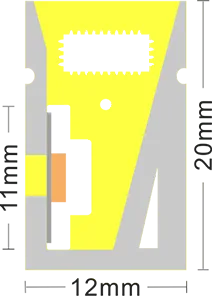

Dimension

5000*12*20mm

CCT

RGB

IP Rating

IP65/IP67

SDCM

N/A

Warranty

3 Years

CRI

N/A

Package Info

L460*W250*H256mm(300m/Box)

Model No.

Input Voltage

Power

LED QTY

CCT

SDCM

CRI

Lumen

Beam Angle

Cut Section

Dimension

IP Rating

Warranty

Package Info

NAQ1220SC

DC24V

12W/m

60LEDs/m

RGB

N/A

N/A

N/A

120°

100mm

5000*12*20mm

IP65/IP67

3 Years

L460*W250*H256mm(300m/Box)

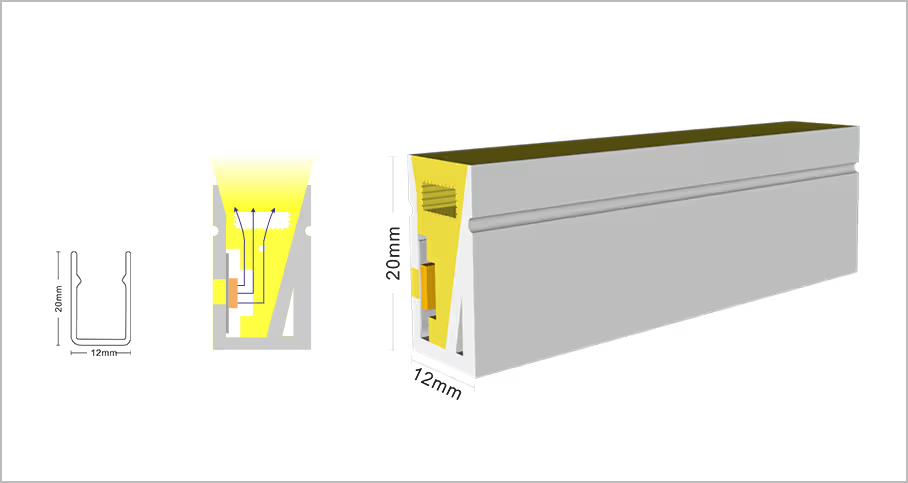

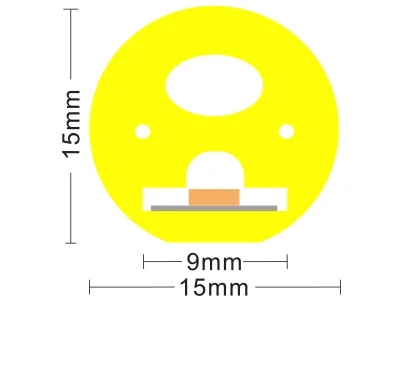

Dimensions:

NAQ1220SC

Advantages:

Customizable design: LED Neon Flex can be tailored to your specific requirements, including size, color, power, voltage, wiring terminals, etc., ensuring a perfect fit for your project needs.

High CRI and brightness; CRI > 80/90.

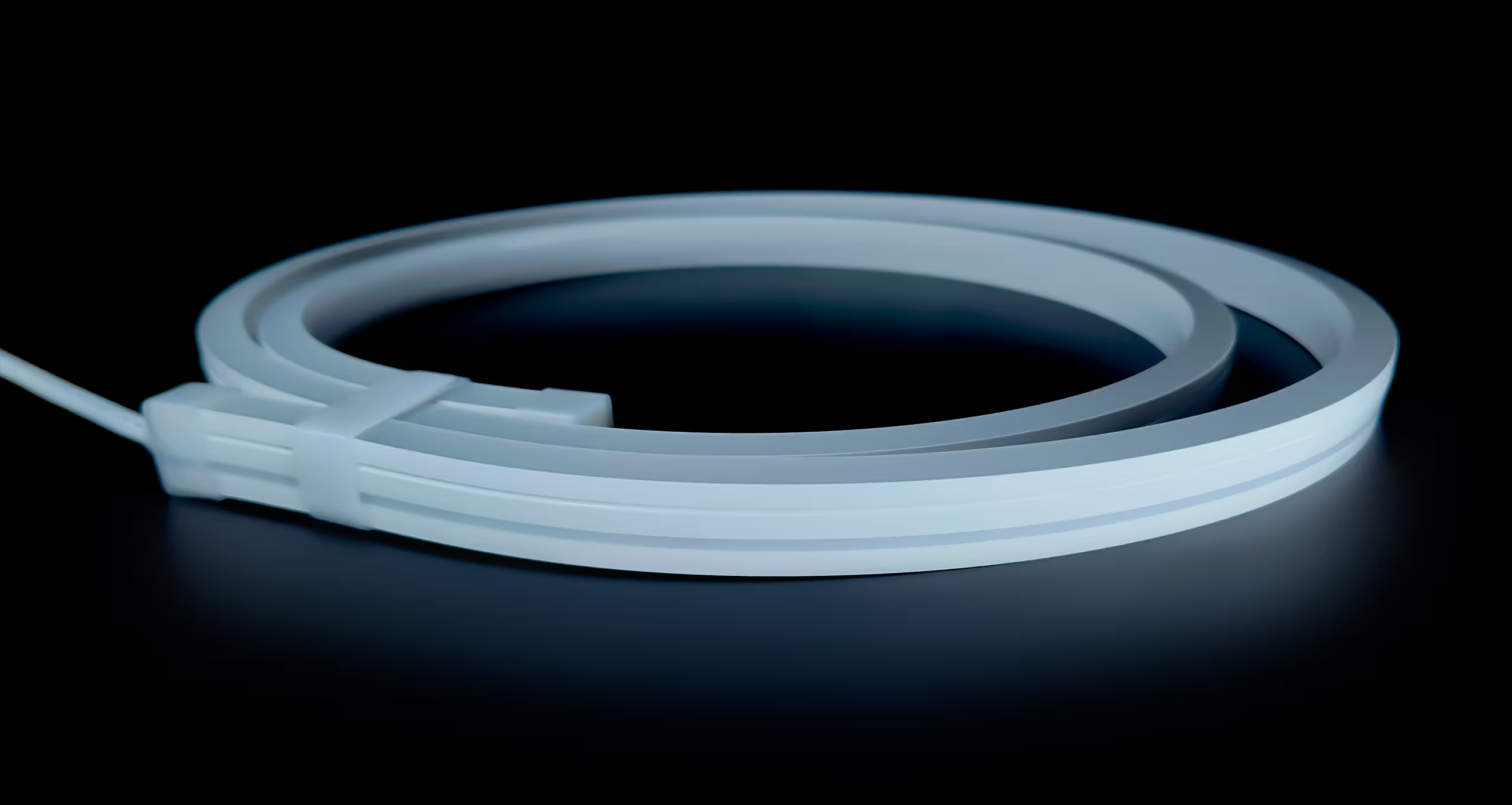

High-light transmittance optical silicone, dot-free lighting.

Environment-friendly silicone material, better transmittance, and a longer lifetime.

UV-resistant, yellowing-resistant, and salt-resistant, the operating temperature is -25°C to 100°C.

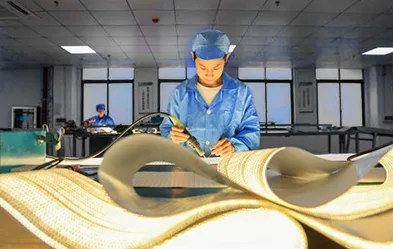

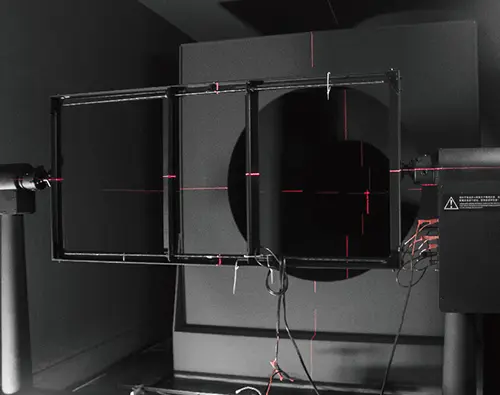

Our Factory

- Factory located in smart manufacturing industry city, Shenzhen.

- A team deeply involved in the industry since year 2010.

- Equipped with complete optical testing instruments.

- Products are UL listed, 100% aged and tested.

- Proficient in OEM & ODM products design, develop and support.

- Deeply cultivate signage and linear led light products more than 10 years.

Product Certificates

We got UL, ETL, CE, ROHS certifiacted to meet different region standards.

Why Choose Us?

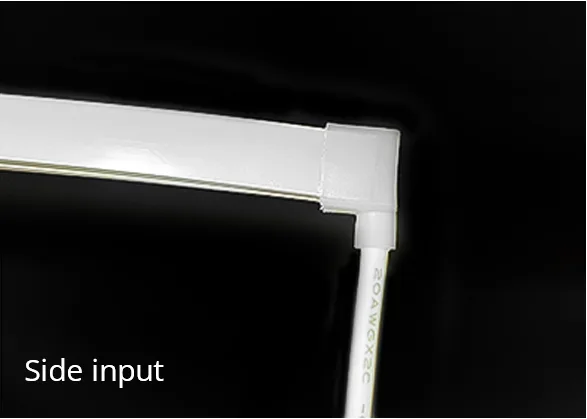

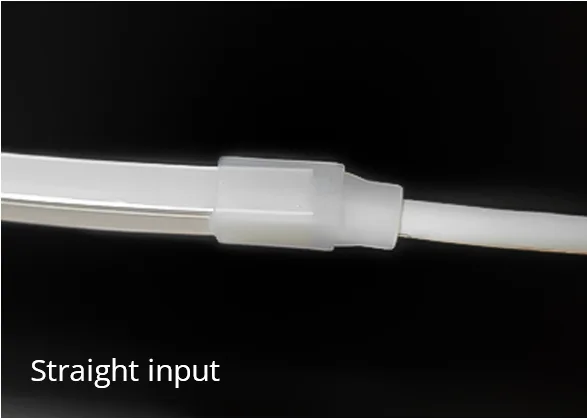

Cable Input Direction

To meet different installation and application, we have developed a variety of outlet plugs for these neon LED strips, namely side, bottom, and front types.

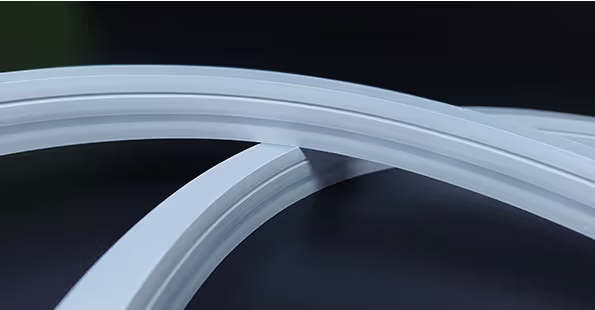

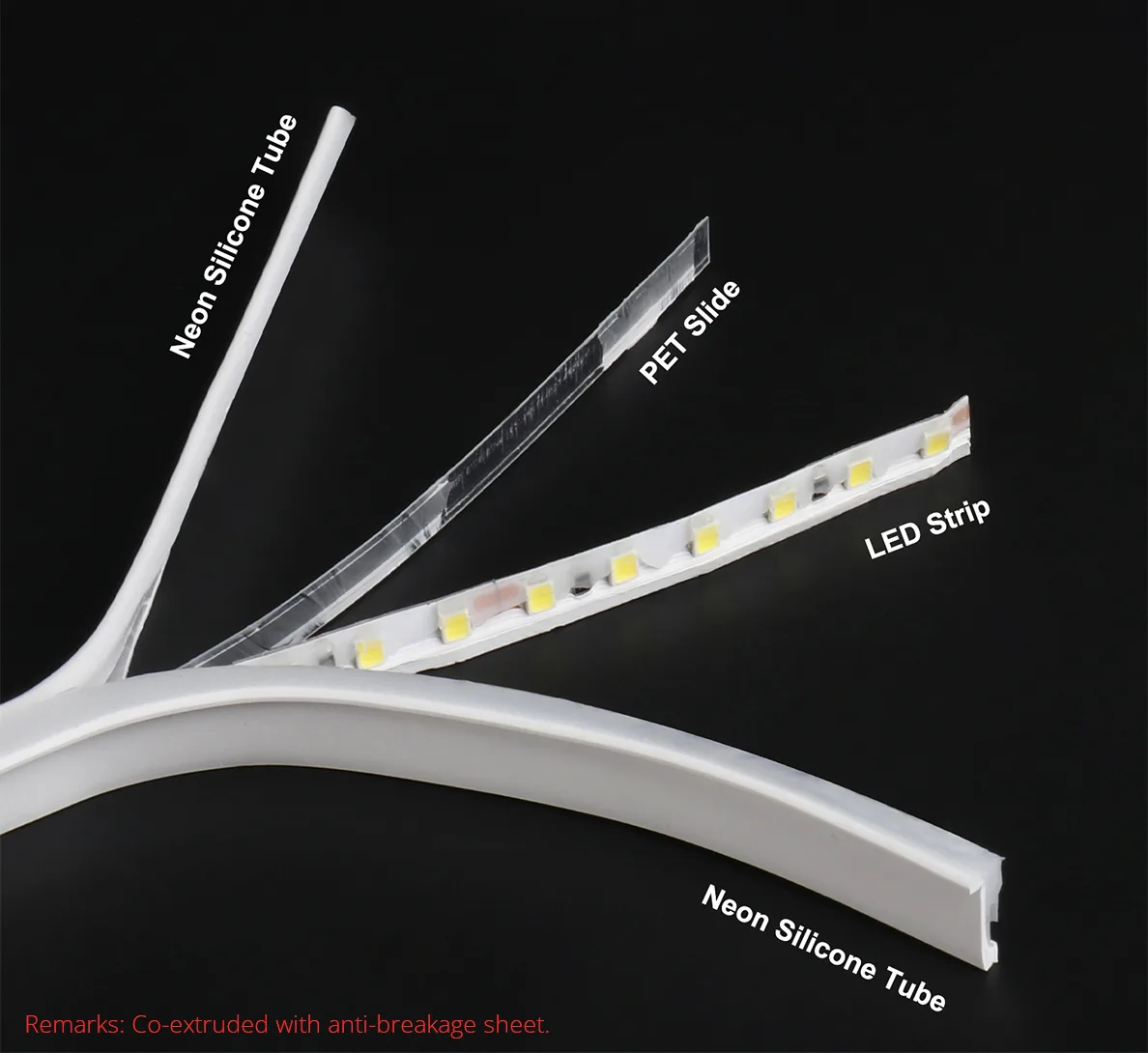

Neon Inner Structure

LED neon light consists of a silicone tube, an LED strip, and a transparent PET anti-break sheet. Among them, the neon silicone tube is formed by co-extruding white silicone and translucent silicone.

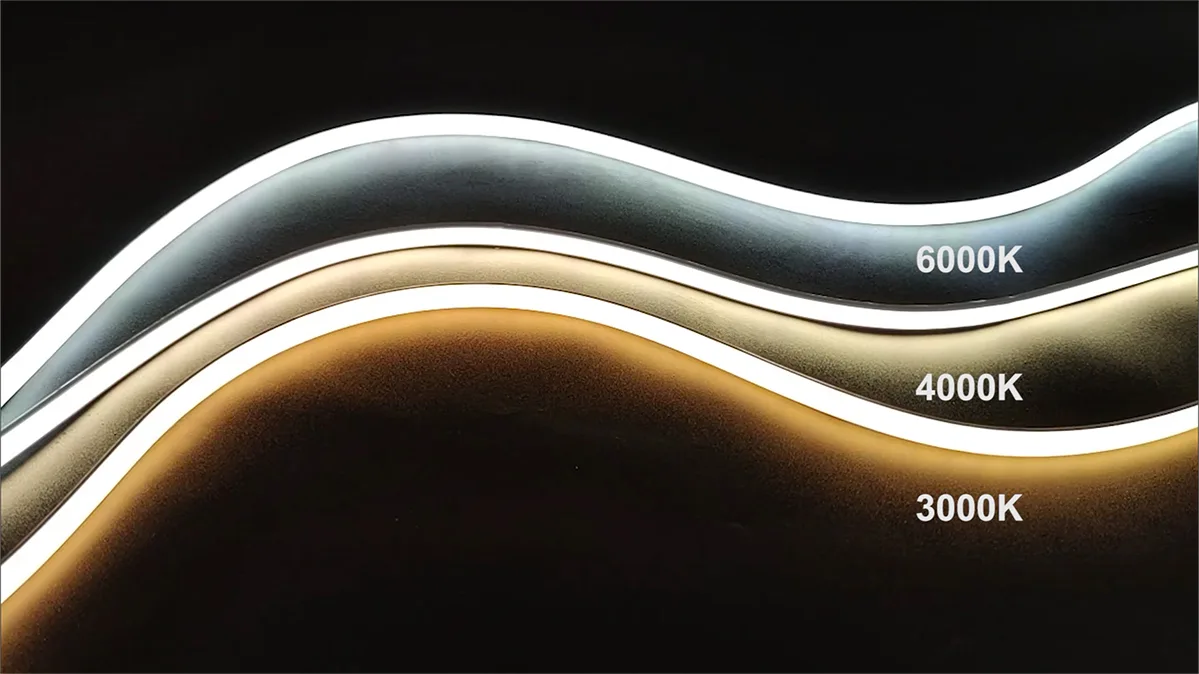

Color Temperature Optional

Bendable, Fireproof, Waterproof

Color Rendering Index

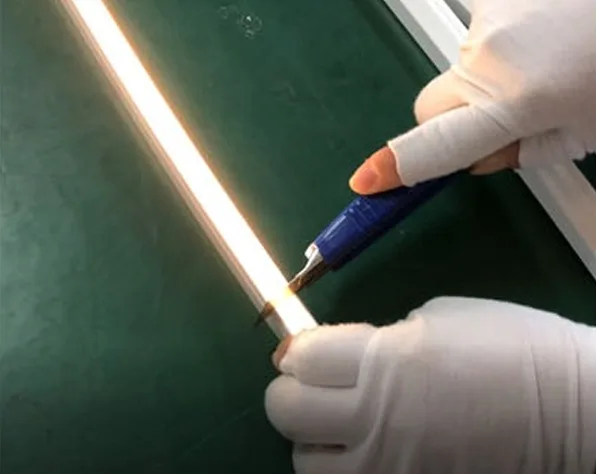

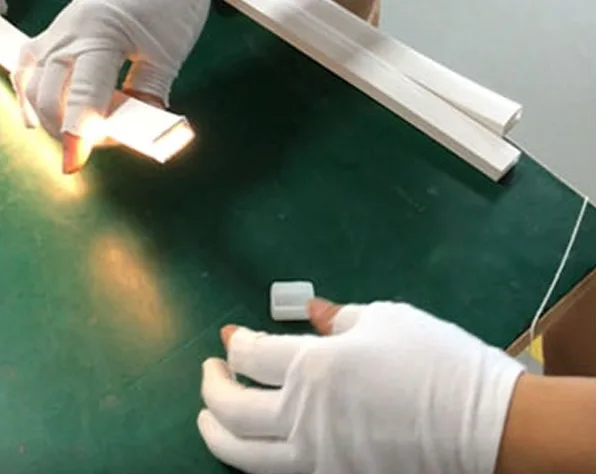

Neon Cutting Process

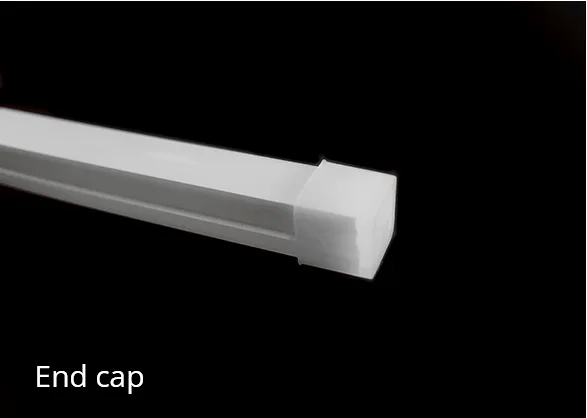

Step 1: Cut according to your needs.

Step 2: Apply silicone glue at the end.

Step 3: Put the end cap on to firmly fit the light.

Step 4: Wipe off redundant glue with a rag.

Applications

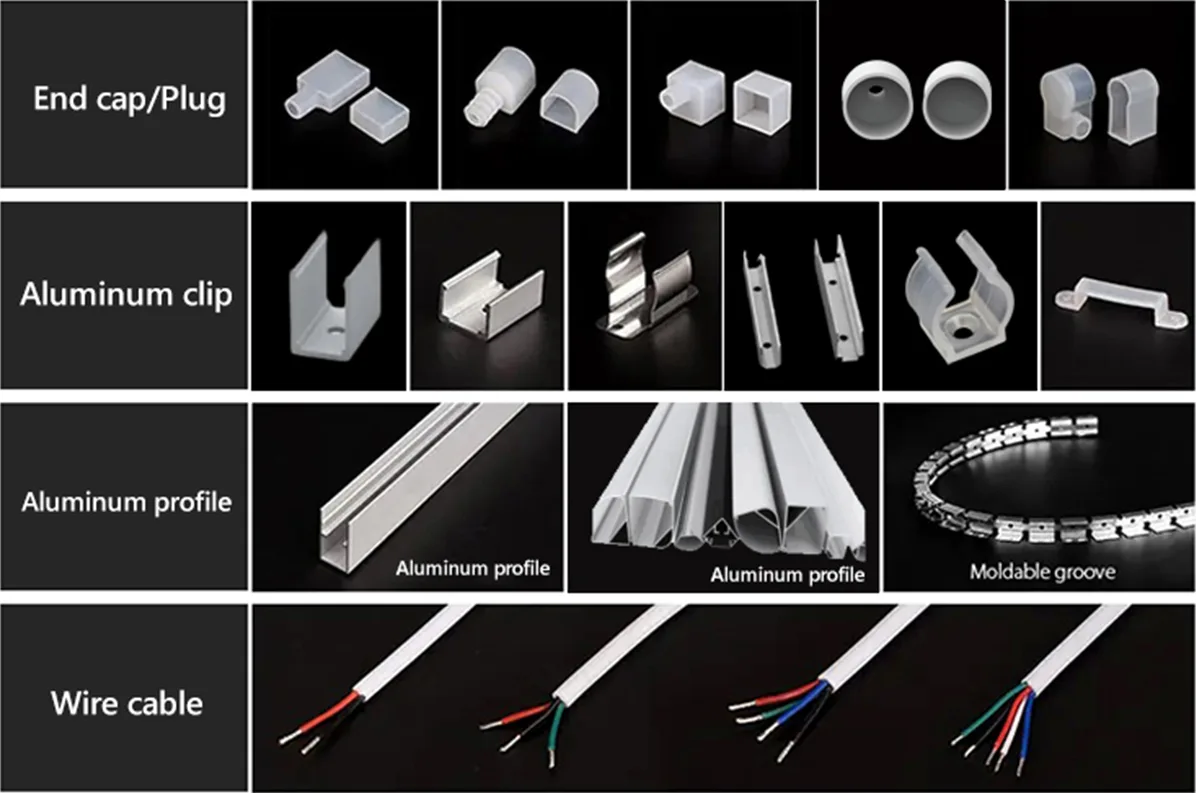

Optional Accessories

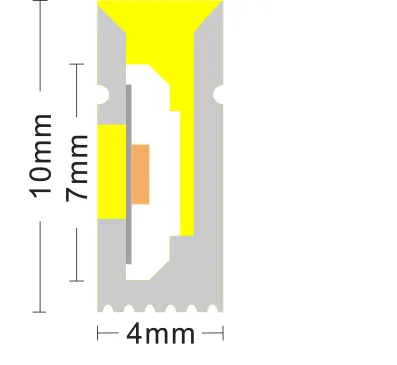

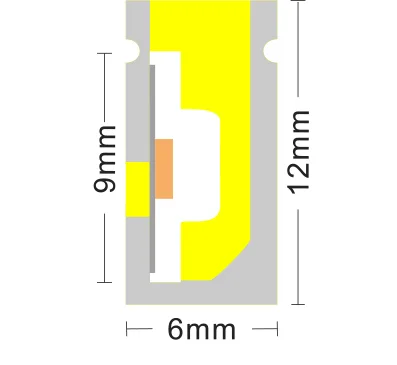

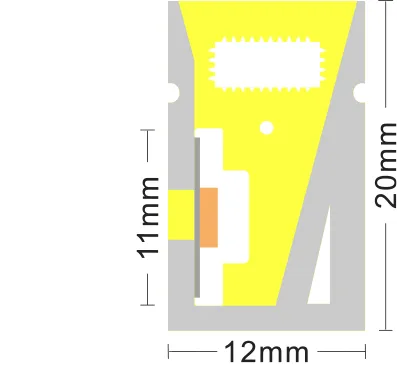

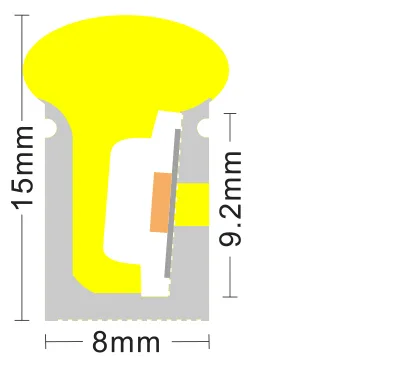

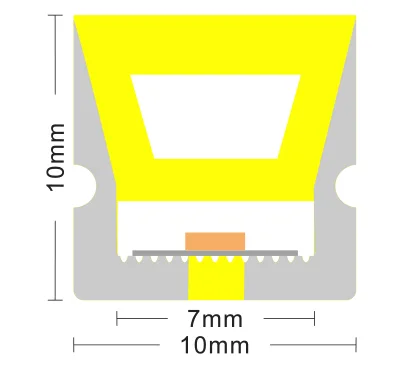

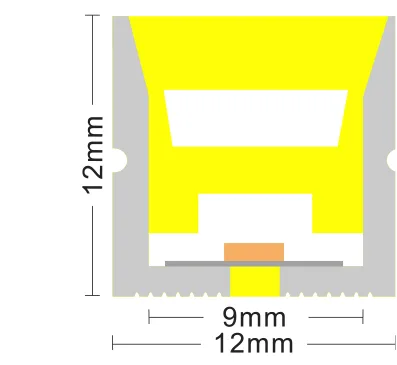

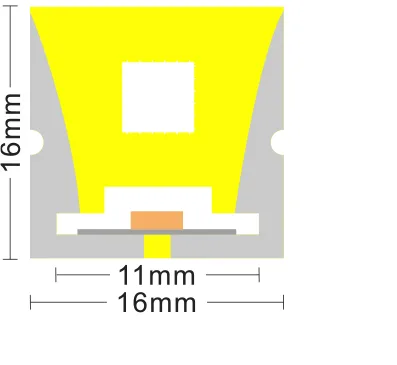

Optional More Sizes

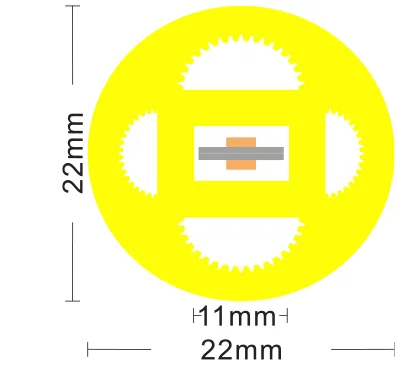

The following is a cross-section of the LED neon strip:

NQX0410SC

NQX0612SC

NAQ1220SC

NQX0815TC

NQX1010TC

NQX1212TC

NQX1616TC

NQX15DC

NQX22CC

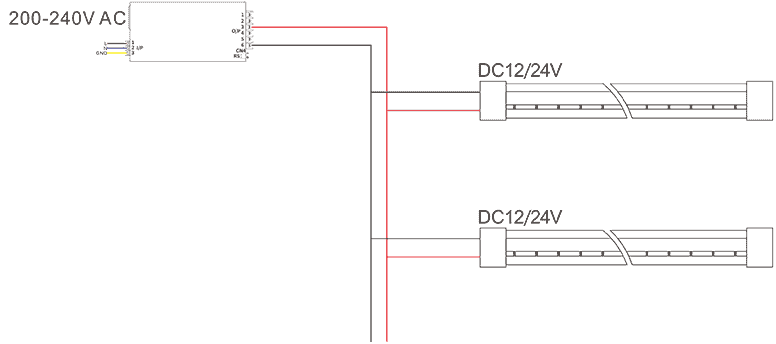

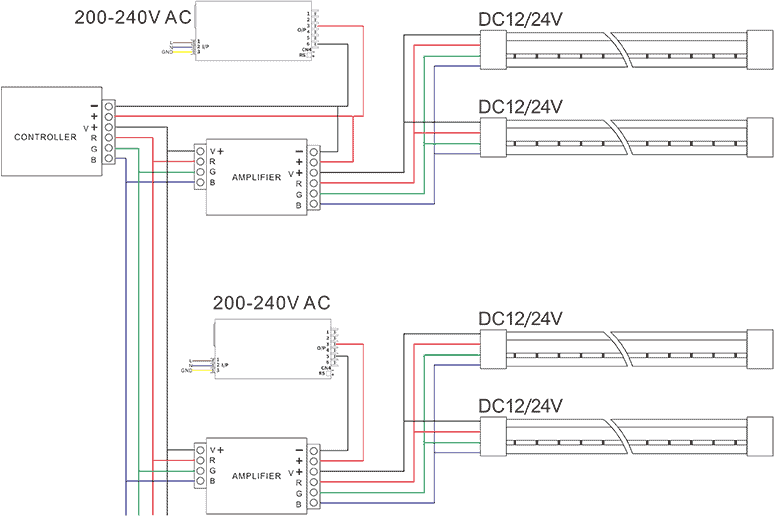

Wiring Installation Diagram

Single Color Wiring Diagram

RGB Wiring Diagram

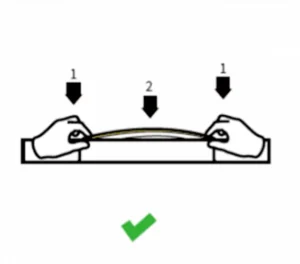

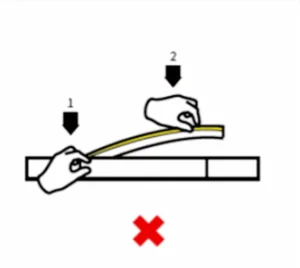

1. When installing the LED neon strip, install it from both ends at the same time; installation from one direction is prohibited.

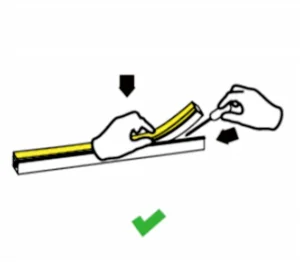

2. Use the tool to disassemble carefully, and do not pull the LED neon strip directly.

Packaging

5meter/reel

Inner anti static bag