Share:

480Chips LED COB Strip Light for Decorative Lighting

Product: COB-480LED-8MM

480chips, 100lm/W, dot-free

180 degree beam angle

CRI90+, for decorative lighting

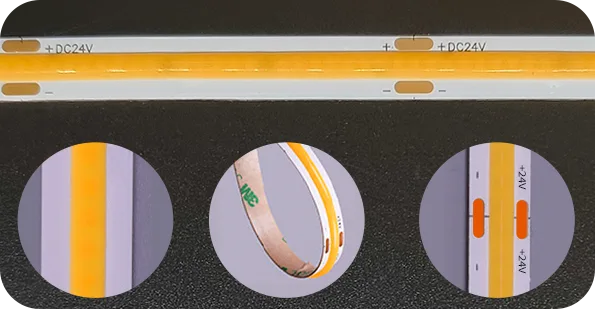

Solderless, reel to reel technology

480Chips LED COB Strip Light for Decorative Lighting

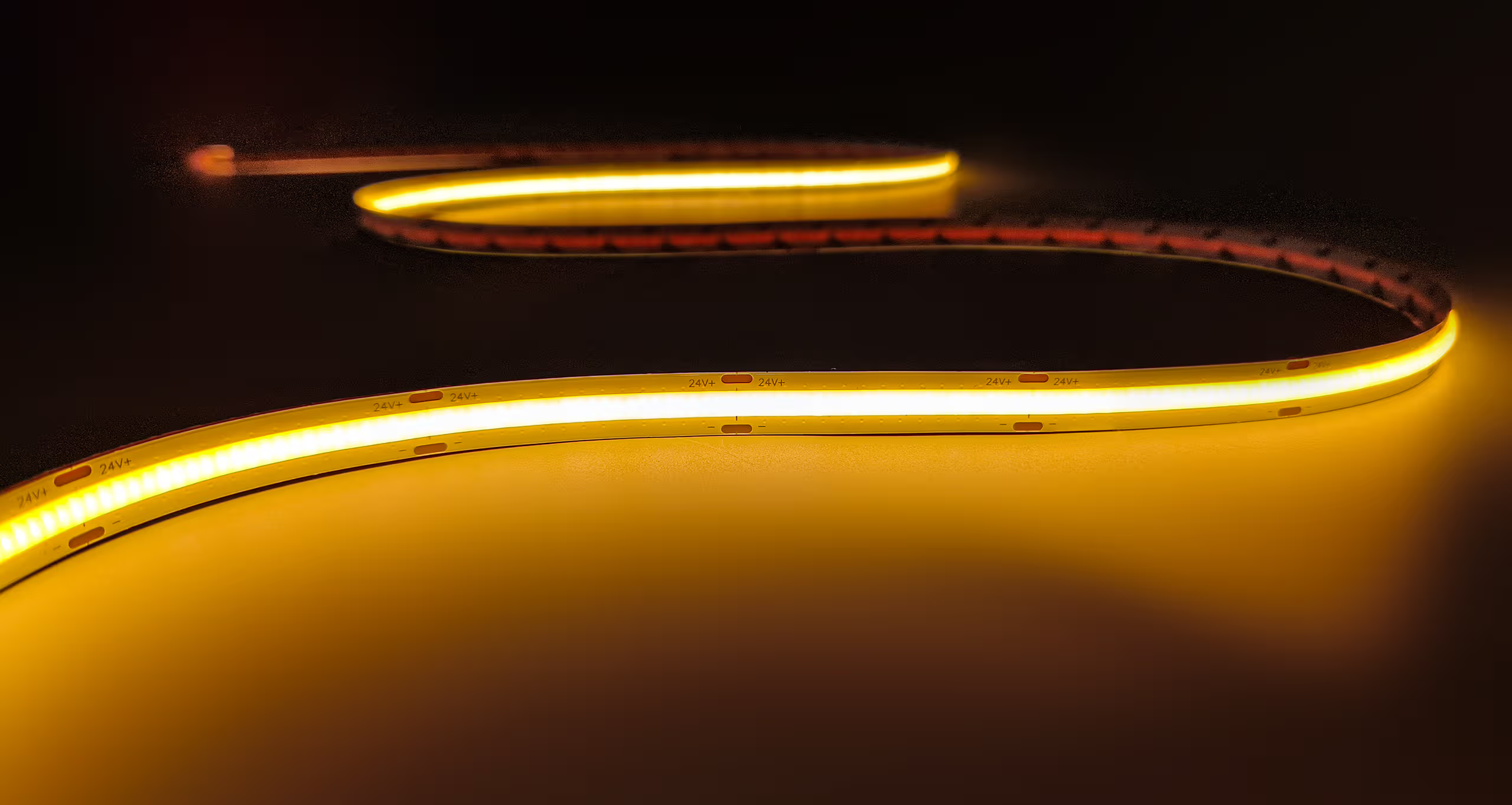

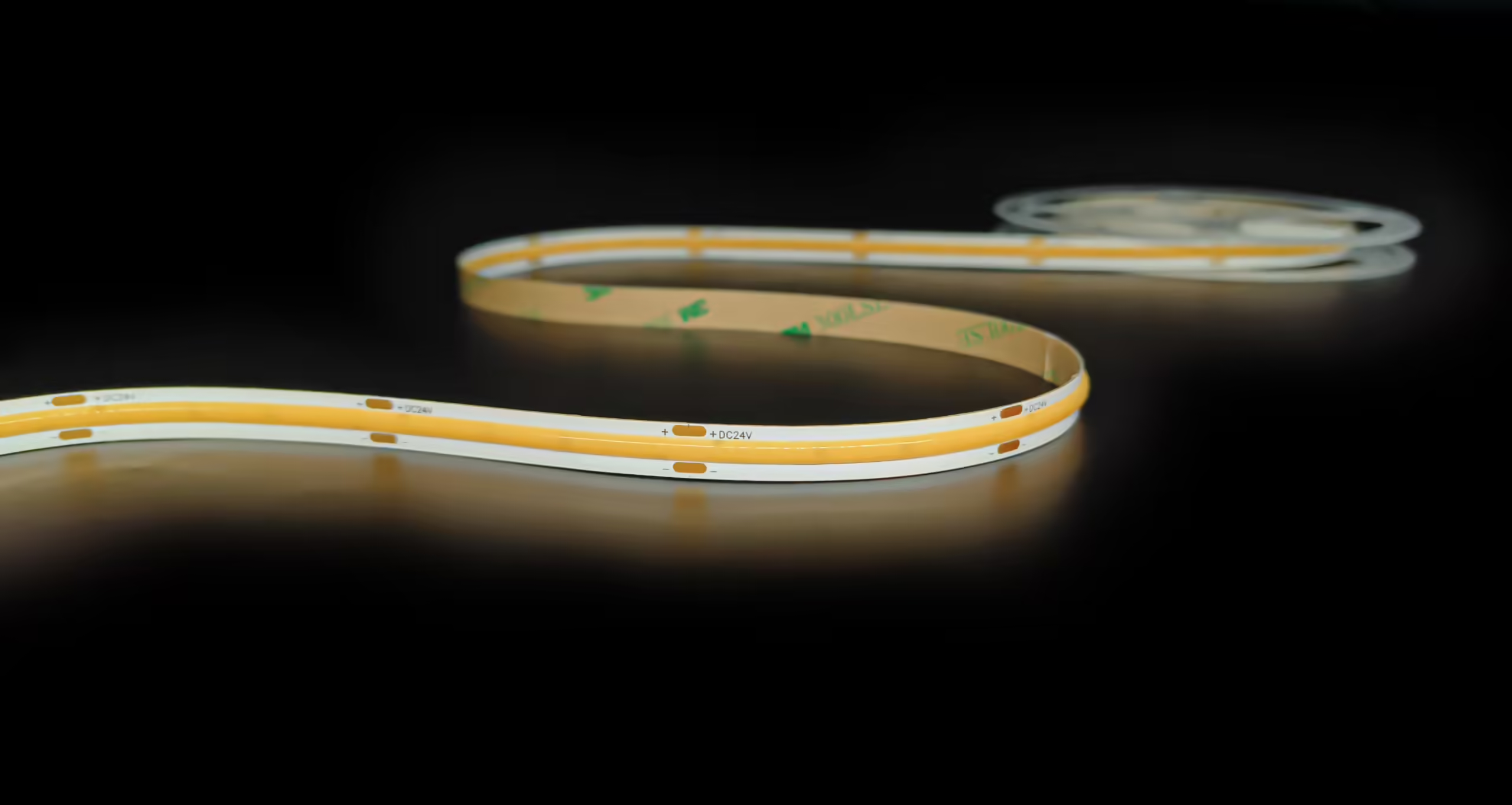

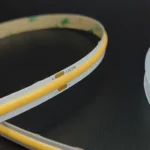

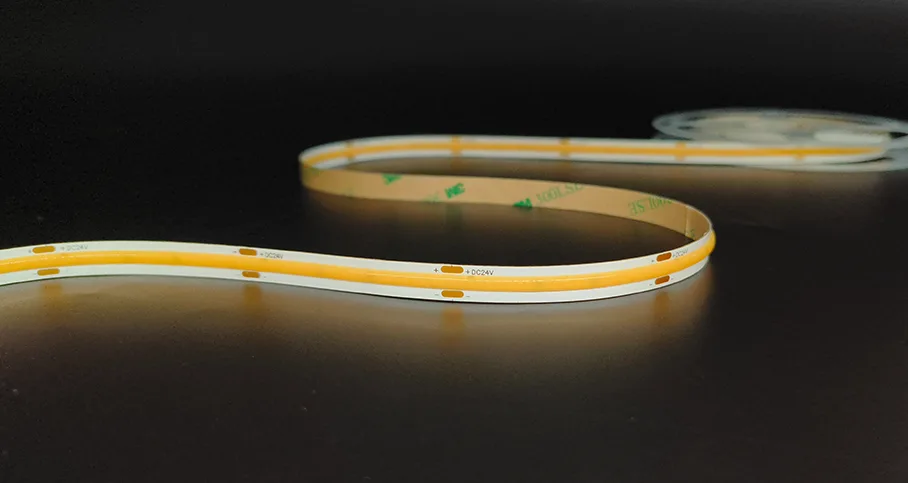

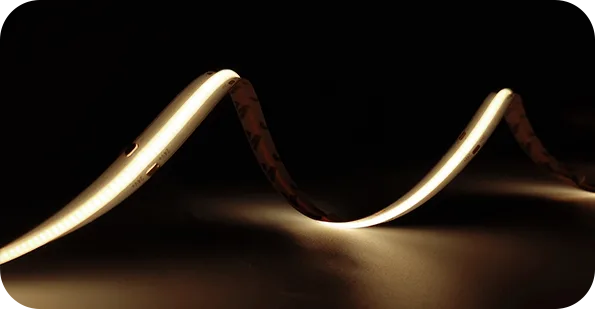

LED COB strip light is a new type of LED strip that outputs uniform illumination without lenses and additional diffused covers. This COB tape light can be field cut to shorten the length, and the affixed strong 3M double-sided adhesive tape mounts easily to most surfaces. The COB LED strip has a high-quality spotless light that is perfect for decorative, cabinet underlighting, or anywhere you need bright and hotspot-free linear lighting.

- 480chips/m, 100lm/W, dot-free

- Available in color temperature 2700K to 6500K

- Dimmable

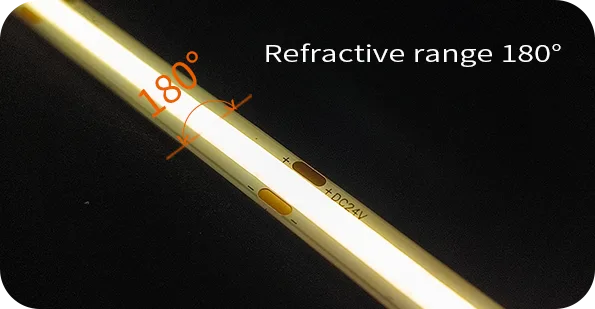

- 180 degree beam angle

- CRI90+, for decorative lighting

- Solderless, reel to reel technology

Specifications:

Model No.

FYX08T480X

Efficiency

>100lm/W

Input Voltage

DC12V/24V

Beam Angle

180°

Power

11W/m

Cut Section

25mm@12V, 50mm@24V

LED QTY

480LEDs/m

Dimension

5000*8*2.3mm

CCT

2700K - 6500K

IP Rating

IP20/IP65/IP67/IP68

SDCM

≤5

Warranty

2 Years

CRI

>90

Package Info

L46*W25*H26cm(400m/Box)

Model No.

RYX06CA

RYX06CC

Voltage

DC12V

DC24V

Power

11W/m

Efficiency

95-100lm/W

Ra

>90

CCT / Wavelength

3000K – 6000K, red, green, blue, yellow

LED Type

COB

LED QTY

480LEDs/m

PCB Width

8mm

Cutting Unit

25mm

50mm

Dimensions:

FYX08T480A

FYX08T480C

Features:

COB strip light is a new type of strip, COB stands for Chip on Board, it’s a technology which package led chips directly on the flexible printed circuit board. It reduces the use of frame and gold thread compared to traditional flexible strip, come with No-hot-spot, wider beam angle, better heat dissipation, etc.

Flexibility

Due to the Chip On Board technology, it is so flexible even for tiny bend radius.

Dotless

Consistent and uniform lights with no hot spots, perfect

solution for a wide variety of applications where you don’t

want to see the dots.

Excellent

From the quality LED chips to the copper core wires, the internal and external artisanal craftsmanship creates comfortable lighting products with peace of mind and durability.

Wider Beam Angle

Uniform light color/high transmittance/no dark area/long

service life, COB strip light angle up to 180°, luminous efficacy

up to 100Im/W.

Our Factory

- Factory located in smart manufacturing industry city, Shenzhen.

- A team deeply involved in the industry since year 2010.

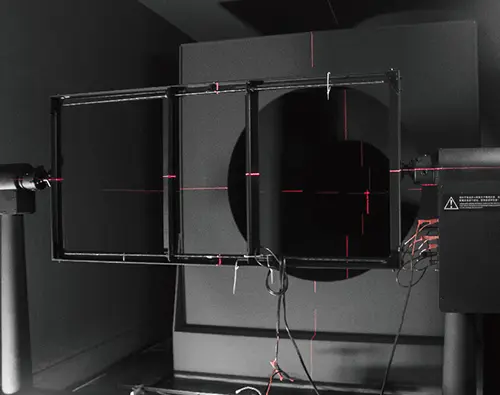

- Equipped with complete optical testing instruments.

- Products are UL listed, 100% aged and tested.

- Proficient in OEM & ODM products design, develop and support.

- Deeply cultivate signage and linear led light products more than 10 years.

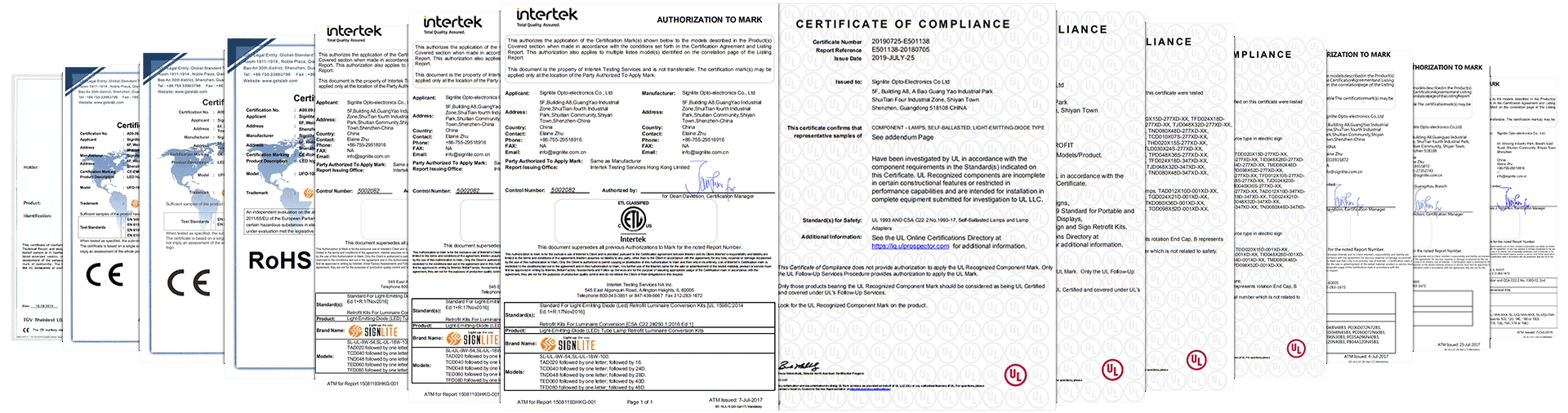

Product Certificates

We got UL, ETL, CE, ROHS certifiacted to meet different region standards.

Why Choose Us?

Production Quality Control Process

We have developed a complete set of production quality control systems, from raw materials to SMT, and even the subsequent assembly, testing, packaging, and shipment of each link are the implementation of strict quality control processes to ensure that our colors LED strip can be perfectly delivered to customers.

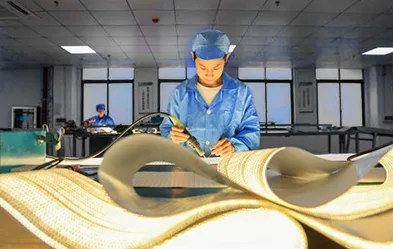

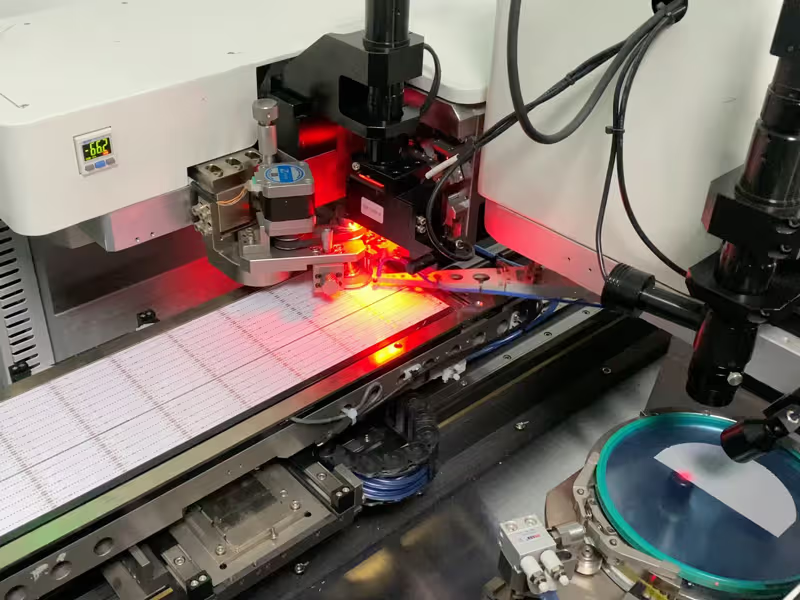

SMT Process

Use high speed automated SMT machine to paste LED chips, IC chips, resistors to make sure all components are in the right place.

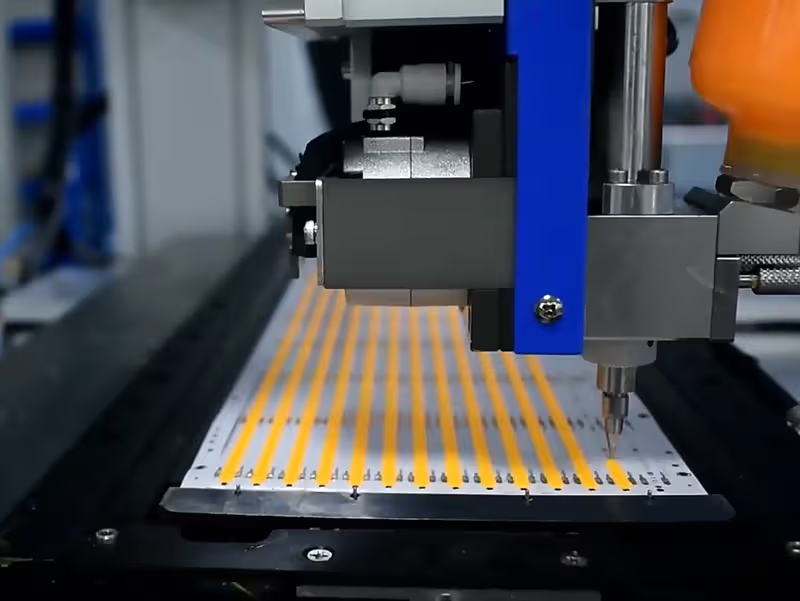

Automated Dispensing

Use multi-nozzle automated dispensing equipment to evenly coat the formulated phosphor on the COB tape light.

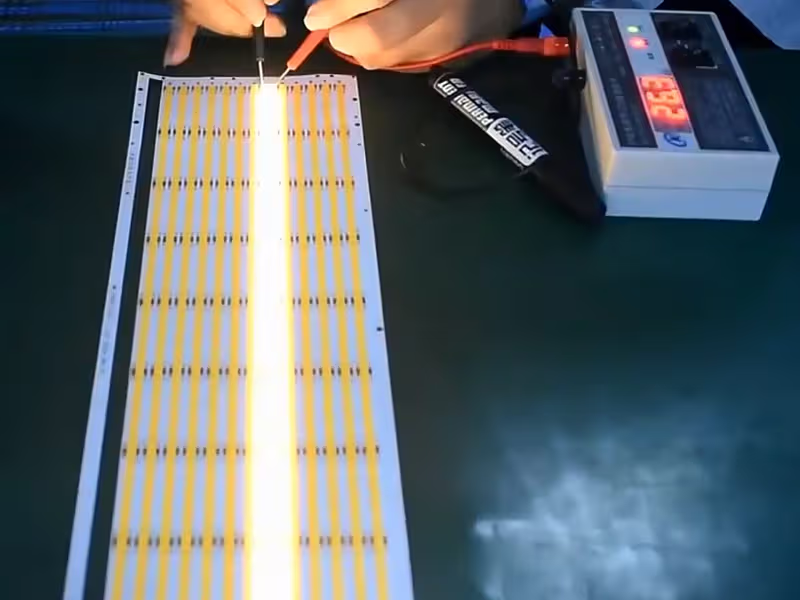

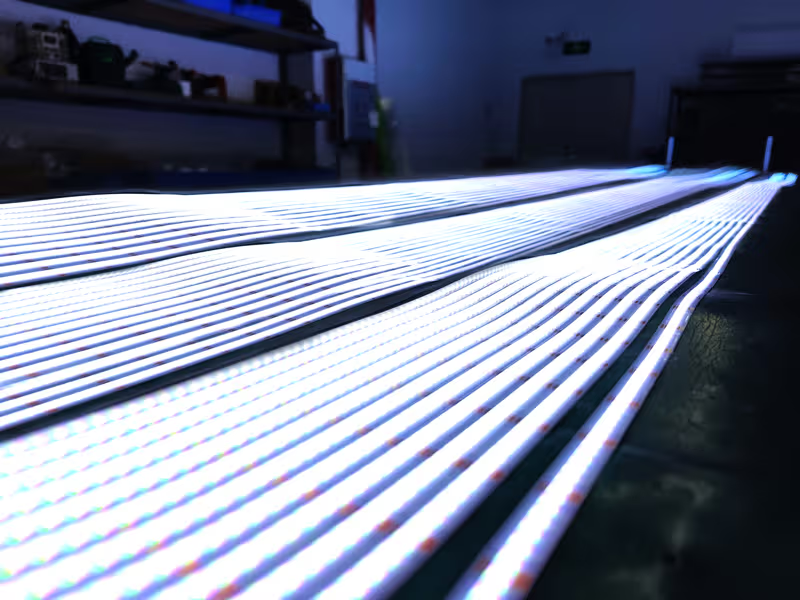

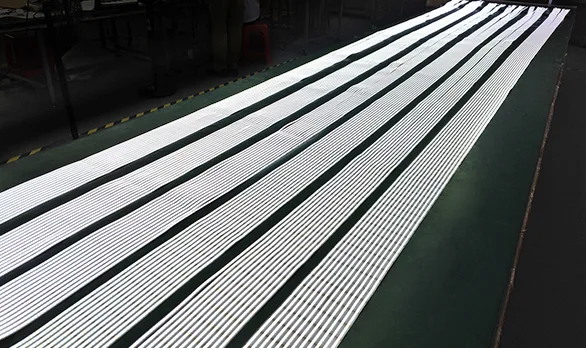

100% QC Inspection

After reflow soldering and high-temperature ovens, the COB strip needs to be tested again at 100% to ensure no defective LEDs.

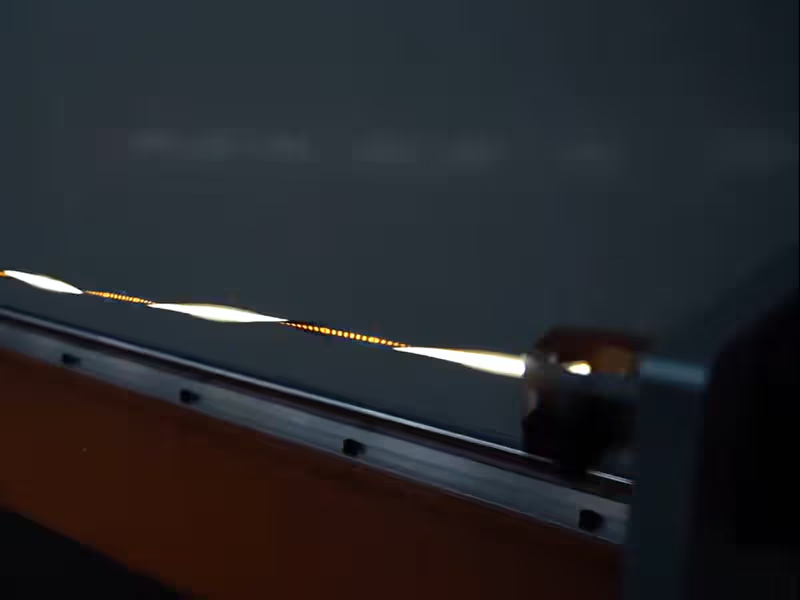

Bending Test

The purpose of the bend test is to test whether the strip light can withstand a certain amount of bending without affecting its performance or life.

Twist Test

The LED strip twist test is mainly used to test the bending resistance and life span of LED strip lights by simulating the deformation of light strips in long-term use.

Aging Test

Aging for 8 hours, ensure each LED runs in good condition. And for the COB LED strip, there will be a slap test to check the stability.

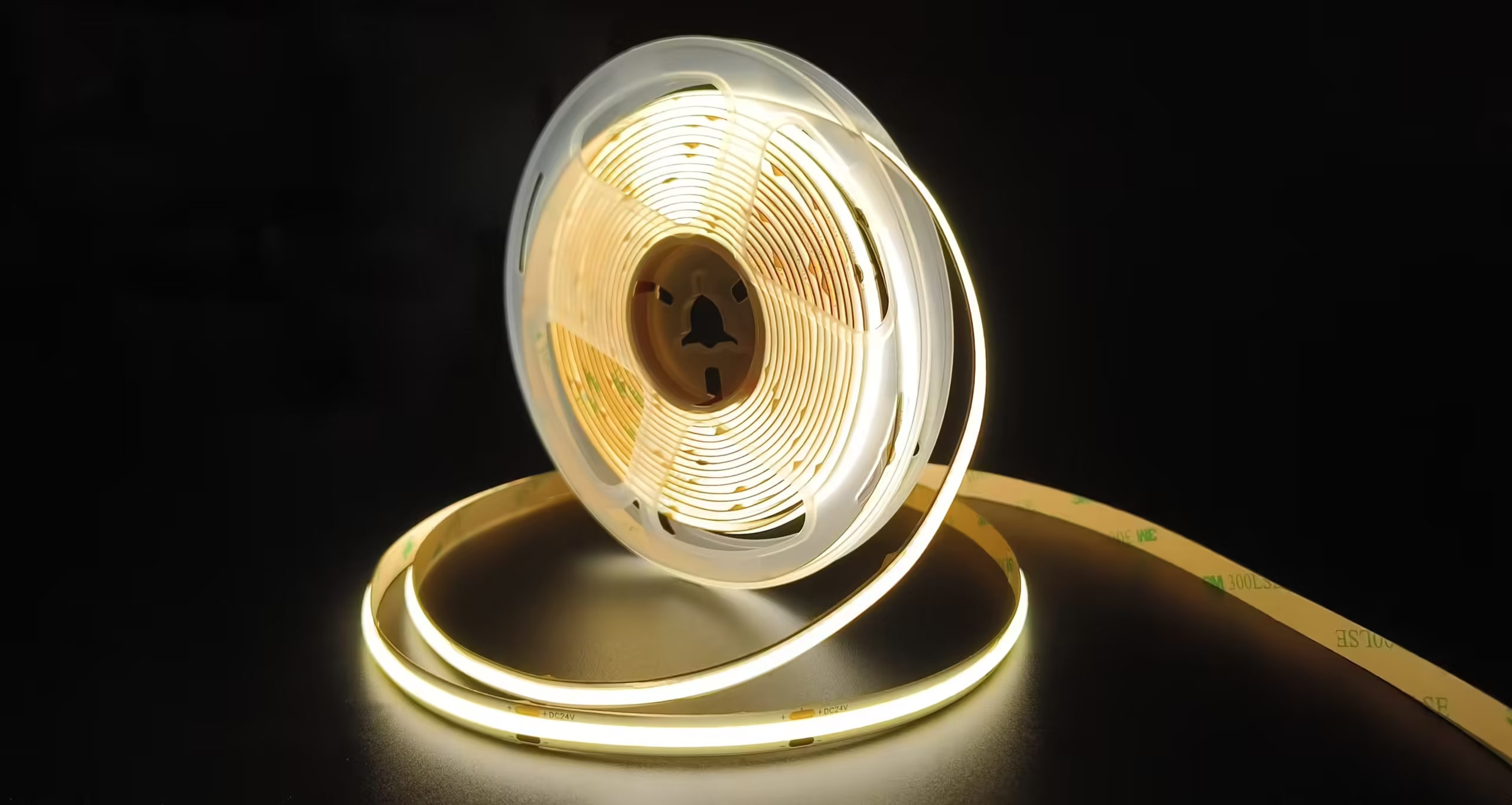

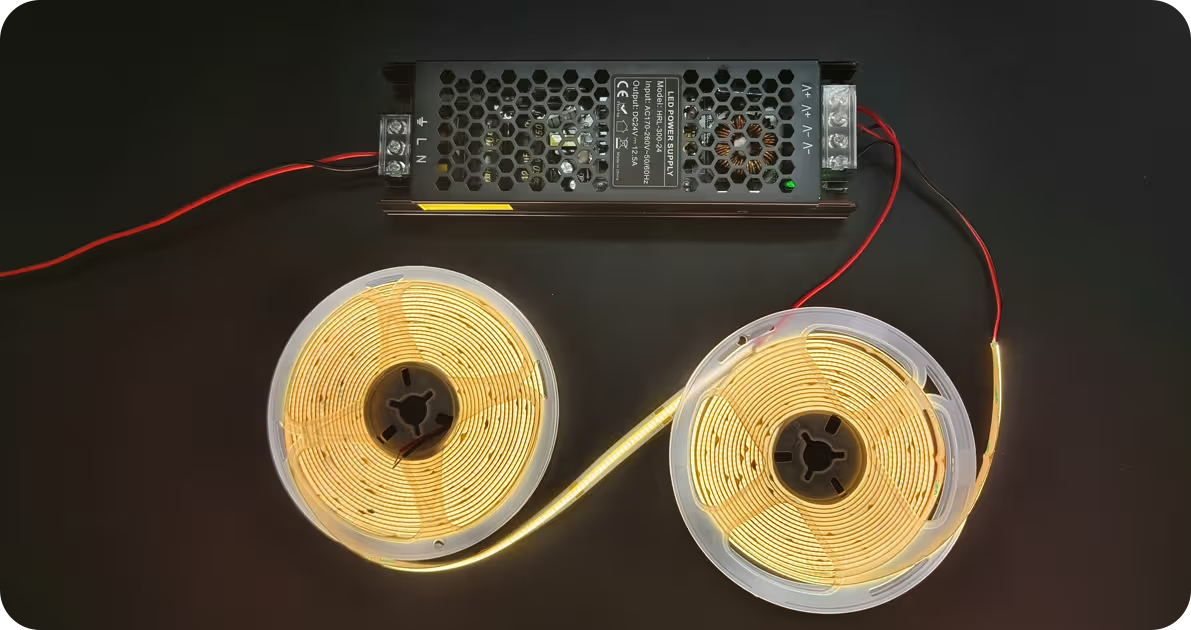

Pasted With 3M Tape

All LED strips pasted with 3M adhesive tape and rolled reels to ensure easy transportation and installation.

Final Product Test

Our quality inspectors conduct a final inspection of each roll of LED strip to ensure the consistency of the light color and the good appearance of the strip.

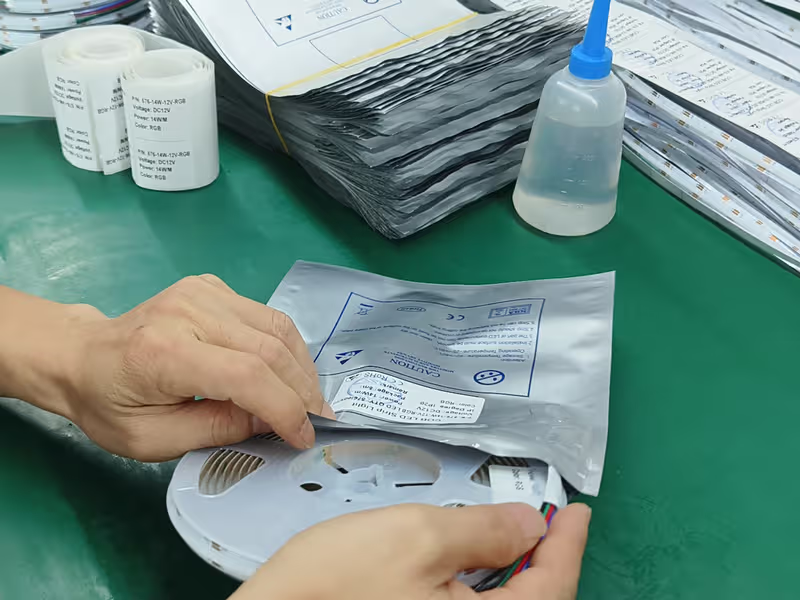

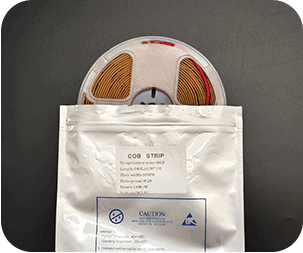

Packaging

Finally, the labels are pasted on the reels and anti-static aluminum foil bags, and the COB strip lights are ready to be boxed and shipped.

IP65 Waterproof Drop Process

This type of waterproof COB strip light add a silicone layer on top of the LEDs basically fully sealing off the top end of the LED

strip, including all the solder joints and contact points. It can provide protection from water, humidity, and dust.

Before

Dropping gel

After

COB Assembly Process

1、Chip die bond, chip bonding wire process

2、Epoxy resin dispensing process

3、IP65 waterproof coating, silicon glue dropping process

4、Finished product aging process

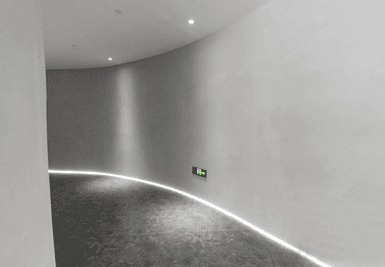

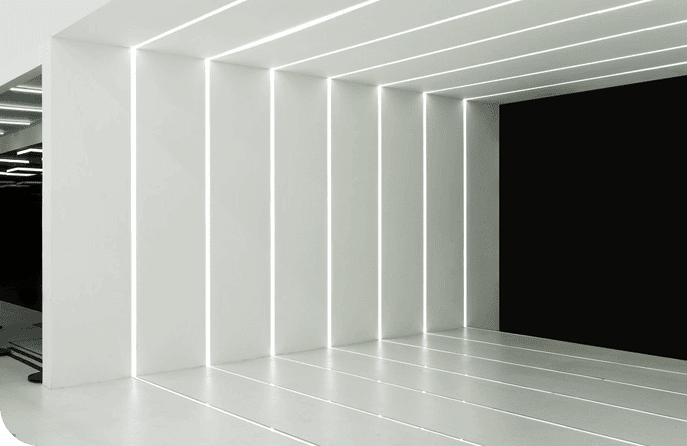

Applications

Wiring Diagram

Packaging

5meter/reel

Inner anti static bag