In recent years, LED neon flex has grown in popularity as an energy- and environmentally-conscious lighting solution. LED neon flex is made composed of tiny, flexible LED lights covered in a silicone or PVC jacket, in contrast to conventional glass neon lights. These LED lights are a safe and low-maintenance lighting solution because of their durability and minimal heat output.

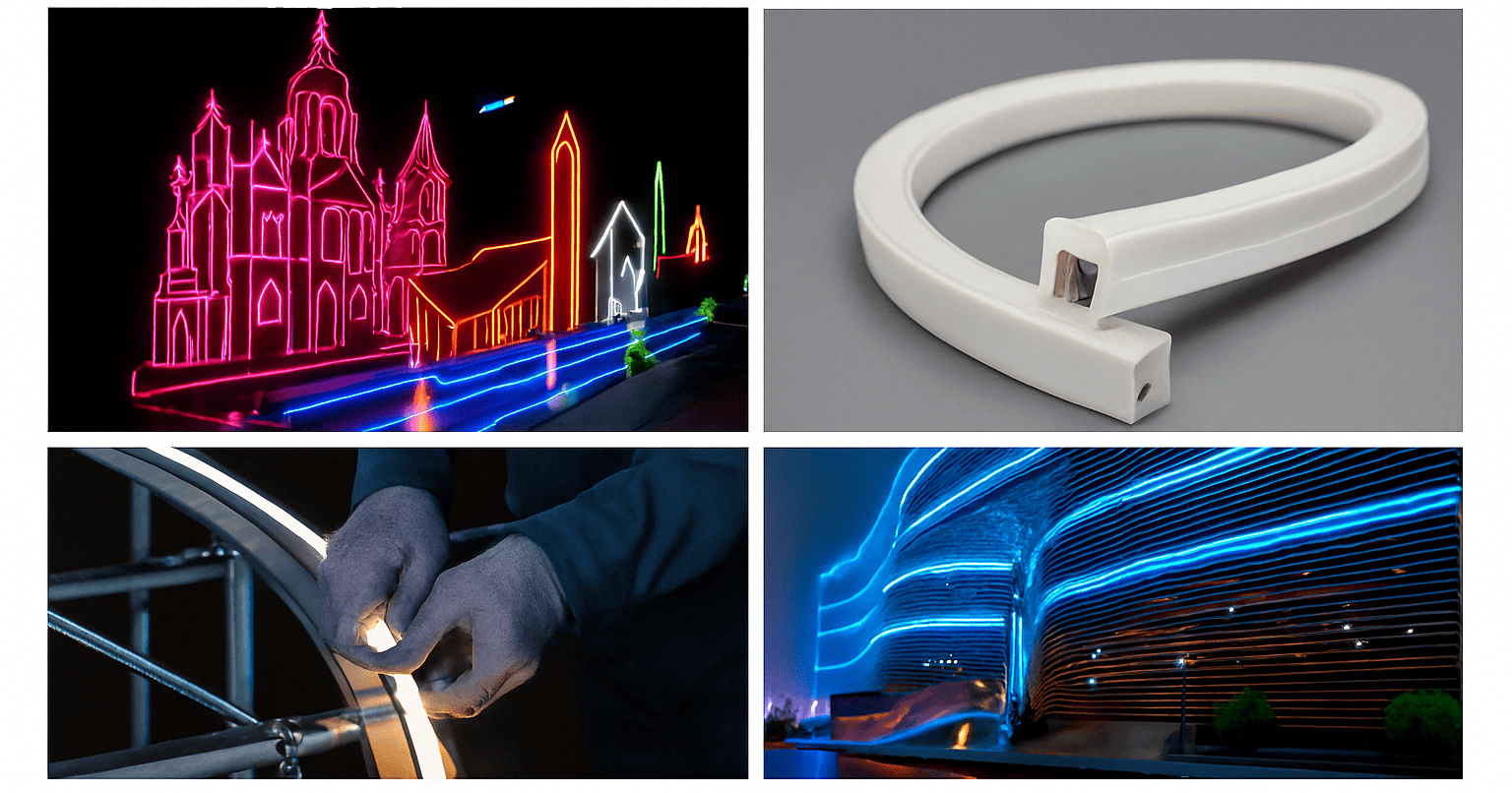

The adaptability of LED neon flex is one of its key advantages. It is the perfect solution for advertising, signage, and decorative lighting applications since the flexible LED lights inside the jacket can be bent and curved to fit any design. Customized designs and shapes that are not achievable with conventional glass neon lights can be made using it. LED neon flex may be customized to meet any room or style because of the extensive selection of colors and patterns available.

Silicone and PVC are the most frequently used materials for LED neon flex, albeit it varies according on the manufacturer and the particular device. Silicone is a strong, flexible polymer that can tolerate high temperatures as well as dampness and UV rays. As a result, it is perfect for use in outdoor settings where the lighting may be subject to weather. In addition to being strong and flexible, PVC is also moisture- and UV-resistant. Due to its tremendous strength and stiffness, it is renowned for being the best material to use indoors when a more rigid lighting alternative may be required.

It’s crucial to take the installation’s unique requirements into account while deciding between silicone and PVC LED neon flex. For intricate designs and installations that call for precise bends and curves, silicone is a more flexible material that is better suited. On the other hand, PVC is a more robust material that works better for installations that don’t require as many bends and curves and are straighter.

Using clips and an electrical source, installing LED neon flex is a reasonably easy process. Before installing the clips and inserting the LED neon flex, the installation surface needs to be carefully cleaned and dried. To guarantee that the LED neon flex is connected to the power supply safely and securely, wiring should be done by a licensed electrician or by someone with electrical competence.

As a result, LED neon flex is a flexible and adaptable lighting option that has numerous advantages over conventional glass neon lights. It comes in a variety of hues and patterns and is made of tiny, flexible LED lights enclosed in a silicone or PVC jacket. Silicone and PVC are the most frequently used materials for LED neon flex, albeit it varies according on the manufacturer and the particular device. It’s crucial to take the installation’s unique requirements into account while deciding between silicone and PVC LED neon flex. LED neon flex is a visually appealing and cost-effective lighting choice that is sure to impress, whether it is used for advertising, signage, or decorative lighting.