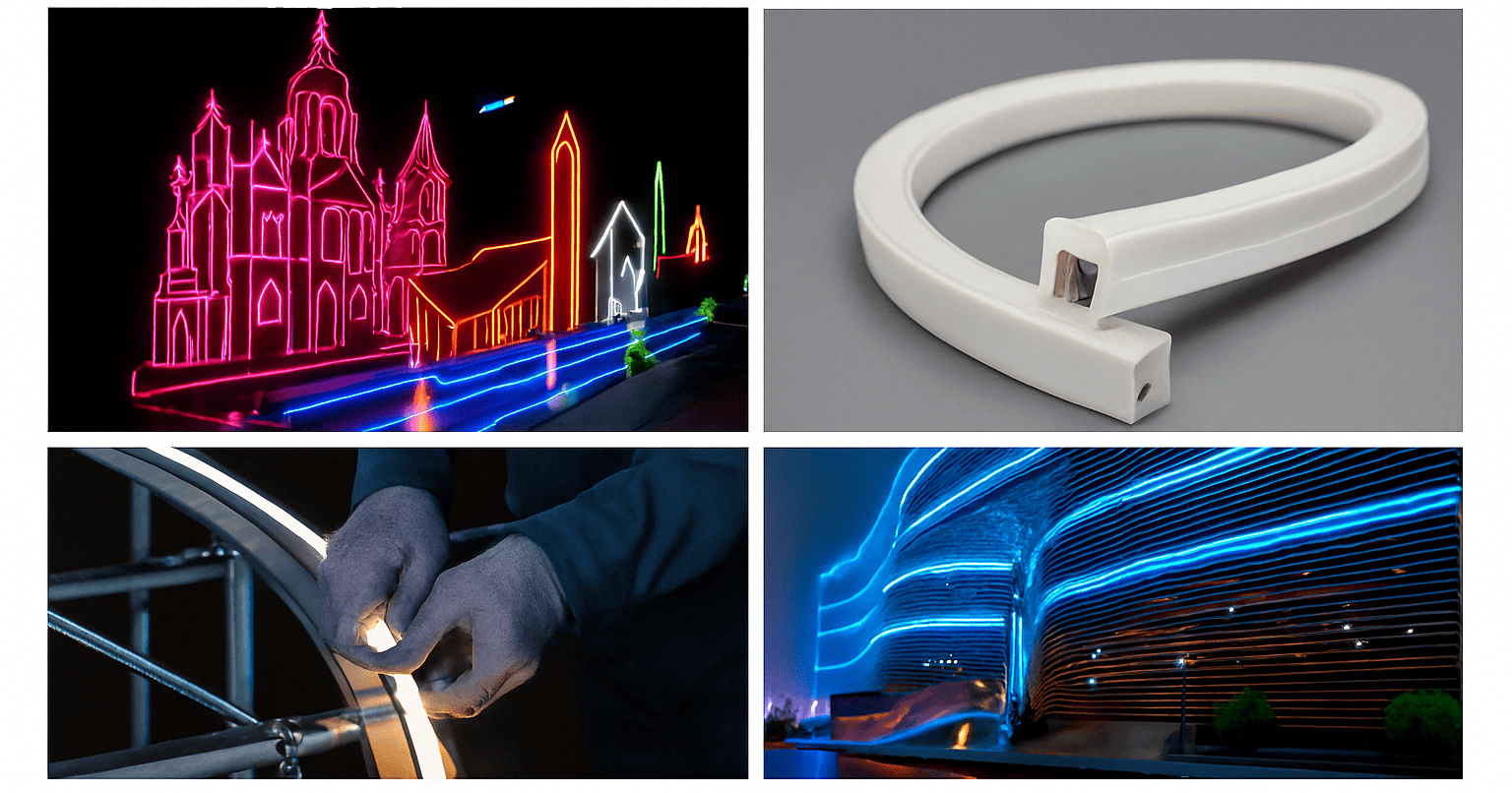

The presence of COB LED light strips adds layers of indoor and outdoor environments, making the spatial environment softer and more moody. In the form of minimalist space, COB LED strip light can also give it a breathtaking beauty. Nowadays, COB LED Strip is gradually becoming the perfect choice for seamless and efficient lighting, gaining more and more popularity.

Designed as a sleek, high-performance lighting solution for professionals and do-it-yourselfers alike, COB LED strips provide smooth, consistent illumination without creating hot spots. Whether you’re brightening up your home, upgrading your workspace, or adding sparkle to a commercial project, these strips can be a game changer!

COB LED strips are not like regular LED strips, so let’s dive into what makes COB strips so special and why they are worth considering over standard LED strips. We hope you’ve read this article to learn more about COB LED strips. Whether you’ve learned about COBs before or not, this article has something for you, so don’t miss it.

What is COB LED Technology?

“Chip on Board” (COB) is one of the latest developments in the field of LED technology. Compared to other standards, we can consider this technology to be quite new and innovative.

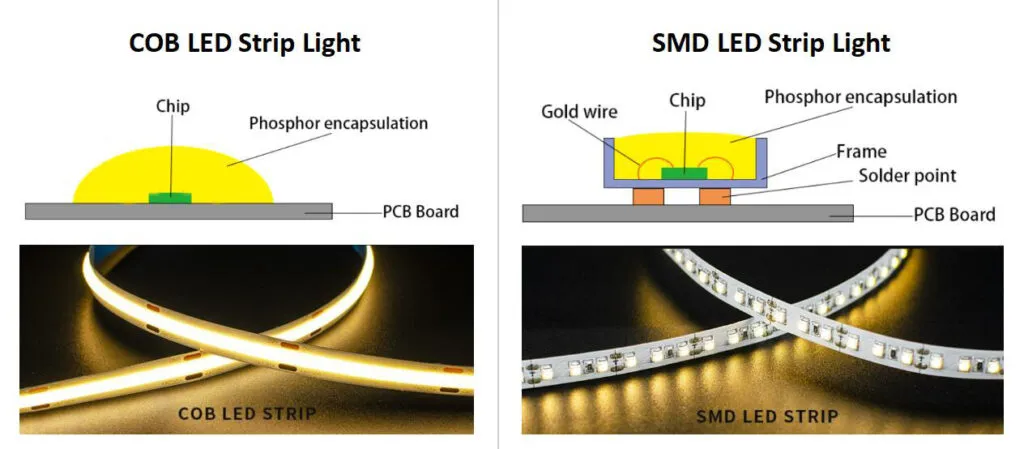

Chip-on-Board, or “COB, refers to the production of LED arrays by placing bare LED chips in direct contact with a substrate (e.g., silicon carbide or sapphire). COB LEDs offer a number of advantages over older LED technologies such as surface mount device (“SMD”) LEDs or dual in-line package (“DIP”) LEDs. Most notably, COB technology allows for higher LED array packing densities, or what optical engineers call “lumen density” increases.

The basic elements of a COB LED include:

- Light-emitting chips, or “dies,” sometimes called blue light pumps, are made from the semiconductor material indium gallium nitride (InGaN), which emit blue photons when energized.

- Phosphor coating that converts blue light into white light: controls the chemistry of the phosphor to produce a specific color temperature of light.

Overall, a COB LED is a single device in which many LED chips are mounted on a thermally efficient substrate or circuit board. Each chip is bare, meaning that the chip does not have its own lead frame, phosphor coating, or lens. This means that the chips can be mounted very tightly on the substrate. The close placement of the LED chips allows for high intensity or light density to be emitted from a much smaller area than a single packaged LED. The COB LED manufacturer then applies a uniform phosphor coating over the entire chip array to convert the blue light to the desired white temperature.

What is a COB LED Strip?

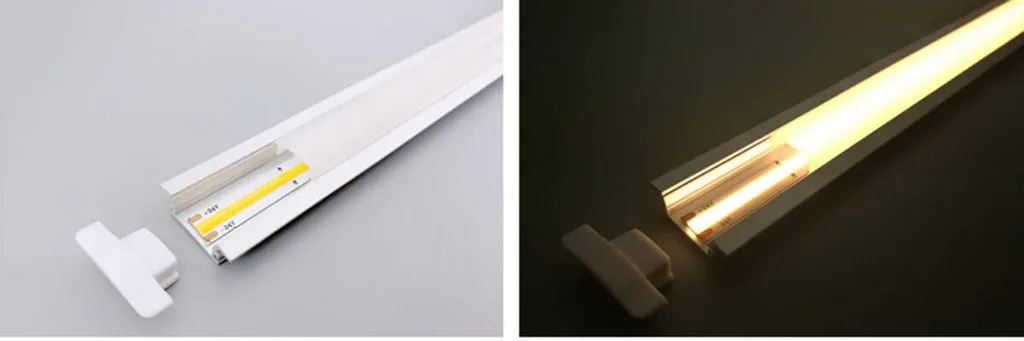

As we know from the previous section, COB stands for Chip on Board in the LED field, which basically means that the LED chip is packaged directly onto a circuit board (PCB). The “Chip on Board” LEDs used in flexible LED strips are sometimes referred to as flip chips.

Flip Chip LEDs are basically a simple method of LED construction. Look at an ordinary SMD (Surface Mount Device) LED, which has a bead holder that encapsulates the LED chip and then is covered with a phosphor coating. The “flip chip” that makes up a COB LED strip removes everything from its design except the LED chip, the yellow phosphor overlay, and the connecting pads.

COB LED strips utilize this flip-chip technology to tightly pack many LED chips onto a single flexible circuit board. This design produces a smooth, continuous light with no gaps or hot spots. Unlike traditional LED strips, where individual LEDs are visible and spaced apart, COB LED strips have denser arrays of LEDs. This produces a more uniform, seamless light and eliminates visible hot spots.COB LED strips are ideal for applications that require smooth and continuous illumination. They are known for their high brightness, efficiency, and durability, making them popular for both commercial and residential lighting projects.

How are COB LED Strips Manufactured?

The manufacturing process of COB LED strips is meticulous and designed to ensure quality, efficiency, and durability. Let’s take a look at the main processes involved in making COB LED strips.

1. Expanded Chips: First, high-quality LED chips are selected for their efficiency, color consistency, and longevity. These chips are then expanded and precisely bonded to a flexible PCB (Printed Circuit Board), a substrate chosen for its durability and thermal conductivity. This direct mounting, known as chip bonding, allows the strip to be flexible and dissipate heat efficiently.

2. Die Bonding: LED chips are bonded directly to the FPC through leads using automated crystallization equipment.

3. Mounting Resistors to FPC: After the chips are mounted, resistors are mounted to the FPC board using an automated process. These resistors are critical for regulating the current flow through the LED chip, ensuring stable performance, and preventing overheating.

4. Reflow Process: Assembled FPC boards with chips and resistors already mounted go through a reflow process. This process involves exposing the FPC boards to temperatures above 65 degrees Celsius to reinforce the connections and ensure that the components are firmly bonded to the board.

5. Phosphor Glue Mix: A specially formulated phosphor glue mix is prepared. This glue is essential to the encapsulation process to protect the LED chips and resistors while enhancing the color quality and uniformity of the light.

6. Dispense Glue: Use an automatic dispensing machine to precisely drop the phosphor glue mixture on the surface of the chip and resistor. This step ensures uniform coverage and optimal encapsulation of each component.

7. Place the Glued COB LED Strip in the Oven: After applying the glue, place the COB LED strip in the oven. The curing process solidifies the glue, ensures a strong encapsulation, and protects the components of the strip from physical and environmental factors.

8. QC Testing of COB LED Strips after Cooling: After cooling, the COB LED strips are subjected to rigorous quality control testing. This includes checking for consistent light output, color accuracy, and overall performance to ensure that the strip meets the high standards expected.

9. Solder PCBs to 5 Meters per Roll or Custom Length: Flexible PCB strips are soldered to lengths, typically 5 meters per roll or customized to customer specifications, to ensure ease of installation and use. This step also includes adding adhesive backing and connectors for power and control.

10. Aging Test, QC Test: Aging tests are performed to simulate long-term use, followed by a final quality control check. This comprehensive testing phase ensures the reliability and longevity of the COB LED strip.

11. Packaging, then Shipping: Finally, the COB LED Strips are carefully packaged and prepared for shipping, ready to light up any space with their efficient, consistent, high-quality light output.

What are the Pros and Cons of COB LED Strips?

If you’ve been looking for a new solution for indoor lighting, then COB strips are the best choice today. This new technology offers huge advantages over traditional LED strips. But before you make a decision, you should be aware of its pros and cons.

Pros

1. Dotless lighting without aluminum profiles. One of the biggest complaints about traditional LED strips is the spots of light across the strip. A spot is a bright area on the strip where you can see where the light is coming from. COB LED strips, on the other hand, even in installations where aluminum profiles are not used, provide a uniform light output without the LED lighting spot effect. This produces a cleaner, more consistent light appearance that enhances the aesthetics of any space.

2. Greater flexibility. COB strips are more flexible than other flexible strips due to the small diode size and even weight distribution. The diodes are so small and closely spaced that no point on the strip is the same. This uniformity makes it easy to install the strips without having to think about placing the 5050 SMD LED strips where they are not needed. This extra flexibility will make it easier to fit them into tight areas and wrap curves around your application or accurately highlight architectural features.

3. More stable, fewer problems. Firstly, the COB light strip is the chip directly attached to the FPCB; there is no self-contained gold wire. Traditional SMD light strips have many problems because of the gold wire inside the LED beads. Because the gold wire is too thin, it is easy to break, resulting in the chip not being bright. Second, the circuit design of the COB strip light uses three chips, first parallel, as a group, and then each group is then connected in series, composed of one step. Even if a group of two chips inside the bad, this one-step light strip can continue to light. And COB one-meter chip as many as 480, even if 1-2 chips are not bright, will not produce a dark area and will not affect the use.

4. Wide light-emitting angle. The traditional SMD strip light emitting angle is 120 degrees, while the COB strip light emitting angle is 180 degrees. The wide angle helps to eliminate shadows and dark spots, creating a more attractive and well-lit environment.

5. Anti-sulfuration. COB LED strip light does not have the gold wire of traditional SMD LED, so it will not be sulfurized. Inside the chip of the SMD LED bead, one electrode is connected to the LED bracket with gold wire, and the other electrode is connected to the bracket through silver glue. However, silver is extremely easy to react with sulfide to generate silver sulfide. Resulting in LED blackening and reduced luminous flux.

6. Stronger anti-static ability. COB LED strips have stronger anti-static ability than traditional SMD LED strips. This feature helps protect the delicate electronic components inside the strip, reducing the risk of premature failure and extending the overall life of the lighting solution.

Cons

1. Difficult to maintain color consistency. Because there is no COB LED strip grading machine on the market yet, and the current COB LED strip manufacturers are only sampling to ensure color consistency, it is difficult to ensure that COB LED strips are 100% within the 3 grades of color tolerance. This may result in a slight change in color temperature and hue, which may be noticeable in some applications, especially when adding new sections to an existing installation.

2. Lower luminous efficacy. The luminous efficacy of COB strips is currently only about 120 lm/W. This means that in some cases, the luminous efficacy of COB strips can be as low as 120 lm/W. This means that, in some cases, they may produce less light per watt of energy consumed. However, for many applications, the superior quality of light and the advantages of uniformity and aesthetics outweigh this factor.

3. Reduce power. 15W/m is the only recommended maximum power for COB strips, because the number of chips per meter is too high, and if the power exceeds 15W/m, the heat from the chips is difficult to dissipate, and the life of the COB strip will be shortened. This characteristic is not necessarily a disadvantage but needs to be considered when planning projects that require high-intensity lighting.

What are the Types of COB LED Strips?

COB LED strips have the basic features of SMD LED strips, with adhesive backing, cuttable, connectable, long life, touch safe, environmentally friendly, and easy to install. And there are many kinds of COB LED strips: different voltages, different widths, different densities, different light colors, and color temperatures, and COB LED strips all have a high color rendering index.

1. Mono COB LED strip light

Mono COB LED strips are the simplest form of COB lighting, designed to emit a single color of light. These strips are ideal for creating ambient lighting, highlighting architectural features, or providing task lighting in spaces that require a specific color tone. They are available in a variety of colors, including warm white, cool white, and daylight, and can be customized to match or enhance the ambiance of any room.

2. Tunable White COB LED Strip Lights

The tunable white COB LED strip can adjust the color temperature of the light from warm white to cool white. This feature allows the user to change the lighting mood depending on the time of day, activity, or personal preference, making it a versatile option for environments that require adjustments in lighting mood and functionality.

3. Dim-to-Warm COB LED Strip Lights

Dim-to-warm COB LED strips offer a unique lighting solution that mimics the dimming characteristics of traditional incandescent lamps, where light becomes warmer as it dims. This technology allows the user to reduce the brightness level while changing the color temperature from a brighter, cooler white to a softer, warmer white. This feature enhances the ambiance of any space and provides the flexibility to create a cozy and inviting atmosphere by simply adjusting the light intensity. Ideal for residential environments, hospitality environments, and anywhere where a cozy and relaxing ambiance is desired, the dim-to-warm COB LED strip combines the efficiency of LED technology with the nostalgic appeal of classic lighting.

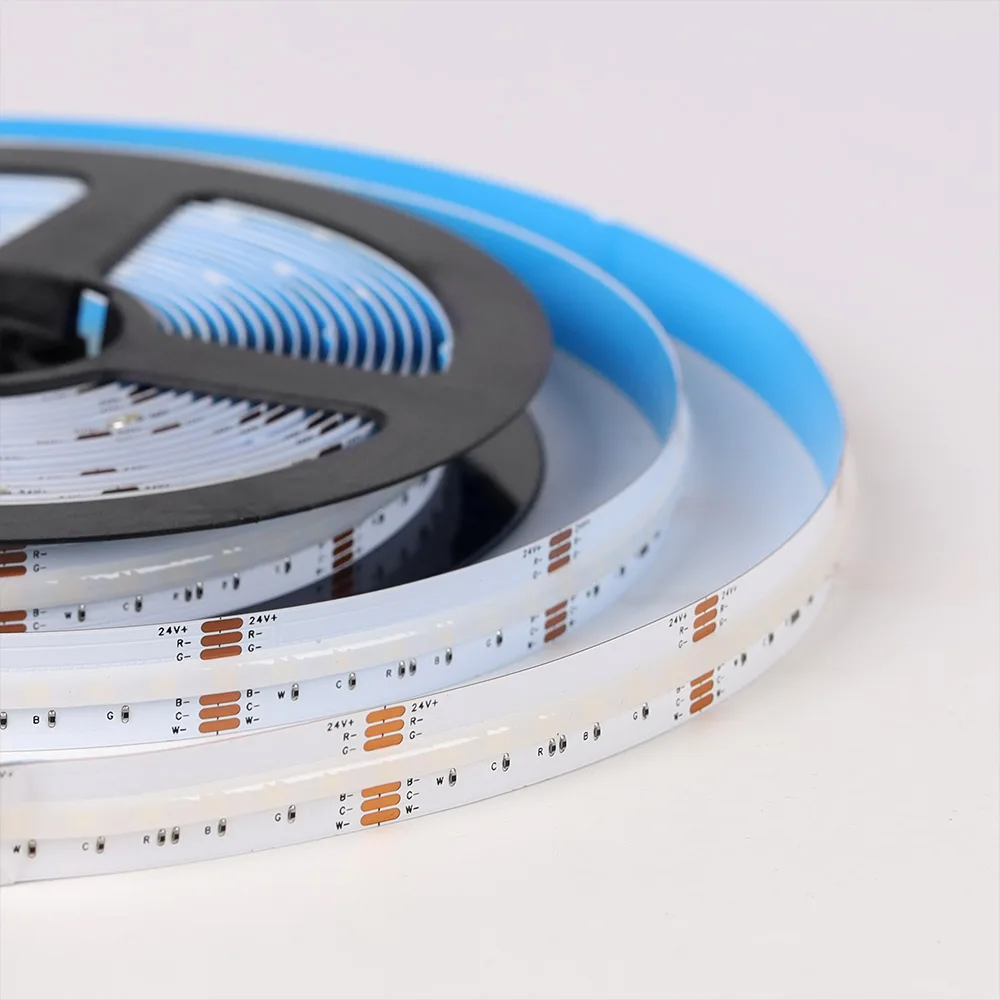

4. RGB COB LED Strips

RGB COB LED strips are capable of producing multiple colors by mixing red, green, and blue light. This type allows for dynamic lighting setups and the ability to switch between multiple colors, making it ideal for entertainment areas, gaming setups, and spaces that require creative and vivid lighting effects.

5. RGBW COB LED Strip Lights

The RGBW COB LED Strip is an extension of the RGB model that includes an additional white chip that allows it to produce pure white light or enhance the brightness and color accuracy of mixed colors. This additional feature makes the RGBW strip an excellent choice for applications requiring both colored and high-quality white lighting.

6. RGBCCT COB LED Strips

RGBCCT COB LED strips combine RGB functionality with correlated color temperature (CCT) control to provide maximum flexibility in color and temperature adjustment. These strips can be created in any color, including different shades of white, making them suitable for advanced lighting designs that require precise control of mood and ambiance.

7. Addressable COB LED Strips

Addressable COB LED strips allow individual parts of the strip to be controlled separately, allowing for complex lighting effects, animations, and color changes. These strips are ideal for creating dynamic visual displays, accent lighting, and customized lighting sequences in commercial and residential environments.

8. Free Cut COB LED Strips

Free-cut COB LED strips are designed with flexibility in mind, allowing users to cut the strips in any position without damaging the remaining LEDs, a feature that is especially useful for custom lighting projects that require precise lengths.

9. Side-Emitting COB LED Strips

Side-illuminated COB LED strips emit light from the edge of the strip, making them ideal for indirect lighting applications such as cove lighting that is hidden from view. This orientation creates a soft, diffused lighting effect that enhances the ambiance of a space.

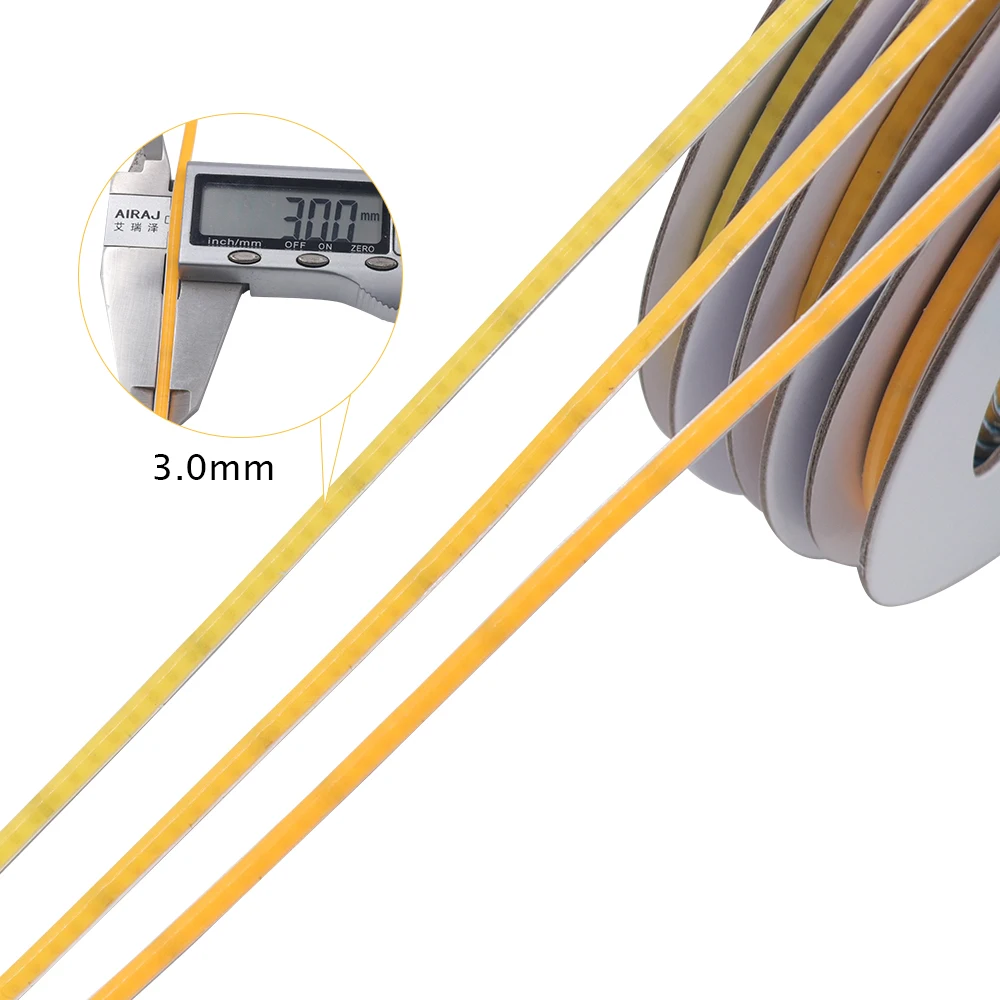

10. Ultra-Narrow COB LED Strips

Designed for space-constrained applications, ultra-narrow COB LED strips are thinner than standard strips and fit into tight spaces where traditional strips may not, such as detailed architectural models or intricate design elements.

11. Reel-to-Reel COB LED Strips

Reel-to-reel COB LED strips stand out in the LED lighting market with their innovative manufacturing process and superior performance. Unlike traditional LED ribbons that are assembled and soldered in sections, reel-to-reel COB LED ribbons are produced in a continuous process without any soldered joints on the entire reel.

12. Constant Current Ultra Long COB LED Strips

Constant current COB LED strips are designed to maintain a consistent level of brightness over the entire length of the strip, even when the voltage fluctuates. This feature ensures even illumination, especially for longer strips where a voltage drop might otherwise cause the end of the line to dim.

13. Double Row Super Bright COB LED Strips

Wide COB LED strips are designed for spaces that require wide, seamless illumination. Its wider design provides broad, spotless illumination and ensures even light across the entire surface.

14. High Voltage AC COB LED Strips

A high-voltage COB LED strip is an LED strip that operates at a higher voltage than the standard low voltage used in most LED strips. It is also known as an AC LED strip because it is driven by AC power, such as AC110V/120V/230V/240V COB LED strips. It is often used for outdoor or indoor decorative lighting.

Where can COB LED Strip Lights be Used?

Commercial Lighting

In commercial environments, COB LED Strip Light is both practical and aesthetically pleasing. Retail stores benefit from the even, bright illumination of COB strips for display lighting, making products more attractive while ensuring accurate color rendering. Offices can use COB LED strips for task lighting to reduce eyestrain and increase productivity or for general ambient lighting to create a welcoming atmosphere for employees and visitors.

Residential Lighting

COB LED strips are a versatile lighting solution for residential environments, offering a wide range of applications to enhance the comfort and aesthetics of your home. They can be used in kitchens for under-cabinet lighting, providing an even light source that illuminates countertops without creating shadows or hot spots. In the living room, COB strips can create ambient lighting to add warmth and depth to a space, or they can be used as accent lighting to highlight artwork, architectural features, or shelving.

Creative and Decorative Lighting

The flexibility and versatility of COB LED strips offer endless creative and decorative possibilities. They can be used for architectural lighting to highlight lines and shapes, for landscape lighting to enhance outdoor features, or for entertainment venues to create dynamic, colorful effects. Event planners and interior designers often incorporate COB LED strips into their projects to create immersive environments and memorable experiences.

Industrial Applications

COB LED strips are also suitable for industrial applications, where their durability and long life make them ideal for lighting manufacturing facilities, warehouses, and workshops. Its uniform light output improves visibility and safety, while its energy efficiency and low maintenance requirements help reduce operating costs.

How to Choose the Right COB LED Strip?

Choosing the right COB LED strip for your project is critical to achieving the desired aesthetic, functionality, and efficiency goals. Below are detailed considerations to guide your choice, including other factors such as voltage, IP rating, PCB width, and color change options:

Color Temperature (CCT)

Choose based on the ambiance you want to create: warm whites (2700K-3000K) for a comfortable atmosphere and cool whites (5000K-6500K) for clearer, more task-oriented lighting.

Color Rendering Index (CRI)

Choose a higher CRI (above 80) to ensure that colors are rendered naturally and vividly, which is critical for spaces where color accuracy is important.

Brightness (Lumens)

Evaluate lumens per meter (or foot) to match the lighting needs of your environment. Brighter is not always better; balance brightness with intended use.

Power consumption and efficiency

Check wattage per meter (or foot) to assess energy use. Choose a more efficient light bar to save money on electricity while maintaining brightness.

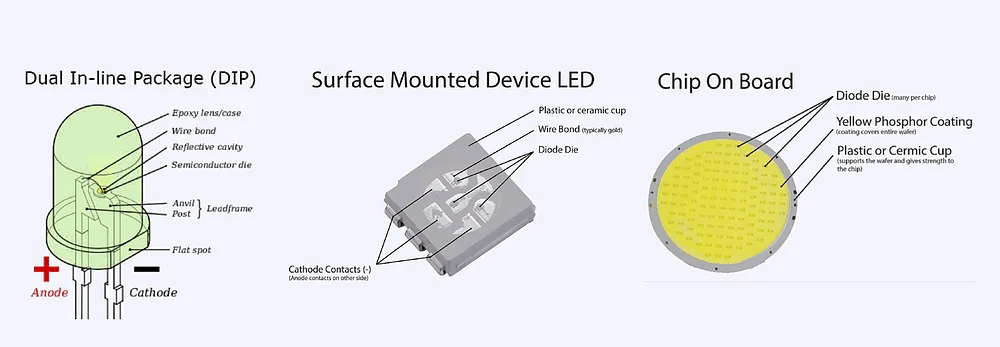

Flexibility and installation requirements

Consider the flexibility of installing the light bar in corners or around curved surfaces. Also, check if specific mounting profiles are required for optimal heat dissipation and light diffusion.

Dimming and control options

If you intend to adjust brightness or color temperature, ensure compatibility with dimming controls or smart home systems to enhance the versatility of your lighting solution.

Voltage

Select the correct voltage for your application (typically 12V or 24V). Higher voltage options can provide longer run lengths without voltage drop, which is important for extended installations.

IP Rating

For installations in wet or outdoor environments, choose a strip with the proper IP rating (e.g., IP65 or higher) to ensure protection against water and dust.

PCB Width

PCB width affects installation flexibility and thermal management. A wider PCB may provide better heat dissipation, which is important for longevity and consistent performance.

Color Change Options

If dynamic lighting is required, consider strips with color-changing capabilities: Adjustable white COB strips allow adjustment from warm to cool white; RGB COB strips provide a full spectrum of colors; RGBW COB strips combine RGB with pure white for enhanced color mixing and brighter whites.

Lengths and Cut Points

Verify maximum continuous run length to ensure consistent brightness. Cut point indication safely trims the strip’s position, allowing customization to accommodate precise measurements.

How to Install COB LED Strip Light?

Installing a COB LED strip light can enhance any space, but proper installation is key to achieving the best results. How to Install COB LED Strip Light Properly? A successful installation requires only a few simple steps.

Step 1: Assess Your Needs

Before you begin, determine the purpose of the lighting and the desired effect. Measure the area to ensure you purchase the correct length of COB LED strip. Consider voltage requirements and select a strip that matches the power supply.

Step 2: Gather the necessary tools and materials

You’ll need some essential tools for this job, including wire cutters, a soldering iron, heat shrink tubing, and a multimeter for testing connections. Make sure you have the proper LED power supply unit that matches the voltage and current specifications of the COB LED strip.

Step 3: Clean the Mounting Surface

Clean the surface on which the COB LED Strip is mounted. Remove any dirt, grease, or debris to ensure proper adhesion. If installing outdoors, make sure the surface is dry.

Step 4: Measure and Cut the COB Strip

If necessary, measure and carefully cut the COB LED strip to the desired length. Be careful cutting the line and make sure to cut neatly to avoid damaging the circuitry. Note the positive (+) and negative (-) terminals to ensure proper connection.

Step 5: Connecting the COB LED Strip to the LED Power Supply

Strip the ends of the LED power supply wires to expose the conductors. Solder or use a connector to extend the LED power supply wires to reach the COB LED Strip. Make sure the connection is secure and matches the positive terminals of the COB Strip and the LED Power Supply.

Step 6: Isolate Connections

Protect soldered joints with heat shrink tubing or electrical tape to prevent short circuits and ensure a solid connection.

Step 7: Test the Strip

Before finalizing the installation, connect the LED power supply to the mains and test the COB LED strip for proper illumination. If necessary, use a multimeter to check the voltage.

Step 8: Fixing the COB Strip

Secure the COB LED strip in place using an appropriate adhesive (e.g., backing on the strip or other mounting hardware). Make sure it is securely attached and avoid sharp bends that could damage the strip.

Step 9: Manage Wiring

Plan and route power and wiring in a safe and aesthetically pleasing manner. Use wire clips or raceways to manage wires and prevent them from posing a tripping hazard.

Step 10: Final Inspection and Enjoyment

After securing the COB light bar in place and neatly arranging the wires, perform a final test to make sure everything is in order. Enjoy your new high-quality lighting solution.

How Do You Cut and Connect the COB LED Strip?

LED light strips have the ability to be cut to better suit different installation needs. COB LED Strip is no exception.

Cutting a COB LED strip to the desired length is a simple process but requires precision to ensure that the functionality of the strip is maintained. The procedure is as follows:

1. Locate the cut line of the COB LED strip and cut along it without cutting into other areas. All LED strips should only be cut with the cut line markings. Cutting into other areas will result in damage to the strip. So be careful.

2. After cutting, it is very important to test the COB strip to make sure it still works properly. Use the appropriate connector to connect the cut COB strip to the power supply. This step verifies that the COB strip lights up and that all parts are working properly.

3. Connect the COB strip. You can choose COB LED connectors to connect the COB LED strip or connect the strip by soldering. Both ways can be used. You can choose your favorite way.

Further Comparison: COB LED Strip vs. Other LED Strips

COB LED Strip vs. SMD LED Strip

The main difference between COB LED strips and SMD LED strips is the distance between the chips and the level of light density emitted by the strip. In an SMD LED strip, the chips are soldered to a circuit board, leaving a gap between the chips. The gap between the chips means that SMD strips have a lower light density, while COB strips have a higher light density.

In short, each LED technology has unique features to suit a variety of lighting needs. COB LED strips are known for their seamless, uniform illumination, which eliminates visible dots and hot spots and provides a smooth light output. In contrast, SMD LED strips offer versatility in terms of brightness and color options for dynamic and customizable lighting environments.

Below is a detailed comparison to illustrate the key differences:

| Feature | COB LED Strip | SMD LED Strip |

| Appearance | Typically has yellow glue due to phosphor mix. | “Dot-like” LED strip using white or black PCB, without glue. |

| Color Tolerance | 5-step Macadam color tolerance. | 3-step Macadam color tolerance. |

| Light Efficiency | Lower due to yellow phosphor mix, 100/130 lm/W | Highest due to lack of glue, 100/150/200 lm/W |

| Light Uniformity | Better, with no light dot effect. | Dot effect due to dispersed light across multiple lamp beads. |

| Packaging | Multiple LED chips integrated on a board, without brackets. | Single LED chip encapsulated in a lamp bead, with brackets. |

| Brightness | Brighter due to multiple LED chips. | Brightness due to LED chips size and density. |

| Heat Dissipation | Complex structure makes it harder. | Easier due to simpler structure. |

| Cost | More | Less |

| Application | Spot-free seamless lighting. | Customized decorative lighting. |

This comparison is designed to shed light on the key differences between COB LED strips and SMD LED strips to help you make decisions about your LED lighting project. Whether you prioritize uniformity or versatility and cost-effective options, understanding these differences ensures that the LED strip you choose will perfectly meet your lighting needs.

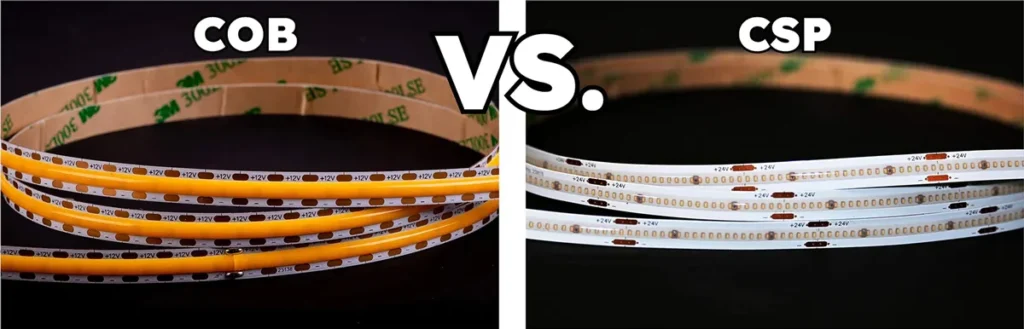

COB LED Strip vs. CSP LED Strip

A CSP (Chip Scale Package) is an LED package that is 20% or less of the size of the LED chip. This is an attempt to reduce the size of the LEDs that can be mounted on the substrate, which essentially means more LED chips on the substrate. These LEDs are placed on microchips so small that they can be mounted directly on the carrier board. This brings unprecedented flexibility and performance to LED strip lighting.

While both COB LED strips and CSP LED strips provide high-quality, uniform illumination, they differ in design, integration, and performance characteristics.COB LED strips are known for their seamless light output and superior thermal management, thanks to a larger substrate for increased durability. On the other hand, CSP LED strips stand out for their compactness and ability to place chips closer together, which can produce higher luminous intensity in a smaller area.

Below is a detailed comparison to illustrate the main differences:

| Feature | COB LED Strip | CSP LED Strip |

| Appearance | Typically has yellow glue due to phosphor mix. | Translucent milky white glue, no phosphor mix. |

| Color Tolerance | 5-step Macadam color tolerance. | 3-step Macadam color tolerance. |

| Light Efficiency | Lower due to yellow phosphor mix, 100/130 lm/W | Higher due to translucent milky white |

| Light Uniformity | Better, with no light dot effect. | with no light dot effect. |

| Packaging | Multiple LED chips integrated on a board, without brackets. | Chips directly to the PCB without an intermediate substrate or package, with brackets. |

| Brightness | Brighter due to multiple LED chips. | Brightness varies, generally less than COB. |

| Heat Dissipation | Complex structure makes it harder. | Better thermal performance. |

| Cost | Less | More |

| Application | Spot-free seamless lighting. | High-quality lighting |

Understanding these differences is critical to choosing the right LED strip for your project, ensuring you achieve the lighting effect, efficiency, and longevity you need. Whether you prioritize the compactness and strength of CSP LED strips or the seamless illumination and durability of COB strips, both technologies offer unique advantages.

How to Troubleshoot COB LED Strips?

COB LED strips are popular for their uniform light output and high efficiency. However, like any electronic device, they can run into problems. Below are common problems and their solutions:

1. COB LED strips do not light up

- Check Power Supply Compatibility: Make sure the voltage and current ratings of the power supply match the requirements of the COB LED strip. For example, a 12V power supply will not work with a 24V COB LED strip.

- Verify Power Supply Function: Use a multimeter to check the voltage output of the power supply. If the voltage is lower than expected, the power supply may be faulty.

- Check Connections: Make sure all connectors and wires are securely seated. Loose connections may prevent the COB strip from lighting up.

- Isolate Accessories: Remove any dimmers or controllers and see if the COB strip lights up without them. This will help determine if the problem is with these fittings.

2. Uneven light

- Quality of COB LED Strips: Low-quality COB LED strips may have inconsistent brightness. Make sure to use certified high-quality COB LED strips to avoid this problem.

- Power Supply Adequacy: Insufficient power supply power can lead to uneven lighting. Make sure the power supply can handle the total power of the COB LED strip.

- Placement: Uneven surface placement can lead to inconsistent light output. Ensure that COB strips are placed evenly and test the layout before permanent installation.

3. Flickering Lights

- Power Supply Issues: Flickering may occur if the power supply is not providing enough power. Ensure that the power supply meets the requirements of the COB LED strip and consider following the 80/20 rule (use only 80% of the power supply’s capacity).

- Faulty LEDs: If specific sections are flashing, the LED may be faulty. If the problem persists, replace the defective part or contact the manufacturer.

4. Dim lights

- Voltage Drop: Measure the input voltage at the COB LED strip connection. If the voltage is significantly lower than the rated voltage, check for loose or corroded connections and make sure the power supply is adequate.

- LED Degradation: LEDs lose brightness over time. If the input voltage is correct but the COB strip remains dim, the LED may be faulty and the strip may need to be replaced.

5. Multiple COB strips with power problems

If you have multiple COB strips connected and one of the strips is not receiving enough power or flickering, consider the following:

- Voltage drop due to cable length: Shorten the cable to minimize the voltage drop. Make sure the cable gauge is appropriate for the current load.

- Power supply capacity: Verify that the power supply can handle the total power of all connected COB strips. If necessary, upgrade to a higher current output power supply.

- Connection Configuration: Ensure that the COB strips are connected correctly. Incorrect wiring can cause power distribution problems.

By following these troubleshooting steps, you can effectively solve common problems with COB LED strips. If the problem persists, it is recommended to contact the manufacturer or seek professional help.

Conclusion

COB LED strips represent a significant advancement in LED lighting, providing superior light quality, uniformity, and efficiency. Whether it’s for residential, commercial, or creative applications, COB LED technology provides a versatile and effective lighting solution.

By considering factors such as color temperature, brightness, and installation requirements, you can choose the COB LED strip that fits your needs and enhances the aesthetics and functionality of any space. As technology evolves, COB LED strips continue to offer innovative possibilities for lighting design, making them a popular choice for lighting professionals and enthusiasts alike.

If you are looking for a COB lighting supplier or custom COB lighting to meet your needs, a member of our team is standing by to answer any specific questions you may have about COBs, so please contact us as soon as possible.