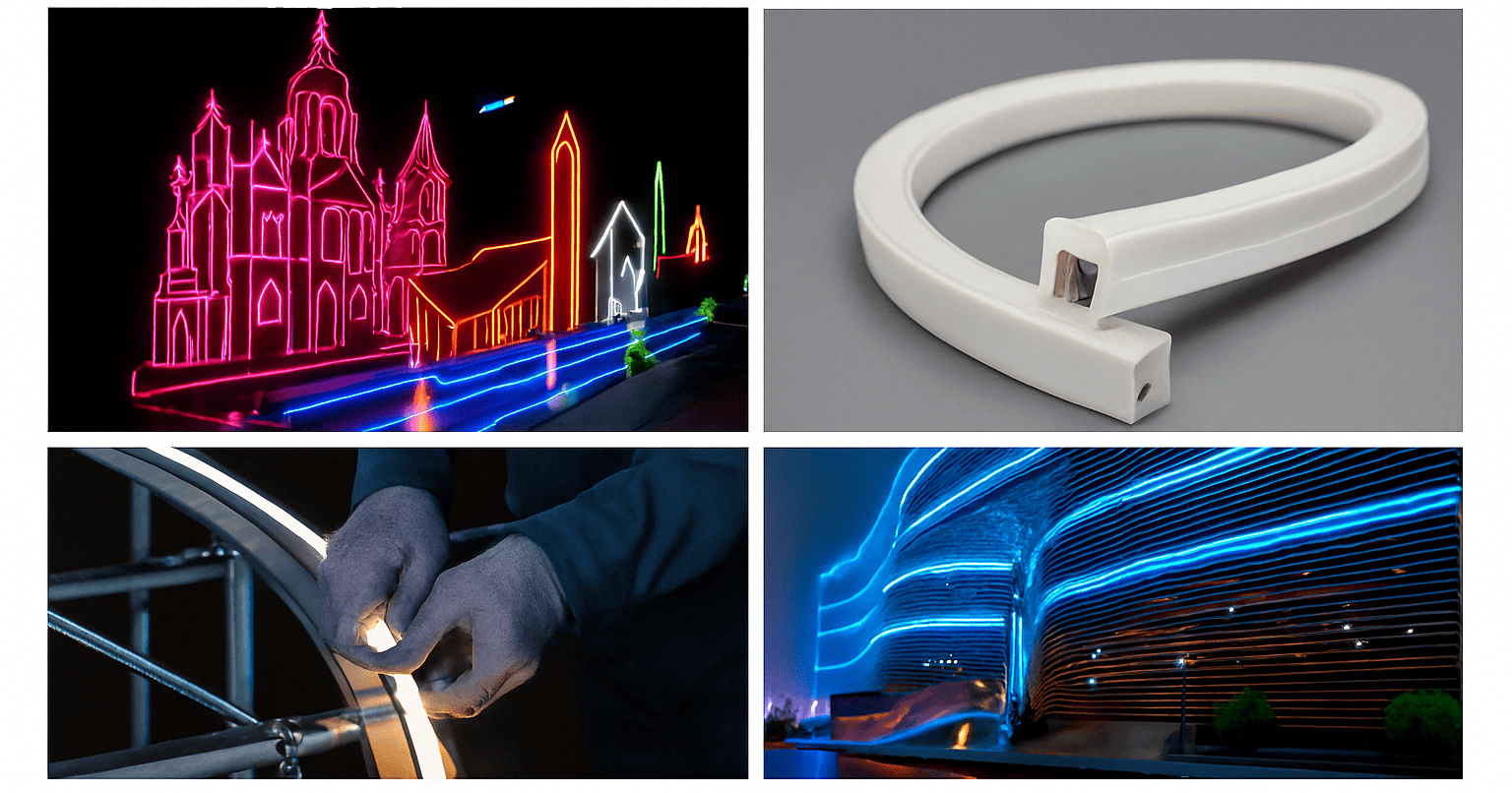

Top LED neon strip manufacturers in China offer a wide spectrum of product quality, advanced customization options, and strong export capabilities—especially in today’s rapidly growing global market for LED neon flex lighting, architectural facade illumination, and flexible linear lighting systems. As demand rises for cost-effective, innovative, DMX512-compatible RGBW lighting systems and application-specific LED solutions, more lighting professionals—including importers, engineering consultancies, architectural designers, and wholesale distributors—are turning to China to fulfill high-volume and technically demanding lighting requirements. Selecting a manufacturer with proven experience, global certifications, and project-ready support is critical for ensuring product performance, delivery reliability, and long-term partnership value.

China has emerged as a global powerhouse in the LED lighting industry, offering a wide range of manufacturers with varying degrees of product quality, technical expertise, and international trade experience. However, not all suppliers uphold the same standards in terms of reliability, product consistency, or long-term performance. Choosing the wrong manufacturer can lead to costly consequences—from delayed deliveries and color mismatches to warranty disputes and inconsistent IP ratings.

This guide provides a step-by-step approach to selecting a reliable LED neon strip manufacturer in China. Whether your project involves large-scale commercial installations, custom signage systems, or architectural lighting applications, these insights will help you avoid common pitfalls, simplify your procurement process, and build sustainable partnerships with dependable suppliers.

Choose Top Manufacturers Specializing in LED Neon Flex Production

When selecting a DMX512 LED neon strip manufacturer in China, one of the most critical factors is their level of expertise—not just in LED lighting overall, but specifically in neon flex strip production for architectural applications. The manufacturing processes, materials, and design requirements for neon flex differ significantly from traditional LED strips or fixtures. Selecting a factory that specializes in this product category ensures a deeper understanding of performance standards, application scenarios, and long-term durability.

A manufacturer with 10+ years of focused experience in LED neon strip production is more likely to have refined its extrusion techniques, improved chip integration methods, and developed advanced solutions for color consistency, waterproofing, and heat dissipation. These factors are critical for outdoor architectural lighting, façade designs, signage, or linear decorative installations.

Here are a few key indicators of valuable experience:

Dedicated production lines for flexible neon light products (not shared with basic LED strip manufacturing)

Proven case studies with exported projects involving DMX512, RGBW color control, or synchronized architectural lighting systems

Familiarity with international compliance standards, such as IP67/68 waterproofing and CE/UL certifications

Past involvement in custom lighting solutions for shopping malls, hotels, building façades, or entertainment venues

Experienced manufacturers also offer better technical consultation during the planning stage, helping clients avoid pitfalls like voltage drop, overbending, or controller incompatibility—issues that can cost time and money during installation.

Pro tip: Ask the manufacturer for a portfolio of past projects or references from overseas clients. A solid project history indicates not only experience, but also their ability to support real-world application challenges.

See How LED Neon Flex is Made – Inside a Modern Factory

Curious about what top LED neon strip manufacturers look like behind the scenes?

Watch this short factory video to explore the extrusion lines, SMT chip placement, and integrated QC stations that ensure precision, reliability, and consistency across every batch of LED neon flex.

Check Global Certifications and Compliance Standards

Check certifications and quality compliance standards is a foundational step when choosing a reliable LED neon strip supplier in China. For B2B buyers, especially those involved in commercial architecture or government lighting contracts, working with a factory that provides certified IP68 LED neon for architecture ensures long-term safety, stability, and ease of import. These certifications are essential for confirming that the product meets the necessary safety, performance, and environmental requirements of your target market. They not only reflect the manufacturer’s commitment to product quality and regulatory compliance but also help ensure smooth customs clearance, minimize legal risks, and prevent technical failures during installation.

A trustworthy LED neon strip supplier should provide up-to-date certificates and detailed quality assurance documentation for different global regions. Key certifications to verify include:

CE: Required for products sold in the European Economic Area, indicating compliance with EU safety and electromagnetic compatibility standards.

RoHS: Ensures the product is free of harmful substances such as lead, mercury, and cadmium.

UL/cUL or ETL Listing: Mandatory for electrical products in North America, especially when integrating with commercial power systems or outdoor installations.

IP67 or IP68 Waterproof Ratings: Critical for outdoor or wet-environment applications, these ratings guarantee protection against dust and water ingress.

ISO 9001 Certification: Indicates that the factory follows a formalized quality management system, with consistent manufacturing processes and continual improvement practices.

In addition to certificates, reputable manufacturers often conduct internal lab testing for:

UV resistance and anti-yellowing performance of silicone or PVC jackets

Color consistency (SDCM level) and CRI measurement

Manufacturers should conduct salt-spray corrosion tests for marine or coastal installations to ensure material durability.

Thermal aging tests to assess longevity in high-temperature conditions

Pro Tip: Don’t just take certificates at face value—ask for digital copies with certificate numbers, issuing authorities, and test reports with batch references. Some manufacturers may falsely claim compliance; verification ensures peace of mind.

Working with a certified manufacturer also improves your credibility when presenting products to clients, architects, or government authorities. It demonstrates that your lighting solutions meet recognized safety, performance, and environmental standards—an essential factor for public buildings, infrastructure, and high-end commercial spaces.

Evaluate Production Capacity and Supply Chain Reliability

Whether you’re sourcing LED neon strips for a nationwide retail rollout, a municipal lighting project, or multiple architectural sites, the manufacturer’s production capacity and scalability can make or break your timeline.

A reliable Chinese LED neon strip supplier should be able to accommodate both standard and custom orders with consistency, especially during peak project seasons. Here’s what to evaluate:

1. Factory Size & Equipment Investment

Large-scale manufacturers typically operate with:

Over 5,000–10,000㎡ of dedicated production space

Automated silicone extrusion machines for precision shaping

High-speed SMT (Surface-Mount Technology) lines for LED chip placement

Integrated aging and waterproof testing equipment

Such setups ensure higher output, reduced defect rates, and consistent batch quality.

2. Monthly Output Capacity

Ask for data on:

Monthly linear meter production (e.g., 100,000m+ per month)

Daily shipment capability

Peak-season vs off-season throughput

This helps assess whether the supplier can scale up if your project expands or deadlines tighten.

3. In-House vs Outsourced Components

Manufacturers who control their own PCB assembly, extrusion, and injection molding typically offer better quality control and faster turnaround times. If too many steps are outsourced, lead times may be longer and consistency harder to guarantee.

4. Supply Chain Reliability

A dependable manufacturer will have:

Stable upstream suppliers for LED chips (e.g., Nichia, Epistar, San’an)

Sufficient raw material inventory (e.g., silicone, copper wire, PCB)

Logistics partners with international shipping experience

Tip: Beware of small-scale workshops that over-promise production capacity. Request factory videos, visit if possible, or use third-party inspection services to verify production capabilities.

Review Customization for Color, Control, and Profiles

1. Color Configurations & LED Types

Color configuration is one of the most vital considerations when sourcing custom RGBW LED neon lighting from a Chinese manufacturer. From single-color commercial accents to DMX-controlled RGBW dynamic displays, the right supplier should offer versatile solutions that align with your branding, control systems, and technical demands.

Single-color strips are often used for signage, accent lighting, or applications with strict color codes (e.g., warm white for hospitality).

RGB and RGBW configurations are widely adopted in dynamic lighting systems, such as theme parks, clubs, and entertainment venues. RGBW strips offer the advantage of pure white output alongside full-color capability, delivering better color rendering and ambient lighting.

For pixel-controlled installations, especially in large-scale media façades or interactive lighting projects, DMX512 or SPI addressable strips allow precise control of each segment, enabling flowing effects, animations, or video playback via LED controllers.

Tunable white strips, which allow for real-time adjustment between cool and warm color temperatures, are highly sought after in museums, galleries, or workspaces to simulate daylight cycles and improve visual comfort.

A manufacturer who understands these options can advise you on not only what’s possible—but also what works best for your project’s lighting intent and installation complexity.

2. Voltage and Power Options

Voltage and power options are fundamental considerations when specifying LED neon strips for commercial and architectural lighting projects. The right voltage selection directly impacts not only the safety and energy efficiency of your system but also determines brightness consistency, system stability, and long-term reliability—especially for large-scale or customized installations.

LED neon strips are available in multiple voltage configurations to accommodate diverse project requirements and wiring scenarios:

12V DC: Best suited for short runs and low-power applications such as display cases, signage outlines, or portable lighting solutions.

24V DC: The industry standard for most general-purpose installations. It provides a reliable balance between current draw and voltage drop, making it ideal for ceiling lighting, indoor outlines, and medium-length runs.

48V DC or constant current systems: Recommended for longer linear installations—such as building perimeters, tunnels, or extended architectural facades—where voltage drop must be minimized and brightness uniformity maintained across distances exceeding 20 meters.

In commercial environments, it’s equally important to match the appropriate power supply units (PSUs), dimming protocols, and control systems. A qualified manufacturer should provide accurate wattage calculations, load balancing, and component compatibility recommendations to ensure stable operation without issues like flickering, overheating, or early failure.

Pro Tip: Power configuration is not just a technical detail—it’s a critical design factor. Using the wrong setup can shorten product lifespan and compromise performance. Always consult the supplier’s engineering team early in the planning phase to avoid costly mistakes.

3. Cutting Intervals & Length Flexibility

Cutting intervals and length flexibility are key factors in ensuring a flexible LED neon strip solution that adapts to irregular surfaces, exact measurements, and architectural shapes. The cutting interval—the distance between two cuttable sections—directly affects the precision and appearance of your lighting layout. For example, a 3.3cm cut-point interval allows for very fine adjustments, ideal for intricate logos or tightly curved signage. Larger intervals (e.g., 10cm or more) may result in visible dead zones at corners or terminations, especially in short or segmented installations.

Professional manufacturers offer customized cutting lengths based on the LED pitch, circuit design, and the client’s layout drawing. Additionally, for large-volume orders or modular project rollouts, suppliers can deliver pre-cut, pre-soldered segments with waterproof connectors, reducing labor costs and errors on-site.

Tip: Ask if the supplier provides factory-prepared “ready-to-install” lengths with customized labeling. It saves huge amounts of time during installation and ensures layout accuracy.

4. Material and Profile Customization

Material and profile customization are essential factors in determining the outer shell of an LED neon strip, which isn’t just cosmetic—it affects its durability, weather resistance, optical effect, and installation compatibility. Silicone-encased neon strips offer superior flexibility, UV resistance, and anti-yellowing performance, making them ideal for outdoor use or curved installations. PVC types are cost-effective and suitable for indoor or temporary use, though they may harden or discolor under prolonged UV exposure.

Cross-section customization is also vital. Options include:

Top-bend profiles for surface lighting (e.g., under shelves, ceilings)

Side-bend profiles for lettering and logo signage

Round or 3D-bend models for complex shapes and organic curves

Advanced suppliers may offer custom profile tooling services, allowing for completely unique light shapes that match your brand identity or project style. Surface finish options such as frosted, clear, or diffused can also influence light uniformity and visual comfort. A well-matched profile minimizes light leakage, glare, and installation complications—choose wisely based on your mounting scenario and visual expectations.

5. Integrate Smart Control Protocols like DMX512 & SPI

With the rise of smart buildings and IoT systems, integrating LED neon lighting into digital control ecosystems is more important than ever.

Leading manufacturers support DMX512 for theatrical-grade control, SPI for pixel lighting, and DALI/0-10V for commercial dimming systems. If you’re unsure which protocol suits your project best, check out our in-depth comparison of DMX 및 SPI control options for RGB LED neon flex to understand the pros, cons, and best-use scenarios of each system.

For retail and residential automation, Zigbee, Tuya, and WiFi-based solutions are becoming increasingly popular due to their app-controlled convenience.

Full control system integration means:

Synchronizing neon lights with music or interactive displays

Running complex light sequences for shows or events

Managing brightness and color temperature based on sensor inputs or time schedules

Technical support should also include wiring diagrams, controller compatibility charts, and optional pre-programming before shipment.

Choose a supplier that not only sells you the light—but also understands the system you’re building.

Strong customization capability means more than color or voltage—it means your project can stand out, stay reliable, and install seamlessly. By partnering with a supplier that offers true flexibility, you gain a tailor-made lighting system that supports your design vision and performs flawlessly in the field.

Watch Real DMX-Controlled RGBW Neon Flex in Action

Want to see how DMX512 brings architectural lighting to life?

Watch this video of a real façade project using RGBW LED neon flex strips with DMX512 protocol to create smooth color transitions and synchronized dynamic effects on a modern building exterior.

Confirm Engineering Support and Pre-Sales Guidance

For large or technically demanding LED neon strip projects, strong engineering support and pre-sales communication from the manufacturer are crucial. This soft power often determines whether a complex lighting plan will succeed—or suffer costly delays.

Here are the specific service capabilities you should expect from a professional Chinese supplier:

1. Lighting Layout Review & CAD/3D Drawing Support

A reliable LED neon strip manufacturer should be able to:

Review your AutoCAD/SketchUp/Revit layout or technical drawings

Propose the most suitable neon models and bending types based on your design

Offer customized lighting layout diagrams, showing cut points, power input points, and controller positions

Some top-tier suppliers even support BIM collaboration or assist lighting designers in optimizing fixture placement for consistent brightness and minimal shadowing.

2. Sample Customization and Prototype Testing

Before placing a large volume order, testing actual samples is a standard part of professional procurement. A qualified supplier should:

Provide customized samples matching your specs (color temp, size, shape, control mode)

Include installation brackets, connectors, and suggested power supply in the sample pack

Offer a quick turn-around time (typically 3–7 working days) for prototyping

Warning: Avoid suppliers that only offer generic samples and cannot match the exact configuration you need—they may lack the flexibility for real projects.

3. System Compatibility Guidance

In many projects, LED neon strips must work alongside:

DALI, DMX, 0-10V control systems

Central power supplies or distributed circuits

Architectural profiles or mounting channels

Professional manufacturers provide:

Wiring diagrams and integration charts

Dimming and power compatibility consultation

Help with controller selection and programming if needed

Ask if the supplier has dealt with similar projects in your industry. Their real-world experience can prevent costly mistakes in control signal mismatches or overload issues.

4. Responsive Communication Channels

Efficient communication plays a vital role during quotation, design revision, and production follow-up stages. Top-tier manufacturers will:

Assign dedicated English-speaking sales engineers or project managers

Respond to technical questions within 24 hours or less

Offer video calls or WeChat/WhatsApp support for real-time discussion

Transparent communication builds trust. Unresponsive or vague replies are a red flag—especially in time-sensitive projects.

5. Documentation and Compliance Readiness

For international projects, especially in Europe or North America, compliance documentation is non-negotiable. A serious supplier will provide:

Photometric and LM80 reports

RoHS, CE, UL, or ETL certifications

IP waterproof test data, fire rating test results, and MSDS for materials

Ask to review certifications before confirming your order. It saves time during import customs or project bidding stages.

Engineering support is more than a bonus—it’s part of the value chain that ensures your lighting solution is feasible, installable, and legally compliant. Choosing a manufacturer with proactive pre-sales service minimizes back-and-forth, avoids misinterpretation, and saves time and money in the long run.

Ensure Strict Quality Control and Product Testing

When selecting a reliable LED neon strip manufacturer in China, ensuring that they adhere to strict quality control and testing standards is essential. This not only guarantees the durability and performance of the product but also mitigates risks related to compliance, safety, and customer satisfaction.

1. Importance of Quality Control

QC is the backbone of any reputable manufacturing operation. For LED neon strips, strict QC ensures that every unit meets the necessary performance specifications, such as brightness, color consistency, and energy efficiency. Moreover, LED neon strips are commonly used in both indoor and outdoor environments, so ensuring their durability and resistance to factors like heat, humidity, and UV exposure is crucial.

2. Key Quality Control Processes

Reliable manufacturers typically implement various stages of quality control throughout the production process. These include:

Raw Material Inspection: The quality of the materials used, including LED chips, PCB boards, and flexible substrates, plays a critical role in the final product’s performance. Top manufacturers will inspect the materials before they enter the production line.

In-Process Quality Control: Continuous checks are performed during manufacturing to detect potential defects early. This may include visual inspections, measurements of light output, and adherence to electrical safety standards.

Final Product Testing: Once the neon strips are assembled, they undergo rigorous testing for color accuracy, power consumption, and overall quality. This can involve using photometers, colorimeters, and other advanced instruments to assess the products.

3. Third-Party Testing and Inspections

Working with manufacturers who engage third-party testing organizations ensures an unbiased evaluation of the products. Certifications from well-known agencies like TUV, SGS, or Intertek offer an added layer of trust, verifying that the manufacturer’s quality control process meets global standards.

4. Establishing Clear Communication with Manufacturers

Once you’ve verified the manufacturer’s quality control and testing processes, establishing open and clear communication with them is crucial. Discussing your specific quality expectations, and requesting periodic reports on inspections and testing results, will help build a transparent relationship. Additionally, request samples from batch production runs to evaluate consistency in product quality before making bulk purchases.

5. Continuous Improvement and Auditing

Reliable manufacturers continually invest in improving their quality control processes. A transparent manufacturer should be able to provide evidence of ongoing training programs for their staff and the adoption of the latest technologies for testing and measurement. Regular audits by both internal and external agencies will help ensure that their quality standards remain at the highest level.

Understand Warranty Terms and Replacement Terms

Understanding warranty terms is a critical part of evaluating a LED neon strip supplier in China. A solid warranty reflects the manufacturer’s confidence in product durability and also determines how much risk you’re taking on post-installation.

When comparing suppliers, pay close attention to the following:

1. Warranty Period

The warranty period offered by manufacturers usually ranges from 2 to 5 years, depending on the product category and intended usage. High-end outdoor-rated neon strips may come with longer warranties, while more economical indoor versions offer shorter terms. Always confirm whether the stated warranty applies to the specific model you are purchasing, not just the brand in general.

2. Scope of Warranty Coverage

The scope of coverage can vary greatly between suppliers. Some warranties only cover dead LED chips, while others also include:

Waterproofing failures

Yellowing or cracking of the housing material

Connector and controller malfunctions

Color fading or significant brightness drop over time

3. Replacement and Credit Process

A reliable manufacturer should clearly define the replacement process in the event of failure. Ask the following:

Do they send replacement units immediately, or require full return and inspection first?

Are freight costs covered by the manufacturer?

Is a credit note or discount offered for verified defects?

Ideally, the supplier should minimize downtime by offering advance replacement shipments or credit toward the next order.

4. After-Sales Support Response Time

Fast response time is especially important for international projects with tight schedules. A supplier who responds to warranty claims within 24–48 hours, provides replacement tracking, and communicates clearly shows they take long-term partnerships seriously.

Tip: Ask whether they have a dedicated after-sales team and how claims are handled. Responsiveness is often the true test of a supplier’s reliability.

Test Samples and Run Pilot Projects for Quality Assurance

Test samples and pilot projects is a crucial step in verifying whether a LED neon strip manufacturer can truly meet your project standards. No matter how promising the catalog or quotation looks, only real product testing can reveal how it will perform under actual conditions.

1. Requesting product samples

When evaluating a supplier, always request product samples that match the exact specifications you intend to purchase—not just generic models. Testing should cover:

CRI and Brightness levels play a major role in achieving accurate color representation—especially in environments like retail displays, art installations, or branded architectural lighting. A high CRI ensures that illuminated surfaces reflect their true colors under LED lighting. You can learn more about the importance of CRI in LED strip lights here.

Color temperature precision, especially important for brand-sensitive or ambient projects

Material softness and texture—flexibility is critical for smooth bending without cracking

Minimum bending radius, to confirm if it suits curved designs or tight installations

Heat and UV resistance, particularly for outdoor or high-temperature environments

2. Conducting a pilot installation

Running a pilot order or test installation on-site is the most effective way to assess long-term performance. This allows you to:

Check how the neon strip integrates with your actual mounting profiles or structures

Evaluate installation ease, including connectors and power setup

Observe real-time issues like color shift, hotspots, or dim segments

Monitor for early failures, discoloration, or IP rating breaches after a few weeks

Analyze Pricing Structure and Secure Payment Terms

Analyze the pricing structure and payment terms of different LED neon strip suppliers is essential to ensure your project stays within budget while minimizing financial risk. A transparent and well-documented quotation allows you to understand what you’re really paying for—and avoid unexpected costs later.

1. Understand the pricing breakdown

A professional supplier should provide a detailed quotation that includes all relevant components, not just the base product price. Look for line items such as:

Per-meter or per-reel pricing for each LED neon model

Accessory costs, including aluminum channels, power supplies, and controllers

Packaging details, such as individual labeling, box dimensions, or branding options

Customs-related info like HS codes, origin markings, or required certificates

Sample fees, and whether they’re refundable upon bulk order

Pro tip: Ask for both EXW and FOB/CIF/DDP terms to compare supplier flexibility and total landed cost.

2. Avoid overly low pricing traps

Extremely low-priced offers often indicate compromises in material quality or performance. Common cost-cutting tactics include:

Substandard LED chips with low lumen output or short lifespan

Thinner copper PCBs that lead to voltage drop and uneven brightness

Recycled or yellowing silicone jackets with poor UV resistance

Always request a component list or BOM (Bill of Materials) if pricing seems suspiciously low. Long-term durability matters more than saving a few cents upfront.

3. Negotiate flexible and secure payment terms

Standard payment terms vary by supplier, but common and safe options include:

30% deposit + 70% before shipment (most widely accepted for mid-sized orders)

Letter of Credit (L/C) for large-scale or public sector projects

Alibaba Trade Assurance, escrow, or other contract-secured options for added protection

If it’s your first cooperation, ask if the supplier offers a low-MOQ trial order with flexible terms to reduce initial risk.

Build Long-Term Success with the Right LED Neon Strip Supplier

Selecting the right LED neon strip manufacturer in China is not just about comparing quotes—it’s about securing a production partner who shares your commitment to quality, reliability, and innovation. The most dependable suppliers offer more than just product—they provide engineering guidance, consistent delivery, customization support, and responsive after-sales service.

To ensure a smooth procurement process and successful lighting rollout, look for manufacturers that:

Align with your technical requirements and project goals

Offer verified certifications and quality control documentation

Provide custom lighting solutions tailored to architectural, commercial, or signage applications

Maintain open communication and a clear warranty policy

By making the right choice, you reduce risks, shorten project cycles, and enhance your brand’s reputation in the marketplace.

Need help sourcing a trusted supplier?

Explore our product line or contact us to get expert advice, request samples, or receive a customized quote for your next project. We specialize in DMX RGBW LED neon flex, waterproof IP68 strips, and architectural-grade LED solutions—engineered for performance, built for longevity.