In our production and sales of LED strip products for more than 10 years, we found that most customers pay more attention to the photoelectric parameters of the LED light belt itself and ignore the back glue, in fact, the light belt back glue should also receive the same degree of attention. Different applications, environments and surfaces should choose different adhesive paper.

Taking 3M as an example, there are hundreds of products of double-sided tape models, suitable for different uses and environmental requirements.

If the adhesive selection of the LED light belt is not good, it may not ensure the best adhesive effect when used by the end user, and poor adhesive adhesion and LED light strip fall off in a short period of time after installation, once these problems occur, it may be illuminated as a whole batch of customers return claims.

Selecting high-quality Led strip backing adhesive is to consider its adhesive force, weather resistance, temperature resistance, anti-aging ability, environmental protection, and ease of operation.

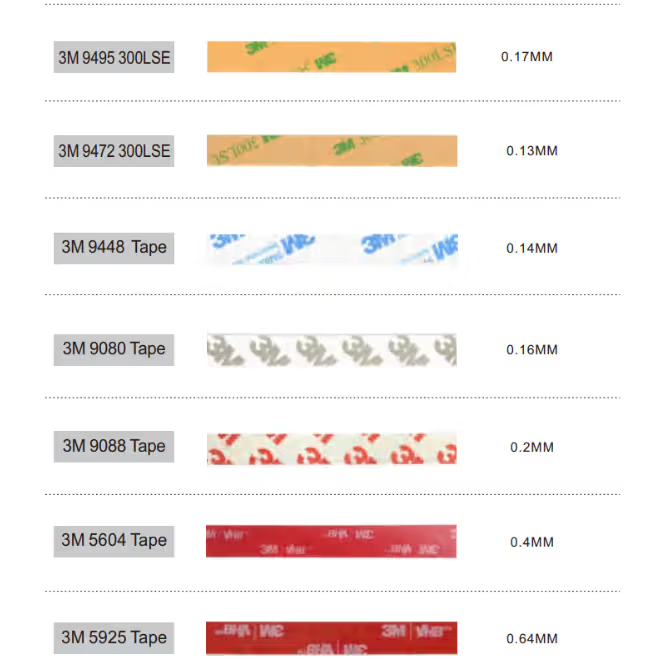

The following is a list of Led Strip tape used by many companies on the market:

| Tape type | Usage Scenarios | AdhesiveThicknessmils (mm) | Adhesion toStainless steel(N/CM) | Application |

| 3M 9495 300LSE | High-temperaturebonding, Automotive andelectronics | 6.8(0.17) | 8.6 N/CM | Indoor |

| 3M 9472 300LSE | General purpose bonding ,metal,Plastic, and wood | 5.2(0.13) | 11.9 N/CM | Indoor |

| 3M 9448 Tape | Low surface energy bonding ,plasticsAnd powder coatings | 5.6(0.14) | 6.8 N/CM | Indoor |

| 3M 9080 Tape | Electronic insulation, film touch switch label, nameplate, decoration | 6.4(0.16) | 7.5 N/CM | Indoor/outdoor |

| 3M 9088 Tape | PE and stainless steel and other substrates | 8.0(0.2) | 6.8 N/CM | Indoor |

| 3M 5604 VHB | Structural bonding ,metal , glass ,andhigh surface energy plastics, outdoorapplication | 16(0.4) | 20.0 N/CM | WaterproofStrip &outdoor |

| 3M 5925 | Structural bonding ,metal , glass ,andhigh surface energy plastics, | 25.6(0.64) | 10.0 N/CM | Indoor/outdoor |

| BlueThermaltape | Heat dissipation for electronics, LED, Strips | 5.2(0.13) | 6.0 N/CM | For aluminumprofiles |

When choosing an adhesive tape for led strip light, it is important to consider the surface to which the tape will be applied, the conditions of use, and the required level of bonding strength. Each of the above-mentioned tapes offers specific features and benefits that make them suitable for various applications. By understanding the properties of each tape, you can choose the right one for your LED strip project and ensure its long-lasting performance.

The double-sided tape of the LED strip usually uses 3M double-sided tape or other brands of high-performance double-sided tape, these double-sided tape has ultra-thin, strong, high temperature resistance, no trace and other characteristics, to ensure that the LED light belt is firmly pasted on a variety of surfaces, while leaving no residue, easy to remove and replace.

The consequences of using inferior tape:

1. The adhesive force is insufficient, and the adhesive properties of the lamp belt cannot be effectively maintained.

2. The adhesive material is poor, and the high temperature when the lamp belt is working causes the adhesive to melt, resulting in the lamp belt falling off.

3. The installation is not firm, and the time is not long before it falls off, and the shock-proof dynamic effect is poor, resulting in the lamp strip falling off.

For indoor LED strips,Signlite LED strips are typically affixed with 300LSE double-sided tape. For stronger adhesion and outdoor use, we recommend 3M VHB double-sided tape. For cost-sensitive LED strips to aid heat dissipation, we suggest using blue thermal tape for rapid heat transfer.

Why did we choose 300LSE tape?

3M 300LSE is a high-strength acrylic adhesive tape that offers excellent adhesion to a variety of surfaces, including metal, plastic, and painted surfaces.

It has a thin, 6.8 mil (0.17 mm) adhesive layer and provides excellent shear strength and high temperature resistance. Adhesion to Stainless Steel: (33 N/25 mm)

For some high requirements or outdoor led strips,Signlite LED strips is affixed with CP5604 VHB double-sided tape , Why did we choose CP5604 VHB tape?

What does VHB mean?

Very High Bond. This is a grade of tape that can be used for mounting and supporting heavier items. For example, our clear VHB tape supports up to 2.2lbs per square inch.

The 3M VHB mounting tape is an excellent choice for mounting LED strip lights. It is waterproof (after curing for 72 hours and while applied in dry conditions.) You get a choice of black or clear mounting tape. The black tape can hoist a hefty 3lbs per square inch!

Acrylic foam tape CP5604 is a medium-density, gray acrylic foam tape with acrylic adhesives. 3M acrylic foam tape CP5604 is characterized by good peel and shear adhesion, high initial adhesion, good low temperature application performance.

Conclusion:

1.This is the reason for the use of 3M tape in the Signlite LED strips, customers can rest assured that they can use it.

2.Our mounting tapes are intended for permanent or semi-permanent applications. Tape can be removed, but there is a chance of hurting the mounted surface, so demonstrate care.

3.Use a heat gun to soften adhesive before attempting to remove tape. A flat utility knife can be gently used to break bond of tape and surface before removing

4.Refer to the specific instructions of each tape as some products require up to 72 hours before bond is fully created.