Connectors are important components to LED strip installations, proper connectors ensure secure connections and reliable performance for application like cabinet lighting , signage lighting, linear lighting. it’s crucial to choose the right connectors for LED strip, how to choose appropriate connectors, check it out here.

What are LED Strip Connectors

LED strip connectors are specialized components used to join or connect LED strips to each other, power sources, or controllers without the need for soldering. They come in various forms, such as clip-on, snap, or solderless connectors, designed to fit different widths and configurations of LED strips. These connectors ensure a secure and reliable connection, making installation easier, especially in complex or custom projects. They are crucial for creating seamless, continuous lighting runs and are commonly used in both residential and commercial LED strip lighting setups.

How Do LED Strip Connectors Work

LED strip connectors work by establishing an electrical connection between the copper pads on LED strips and the power source, controller, or another strip. Solderless connectors typically use a clip or snap mechanism to securely hold the strips in place, allowing electricity to flow without the need for soldering.

Types of LED Strip Connectors

LED strip connectors come in different types and styles, common types include solderless connectors for easy connection, such as snap-on connectors and stab-in connectors, waterproof connectors for damp location and corner connectors for angled installations each designed to meet specific needs and installation requirements. Whether you’re looking to extend a strip, create a corner connection, or add a power source, there’s a connector out there to suit your project.

Solderless Connectors

Solderless connectors feature easy installation, secure connections, compatibility with various strip types, no soldering required, and versatility for straight or angled configurations, enhancing convenience and efficiency. Snap-on connectors and stab-in connectors are two types of solderless connectors, they vary in different size, shape, function, etc.

1. Pins of Connectors

LED strip connectors’ pin is to make electrical contact with the copper pads on LED strips. These pins come in various configurations depending on the type of connector:

* 2-pin connectors: For single-color LED strips, white, red, green, etc.

* 3-pin connectors: For dual-color LED strips, color selectable strip, CCT adjustable strip (CCT tunable), addressable RGB strip(SPI, succh as WS2811, WS2812).

* 4-pin connectors: For RGB LED strips.

* 5-pin connectors: For RGBW LED strips, addressable RGB strip(DMX512).

* 6-pin connectors: For RGBWW, RGBCW, RGBCCT LED strips.

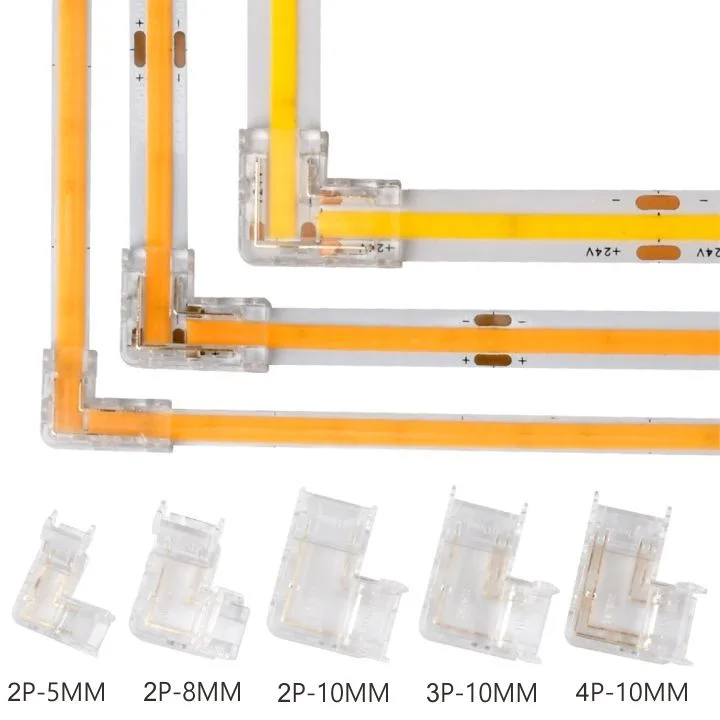

2. Connectors for Different Width Strips

LED strip connectors come in different widths to match the corresponding LED strip sizes, ensuring a secure fit and reliable connection, including:

* Connectors for 5mm width LED strips.

* Connectors for 8mm width LED strips.

* Connectors for 10mm width LED strips.

* Connectors for 12mm width LED strips.

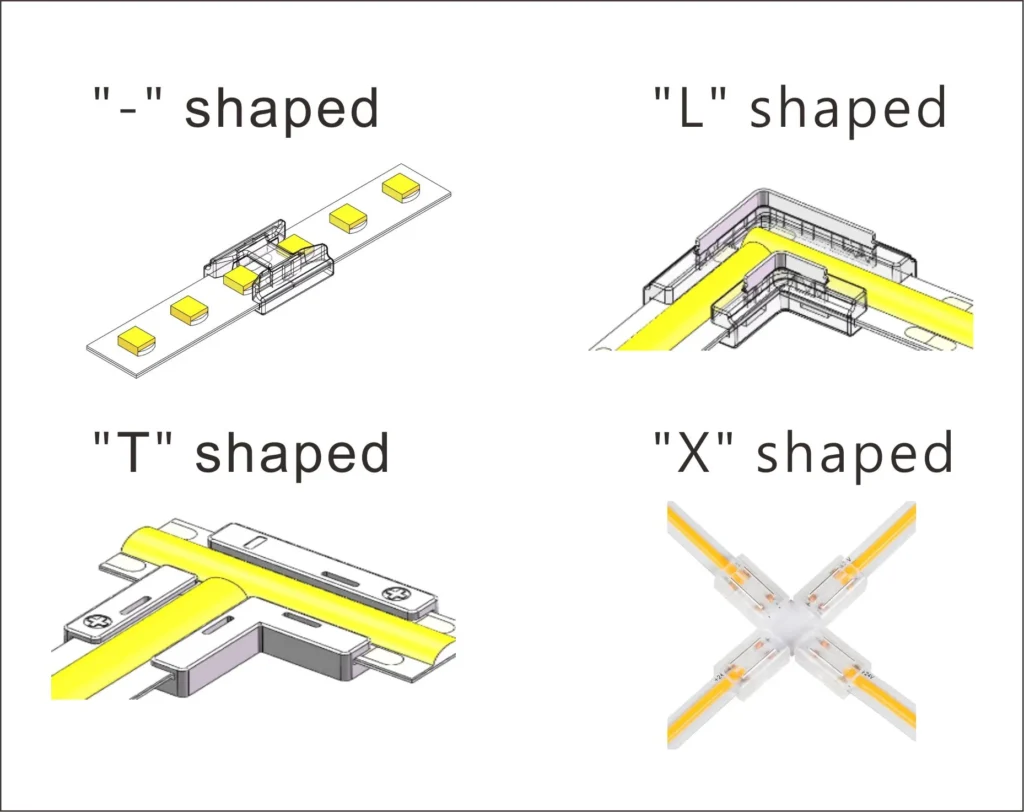

3. Shapes of Connectors

* Straight connectors: Used to connect two LED strips end-to-end, extend the length of LED strips, allowing for a continuous run.

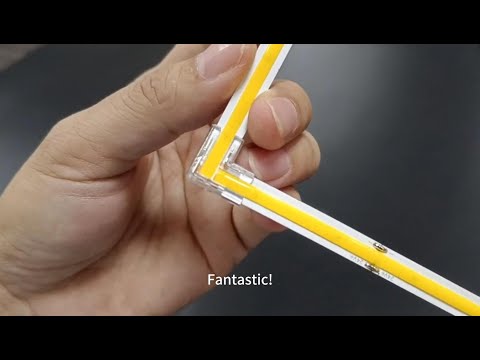

* L-shaped connectors: Designed for 90-degree turns, making it easy to navigate corners and create angles in your lighting setup.

* T-shaped connectors: Used for branching connections, allowing a single LED strip to split into two directions, like T-junction applications.

* X-shaped connectors: Useful for connecting multiple strips in a cross pattern, ideal for intricate designs.

4. Connectors for Different Functions

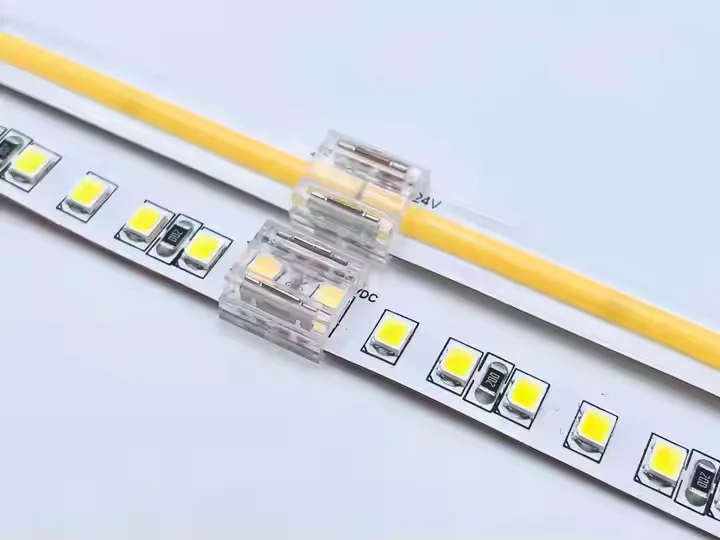

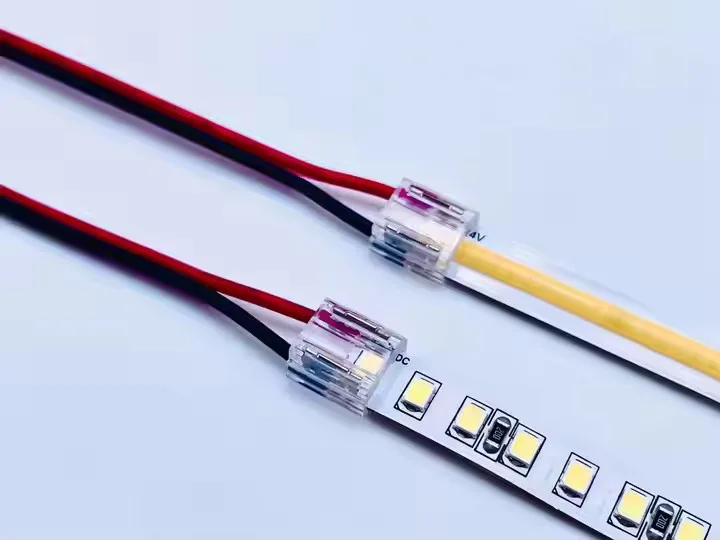

* Strip-to-strip connectors: Use to connect two strips together, allowing you to extend the length of your LED strip lighting without the need for additional power supplies or controllers.

* Strip-to-wire connectors: This type of connectors are often used when you need to connect an LED strip to other devices. So one end is to connect strips, the other end is to connector power supply, controller or other components.

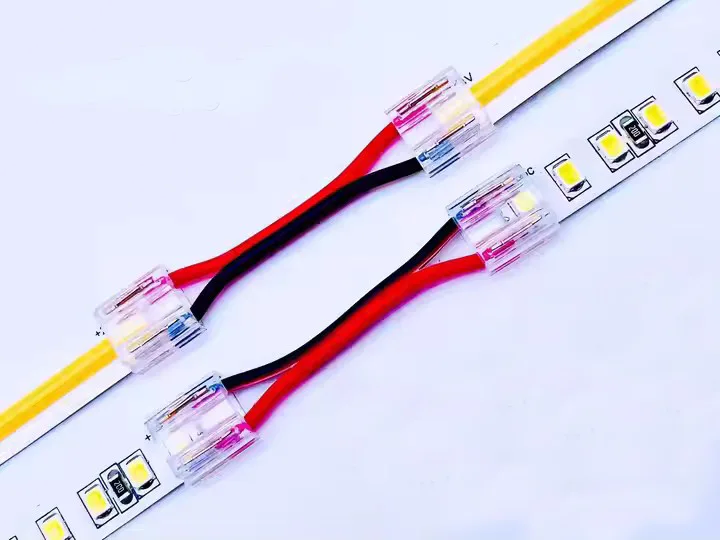

* Strip-to-wire-strip connectors: Usually this type of connectors combined by strip-to-strip connector one each on both end, but connected by wire or flex PCB. Same function with strip-to-strip connectors, but strips are separated apart and provide incontinuous lighting.

5. Connectors for Different Strip Types

* Connectors for SMD LED strips.

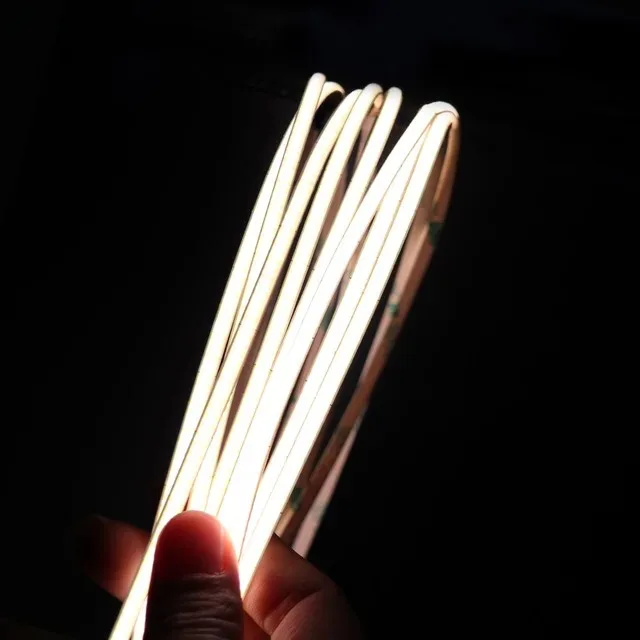

* Connectors for COB LED strips.

* Connectors for AC LED strips.

* Connectors for waterproof LED strips.

* Connectors for non-waterproof LED strips.

How to Choose the Right LED Strip Connector

Choosing the right LED strip connector is crucial for ensuring a secure and reliable electrical connection. It prevents issues like flickering, voltage drops, and installation failures. Proper connectors also enhance the longevity and performance of the lighting system, ultimately ensuring a safe and effective LED lighting setup. Here are steps for choosing right connector for LED strips.

1. Waterproof or Non-waterproof Strips

Where are you going to install LED strips, indoor or outdoor? If it’s for damp location, choose IP65 connectors. IP20 connectors are too small to fit in waterproof LED strips.

2. SMD or COB Strips

Due to different solder pad distance, mostly SMD LED strip and COB LED strip do not share the same connectors, choose the correct one according to your needs.

3. LED Strips Color

Determine what color of your strip, choose 2-pin connectors for single color; 3-pin connectors for tunable white or addressable RGB, such as WS2811 LED strips; 4-pin connectors for RGB; 5-pin connectors for RGBW or DMX512 LED strips; 6-pin connectors for RGBWW, RGBCW, RGBCCT LED strips.

4. Width of Your Strips

All connectors are designed to fit specific width of LED strip, you will not be able to put 8mm strip into a 5mm connector, and you will not get a good connection to put 5mm strip into a 8mm connector. So it’s very important to choose the right connector according to the width of LED strip.

5. Function of Connectors

What’s your purpose of using connectors, if it’s for connecting two strips together, choose straight connectors. If it’s for L-corner, choose L-shaped connectors. If it’s for multi-connection, choose T-shaped or X-shaped connectors. If it’s for connecting to power supply or controller, choose strip-to-wire connectors.

For example, if you are going to buy RGBCCT COB strip connectors for indoor use, you can choose our CNT-COB-6P-12MM-D. It’s 6pins, for 12mm RGBCCT COB strip, IP20, strip to strip directly.

Factors to Consider

1. All connectors has max load current, check it with supplier and calculate the current you will load, don’t overload.

2. Color sequence of strip may be differ from factories, especially for multi-color strips. Some of them is +RGB, but some of them is +RBG, different color sequence. So you have to check if the connectors fits properly.

3. If it’s for outdoor use, choose waterproof connectors, and extra silicone filling to insure it’s IP65 rated.

4. Connector size, for some application, strips has to be put in aluminum profile or curved space, get one fit the size.

Common Issues and Troubleshooting

You may face some problems even you choose the right connectors, here are some common issues and troubleshooting.

1. Flickering Lights: This may result from a loose connection. Ensure connectors are securely attached to the LED strips and check for any damaged pins.

2. No Light Output: Verify that the power supply is functioning and providing the correct voltage. Also, check if connectors are properly aligned and connected.

3. Voltage Drop: Long runs of LED strips can lead to reduced brightness. Use thicker gauge wire or install connectors closer to the power source to minimize this issue.

4. Overheating: If connectors become hot, it could indicate a poor connection or overloading. Check for any loose connections and ensure the total load is within the connector’s rating.

5. Corrosion or Damage: Inspect connectors for corrosion or physical damage, especially in humid environments. Replace any damaged connectors to maintain a reliable connection.