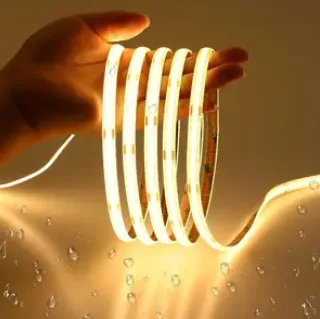

LED strip are widely used, in households and offices. But on many occasions, we need to use waterproof strips. Such as in the bathroom, kitchen, outdoor, swimming pool, sauna, and so on.

There are different waterproofing levels for the led strip.Do you know what kind of glue is used for waterproof light strips? How are they constructed and produced? How should we choose to use the appropriate waterproof light strip? This article will tell you the answer.

What is waterproof LED strip?

Applying glue to the LED strip creates a protective coating that makes it waterproof. This prevents dust, dirt, moisture or water from coming into direct contact with the led. Thus, bonding makes the LED strip waterproof and suitable for outdoor use and applications with high moisture content. In addition to being waterproof, the ends and joints of the LED strip are also sealed with glue.

According to the waterproof grade requirements are divided into: Dispensing waterproof LED strip (waterproof grade IP65) half sleeve waterproof LED soft light strip (waterproof grade IP67), full sleeve waterproof LED soft light strip (waterproof grade IP68),

Which full sleeve is divided into simple full sleeve sleeve LED light strip waterproof, silicone filled LED strip waterproof, filling waterproof effect is significantly better than simple full sleeve waterproof light strip.

Why use glue for waterproof LED strip?

Applying glue to LED strips creates a protective coating that makes them waterproof. This prevents dust, dirt, moisture, or water from directly contacting the LEDs. Thus, gluing makes LED strips water-resistant and suitable for outdoor use and applications with high moisture content.

Waterproof LED strip glue difference:

At present, the glue used for waterproof LED strips is the following four kinds: epoxy resin glue, PU glue, silicone glue, PVC glue.Let’s take a look at the differences between these types of glue.

kinds of glue difference:

1. Epoxy resin glue is popular because of its affordable price. This is mainly used for cheap LED strips. The disadvantage of using epoxy resin adhesive LED strips is that the glue will turn yellow. The color of the light changes after a few months of use.They lose less heat. This will directly affect the service life of the led.

2. Polyurethane, commonly known as PU glue, is a better LED strip adhesive than epoxy resin. The price is slightly more expensive, and it has a certain ability to resist yellowing. PU adhesive also has high thermal conductivity, which will not allow the led to easily overheat, thus extending the service life of the led strip.However, the main disadvantage of PU adhesive is that some toxic low molecular compounds are produced when curing. These are bad for your health and they smell bad. PU adhesive is not resistant to high temperature. Do not install LED lights at temperatures higher than 80 degrees.

3. High-grade, high-quality LED strip using silicone. It has the advantages of epoxy resin and PU adhesive. Silicone can be used in hot weather. Can be used for years without any color degradation,

Silicone for light belts suitable for outdoor and commercial Spaces, such as hotels, restaurants, shopping malls, etc., in addition to the anti-corrosion properties of silicone glue is also very good, you can use them in chemical plants, wet seaside, or gas stations.

4. PVC, also known as polyvinyl chloride, is a common plastic. It is used as an outer coating for waterproof LED lamp strips. PVC is cheap and produces toxins like HCl and other chlorinated substances. It is not very transparent and turns yellow easily. In addition, the thermal conductivity of PVC is also very low. However, as a cheap variant, it is widely used in high voltage LED lamp strips.

Four kinds of glue difference

| Criteria | Epoxy Resin Glue | PU Glue | Silicone Glue | PVC |

| Temperature resistance | 0-60℃ | -40-80℃ | -40-220℃ | Up to 65°C |

| Heat conductivity | Low | High | High | Low |

| Yellowing | Yes (within six months) | No | No | Yes |

| Toxicity | Low | High, bad smell | No | High |

| Light transmission rate | 92% | 95% | 96% | 95% |

| Cost | Low | High | Highest | Cheapest |

What is an IP Rating?

IP is an acronym “Ingress Protection”. Two digits indicate the IP rating—the first one defines the protection against solids, and the latter one is against liquids.

The rating consists of the letters IP followed by two digits, the higher the number the better the protection. Sometimes a number is replaced by X, which indicates that the enclosure is not rated for that specification.

| First digit | Intrusion protection | Second digit | Moisture protection |

| 0 | No protection. | 0 | No protection. |

| 1 | Protected against solid objects over 50mm, e.g. accidental touch by hands. | 1 | Protected against vertically falling drops of water, e.g. condensation. |

| 2 | Protected against solid objects over 12mm, e.g. fingers. | 2 | Protected against direct sprays of water up to 15 degrees from the vertical. |

| 3 | Protected against solid objects over 2.5mm, e.g. tools & wires. | 3 | Protected against direct sprays of water up to 60 degrees from the vertical. |

| 4 | Protected against solid objects over 1mm, e.g. wires & nails. | 4 | Protected against water splashed from all directions, limited ingress permitted. |

| 5 | Protected against dust limited ingress, no harmful deposits. | 5 | Protected against low pressure jets of water from all directions, limited ingress permitted. |

| 6 | Totally protected against dust. | 6 | Protected against strong jets of water, e.g. on ships deck, limited ingress permitted. |

| 7 | Protected against the effects of immersion between 15cm and 1m | ||

| 8 | Protected against the effects of immersion between 15cm and 3m |

LED strip with waterproof grade how to divide?

The common led light belt products can be divided into four levels according to the dustproof and waterproof level, which is expressed by IPXX.

IP20

Bare plate led strip, surface without glue or sleeve protection, not waterproof, protection level IP20.

IP65

Surface silicone coating bonding ,An IP65 rated LED strip light is resistant to low pressure jets of water of from all directions. The top side of the strip (which includes the circuit board, LEDs and resistors) is coated with a thick layer of epoxy or polyurethane (PU) glue. LED strip lights with an IP65 rating are typically designed for installation under kitchen cabinets and in bathrooms, and any interior area where the LED strips may be exposed to spraying or splashing water.

IP67

Sleeve waterproof led strip ,An IP67 rated LED strip light is protected against the effects of immersion between 15 cm and 1 m. This strip is suitable for installation under the nosings of steps, the eaves of buildings, seating and balustrades, and for outlining water features, building and garden structures. The strip is fully encapsulated by a silicon sleeve and comes with an additional glue seal at each end.

IP68

IP68 grade led light strip, is made of silicone extrusion wrap, can prevent long time soaking more than 1 meter. This diving bar is suitable for areas that are immersed in water for long periods of time (i.e. showers, saunas, spas, swimming pools and areas where direct contact with water is unavoidable).

How to Choose Waterproof LED Strip Lights?

1. If you are only using it indoors, there are water drops and splashes, and so a waterproofing level of IP65 basically is good enough.

2. IP65 led strip Suitable for wet or water splashed areas for e.g. the kitchen, bathroom, eaves. As the casing is hollow, it’s not recommended for outdoor use.If you want to install led light strips in the kitchen or bathroom, you must use IP65 waterproof rating light strips. You do not need to install IP67 or IP68 strips here, except where water is frequently sprayed

3. IP67 led strip suitable for areas that are often invaded by water for e.g. ground, beach, cruise ship. Direct underwater use is not recommended.If you’ll install an outdoor LED strip which will be wet by heavy rain for a long time, but it won’t be soaked in water. We recommend using an IP67 or IP68 strip.

4. If you install the strip directly in the water, such as a swimming pool, fish tank. Then we recommend using the IP68 strip with the highest level of protection. You do not need to install IP67 or IP68 strips here, except where water is frequently sprayed.

Conclusion: Waterproof LED light strips are suitable for outdoor and indoor lighting, and the waterproof strength has a lot to do with the glue and protective shell used in the product. For example, the LED strips you use for swimming pool lighting need to be more waterproof than kitchen fixtures. By understanding their properties, you can customize them for your specific project. Proper application can save more time and money for your project.

Signlite LED strips have a wide range of products to meet your various application needs. If necessary, you can click on here and see the LED Strip category for more information.