In today’s lighting market, LED strip lights have become a popular choice for many consumers in decoration and lighting due to their advantages such as energy – saving, long lifespan, and flexibility. But did you know? The LED strip light family has numerous members, and different types of strip lights have their own unique functions and characteristics, which can meet the needs of various scenarios. Next, we will introduce the classification of LED strip lights in detail, so that you can easily select the most suitable one for yourself.

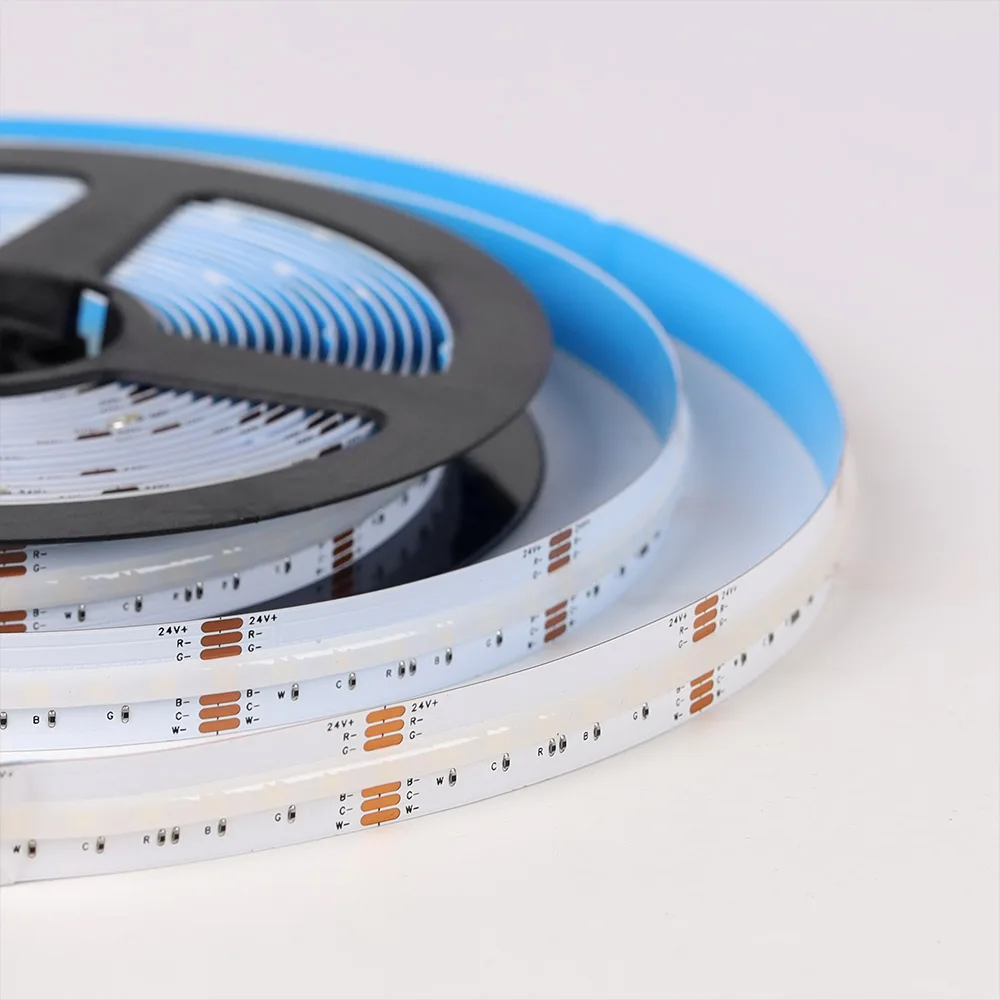

What’s LED Flex Strip ?

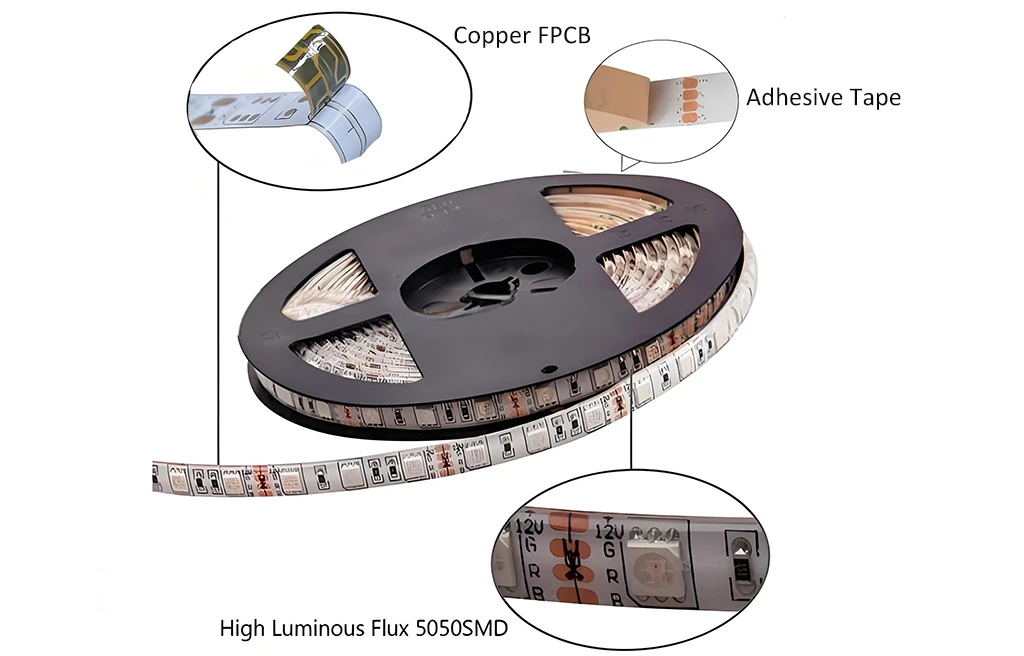

The LED (Light Emitting Diode) in the LED light strip is the core light-emitting component. When an electric current passes through the LED chip, the electrons and holes in the chip recombine, releasing energy that is radiated in the form of light. Different chip materials and structures will produce different colors of light. The FPCB (Flexible Printed Circuit Board) integrates components such as circuits and resistors, which are used to control the current and distribute the voltage to ensure that each LED ( 2835/ 5050/ 3528/ 3014/ 2216 SMD LED ) can emit light stably and normally.

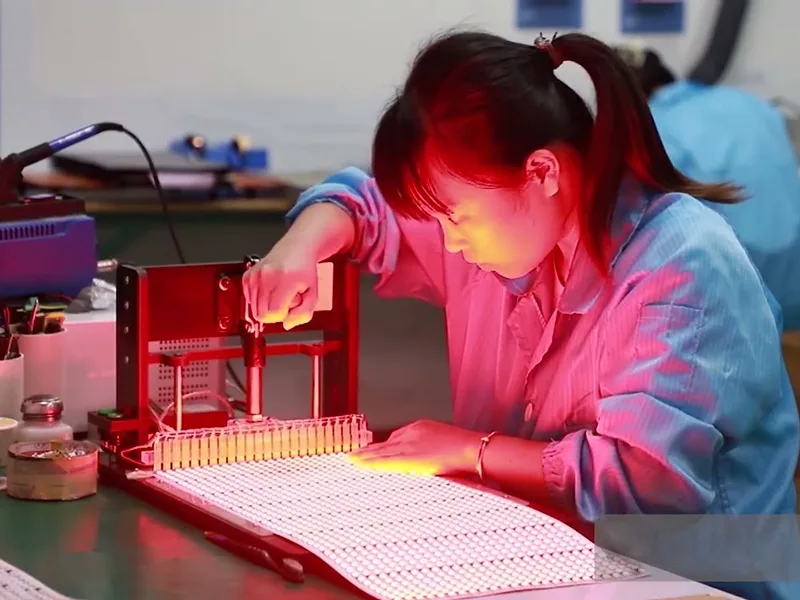

Manufacturing Process

• Printed Circuit Board Production: First, the copper foil is etched and other processes are used to form conductive circuits on the FPCB. Then, a solder resist layer and a character layer are coated on the surface to protect the circuits and mark relevant information.

• Chip Mounting: A high-precision chip mounter is used to accurately mount the LED chips on the designated positions of the FPCB. Then, processes such as reflow soldering are used to achieve electrical connection and mechanical fixation between the chips and the circuits.

• Packaging: Usually, potting adhesive is used to package the LED light strip to protect the internal chips and circuits from the external environment, improving the stability and reliability of the light strip.

Which LED Chip Type Delivers the Best Lumen/Watt for Your Project?

• 2835 SMD LED: They are small in size and have a low power, with a single LED being 0.2W, and the light emission is relatively soft. They are often used in places where the brightness requirement is not high but the atmosphere creation is emphasized, such as under the bed in the bedroom, which can provide soft light when getting up at night without being glaring.

• 2216 SMD LED: The 2216 SMD LED are relatively small in size, with dimensions of approximately 2.2mm by 1.6mm. They are designed to be energy – efficient, typically consuming around 0.2W per bead. Despite their small size, they offer a good balance between brightness and power consumption. These LED beads produce a relatively focused and bright light output. Their small form factor makes them highly suitable for applications where space is limited. In automotive interior lighting, 2216 SMD LED are often used to create ambient lighting in car cabins, such as along the door panels or under the dashboard, adding a touch of style without taking up much space. They are also popular in small – scale electronic devices like portable reading lamps, where their energy – saving nature helps to extend battery life while still providing sufficient illumination for reading. In some intricate DIY lighting projects, like creating custom – made jewelry box lights or model railway lighting, the small size of 2216 SMD LED allows for precise and delicate placement to achieve the desired lighting effects.

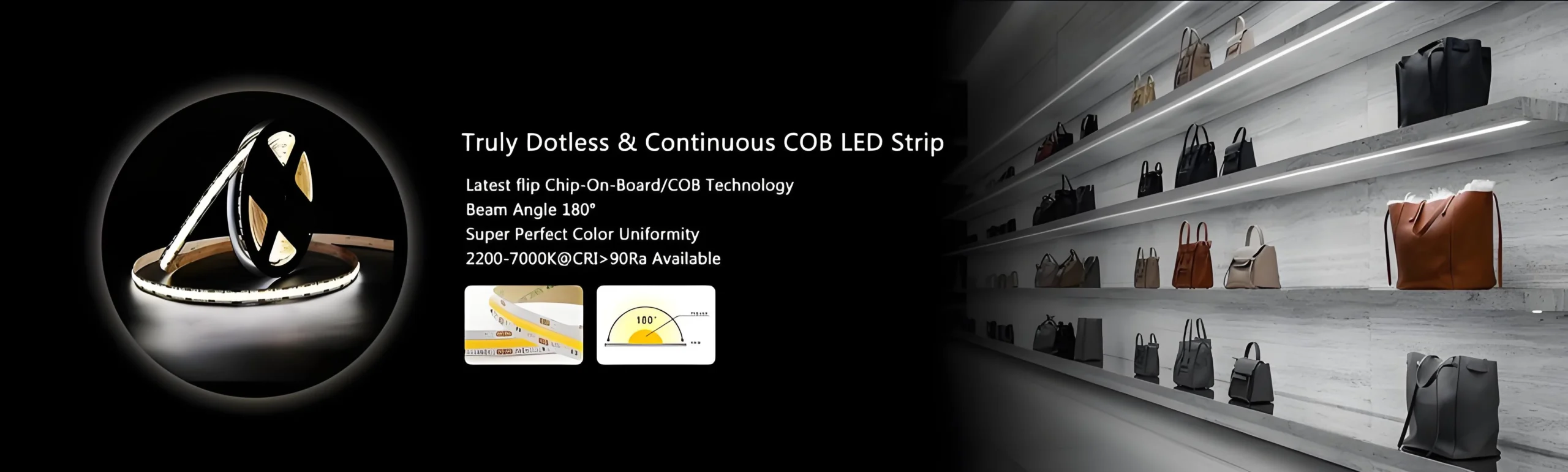

• COB LED: COB (Chip on Board) technology directly mounts multiple LED chips onto a circuit board, eliminating the need for individual lamp bead packaging. This results in a more compact and integrated design. COB LED strip lights offer extremely high brightness and a more uniform light distribution compared to traditional SMD LED strip lights. The absence of visible gaps between LED reduces light spots, creating a smooth and continuous glow. They are highly efficient, consuming less power while delivering intense illumination. These strip lights are ideal for applications where high – quality, bright, and even lighting is crucial. In commercial settings, they are frequently used in high – end retail stores to showcase luxury goods, as the uniform light enhances the product’s appearance. In large – scale exhibition halls, COB LED strip lights can effectively illuminate exhibits, ensuring every detail is clearly visible. In home decoration, they can be installed in areas like kitchens, where bright and shadow – free lighting is essential for food preparation, or in living rooms to create a well – lit and inviting atmosphere.

SMD2835 LED Strip Light

SMD2216 LED Strip Light

COB LED Strip Light

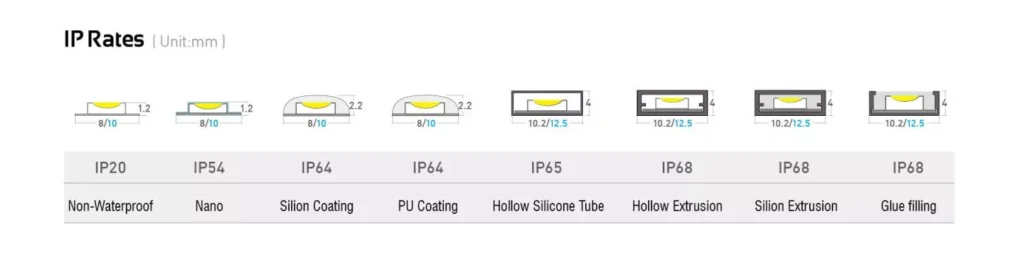

Different Waterproof Level for LED Strip

• Non–waterproof IP20: This is the most basic type without additional waterproof measures, and the price is relatively low. It is suitable for installation in dry indoor environments, such as the edges of the living room ceiling, the bedside background wall in the bedroom, and the bookshelf shelves in the study, to create a warm ambient light. For example, installing non-waterproof LED strip lights around the TV background wall in the living room can make the TV area look more hierarchical and relieve eye fatigue during movie – watching.

• Silicone Glue IP64: Silicone waterproof LED strip lights are highly regarded for their outstanding waterproof capabilities. The main waterproof mechanism lies in the use of high – quality silicone materials. Silicone has excellent water – resistance, flexibility, and durability. These strip lights are usually encapsulated with a layer of silicone, which not only protects the internal components from water ingress but also provides additional protection against dust, moisture, and even some chemical substances. The silicone layer tightly seals the circuit board and lamp beads, ensuring that no water can penetrate, even in harsh environments.

• Silicone Tube IP65: The silicone tube used in these strip lights is made of high – purity silicone polymer. It has a smooth surface that not only effectively blocks water but also resists dirt adhesion, making it easy to clean. Its high flexibility allows the strip light to be bent into various shapes without cracking or losing its waterproof properties.

• Silicone Extrusion IP67: These strip lights are made by fully wrapping the LED strips with silicone through an automatic production line. The silicone and the strip lights are formed together through an integrated silicone extrusion molding process, which can achieve solid – core (filled with silicone), hollow – core (like a tube), or half – pack (shaped like IP65 silicone waterproof) structures

Understanding the PCB Width Options of LED Strip light

• 5MM Width: The line is thin and very flexible, suitable for installation in narrow spaces with strict requirements for installation size, such as the corners of small handicraft display cabinets, which can cleverly illuminate the exhibits without taking up too much space.

• 8MM Width: It has a relatively moderate width, achieving a good balance between flexibility and the number of led it can carry. It has a wide range of application scenarios and is applicable to both home decoration and commercial display. For example, it can be used above the clothes hangers in a clothing store to highlight the colors and styles of the clothes.

• 10MM, 12MM, 15MM Width: The width is relatively wide, which can carry more led, has higher brightness, and better stability. It is often used in large – scale building decoration lighting, such as the ceiling decoration of a hotel lobby, which can create a magnificent and elegant lighting effect.

12V & 24V LED Strips: Lighting Solutions for Every Application

In the world of LED lighting, 12V and 24V LED strips stand out as two popular choices, each with distinct features and applications. Understanding their differences helps you make the right decision for your lighting projects.

• 12V LED Strips: Safe and Ideal for Small – Scale Setups

12V LED strips operate on a low – voltage system, making them a remarkably safe option, especially in residential settings where safety is a top priority. This voltage level reduces the risk of electric shock, making it suitable for DIY enthusiasts and applications where human contact is possible.

They are perfect for small – scale projects such as under – cabinet lighting in kitchens, backlighting for wall art, or creating ambient lighting in bedrooms. Since they consume less power, 12V LED strips are also energy – efficient, helping you save on electricity bills. However, due to the lower voltage, their power output is relatively limited, and they may not be suitable for large – scale commercial or industrial applications.

When installing 12V LED strips, shorter runs are recommended to avoid voltage drop issues. Voltage drop can cause the strip to dim at the far end, affecting the overall lighting quality.

• 24V LED Strips: Powerful and Versatile for Larger Projects

24V LED strips, on the other hand, offer higher power output, making them suitable for large – scale projects. They can cover longer distances without significant voltage drop, making them ideal for commercial spaces like shopping malls, offices, and large – scale outdoor landscapes.

With a higher voltage, 24V LED strips can support more LEDs per meter, resulting in brighter illumination. This makes them an excellent choice for areas that require intense lighting, such as display areas in stores or pathways in large gardens.

Although they operate at a higher voltage, proper installation and use of safety equipment ensure they are just as safe as 12V LED strips. They are also more efficient for longer runs, as they require fewer power supplies to cover the same distance compared to 12V LED strips.

Both 12V and 24V LED strips from our collection come with silicone extrusion for waterproof protection, ensuring they can withstand various environmental conditions. Whether you’re planning a small home improvement project or a large – scale commercial installation, we have the right LED strip for you.

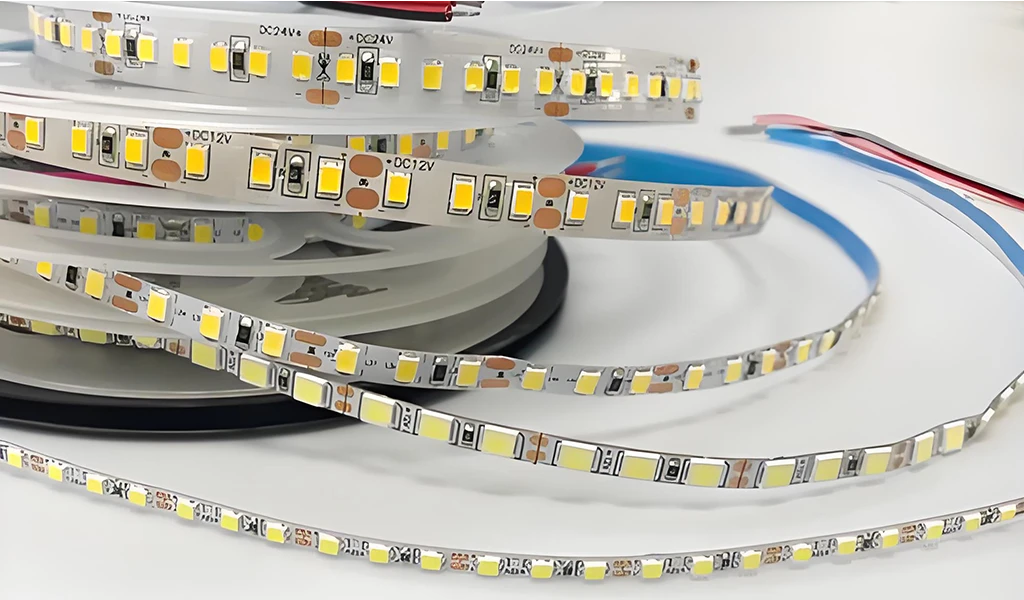

The stip below is the most cost-efffective one with 170lm/W efficiency.

170+lm/W LED Strip Light

Model No.: FQX10T128C

Input Voltage: DC24V

Power: 14W/m

LED QTY: 128LEDs/m

CCT: 2700K, 3000K, 4000K, 6500K

CRI: >80

Efficiency: 170lm/W

Beam Angle: 120°

Cut Section: 62.5mm

IP Rating: IP20/IP65/IP67/IP68

Warranty: 3years

Why the Color temperature and CRI are important for LED Strip ?

• Color Temperature

Color temperature is a measure of the color appearance of a light source, expressed in Kelvin (K). It describes the visual warmth or coolness of the light.

Warm White (2700K – 3000K): Light in this range has a yellow – orange hue, creating a cozy and inviting atmosphere, similar to the light from traditional incandescent bulbs. It is often used in bedrooms, living rooms, and restaurants to provide a relaxing environment.

Neutral White (4000K – 4500K): This color temperature offers a more balanced, white light without a strong yellow or blue tint. It is suitable for areas where a natural – looking light is desired, such as in offices, hallways, and some retail spaces.

Cool White (5000K – 6500K): Cool – white light has a bluish – white tint and provides a bright, crisp illumination. It is commonly used in kitchens, bathrooms, and workspaces where high – visibility and a more energetic atmosphere are needed. In outdoor applications like street lighting, cool white can also enhance visibility.

The CRI is a measure of how accurately a light source can reproduce the colors of objects compared to a reference light source. It is expressed as a number from 0 to 100. A higher CRI value indicates that the light source can display colors more accurately. For example, a CRI of 100 means that the colors seen under the light source are identical to those seen under a perfect reference light. In practical applications, a CRI of 80 or above is generally considered good for most general lighting purposes, while a CRI of 90 or higher is excellent and is often required for applications where color accuracy is crucial, such as in art galleries, photography studios, and high – end retail stores selling colored products.

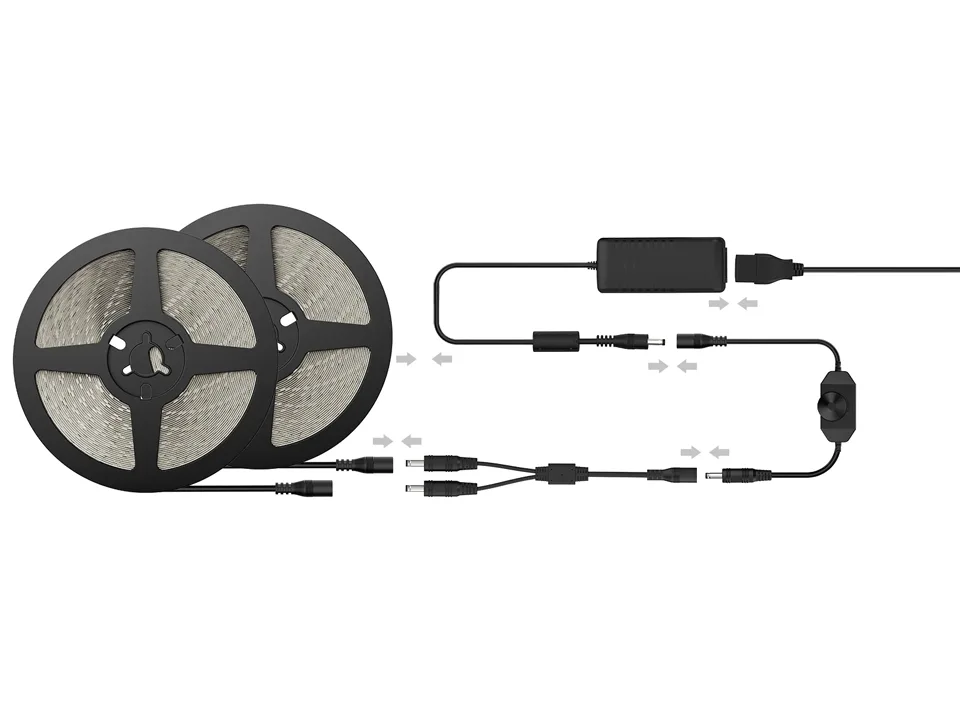

How to Connect the LED Strip Lights?

• Connecting with Connectors

Prepare the strip lights: Measure the space to figure out the required length of the lights. Mark the cutting points on the strip according to the measurements and cut along the designated lines with sharp scissors.

Select the connector: Choose a strip connector that is suitable for your LED strip lights. The main types include clip – on and fold – over connectors. Make sure it is compatible with the wires of your strip lights. For example, a different connector might be needed for a monochrome strip light than for an RGB strip light.

Insert the strip into the connector: Gently slide the cut end of the light strip into the open end of the connector.

Align the wires: Align the wires with the corresponding colors or markings on the strip. The strip usually has letters or signs indicating which colored wire goes to which position. For example, if the connector has wires in blue, red, green, and black, align them with the connection dots labeled B, R, G, and 12V. If there are only two wires, the strip will likely have a + and – sign on each side.

Close the connector: Close the connector according to its type. For a fold – over connector, press down on the flap until it latches. For a clip – on connector, press the gray or black button on each side to lock the strip in place.

• Soldering the Wires

Prepare the tools and materials: Besides the LED strip lights, you need a soldering iron, solder wire, safety glasses, protective gloves, and other tools. Choose a well – ventilated area for soldering, such as a room with a fan or an outdoor space.

Put on safety gear: Wear safety glasses and protective gloves to prevent burns and other injuries. Tie up long hair and avoid wearing loose clothing.

Prep the strip and wires: Strip a small section of the insulation from the wires to be soldered. Clean the soldering points on the LED strip to ensure good solder adhesion.

Solder the wires to the strip: Heat the soldering iron and apply a small amount of solder to the soldering points on the strip. Then, touch the stripped wire to the soldered point and let the solder flow around the wire to form a connection. Make sure the soldering is firm and there is no short – circuit.

Insulate the connections: After soldering, use insulating tape or heat – shrink tubing to cover the soldered connections to prevent short – circuits and electrical leakage.

• Connecting to the Power Adapter

Check the power adapter: Ensure that the output voltage of the power adapter matches the rated voltage of the LED strip lights. Usually, the voltage of LED strip lights is 12V or 24V.

Connect the adapter to the strip: Insert the plug of the power adapter into the corresponding socket on the LED strip. The positive pole should be connected to the positive pole, and the negative pole to the negative pole. Make sure the connection is firm.

• Notes :

Fix the strip lights: Use tape, clips, or adhesive to fix the LED strip lights in the desired position before connecting the power.

Check the connections: Before turning on the power, check all connections to make sure they are firm and there is no looseness or short – circuit.

Test the lights: After connecting everything, plug in the power adapter or turn on the power to test if the LED strip lights work properly. If the lights don’t turn on or there are other problems, check the connections and the power adapter.

If you still don’t understand how to connect the LED strip lights, watch video below

Signlite manufactures High CRl LED strip, 95 CRI COB led strip and LED neon flex, All of our products go through high-tech laboratories to ensure the utmost quality. Besides, we offer customizable options on our LED strips and neon flex, So, for premium LED strip and LED neon flex, contact Signlite ASAP!