LED strips have gained immense popularity due to their versatility. When embarking on a lighting project, one of the crucial decisions is whether to opt for high or low voltage LED strips. This choice can significantly impact factors such as installation complexity, energy efficiency, and overall project cost. Understanding the key differences between these two types of LED strips will help you make an informed decision that aligns with your specific needs and preferences. In this article, you will get an idea of when to choose high voltage LED strips or low voltage LED strips.

What Are Low Voltage LED Strip Lights

Low voltage LED strip lights operate on safety voltage under 50V power, typically at DC12V or DC24V. They are commonly used for residential and decorative lighting applications. Low voltage LED strips are safer to handle, produce less heat, and are more energy-efficient compared to high voltage LED strips. Due to their lower voltage, they are ideal for shorter runs or areas where flexibility and precision are needed, such as under cabinets, in shelves, or for accent lighting. They also require a compatible power supply or transformer to convert standard household voltage into the required lower voltage.

Features:

*Safety: Operating at 12 or 24 volts, they are safer to handle and install, pose minimal risk of electrical shock even without electrician’s help.

*Flexibility: They can be easily cut and connected to create custom lighting solutions for different spaces and shapes.

*Dimmability: Allowing you to adjust the brightness to suit your needs and create different atmospheres by working with controller.

*Energy Efficiency: Consume less power while delivering brighter illumination, up to 180lm/W efficiency, reducing electricity bills.

*Long Lifespan: Less heat emission results in longer lifespan, 3years to 5years warranty, reducing the need for frequent replacements.

*Versatility: Low voltage strips are available in a wide range of colors, static color, RGB and addressable RGB. Strip size varies from 3mm ultra-narrow to 30mm ultra-wide LED strip lights.

Applications

Low voltage LED strip lights are commonly used in a variety of applications due to their safety and flexibility. They are ideal for accent lighting in areas like under cabinets, shelves, and staircases, providing subtle, decorative illumination. They are also popular in task lighting for workspaces, backlighting mirrors, and furniture integration where precise, low-heat lighting is needed. Additionally, they are used in automotive interior lighting, architectural lighting, and outdoor projects with waterproof versions for patios or gardens. Their low power consumption and customizable lengths make them versatile for both residential and commercial use.

Pros & Cons

| Pros | Cons |

| Safety: Operates on 12V/24V, low risk of electric shock | Requires Transformer: Needs a power supply to convert from AC to DC |

| Energy Efficient: Uses less power, saving energy | Voltage Drop: Limited run length before brightness decreases |

| Flexible Installation: Easy to install in tight spaces | Lower Brightness: May not be as bright as high voltage options |

| Dimmable: Can adjust brightness with proper controllers | Initial Cost: Transformer and accessories can increase cost |

| Low Heat Emission: Suitable for heat-sensitive areas | Shorter Runs: Requires more power connections for long installations |

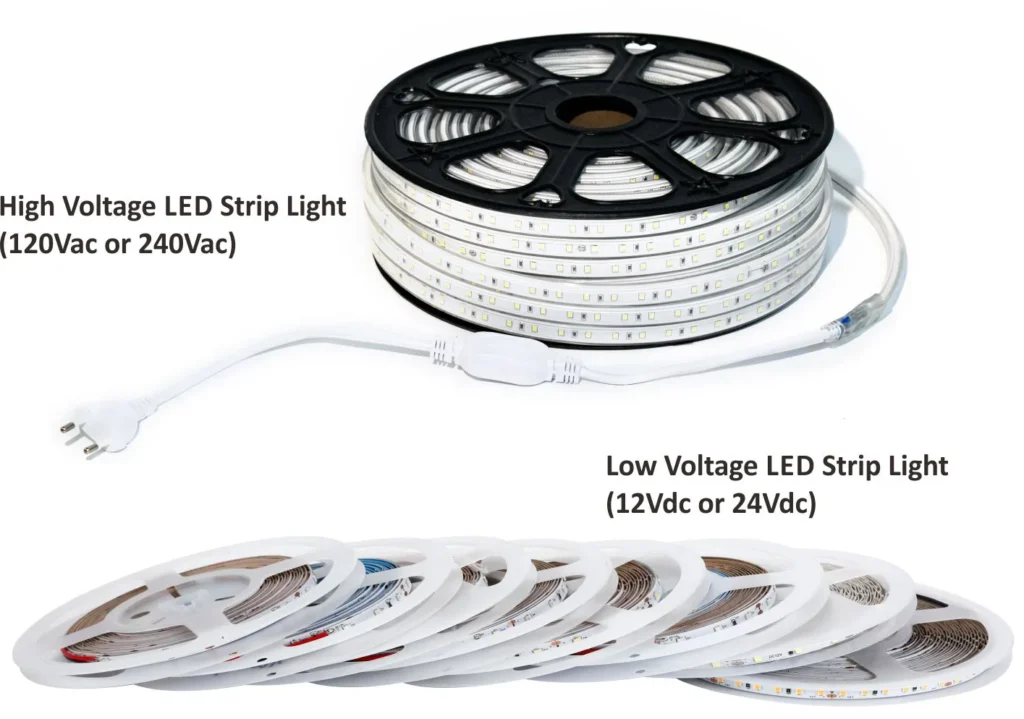

What Are High Voltage LED Strip Lights

High voltage LED strip lights operate on 120V or 240V AC, allowing them to run directly from mains power without the need for a LED driver. These strips are suitable for longer runs, as they experience less voltage drop compared to low voltage strips, making them ideal for large-scale outdoor or commercial lighting projects. High voltage LED strips are often used in architectural, landscape, or building perimeter lighting, and are typically waterproof for outdoor use. However, they require proper insulation and safety measures due to their higher electrical power.

Features

*Direct Mains Power: Operates on 120V or 240V AC, no need for LED power supply.

*Longer Runs: Can be installed in longer lengths without noticeable voltage drop.

*Waterproof: Mostly are IP65+ rated for both indoor and outdoor use.

*Easy Installation: Eliminating the connection to LED power supply, less work for installation, simplifying setup for large areas.

*Potential Cost Savings: In some cases, the elimination of LED power supply can lead to lower overall costs.

Applications

High voltage LED strip lights are ideal for large-scale applications that require long, uninterrupted runs. They are commonly used for outdoor architectural lighting, including building perimeters, landscapes, and signage. These strips are also used in commercial spaces for general illumination or decorative lighting in large areas like malls or event venues. Street and pathway lighting, bridges, and parking lots also benefit from high voltage LED strips due to their durability and brightness. Additionally, they are popular for holiday lighting displays, where long continuous runs are needed with minimal voltage drop.

Pros & Cons

| Pros | Cons |

| Direct Power: Connects to mains (120V/240V) without a transformer | Safety Risk: Requires proper insulation due to high voltage |

| Longer Runs: Ideal for extended installations without voltage drop | Less Flexible: Less suitable for tight spaces or intricate designs |

| Higher Brightness: Provides more powerful illumination | Higher Power Consumption: Consumes more energy than low voltage strips |

| Waterproof Options: Ideal for outdoor and large-scale lighting | More Complex Installation: Requires careful handling and safety measures |

| Fewer Power Supplies: Requires fewer power sources for longer runs | Heat Generation: Produces more heat, requiring proper ventilation |

Low Voltage VS High Voltage LED strip lights

Appearance

Low voltage LED strip lights: Shorter cutting unit,usually less than 100mm, they are marked with “+”, “-” and DC input voltage. Various of IP rating typle, like IP20 non-waterproof, IP65 silicone coating, IP65 silicone tube, IP65 silicone spray, IP68 silicone extrusion, IP68 silicone filling.

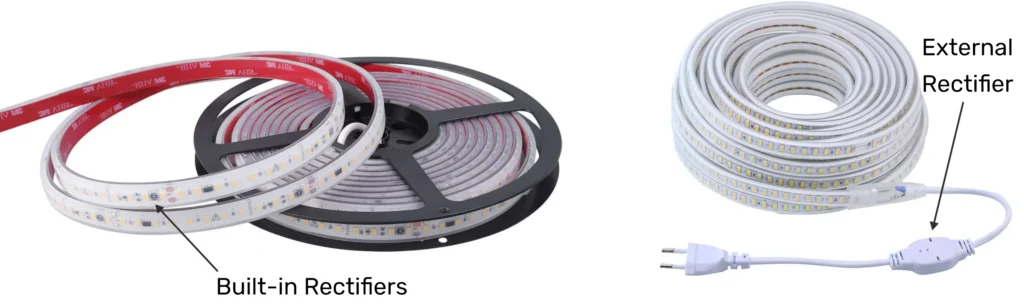

High voltage LED strip ligths: Longer cutting unit, minimum at 100mm, marked with “L”, “N” and AC240V or AC120V. Mostly comes with built-in rectifiers and IP68 waterproof form for safety.

Input Voltage

Low voltage LED strip lights: Operate on low voltage, like DC5V, DC12V and DC24V, require LED power supply to drive it.

High voltage LED strip lights: Directly connect to main power, 120V or 240V.

Efficiency

Low voltage LED strip lights: Due to less components, they are more energy-efficient for short runs, up to 200lm/W by well designed circuit. However, efficiency drop significantly on long run, as they may experience voltage drop over longer distance and require more connections.

High voltage LED strip lights: For easier installation, high voltage LED strip lights are designed with built-in IC to convert AC to DC, this components causes lower energy-efficient.

Cutting Unit

Low voltage LED strip lights: Due to they are low voltage, LED chips are designed with an unit with only a few LED chips, so the cutting unit is shorter, usually less than 100mm, minimum 10mm.

High voltage LED strip lights: longer cutting unit, minimum 100mm.

Packaging

Low voltage LED strip lights: Considering about voltage drop, they are always packed as 5m per roll, for long run strip light, at most 20m per roll.

High voltage LED strip lights: Packaging typically offers longer rolls, ranging from 50 to 100 meters per roll.

Running Length

Low voltage LED strip lights: It’s more prone to voltage drop, especially over long runs. As the distance increases, the brightness diminishes due to resistance in the wires. To counteract this, frequent power injections or shorter runs are needed. With great design, maximum to 20m long run.

High voltage LED strip lights: Experience much less voltage drop over longer distances, allowing for extended runs without significant loss in brightness. Some of them can achieve 100m long run, making them better for large-scale installations with minimal power points.

Flickering Issue

Low voltage LED strip lights: LED power supply converts AC to DC power, working under DC power, low voltage LED strip lights do not have flickering issue.

High voltage LED strip lights: The frequency of AC power is 50Hz or 60Hz, which means it turns on and turns off the light 50 or 60 times a second, this is how flickering issue comes.

Safety

Low voltage LED strip lights: Under safety voltage, they are generally safer for home and indoor use due to the lower risk of electric shock and less heat generation. They are suitable for areas where close contact with people or sensitive materials is expected.

High voltage LED strip lights: Higher risk of electric shock and requires careful insulation and protective measures during installation, especially for outdoor or commercial projects. Proper handling, grounding, and insulation are critical to ensuring safety with high voltage systems.

Lifespan

Low voltage LED strip lights: Longer lifespan due to lower power consumption and heat generation, which reduces stress on the LEDs and components. Less components, smaller failure rate. Typically, last for 30,000hrs to 70,000hrs.

High voltage LED strip lights: They generate more heat, potentially reducing their longevity, especially if not properly ventilated or managed. Typically, last for 20,000hrs to 30,000hrs.

Installation

Low voltage LED strip lights: Easier to install in small, intricate spaces due to their flexibility and lower power requirements. However, they require a transformer or driver to convert mains AC power to DC, adding complexity.

High voltage LED strip lights: More straightforward for long, continuous runs, as they connect directly to the mains without needing a transformer, but require more caution due to higher voltage. Safety precautions, such as proper insulation, are critical for high voltage installations, especially outdoors or in wet environments.

Here is a chart for you to understand it more clearly.

| Items | Low voltage LED strip lights | High voltage LED strip lights |

| Working Voltage | DC5V, DC12V or DC24V | AC100-120V or AC200-240V |

| Efficiency | Higher, up to 200lm/W | Lower, up to 120lm/W |

| LED Driver Needs | Yes | No |

| Cutting Unit | Shorter, less than 100mm | Longer, more than 100mm |

| Packaging | Smaller, 5m/roll or 10m/roll | Bigger, 50m/rool or 100m/roll |

| Maximum Running Length | Up to 20m | Up to 100m |

| Flickering Issue | No | Yes |

| Waterproof Options | Various types, IP20, IP64,IP65, IP67, IP68 | Usually in IP68 form |

| Safety | lower risk | Higher risk |

| Lifespan | Longer, up to 100,000hrs | Shorter, up to 30,000hrs |

| Installation | More complicated by connecting LED driver and controller | Easier to install, but requires professional electrician |

| Costs | Cheaper on IP20 non-waterproofMore expensive on waterproof LED strip together with power supply | Cheaper for long run |

The Factors to Consider Before Choosing High Voltage and Low Voltage LED Strip Lights, How to Choose?

Safety

Safety is the first thing to consider, high voltage LED strips is not as safer as low voltage LED strips, they require professional electrician to prevent electrical hazards. Also, they generate more heat, there is fire risk. So choose low voltage LED strips if you are not able to take enough measures to avoid these risks.

Lighting Projects Scale

Low voltage LED strips are ideal for smaller projects with shorter runs due to limited voltage drop and higher flexibility. For large-scale projects or long continuous runs, high voltage LED strips are more suitable, as they can cover greater distances without brightness loss.

Dimming Compatibility

Low voltage LED strips are compatible to DALI, PWM, 0-10V, TRIAC, ZIGBEE controllers, while high voltage LED strips can only work with TRIAC dimmer. So you have more choice for low voltage LED strips, but choose the one compatible to your existing dimmer.

Installation and Maintenance

For small projects, you can choose low voltage LED strips without any installation problem, and you don’t need electrician’s assistance. For big projects, you can choose high voltage LED strips, they do not require any LED driver, less connection work, much easier to install.

On the other hand, the size of LED strip can also be a crucial factor on installation and maintenance. Low voltage LED strips can be as ultra-narrow as 3mm, ideal choice for tight and confined spaces. While high voltage LED strips usually are made with IP68, not as slim as low voltage LED strips.

Versatility

Low voltage LED strips are more adaptable due to their versatility, they vary in input voltage, color, cutting unit, size, waterproof type, etc. Making them ideal for decorative, accent, or task lighting in varied spaces. Also providing more opportunities for DIY projects. High voltage LED strips offer less options, limiting their use in large-scale projects and detailed installations.

In conclusion, When choosing between low and high voltage LED strips, consider the project’s specific needs. Low voltage strips (12V/24V) are safer, more versatile, and ideal for small, flexible installations like accent or task lighting. High voltage strips (120V/240V) excel in large-scale projects, offering longer runs with minimal voltage drop but require more safety precautions. Factors such as safety, run length, flexibility, and power supply complexity will help determine the best option for your application. Choose based on the scale, environment, and design requirements of your project.