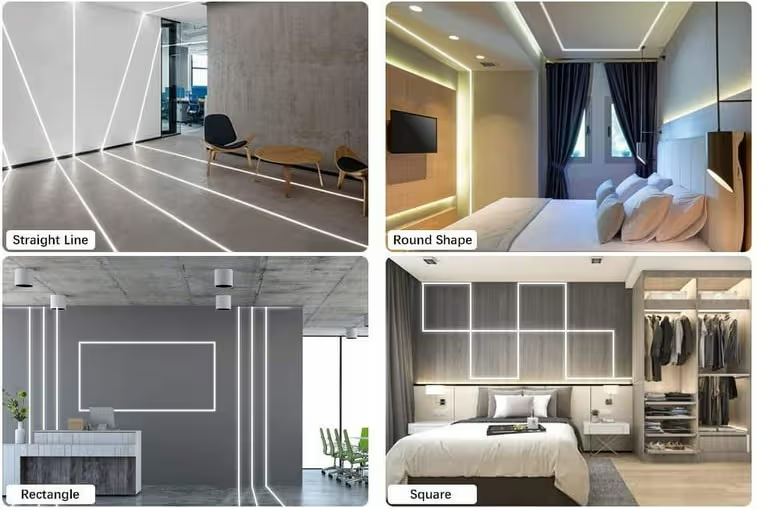

Due to its adaptability, energy efficiency, and simplicity of installation, neon flex is a well-liked lighting option. Small, flexible LED lights enclosed in a silicone or PVC jacket make up this flexible substitute for conventional glass neon lights. We’ll look at neon flex connection in this blog post.

Utilizing connectors makes connecting neon flex an easy operation. To generate longer lengths or unique shapes, connectors are used to join several neon flex pieces together. They are available in many different designs, such as T-connections, L-connectors, and straight connectors.

Follow these steps to connect neon flex:

Step 1: Neon flex should be cut to the appropriate length. Cut the neon flex at the specified cut spots with a knife or a pair of scissors. To prevent the LED lights from being harmed when cutting neon flex, be sure to carefully follow the manufacturer’s instructions and cut along defined cut spots.

Step 2: Connect the neon flex. After cutting the neon flex to the required length, use a connector to join the pieces together. For a safe and seamless connection, connectors are made to be placed into the ends of neon flex. Make sure the connector you select works with your neon flex.

Step 3: Connection security. Use a tiny screwdriver to tighten the connector’s screws after it has been inserted into the neon flex’s ends. This will make sure the connection is solid and stop the neon flex from separating.

It’s crucial to take your setup’s voltage and current requirements into account while attaching neon flex. To avoid damaging the LED lights, be sure to select a connector that is appropriate for the voltage and current of your neon flex.

The fact that not all neon flex can be connected directly to a power source should also be noted. For some neon flex, a power source or driver is needed to control the voltage and current. Be sure to read the product specs before attaching neon flex to make sure you have everything you need.

In conclusion, utilizing connectors to link neon flex is a straightforward process. Neon flex should be cut to the required length, connected with a connector, and then secured. Check the product specifications to make sure you have the components you need for your setup and make sure the connector you chose is compatible with the voltage and current of your neon flex. Neon flex is a flexible and adaptable lighting solution that may improve any area or environment thanks to its connection capabilities.