DMX512 control systems are widely used in modern architectural contour and façade lighting projects to achieve precise and dynamic lighting effects. In contrast to RGB strips, which can only change color as a whole, pixel LED neon strips are addressable on a point-by-point basis. You can control each pixel independently through the DMX controller to realize the effects of chasing light, flowing water, dazzling color, etc., which greatly enhances the visual expression and freedom of design.

The DMX512 LED neon strip is redefining the boundaries of spatial aesthetics and user experience by transforming “light” into a programmable digital medium, weaving a world of dreamy light and shadow under precise control. The outline of the building is outlined by gradient colors, sometimes light and shadow, sometimes like a river of stars falling.

What is a DMX512 Pixel LED Neon Strip?

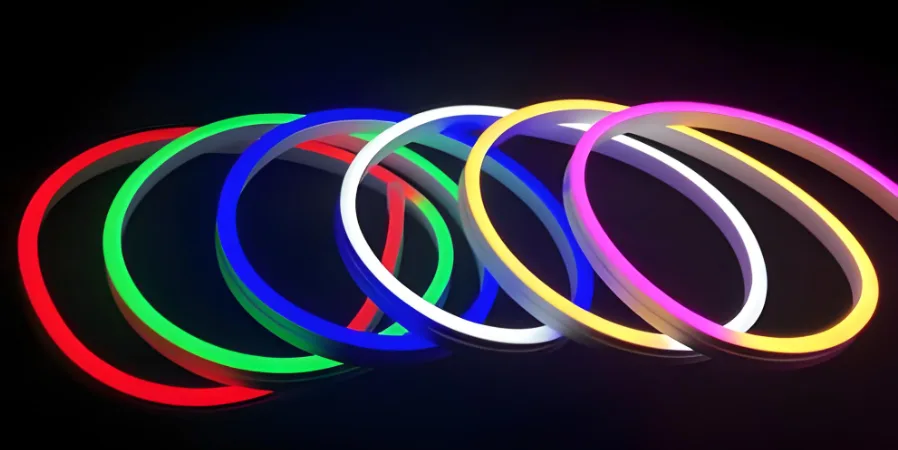

The DMX512 Pixel LED Flex Neon Strip is a digitally programmable LED strip controlled via the DMX512 protocol, where each LED pixel is independently addressable, for scenes that require highly dynamic, customized lighting effects. It combines the visual effects of traditional neon with the flexibility and controllability of modern LED technology.

The DMX neon strip can be used in situations where dynamic lighting effects are required, such as stage lighting, architectural silhouette lighting, and landscape lighting. Each LED pixel can be independently controlled by DMX512 protocol to achieve complex lighting animation and color change.

In addition, this type of neon LED strip has a high degree of flexibility and can be bent to fit the shaped architectural structure, whether it is curved walls, cylindrical columns, or artistic sculptures, to achieve seamless fit lighting design. Therefore, it has become one of the indispensable digital lighting solutions in modern lighting design.

The DMX512 neon strip is a neon strip consisting of multiple independently controllable LEDs, each of which can be regarded as a pixel. The pixel LED strip has RGB, RGBW, RGBWW, and other types of lamp beads with built-in IC control chips, which can realize complex lighting animations such as color change, brightness gradient, point-by-point light chasing, and so on. You can flexibly program through software, and with the use of a DMX controller or DMX decoder, you can adjust the color and brightness of individual pixels.

What are the Features of DMX512 Pixel Neon Strip?

DMX512 Pixel Neon Strip is a high-end linear lighting product that combines flexible structure and digital control technology with the following core advantages:

- It consists of multiple independently controlled RGB/RGBW LEDs (pixels), and each pixel can be individually adjusted in color and brightness to form a dynamic pattern or gradient effect. Each LED can be programmed independently to achieve delicate animation effects (e.g., running water, flashing, fading).

- The is more energy efficient and durable than traditional neon lights and supports programming control.

- Uses flexible materials (such as silicone and PVC) to wrap the LED strip, which can be bent and cut to adapt to the installation environment of complex shapes (such as curved walls, curved buildings, columns, signage letters, etc.), realizing a true outdoor and architectural flexible lighting solution.

- Long distance transmission (up to 1200 meters), high compatibility, can control multiple devices at the same time, to meet the bridge, building, stage, garden and other ultra-long distance applications.

- It supports high-resolution display for text, patterns, and moving images.

- Can be programmed by DMX master control software (e.g. Madrix, xLights), and can be synchronized with other stage lighting equipment such as moving head lights, laser lights, etc. to create a panoramic dynamic lighting system.

- Seamlessly connects with mainstream DMX controllers and DMX decoders through DMX512 control protocol, supports multi-Universe expansion, and meets the needs of large-scale installations (e.g., building facades, large stages).

- Waterproof to IP65/IP67/IP68, suitable for indoor and outdoor use.

- Cuttable design, adjust the length as needed to reduce installation complexity.

Application Scenarios of DMX512 Neon Strip

Outdoor Lighting: DMX512 protocol is widely used in outdoor lighting, such as scenic buildings, outdoor lighting along the river, large-scale light shows, and other occasions. Through the DMX512 signaling protocol, it can realize remote control of the DMX neon strip, carry out complex lighting changes and effect displays, and enhance the visual effect and ornamentation of the landscape.

Stage Performance: DMX512 LED neon ribbon plays a vital role in stage lighting control. Through the DMX512 signal protocol, it can realize precise control of the neon strip’s brightness, color, motion, and other parameters. In stage performances, concerts, theaters, and other occasions, DMX512 neon ribbons are able to provide complex lighting effects to meet various performance needs.

Commercial Display: DMX512 neon strips can be customized with text and patterns to strengthen brand identity, with dynamic colors to create an immersive atmosphere, and applied to windows, booths, and doorways to attract traffic and highlight promotional information to enhance the visual impact of the night and the sense of fashion in the commercial space.

Entertainment: DMX512 neon ribbon can be programmed to achieve a variety of lighting effects, such as light chasing, color changing, flashing, and so on. Dimmers can use controllers to adjust the light brightness, color, and motion trajectory according to different application scenarios such as bars, nightclubs, KTVs, etc. to create a variety of ambient lighting.

What is the DMX512 System?

DMX512, the full name is Digital Multiplex With 512 Pieces of Information, meaning multiple digital transmissions. This protocol was originally developed by USITT (United States Institute of Theater Technology) to efficiently control dimmers from a console via a standard digital interface. Unlike DALI systems, which focus on static lighting effects, DMX512 is more focused on creating dynamic lighting effects. Luminaires controlled by DMX are able to present ever-changing colors to create a suitable atmosphere and are therefore particularly suitable for areas such as landscape lighting and stage lighting.

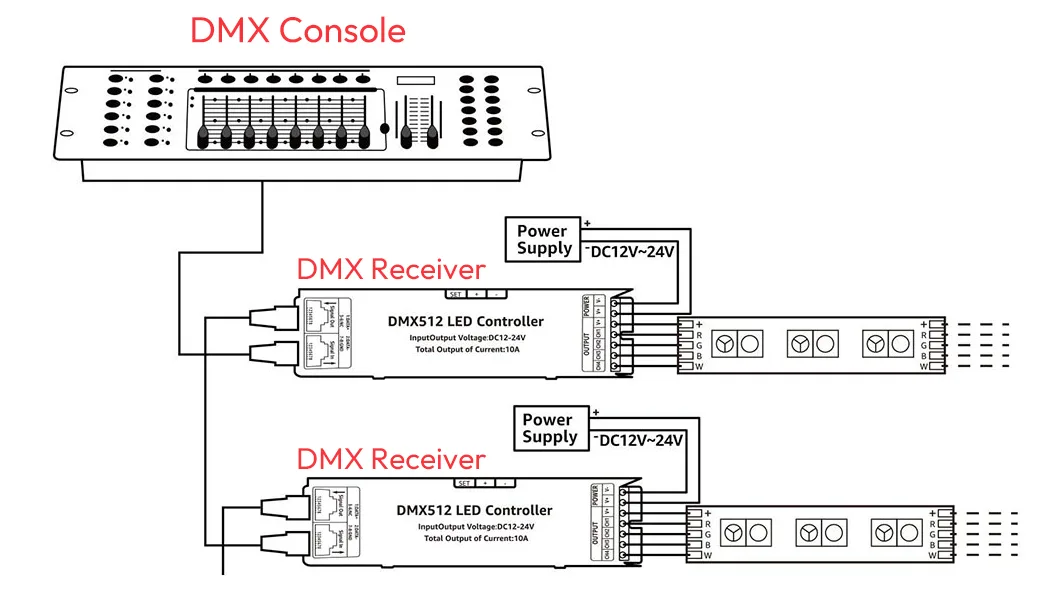

The DMX512 system consists of the following parts:

DMX Console: The main device (e.g., lighting console or software) that sends the control signal.

DMX Receiver: Decoder module in the fixture or other equipment to receive and execute commands.

DMX Cable: Specialized shielded twisted pair cable, usually with a 5-pin or 3-pin XLR connector.

The “512” in DMX512 represents that each packet supports up to 512 independent control channels; each channel corresponds to 8-bit data (0-255), which is used to accurately regulate the brightness, color, and other parameters of the stage lighting and special effects equipment.

Usually, each pixel requires multiple channels (e.g., three channels of RGB), each of which controls a different parameter of the lighting (e.g., color, brightness, motion). This means that each output port can support a certain number of devices depending on the individual channel occupancy of the connected devices. To control different types of lights, you need to occupy different channels:

a. For monochrome lights, the total number of channels is 512 ÷ 1 = 512.

b. For RGB lights, each fixture needs 3 channels, and the total number of channels is 512 ÷ 3 = 170.

c. For RGBW lights, each fixture needs 4 channels, and the total number of channels is 512 ÷ 4 = 128.

A DMX512 channel can only control one color channel for one pixel. If there are 100 pixels and each pixel needs 3 channels, then a total of 300 DMX channels are needed, and a DMX512 Universe supports up to 512 channels, so in this case one Universe can control about 170 pixels (512/3). However, the actual product may be addressed differently, e.g., by using a more efficient protocol or by dividing it into multiple universes.

The DMX512 control system follows a specific bus structure, which ensures an organized and efficient signal transmission. This structure has well-defined start and end points, similar to the familiar concept of switches in electrical circuits.

The standard transmission rate of the DMX512 protocol is “250 kbps” (kilobits per second). This means that 250,000 binary bits (bits) can be transmitted per second. DMX uses asynchronous serial communication in 8N2 format (8 data bits, no parity, 2 stop bits) with a transmission time of approximately 23 ms for 512 channels containing break, MAB, start code, and all channel data. The maximum refresh rate is about 44 times per second (1 sec / 23 ms ≈ 43.5). 250 kbps is the hard standard of DMX512, which is much lower than Ethernet (e.g., Art-Net’s 100 Mbps+). The low transmission speed can improve the reliability of the signal. Higher bit rate signals, on the other hand, are relatively less resistant to interference.

When applying DMX512, in order to ensure smooth and stable control, the following points should be noted:

Firstly, the transmission distance of Super Category 5 network cable is limited to 100 meters; if the distance between controllers exceeds this range, it is recommended to use an optical fiber connection.

Secondly, following the EIA485 protocol, the number of nodes connected to each repeater shall not exceed 32. In addition, the wiring of each control loop must be reasonably laid out according to the bus structure.

Finally, in order to avoid signal interference, signal lines and power lines should be laid in separate pipelines. Following these recommendations will help you better meet the challenges of DMX512 control.

How does DMX512 Control the Pixel Neon Strip?

DMX512 controls the pixel neon strip via digital signals; each pixel corresponds to a separate address. A DMX controller needs to be connected to a decoder to convert the signal to a protocol (e.g., SPI) that is recognized by the pixel lights. Each pixel occupies 3 DMX channels (RGB tri-color), and the starting position is set by address coding. The controller sends 512 channel data packets, corresponding to the brightness value of each pixel in sequence, to achieve color change and dynamic effects. Attention should be paid to channel allocation, signal synchronization, and transmission distance limitation (a signal amplifier is recommended). Support programming preset lighting scenes suitable for stage, building, and other dynamic lighting projects; need to support DMX-compatible pixel light tape and driver equipment.

About how DMX512 controls the pixel LED strip light, please read the article: How does DMX control the LED strip light? And how to connect them?

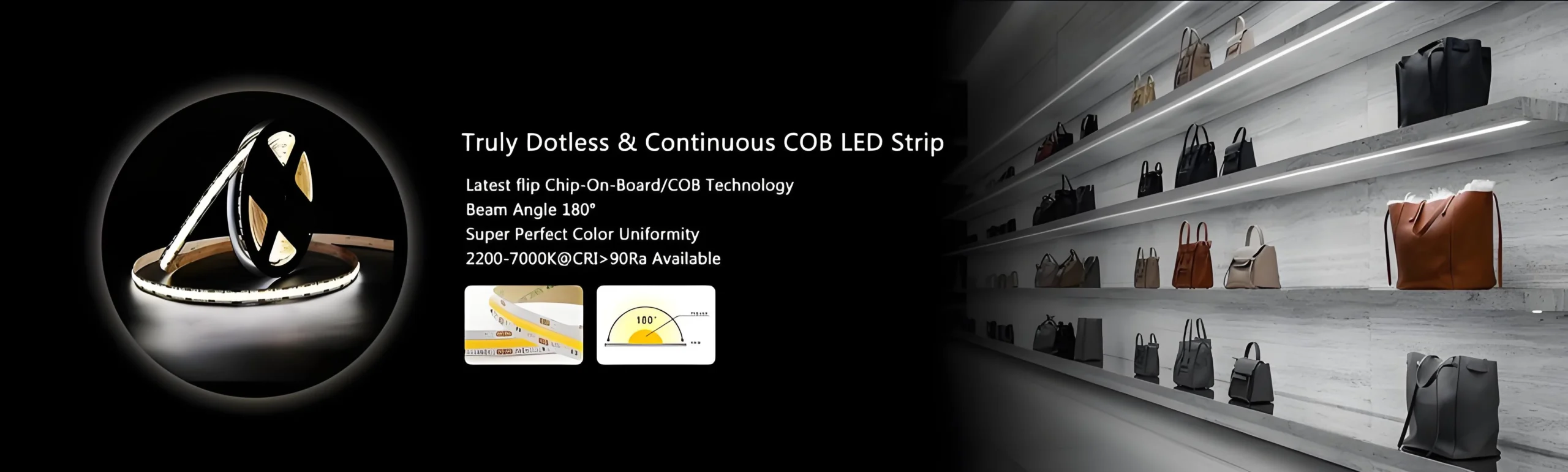

SignliteLED is a high-tech enterprise specializing in the research and development and production of LED strip lights. The main products are DMX LED strip lights, LED neon strip lights, and COB LED strip lights. The company has rich experience in the use of DMX products; if you are also looking for this kind of product or equipment, then you are in the right place. You can contact our engineers and technicians with your project plan, and we will build the program you want according to your needs, thus reducing your worries.

To control the pixel neon strip, you first need to find a DMX controller. K-1000C and K-8000C are the more used controllers nowadays, which are characterized by simplicity and practicality, ease of control, and economy. The controllers support offline control without the need to connect to a computer. You only need to save the pre-programmed file to the SD card and then insert the SD card into the controller to realize your programmed effect.

The K-1000C and K-8000C are suitable for offline control. They can be used for a single unit or multiple cascades to drive more LED pixels. If the total control fixtures are under 8000 pixels, the K-1000C DMX pixel controller is recommended. If the total control fixtures are 8000 ~ 20000 pixels, the K-8000C DMX LED Pixel Controller is recommended.

How to decide if a DMX controller is right for your project? If you have a small LED neon installation, then you may not want a complicated controller and prefer a small wall controller that is easy for anyone to use. But if you want to control each zone individually, then PC-based DMX controllers may be more suitable as they offer more control.

Good control cannot be separated from a good power supply. Selecting a branded power supply ensures stable operation of the DMX512 system, providing accurate voltage output, strong anti-interference, high compatibility, and effectively reducing the risk of signal degradation. At the same time, with multiple security protections, durable and reliable, to avoid power failures resulting in loss of control of the lights or equipment damage, to enhance the overall control stability and security. Brand power supplies can choose Meanwell, Osram, Philips, and so on.

Mean Well XLG Series IP67 Constant Voltage LED Power Supply

Model: XLG-75, XLG-100, XLG-150, XLG-200, XLG-320

Input Voltage: AC100-305V

Output Voltage: DC12V/DC24V

Output Current: 5A-18A@DC24V, 3.1A-13A@DC12V

Power: 75W-320W

Efficicency: 89%-94%

PF: >0.95

Dimming: 3 in 1 dimmable

IP Rating: IP67

Certification: UL, CE, ROHS

Warranty: 5 years

The SignliteLED DMX neon strip is known for its high brightness, low energy consumption, flexible LED strip, uniform light emission, support for DMX512 intelligent control, and easy realization of dynamic color change. IP65/IP67/IP68 waterproof and dustproof, suitable for architectural silhouettes, stage decorations, and commercial spaces, easy to install, life expectancy of more than 50,000 hours, it is the preferred choice of professional lighting design solutions. It is the preferred solution for professional lighting design.

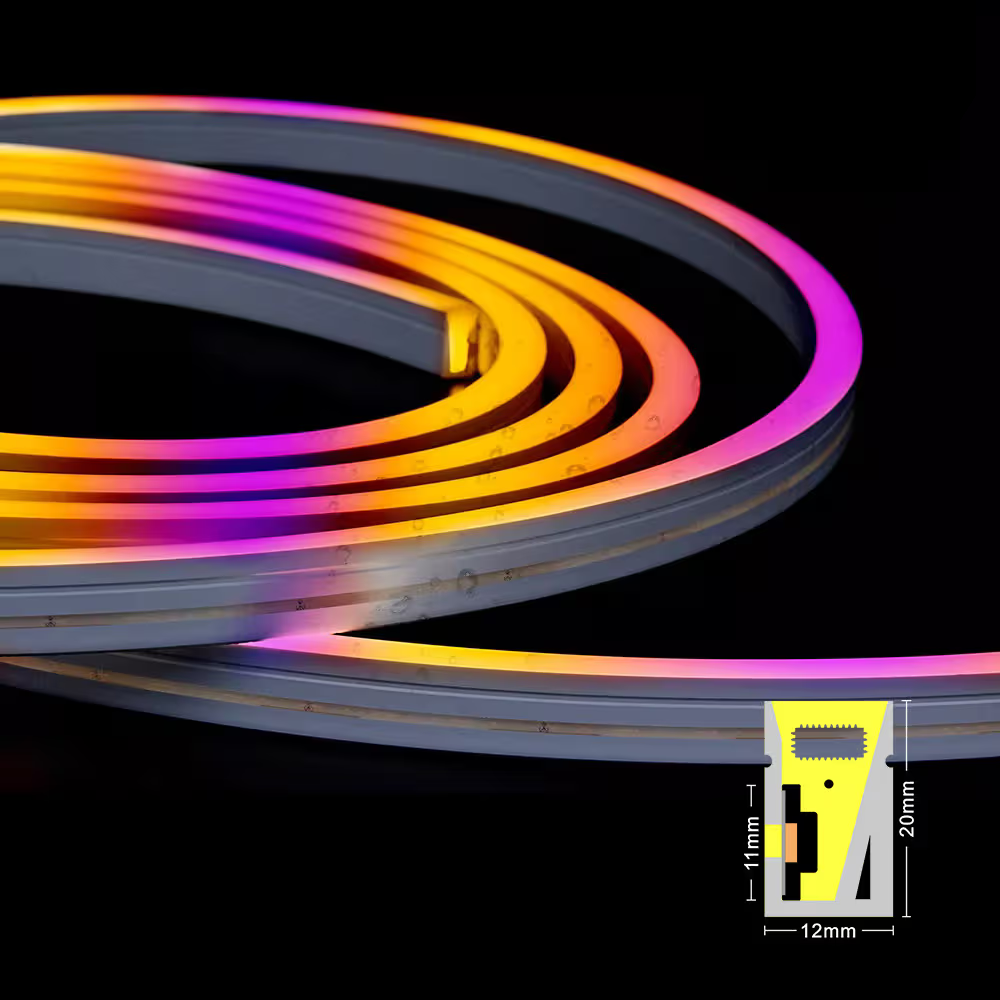

Side Bend S1220 Silicone Adressable LED Neon Strip for Architectural, Wall Glazer & Facade Lighting

Input Voltage: DC24V

Watt: 12W/m@RGB, 19W/m@RGBW

LED QTY: SMD5050 60LEDs/m

Color Temperature: RGB/RGBW(2700K-6500K)

Signal Type: SPI/DMX512

IP Grade: IP65/IP67

Cable Entry: Front

Min Bending Diameter: 100mm

Cuttable Length: 100mm

Length: 5meters/roll

The Working Principle of the DMX512 Control System

To figure out the working principle of DMX512, we first need to figure out how the DMX control signal is sent and received. In the RGB LED strip light connection, the DMX main controller sends data packets, and each LED is equipped with a DMX module inside and then receives the corresponding control signal according to the address. And each channel contains 8 bits of data, which is the value of 0-255, used to adjust the brightness or color change of the precise control.

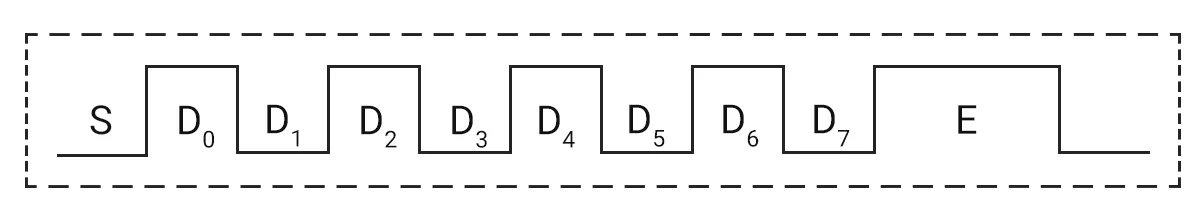

In a DMX control system, each control byte is referred to as a command frame, which represents a separate control channel capable of manipulating one or more functions of the lighting equipment. A standard DMX command frame consists of 1 start bit, 8 data bits, and 2 end bits, for a total of 11 bits, which are exchanged via a unidirectional asynchronous serial transmission.

In the above figure, the S in the dotted control instruction represents the start bit, which is one bit wide and mainly serves as the start flag for the controlled fixtures to prepare to receive and decode the control data. E, on the other hand, represents the end bit, which is two bits wide and is used to mark the end of an instruction frame.

In the DMX control system, D0 and D7 constitute the 8-bit control data, and their level combinations are capable of varying from 0000 to 1111 1111, for a total of 256 states (corresponding to decimal numbers from 0 to 255). These states are capable of generating 256 different brightness levels when controlling the brightness of the lights, where 0000 (0) corresponds to the dimmest lights and 1111 1111 (255) corresponds to the brightest lights. In addition, the DMX512 instruction has a bit width of 4s and a width of 44s per frame, and its transmission rate is 250 kbps.

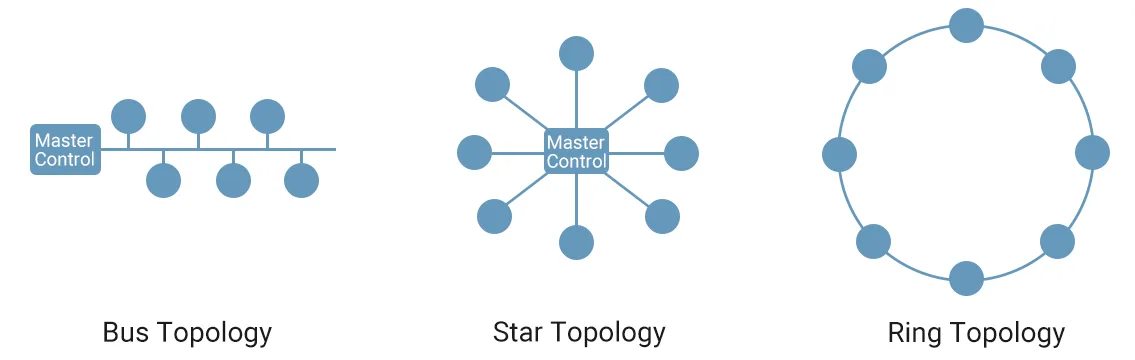

In addition, the system uses a standard EIA485 interface, which has a bus topology and does not support ring or star networks. In this structure, up to 32 nodes can be connected to the same bus. The DMX512 control system follows a specific bus structure that ensures orderly and efficient signal transmission. This structure has defined start and end points, similar to the familiar concept of switches in electrical circuits.

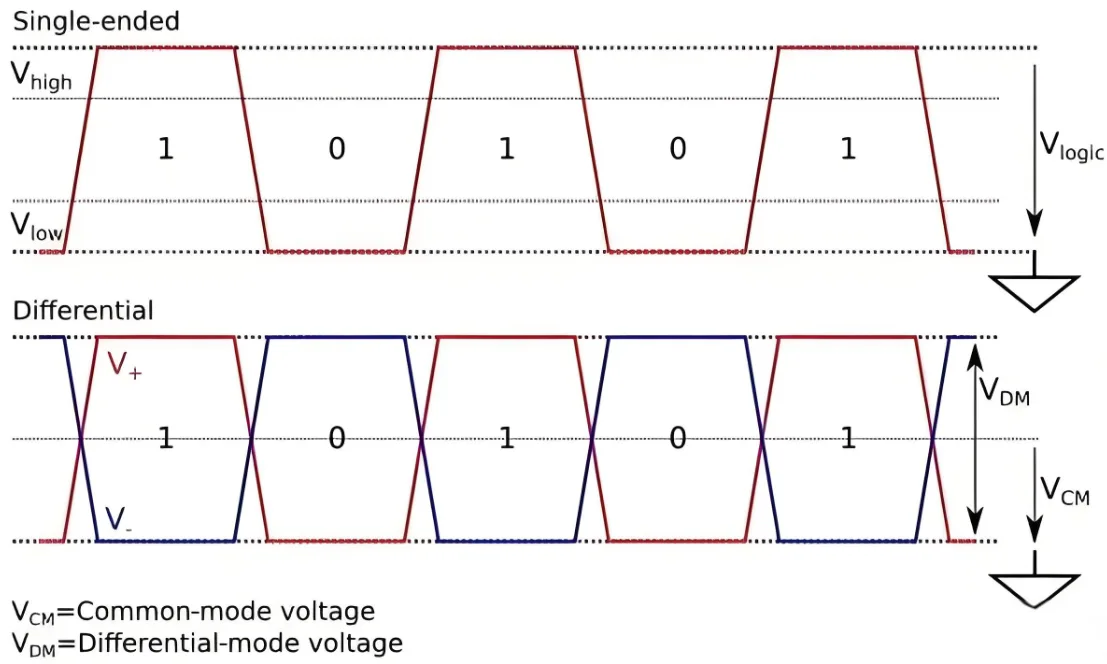

The DMX512 protocol uses EIA-485 differential signals as its physical layer for signaling. A differential signal is a pair of electrical signals that are inversely related to each other but correlated. One of these signals is called the forward signal, and the other is called the reverse signal. The two signals are equal in amplitude but 180° out of phase (i.e., in opposite directions), and they have the same DC voltage VCM (i.e., reference potential). The essence of a differential signal is the difference between these two voltage signals, and the logic state sent by the transmitter is determined by comparing the difference between these two voltages.

Advantages of using differential signals:

Strong anti-interference ability: EIA-485 differential signals are transmitted through twisted-pair wires, which can effectively resist electromagnetic interference and electrostatic discharge, and are suitable for stage lighting and other complex environments.

Unidirectional transmission: DMX512 protocol is unidirectional; data is transmitted from controllers (e.g., lighting consoles) to dimmers and special effects equipment and does not include automatic error checking and correction functions.

Transmission rate: The DMX512 transmission rate is 250 kbps, and each command frame is 44 microseconds wide.

Overall DMX512 system control is via a dedicated digital signaling protocol where the controller sends 512 individual channels of dimming data to the LED fixtures. Each lamp bead or segment is assigned a specific address and receives brightness and color commands for the corresponding channel. The signals are transmitted anti-interference through differential transmission, and the controller refreshes the data frame by frame to achieve synchronized control of multiple light strips. The system supports serial expansion and can accurately adjust RGB color mixing and dynamic effects, which is suitable for centralized management of complex lighting scenes such as stages and buildings.

Common Problems and Solutions

First confirm the controller signal output status; if conditions allow, try to use a new controller to test the circuit individually to determine whether it is controlled. According to the test results, the following analysis can be made:

a. If controlled, the problem may be in the original controller’s signal output or wiring files, port hardware, and port wiring.

b. If not controlled, it is necessary to further troubleshoot;

c. In order to determine whether it is a controller problem or the subsequent light bar on the signal of the interference, you can try to disconnect the back of the problematic light bar, retain a group of normal operation for individual testing, and if the first group is normal, you can try to use a new controller to test the circuit individually to determine whether it is under control. Test if the first group is normal; basically, determine if the back of the light bar is a problem.

Verify the controller wiring

Ensure that the controller wiring is correct and the number of lamps and lanterns recorded on the wiring document and the actual number of lamps and lanterns installed on the site are completely consistent.

Comprehensive testing of the wiring file

First of all, conduct a comprehensive control test of the controller through the test program to ensure that the single-port wiring file from 1 to 512 Channels can be smoothly laid. There are two things that can happen during the test:

a. If some of the fixtures are flashing, this is usually an indication that there is a problem with the coding of the fixtures on that circuit. In this case, simply rewrite the code for the circuit fixtures, and the problem will be solved.

b. If individual fixtures can not be controlled, it is necessary to further check whether the signal output of the fixture is wired correctly, or whether there is any quality problem with the fixture itself.

Signal amplifiers not only amplify signals, i.e., boosting weak signals to the starting point, but also act as signal isolation, designed to protect the controller from luminaire faults. In compliance with the standard EIA485 protocol, one signal amplifier should be installed for every 32 nodes to ensure stable control and avoid flickering when the signal from the fixtures is degraded by rain or other unfavorable conditions.

According to the standard of the EIA485 protocol, it is usually recommended to install one signal amplifier for every 32 nodes. However, in practical applications, sometimes this number may be exceeded to more than 60 nodes. However, it should be noted that this may face the risk of signal instability.

In practice, many projects choose to use network cables as signal cables, and such cables often do not come with shielding. Although the transmission distance will be affected to some extent, the specific distance still needs to be determined according to the actual situation of the project. Generally speaking, the farthest transmission distance can reach about 100 meters.

When there is an obvious signal delay problem on different ports on the same splitter, we can solve the problem by resetting the parameters of the controller. This is usually due to the parameter settings of the controller itself that cause the output frequencies of the ports to be inconsistent, which in turn triggers the signal output to be out of sync. By resetting the parameters, we can ensure that the signals of each port can be output in synchronization, thus solving the problem of time asynchrony.