In advertising light boxes, the choice of LED light source directly affects the display effect, especially in airports, subways, shopping malls, retail chains, and other scenarios. The lightbox not only conveys information but also carries the brand image. Compared with traditional light sources, LED rigid strips have become the first choice of modern light box lighting by virtue of their high brightness, stable light effect, low energy consumption, long life, and other characteristics.

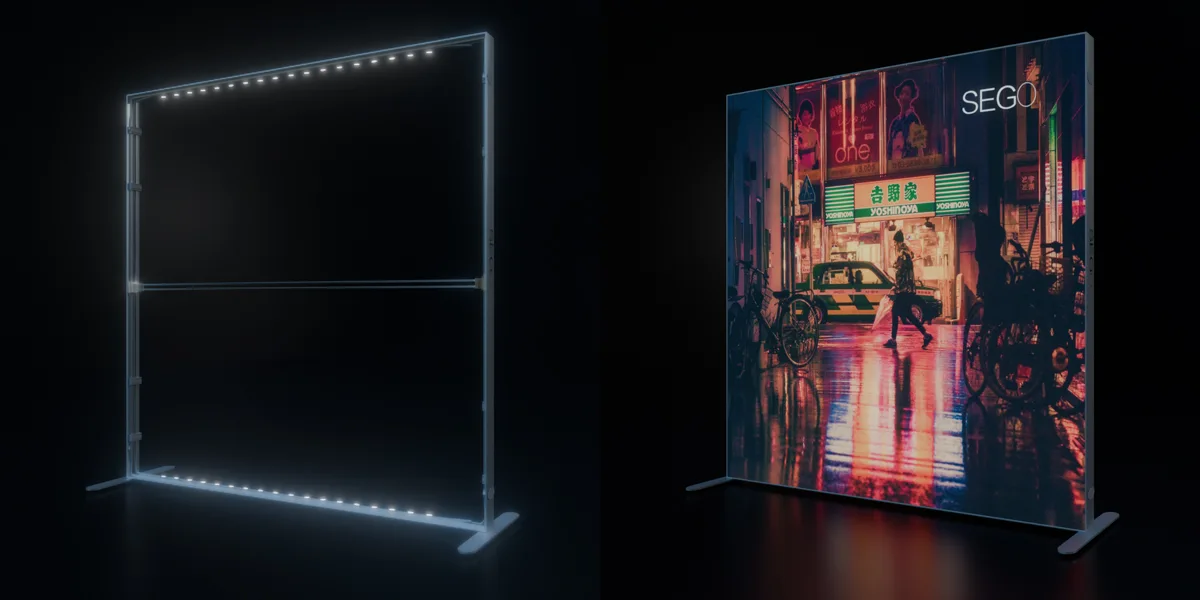

Common light boxes can be roughly divided into two categories: one is the back-lit light box, which emits uniform light from the back; the other is the edge-lit light box, which has the light source placed in the frame and is mostly used for fabric light boxes. Different light source arrangements on the LED strip structure design, optical characteristics, and installation put forward different requirements, such as beam angle, bead density, voltage input, etc., which will directly affect the uniformity of lighting and project landing effect.

This article will focus on these two lighting methods, from the structure logic, product parameters, application scenarios, and other aspects of the system comparison, and provide targeted selection recommendations.

Lightbox Lighting Analysis: Back-lit vs. Edge-lit

In the actual project, the different structure of the advertising lightbox directly determines the arrangement of the LED light source. Currently the mainstream lightbox lighting is divided into two categories.

Backlit Lightbox Lighting

A backlit rigid LED strip is used as the main light source of the light box. The LED strip is arranged on the back panel of the light box, and the light penetrates the diffusion cloth or light guide plate vertically to form a high uniformity of the front lighting. Suitable for light boxes with thickness ≥30mm. Combined with a wide-angle lens diffusion light bar (e.g., 170°), it can cover a larger area and reduce shadows and dark spots.

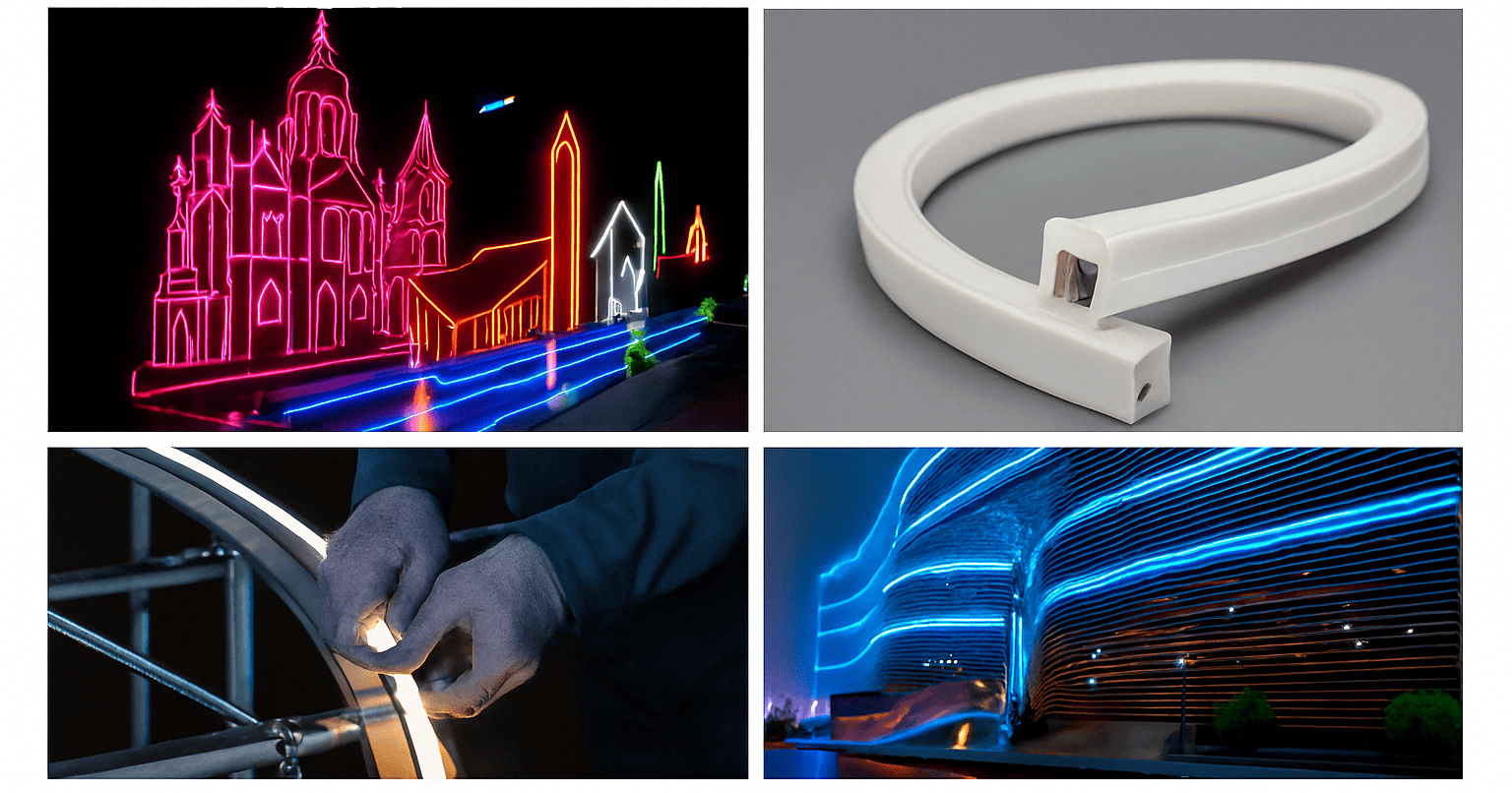

Edge-lit Lightbox Lighting

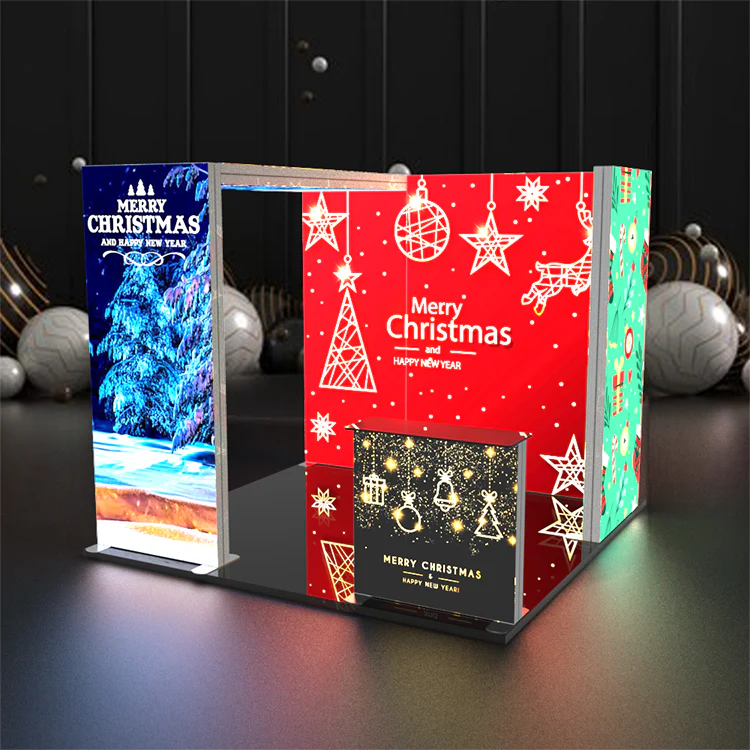

Edge-lit lightbox Lighting is a rigid edge-lit LED strip installed in the lightbox frame; the light spreads sideways with the help of light guide cloth or diffusion cloth, forming a soft and even light effect on the whole surface of the screen. It is suitable for a cloth light box with a thickness of 60~120mm. This kind of lightbox is suitable for hanging, wall-mounting, and other forms, which is very suitable for shopping mall guides, chain brand windows, booth lighting, and other application scenarios.

The following table summarizes the main differences between the two types of light boxes:

| Comparison items | Light source position | Beam angle design | Recommended light box thickness | Typical application scenarios |

| Back-lit light box | The strip is located at the back of the screen | Wide angle lens (170°) | ≥30mm | Light box advertisement, window, station light box, stretched ceiling |

| Edge-lit light box | Stripes are arranged on both sides of the frame | Narrow angle lens (15×45°) | 60~120mm | Fabric light box, shopping mall guide, exhibition display system |

Recommended Solution for Backlit Rigid Svoyages

For advertising light boxes with a thickness of more than 30mm, backlit lighting solutions are widely used in the field of advertising light boxes due to their high uniformity, strong brightness, and wide applicability. Common applications include bus shelter light boxes, subway light boxes, window signs, stretch ceiling, and showroom background light boxes.

We recommend using a high-efficiency backlit rigid LED strip for a light box with a 170° wide-angle lens, which has the following advantages:

- Excellent luminous efficacy: Adopting a high-brightness SMD2835 light source, the whole luminous efficacy can reach 150 lm/W, which can ensure the brightness and control the energy consumption at the same time;

- Uniformity of light emission: 170° optical lens design can realize uniform illumination over a large area, suitable for ultra-thin light boxes with a thickness of more than 3cm;

- Efficient installation: support daisy chain cascade connection, simple wiring;

- Flexible size: support each strip of light according to 80mm/160mm unit cuts to meet a variety of light box specifications;

- Convenient construction: adopts double-strand flexible cable or 5557 connector, low voltage drop, and high reliability;

- Flexible protection: IP20 is suitable for indoor use; the IP65 version can be used in outdoor semi-closed scenes.

Bande LED rétroéclairée IP20

Tension d'entrée : DC12V/DC24V

Length: 480mm/960mm

LED Chips: 12/24LEDs, 1W SMD2835

Power: 5W/10W

Efficacy: 150lm/W

CCT: 3000K/4000K/5000K/6500K/Tunable White

IRC : >80

Beam Angle: 170°

Connector: 18AWG wire or 5557 connectors

Wiring: Daisy Chain

Indice de protection IP : IP20/IP65

Cut Section: 80mm, 160mm

Lifespan: 30,000 hours

Garantie : 3 ans

Certifications: CE, ROHS

This backlit rigid LED strip has become the solution of choice for many project managers and lightbox manufacturers due to its luminous efficacy, uniformity, and ease of construction. It not only optimizes the installation process but also helps customers control energy consumption while ensuring visual impact, making it a truly cost-effective lighting option for light boxes.

Applications :

Edge-lit Rigid Strip Recommended Solution

For advertising light boxes with a thickness between 60 and 120 mm, especially cloth light boxes or double-sided signage light boxes, the edge-lit lighting method has become the mainstream choice for commercial systems due to its advantages of even light output, space saving, and simple structure.

The edge-lit structure adopts edge-lit rigid LED strips arranged on both sides of the light box frame and utilizes optical lenses to accurately project light onto the surface of the screen, forming a soft and uniform lighting effect. In order to improve the uniformity of the long-distance light guide, we recommend the edge-lit rigid LED strip equipped with a 15 x 45° lens, which has the following advantages:

- Precise llumière distribution dconception: Using PMMA concave optical lenses to control the angle of light and effectively reduce the phenomenon of over-brightness in the center and dark areas at the edges;

- High brightness and energy-saving output: Equipped with 1W SMD2835, the whole light efficiency is up to 150 lm/W, which reduces energy consumption while ensuring brightness;

- Flexible shear structure: the smallest shear unit is 2 LEDs (48 mm/96 mm), supporting on-site size adjustment, adapting to various non-standard light boxes;

- Easy and fast construction: Plug-in connector + high thermal conductivity adhesive backing, also supports screw-fixed installation;

- Protection level options: IP20 for indoor signage light box, IP65 version supports complex outdoor environments;

- Dual driver options: constant voltage version for regular projects, constant current version for extra-long series, ensuring consistent brightness throughout the strip.

Bande LED Edgelit à tension constante

Tension d'entrée : DC12V/DC24V

Length: 480mm/960mm

LED Chips: 10/20LEDs, 1W SMD3030

Power: 10W/20W

Efficacy: 150lm/W

CCT: 3000K/4000K/5000K/6500K

IRC : >80

Beam Angle: 15×45°

Indice de protection IP : IP20/IP65

Cut Section: 48mm/96mm

Lifespan: 30,000 hours

Garantie : 3 ans

Certifications: CE, ROHS

With precise beam control, flexible size cutting, and great ease of construction, this edgelit rigid LED strip for fabric light boxes provides project contractors and advertising light box manufacturers with a stable, energy-efficient, and easy-to-maintain sidelighting solution.

Scénarios d'application typiques :

- Indoor and outdoor fabric light box (single-sided/double-sided)

- Shopping mall window guide/image light box

- Exhibition display system light box

Comment faire Choose the RLED d'éclairage Lightbox Svoyage According to the Project Requirements

In the actual project, the thickness of the lightbox, the display area, the installation method, and the use of the environment will affect the type of LED light bar and the choice of light distribution program. The following is the recommended configuration of common lightbox types to help you quickly determine the required program:

| Application Type | Light Box Thickness | Recommended Strip Type | Installation | Typical Application |

| Shopping Mall Light Box | 30~60mm | Back-lit LED strip | Back mounted | Indoor superstore, window, chain store signage |

| Extérieur Advertising Llumière Box | ≥60mm | Backlit / Edgelit strip | Back / Edge | Outdoor Light Box |

| Fabric Light Box (Double Side) | 60~120mm | Edge-lit LED strip | Left and right/up and down sides | Airport, shopping mall, exhibition |

| Stretch Ceiling / Soft Film Ceiling | ≥30mm | Back-lit LED strip | Back row | Office space, showroom ceiling |

Quick judgment recommendations:

1. The thickness of the lightbox is greater than or equal to 3 cm, and for the back of the installation space, we recommend the use of a diffuse back-lit light bar.

2. Light box for vertical double-sided fabric or soft film materials, the choice of edge-lit rigid light bar;

3. To display high image clarity, it is recommended to use CRI ≥ 90 for LED light bars.

4. Outdoor application scenes must use IP65 or above versions.

Whether you are faced with the stringent requirements of an ultra-thin light box on the uniformity of lighting or large-scale cloth signs on the brightness of the challenge of consistency, the correct matching of the applicable LED rigid strip solution will bring twice the result with half the effort for the project. If you are still not sure which LED rigid strip is best for your lightbox design, please contact us for customized solutions and sample testing suggestions.

FAQ in Lightbox Lighting

It is recommended to prioritize the use of backlit rigid LED strips with 170° ultra-wide-angle lenses. Compared with edgelit, the backlight solution can achieve higher illumination uniformity within a limited depth, and at the same time, the wiring is more concise.

Support. Our rigid strips are designed with standard cut units (e.g., 80 mm/96 mm) and clear pads for each section. You can cut and reconnect them with soldering as needed to fit various lightbox sizes.

IP20: Suitable for indoor environments, such as shopping malls, exhibition halls, office building ceilings, etc.

IP65: With waterproof capability, recommended for semi-outdoor or dusty and humid environments, such as bus stops, outdoor advertising light boxes, subway channel light boxes, etc.

The project is located in an outdoor or high air humidity area; it is recommended to prioritize IP65.

Yes, all of our rigid LED strips for light boxes are CE/RoHS certified. Some models also support UL and FCC certificates to meet the compliance needs of the European and American markets and are suitable for bidding, government projects, or brand chain applications.

It is recommended to provide the following information; we will match the program for you quickly:

– Thickness, size, and mounting method of the lightbox;

– Whether it is a single/double-sided fabric structure;

– Specific requirements for brightness, uniformity, and color rendering;

– Whether it is located outdoors, restricted wiring, or installation depth.

Our rigid LED strip for light boxes supports DC12V and DC24V inputs.

– The 12V system is suitable for short-distance, single-section light deployment and is highly adaptable for small- to medium-sized light boxes or sample development.

– The 24V system has less voltage drop and is suitable for series connection of multiple sections, which is the recommended solution for large-size advertising light boxes or long-distance wiring projects.

Conclusion and Cooperation

In the field of advertising lightbox lighting, rigid LED strips have become the ideal light source for backlit and edgelit light boxes due to their high efficiency, easy installation, and customizable advantages. By choosing the right lighting method, light box structure, and optical parameters, you can not only optimize the visual effect but also effectively control the project cost and maintenance efficiency.

Whether you are developing a large-scale shopping mall signage system or a sophisticated indoor fabric light box project, SignliteLED can provide you with one-stop support from selection recommendation and optical simulation to OEM customization. Whether you’re an engineering contractor, lighting designer, or signage manufacturer, we’re ready to support your next project with professional rigid LED strip solutions tailored for light boxes.