LED lamps are constantly being upgraded to improve their usability, adaptability, and energy efficiency. LED lamps are very popular because they last up to 25 times longer and consume less power than standard incandescent lamps.The two main types of LED lamps available today are COB and SMD LED lamps. Both components produce high-quality illumination, have a long service life, and are the most efficient to date.

COB (chip-on-board) LEDs and SMD (surface mount device) LEDs are two popular technologies used in LED lighting. Both offer advantages in terms of energy efficiency, durability, and lifetime.

In this comprehensive guide, we will explore these two outstanding LED technologies that are revolutionizing the lighting industry. Whether you’re a lighting enthusiast, a fixture manufacturer, or just curious about the advances in LED technology, we’ll focus on how these two LEDs work. We’ll also discuss their features and manufacturing processes, as well as compare their capabilities.

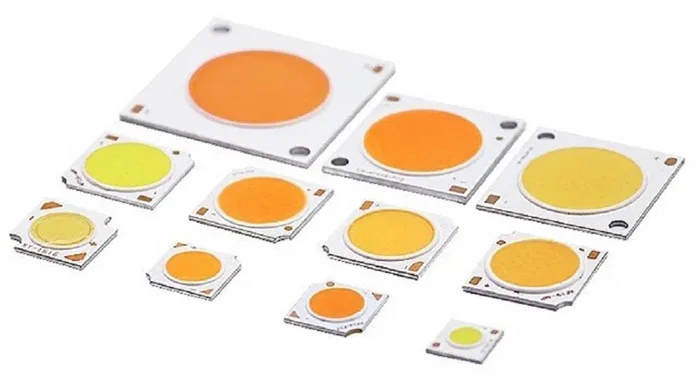

What is SMD LED?

SMD LED stands for Surface Mount Device LED, and SMD is a technology that produces circuits in which components are mounted on a circuit board. In this technology, components are mounted on a circuit board.SMD LEDs produce bright illumination at lower wattages and are a type of LED that incorporates three primary colors in one package.It uses a polarization process to assemble the circuit board, which requires high-quality equipment to complete.SMD LEDs are very small in size, and their lack of pins and leads makes them better suited for automated assembly by machine rather than by hand. SMD LEDs also offer a wide viewing angle due to the lack of a hemispherical epoxy housing.

SMD is the most common type of LED on the market. It is available in different sizes, denoted by numbers such as 2835, 3528, or 5050. These numbers refer to the physical size of the LED chip. The larger the number, the larger the chip, which affects its light output and other characteristics. To better understand this, let’s look at a table to get a clearer picture of the physical dimensions of SMD LEDs.

| SMD LED | Dimensions(mm×mm) | Power(watt) | Flux(lumen) | CRI(Ra) | Forward Voltage (V) | Beam angle(degree) | Heatsink | Efficacy(min) (lm/W) | Efficacy(max) (lm/W) |

| 2835 | 2.8 × 3.5 | 0.2 | 24–36 | 80–90 | 2.6–3.2 | 120 | yes | 100 | 220 |

| 3014 | 3.0 × 1.4 | 0.2 | 17–27 | 70–90 | 2.8–3.3 | 120 | yes | 102 | 151 |

| 3020 | 3.0 × 2.0 | 0.5 | 36–58 | 70–90 | 2.8–3.3 | 120 | yes | 112 | 160 |

| 3030 | 3.0 × 3.0 | 1.0 | 110–160 | 70–90 | 5.8–6.2 | 120 | yes | 135 | 209 |

| 3528 | 3.5 × 2.8 | 0.06–0.08 | 4–8 | 60–70 | 2.6–3.2 | 120 | yes | 70 | 100 |

| 3535 | 3.5 × 3.5 | 0.5 | 24–49 | 70–90 | 2.8–3.4 | 120 | yes | 100 | 168 |

| 4014 | 4.0 × 1.4 | 0.2 | 22–32 | 70–90 | 2.8–3.3 | 120 | yes | 110 | 160 |

| 5050 | 5.0 × 5.0 | 0.2 | 18-28 | 70–90 | 2.6–3.2 | 120 | no | 100 | 150 |

| 5630 | 5.6 × 3.0 | 0.2 | 24–41 | 70–90 | 2.8–3.2 | 120 | yes | 100 | 210 |

| 5730 | 5.7 × 3.0 | 0.5 | 60–70 | 70–90 | 2.8–3.4 | 120 | yes | 100 | 120 |

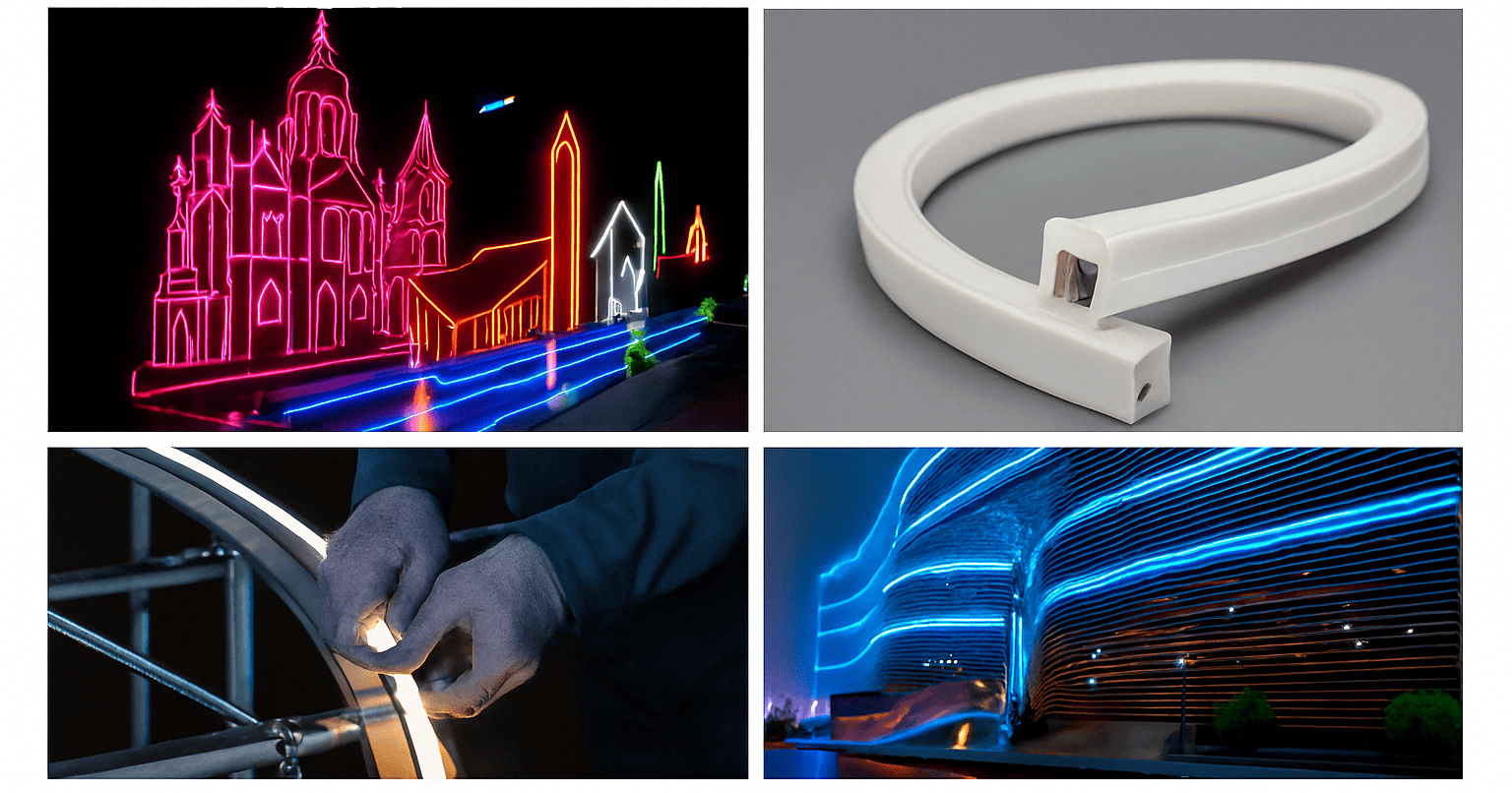

SMD LED lighting is also best suited for use as a point light source because it has a coupling effect due to the glare created by multiple surface-mounted light sources. As a result, SMD LED lighting is often best suited for signage in bars, clubs, hotels, and restaurants, as well as generally for outdoor wall sconces and spotlights. It is also ideal for task lighting in bathrooms and kitchens, among others.

Benefits of SMD LED

SMD LEDs have a number of unique characteristics that make them popular for a variety of lighting applications. They are applied directly to the surface of the circuit board, eliminating the need for additional leads and reducing material usage. They emit light at a wide angle, typically around 120-160 degrees, for uniform illumination and enhanced visual appeal. In addition, SMD LEDs operate at lower voltages and currents, which reduces energy consumption and heat generation, contributing to their longer life and improved stability.

- Consistent off-angle viewing brightness produces better “perceived” brightness.

- Excellent color reproduction

- Excellent contrast ratio

- Pixel pitch as fine as 0.9 millimeters

- Durable in both indoor and outdoor environments

Disadvantages of SMD LED

- Consumes more power (up to 35% more)

- Reduced direct (front) field of view brightness

- Less efficient heat dissipation; requires active cooling

What is COB LED?

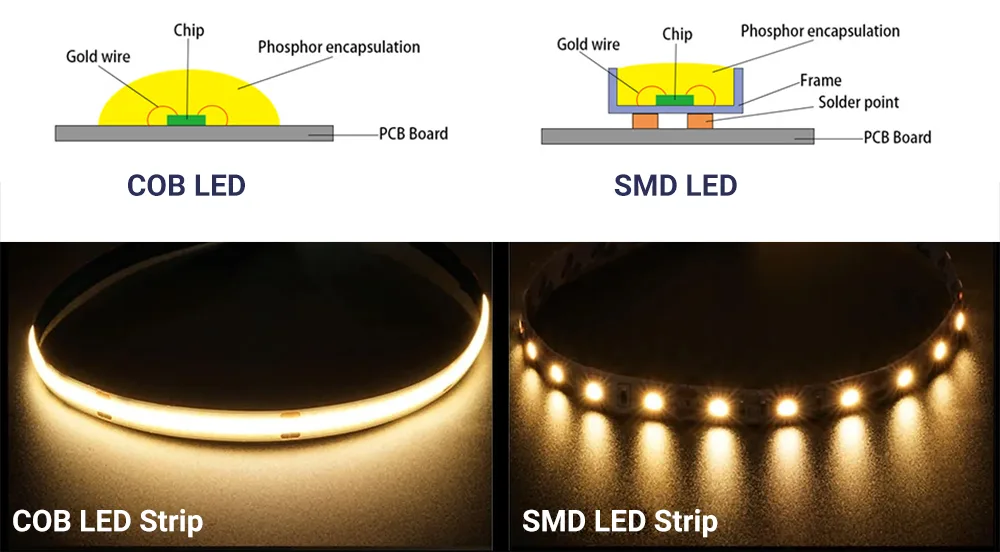

COB LED is an advanced chip-scale packaging LED technology. COB stands for chip on board and is one of the latest developments in the LED field. Compared to other standards, we can consider this technology quite new and innovative.COB LEDs move away from the traditional discrete package by densely integrating multiple LED chips onto an insulating layer and an aluminum substrate (heat sink) of various shapes (e.g., round, square, rectangular, moon or star).

Typically, COB chips have nine or more diodes. Regardless of the number of diodes, a COB chip has only two contacts and one circuit. On larger chips, this produces a more powerful illumination of up to 250 lumens (at 20 mA).The panel-like appearance of COB LED lights is attributed to the basic circuit design of the chip.

COB LEDs feature multiple light-emitting diodes tightly packed on a printed circuit board, which necessitates an aluminum heat sink in the middle to dissipate the heat generated by the COB LED lamp. This means it can survive longer at higher temperatures, making it a better choice for high-pressure environments such as street lighting and industrial lighting. However, this results in COBs requiring more built-in cooling capacity than SMDs. This also means they are more energy efficient, producing about 80 lumens per watt compared to about 50 lumens per watt for SMDs.

COB LEDs tend to be a higher quality light source because they use reflectors to provide more uniform, brighter, and higher-quality lighting. They also do not have the frosted lenses that come with SMD LEDs. This means that COB LED lighting has a clearer light with no glare, making it ideal for rooms with high ceilings. As a result, these LEDs are known as high-end fixtures, used to create a more architectural look that is best suited for long-term living in the property where they are installed. They are also very popular with filmmakers and photographers due to their even brightness and wide beam angle.

Benefits of COB LED

COB LEDs offer a variety of unique features that make them the preferred choice for specific lighting applications. Tightly packed multiple LED chips increase light output per square inch, allowing COB LEDs to achieve impressive brightness levels in a compact form. In addition, COB LEDs require only one circuit and two contacts to drive the entire chip array, simplifying circuit design, reducing energy consumption, and minimizing the risk of failure. Unlike traditional LEDs, COB LEDs have no leads, phosphor layers, or lenses, which reduces the light-emitting area (LES) and increases the center beam candlepower (CBCP). This improves light efficiency and reduces light loss. The substrate materials and heat sinks of COB LEDs exhibit excellent thermal performance, ensuring that the heat generated by the chip is efficiently conducted, resulting in low-temperature operation, extended LED lifetime, and improved stability.

- It provides sufficient light due to the use of multiple diodes.

- It produces more lumens while consuming less energy.

- Due to the limited light-emitting area, the device is smaller. As a result, the lumens per square centimeter/inch increase significantly.

- To activate the multiple diode chips installed in the COB LEDs, a single circuit with only two connections is used. As a result, fewer parts are required per LED chip, allowing for normal performance. In addition, by reducing the number of components and eliminating the standard LED chip architecture package, the heat generated by each LED chip can be reduced.

- The entire temperature range of the entire assembly is lower due to the extremely simple installation of an external heat sink. When you keep items at set temperatures, they last longer and are more reliable, saving you money.

- Clarity is improved and efficiency is increased.

- It has a huge focusing area because it can cover a large area with one chip.

- Excellent shock resistance

Disadvantages of COB LED

- Carefully designed external power supply. This is because it requires stable current and voltage to avoid damaging the diode.

- The well-designed heat sink is very important. If the heating element is not placed properly, the diode can be damaged due to overheating. A large amount of heat is generated due to the highly focused light waves emitted from a limited area.

- Lighting fixtures that utilize COB chips are less repairable. This is because if one of the individual diodes in the COB is damaged due to mechanical failure, the entire COB LED must be replaced with a newer LED. However, with SMD LEDs, if one fails, it can be easily replaced and brought back into operation at a lower cost.

- Is more expensive than SMD chips.

Differences between SMD LED and COB LED

One of the main differences between COB and SMD LEDs is their size and design. COB LEDs are larger and consist of multiple LED chips mounted directly on the substrate. This allows for higher light output density and more efficient space utilization. SMD LEDs, by contrast, are smaller and consist of a single LED chip mounted on a printed circuit board (PCB). This results in lower light output density but greater flexibility in design and placement.

Another key difference between COB and SMD LEDs is their beam angle and light output effect. COB LEDs tend to have a wider beam angle, which means they can provide more uniform and diffuse illumination over a larger area. This makes them ideal for applications that require a wide, even distribution of light, such as in a workshop, jobsite, or garage. SMD LEDs, on the other hand, have a narrower beam angle and are more directional, making them better suited for task lighting or focusing on specific areas.

COB LEDs have multiple LED chips in a high-density package, so they provide higher light output and center beam candlepower. This makes them suitable for applications that require high brightness and focused illumination, such as LED spotlights and LED downlights. SMD LEDs may not be able to achieve the same level of brightness as COB LEDs in a single chip. However, they have the advantage of producing uniform, soft illumination over a wider angle of illumination, making them ideal for uniform lighting in applications such as LED strips and LED bulbs.

In terms of energy efficiency, both COB and SMD LEDs are very efficient and have a longer lifetime compared to traditional LED technology. However, COB LEDs tend to be slightly more efficient because they have a higher light output density and use fewer components. This extends the life of the LED.

Durability is another important consideration when choosing a work light, and both COB and SMD LEDs are known for their long life and resistance to damage. However, COB LEDs tend to be more durable because they are larger and have fewer components, making them less prone to failure.

The cost difference between COB LEDs and SMD LEDs is multifaceted. While COB LEDs may be more cost-effective in terms of streamlining the production process, they require better materials and heat dissipation solutions. SMD LEDs, on the other hand, involve separate substrates and fluorescent layers for each chip, as well as more complex circuit design and production processes. However, advances in automation have reduced the production costs of SMD LEDs, making them more cost-competitive in some cases.

In summary, both COB LEDs and SMD LEDs have unique advantages and disadvantages for different lighting applications.The choice between COB and SMD LEDs depends on the specific requirements of each application. If brightness, high light concentration, and cost-effectiveness are the main considerations, COB LEDs may be the better choice. On the other hand, if light uniformity, energy efficiency, and multiple color options are more important, SMD LEDs may be preferred.

When buying, SMD vs. COB LED, which is better?

LED lights play an important role in our daily lives, and the choice between COB LEDs and SMD LEDs plays a crucial role. Each type has unique advantages to meet specific lighting requirements.

SMD LEDs are particularly well suited for products that require wide-angle illumination and uniform illumination. Because of their wide angle of illumination, typically around 120-160 degrees, they are commonly used in LED strips, LED panels, LED bulbs, and a variety of architectural lighting applications. SMD LEDs are available in a wide range of colors, allowing for multicolor or full-color displays, making them ideal for dynamic lighting effects.

COB LEDs excel in applications that require high brightness, concentrated light, and excellent luminous efficacy. The tightly spaced multiple LED chips increase light output per square inch, making COB LEDs suitable for use in COB LED strips, LED spotlights, LED downlights, LED streetlights, and other high-brightness lighting fixtures. Due to their efficient heat dissipation design and long lifetime, COB LEDs are also favored for industrial and commercial lighting applications that require extended operation in high-temperature environments.

We hope this article has helped you understand the differences between SMD and COB LEDs and helped you weigh the pros and cons of each LED light to decide which is best for your home. So, when it comes to buying SMD vs. COB LEDs, which is better? In addition to the different application scenarios we mentioned above, let’s take a look at what other factors come into play:

- Cost Efficiency: First of all, LED lights are more economical than other traditional lamps. They are more popular because they last longer, are more energy efficient, and are brighter. In the case of COB and SMD LEDs, the former is more cost-effective.

- Energy Efficiency: Again, it is a fact that LED lights are more energy efficient than any other bulbs. In the case of SMD and COB LEDs, this characteristic depends on the lumens used. The higher the lumens used, the higher the energy efficiency.

- Brightness: When we talk about lights, the first thing that comes to mind is brightness. COB LEDs are brighter. This is because it has higher lumens compared to SMD LEDs.

Conclusion

The innovative technology of COB and SMD LEDs has transformed the lighting industry and continues to provide versatile solutions for a variety of applications. When choosing between COB and SMD LEDs, consider the specific lighting requirements and characteristics of each LED type to make an informed decision. Whether you are a luminaire manufacturer or an LED enthusiast, the right LED choice can bring brilliance and efficiency to your lighting solution.

We are a professional China factory specializing in producing high-quality custom SMD LED Strip Lights, COB LED Strip Lights, and LED Neon Strip Lights. If you need to buy LED lights, please contact us.