Our team was both excited and stressed when our customer asked for a 1.2-meter LED tri-proof lamp with CE certification and low harmonics to develop the market. CE certification covers a wide range of test items, from electromagnetic compatibility (EMC) to the Low Voltage Directive (LVD), each of which has a bearing on the ability of a product to pass the CE test.

At the beginning, we sent our carefully prepared samples to the professional certification body with confidence, thinking that we could pass the test without any problems, but it turned out to be not what we had hoped for. The list of questions we got back from the certification body made us realize that the road to CE marking is not as smooth as we thought. Read on to learn more about CE marking and the rigors of its testing program, as well as the changes we’ve made to customize our LED tri-proof lights.

What is CE Certification?

CE certification, known as “Conformité Européenne”, which means “European Conformity Assessment” in French, is a mandatory safety mark of conformity specific to the European Union. It is carefully formulated by the European Commissioners of technical regulations, which are the basic conditions for the sale of LED products in the European market, all only to ensure the safety and health of users.

At present, the countries recognized by CE certification cover 25 member states of the European Union, such as France, Germany, Italy, and the Netherlands, and other economic powers are listed. In addition, Switzerland, Iceland, and Norway, which are also recognized by the three members of the European Free Trade Association, are included. In addition, Switzerland, Iceland, and Norway, three members of the European Free Trade Association, are also recognized. It can be said that the CE marking is the “key” for the products to travel freely in the markets of the EU countries and the EU Free Trade Association countries.

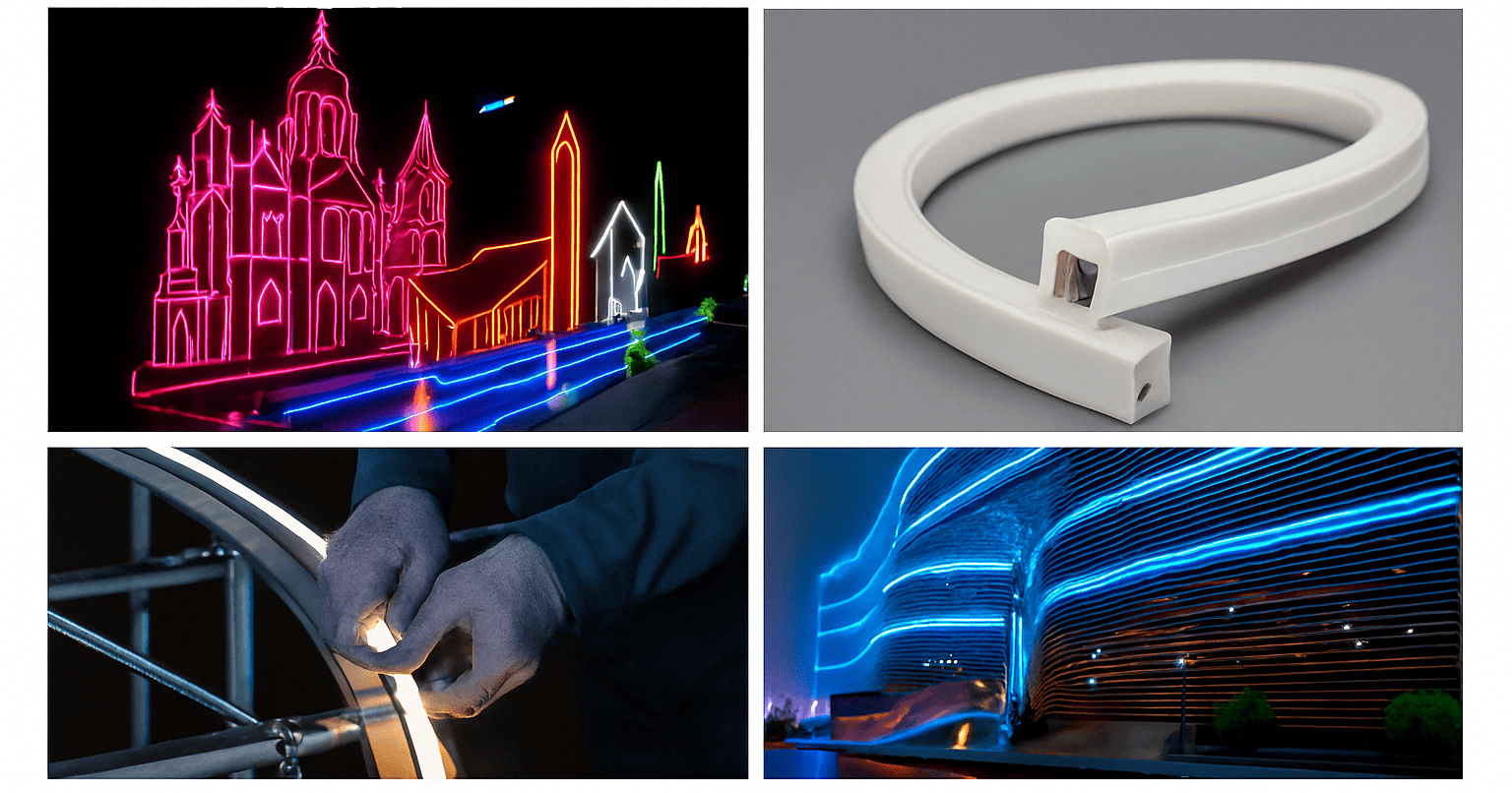

Customized ECO Series LED Tri-proof Lights

LED tri-proof lights can also be called LED vapor tights, LED batten lights, LED walk-in freezer lights, and so on. Completely sealed to the housing by end caps and silicone strips, this ECO Series LED tri-proof light is IP65 rated for outdoor and indoor LED lighting solutions.

ECO Series LED Tri-proof Light

- Model No: TRD12X40M

- Dimensions: 1200*68*48mm

- Input Voltage: 85-265VAC, 50/60Hz

- Watts: 40W

- Efficacy: 120lm/W

- CCT: 3000K/4000K/6500K

- CRI: >80

- Beam Angle: 120°

- THD: <15%

- IP Rating: IP65

- Lifespan: 30,000hrs

- Warranty: 3years

- Certification: CE, ROHS

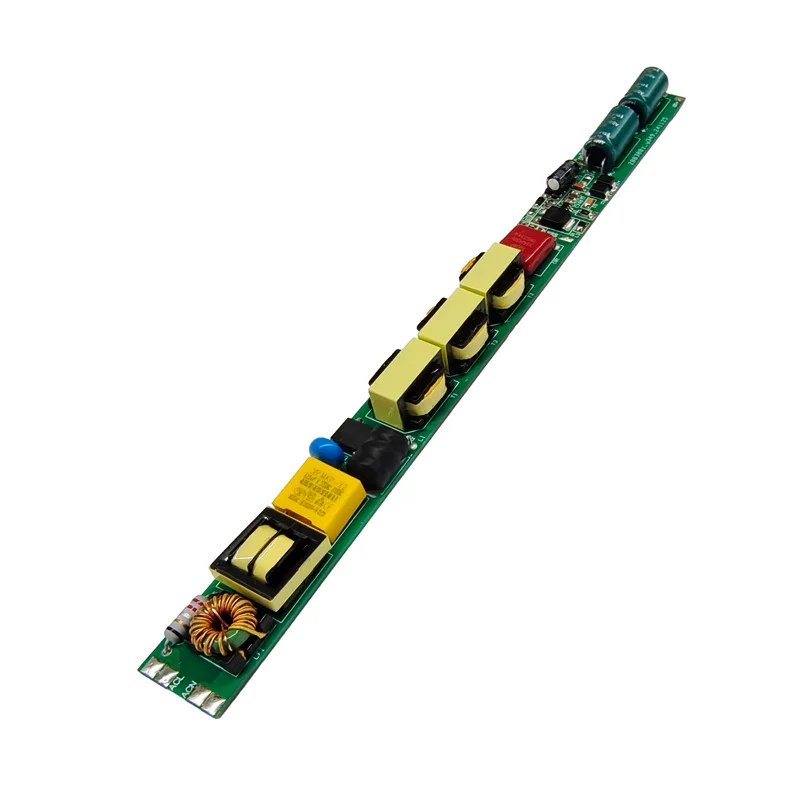

In fact, the CE certification of a finished LED tri-proof light usually has a lot to do with the LED driver it uses. Below are the specifications for this LED driver, and by understanding these specifications, you will have a better understanding of why the CE certification test program is so closely related to the LED driver.

Low THD LED Driver

- Model No: HPF044

- Input Voltage: AC100-277V

- Output Voltage: DC50-80V

- Output Current: 500-600mA

- Power: 40W-50W

- Efficicency: >90%

- PF: >0.9

- THD: <15%

- IP Rating: IP20

- Certification: CE, ROHS

- Warranty: 5years

- Dimensions: 217*17.6*11.7mm

What are the Key Tests Covered by CE Certification?

EMC Testing

EMC, the full name is Electro Magnetic Compatibility, that is, electromagnetic compatibility. On the one hand, EMC is to constrain the electromagnetic interference (EMI) generated by the product itself, not to cause adverse effects on the surrounding electronic equipment; on the other hand, EMC gives the product a strong electromagnetic immunity (EMS), so that it can maintain normal operation in the complex and changing electromagnetic environment.

Now let’s delve into the details of the EMC test program. First, there’s the EMS test, which includes a number of key tests:

- Electrostatic Discharge Immunity (ESD) test, simulating human body or object electrostatic discharge scenarios, requiring the product to be exposed to ±4kV, air ±8kV discharge voltage, the internal circuit will not be broken, and the function will operate normally, the classification of which is based on the IEC/EN 61000-4-2 standard.

- Radio Frequency Electromagnetic Field Radiation Immunity Test (RS), according to IEC/EN 61000-4-3 standard, the product needs to be under 80 MHz – 1000 MHz, with field strength of up to 3 V/m radio frequency electromagnetic field radiation, to maintain stable communication and precise control without interference to ensure that the light brightness, color, and other parameters are without abnormal fluctuations.

- Electrical Fast Transient Pulse Group Immunity Test (EFT), based on IEC/EN 61000-4-4 as a guideline, the product should bear the impact of 5 kHz repetition frequency, ±2 kV pulse voltage, ensure the power supply output is smooth, and the lamps and lanterns are free from abnormalities such as flickering, extinguishing, and so on, to guarantee the continuity and stability of lighting.

- Lightning surge (impact) immunity test: according to the IEC/EN 61000-4-5 standard, the product faces a 1.2/50μs open-circuit voltage wave and an 8/20μs short-circuit current wave of lightning simulation impact, in ±2kV (line-ground) and ±1kV (line-line) voltage. The protection circuit can effectively divert the energy to ensure that the equipment is not harmed and continues to work normally. continue to work normally.

- Conducted Harassment Immunity Test (CS) for RF Field Induced Conducted Harassment, following IEC/EN 61000-4-6 standard; the product has solid electrical performance in the frequency range of 150 kHz – 80 MHz, 3V (RMS) RF Field Induced Conducted Harassment, with no malfunctioning, and maintains the normal lighting control function.

- Voltage dips, short-time interruptions, and voltage changes immunity tests (DIPs), in accordance with IEC/EN 61000-4-11 standards, when the voltage dips by 60% for 10 cycles, or short-time interruptions in 3s, the product can be quickly adjusted to ensure that the key functions continue to run, and the lights do not go out to avoid the safety hazards of darkness.

The EMI test is also not inferior, including the following two key items:

- Conducted a Nuisance Test (CE) for the product’s power supply port and other external connection ports in the frequency range of 150 kHz – 30 MHz, in accordance with EN 55011, EN 55032, and other standards, to strictly limit the nuisance voltage or nuisance current of the conduction emission, to prevent it from being secretly emitted through the cables and interfering with the normal operation of other equipment. For example, LED power supply in this test must be conducted with nuisance control within the standard limits to ensure that the lamps, controllers, and other equipment connected to it are not interfered with and work together smoothly.

- Radiated nuisance test (RE), in the 30 MHz – 1 GHz, or even higher frequency range, in accordance with EN 55011, EN 55032, and other standards, the electromagnetic energy radiated by the product to the outside needs to be lower than the specified limit value to avoid, like the “electromagnetic broadcasting,” to the surrounding wireless communications, broadcasting, and other equipment to ensure the orderly utilization of the electromagnetic spectrum.

LVD Testing

LVD, or Low Voltage Directive, guards the safety of LED products. In the EU market, as long as the rated voltage of the product is in the range of 50V to 1000V AC and 75V to 1500V DC, it must be subject to the stringent test of LVD to ensure that it will not pose a threat to the user’s personal or property safety in normal use or even in case of a sudden failure.

The LVD test covers six key items, each of which has a bearing on safety:

- The temperature rise test simulates the heat generation of a product under full load operation for a long period of time. For example, an LED power supply is operated at rated power for several hours, and the temperature rise profile of critical areas such as power semiconductors, transformers, etc. is monitored by a high-precision thermocouple thermometer. According to standards such as EN 60335, the temperature rise in these areas must be controlled within safe thresholds to prevent overheating from causing deterioration and failure of insulation materials, which can lead to short circuits, fires, and other hazards.

- Voltage withstand test, also known as electrical strength test. In accordance with standards such as EN 60950, a test voltage several times higher than the rated working voltage of the product (usually 1000VAC or 1500VAC, depending on the insulation level of the product) is applied between the live parts and the accessible metal parts or insulated enclosure for 1 minute. During this time, the LED product must not break through the insulation, and the leakage current must be nearly zero.

- Leakage current test. Use a professional leakage current meter to accurately detect the tiny amount of current that flows from energized parts to accessible parts of the product under normal operating conditions. For LED power supplies and lamps, the contact leakage current and protection conductor current should be far below 0.5 mA (according to different product categories, standards are slightly different) to ensure that the user will not have the electric shock of the numbness of the electric shock, to protect personal safety.

- Grounding resistance test, mainly for products with grounding measures. Through the professional grounding resistance tester, measure the resistance value between the product grounding terminal and the grounded metal parts, which shall not exceed 0.1Ω (depending on the standard), to ensure that in the event of an electrical fault, the grounding path can quickly lead the current into the earth to avoid electrocution of the user.

- Insulation resistance test, using an insulation resistance meter to measure the insulation resistance between the product’s energized parts and the enclosure and between energized parts of different polarities. After applying a voltage of 500V or 1000V DC, the insulation resistance should meet the requirements of the standard and should generally be in the range of several megohms or even higher. For example, the EN 60335 standard stipulates that the insulation resistance should not be less than 2 MΩ under normal conditions to ensure good insulation performance and prevent electrical accidents.

- Mechanical strength tests, simulating the product in the transportation, installation, and use of the process, may be subjected to collision, impact, vibration, and other mechanical forces. For example, the LED three-proof light drop test, from a certain height to make its free fall to the specified impact surface, and the vibration test, is to simulate the vibration environment in transportation and industrial equipment operation. After these mechanical strength tests, the product shell is not broken, internal parts are not loose, the electrical connection is solid, and the function is normal and safe operation.

THD Testing

THD, or Total Harmonic Distortion, is a key measure of the purity of the current in an electrical system. In an ideal electrical environment, the current should have a perfect sinusoidal waveform that transmits energy in a smooth and orderly manner. However, the reality of electronic equipment, due to the presence of various nonlinear components, such as rectifier bridges and switching transistors in LED drivers, can distort the current waveform and produce a series of harmonic components.

For LED drivers, THD tests are significant. When the THD value of the LED driver is too high, it means that the current contains a large number of harmonics, and these harmonics can cause many problems:

- Harmonic current flow in the power grid will make the grid voltage fluctuations and distortions, affecting the normal operation of other equipment under the same grid, such as leading to increased measurement errors in precision instruments and audio equipment, such as noise.

- High THD will also reduce the power factor of the LED driver itself, so that the power utilization is greatly reduced, resulting in energy waste.

- Too much harmonic current will make the LED driver internal inductance, capacitance, and other components heat, accelerate component aging, shorten the life of the power supply, and may even lead to failures, so that the LED triple-proof lights flicker, dim, and other abnormal lighting phenomena, affecting the lighting effect and the use of experience.

In the International Electrotechnical Commission (IEC) and the EU standards, there are strict limits on the THD of LED lighting products. Generally speaking, for LED lamps with power less than 25W, THD is required to be controlled within 30%; for power between 25W and 60W, THD is required to be lower than 20%; for high-power LED lighting equipment above 60W, THD is strictly limited to less than 10% to ensure that the current is as close to sinusoidal as possible, to reduce harmonic contamination, and to ensure the harmonious coexistence of various types of electrical equipment and efficient operation. operation.

Write in the end

CE certification regulations and standards are not set in stone, but with the rapid development of science and technology, the market demands constant change and the deepening of safety and environmental protection knowledge in the dynamic update. For LED lighting manufacturers, paying close attention to changes in CE marking regulations is not an optional extra but a key point that can help customers.

SignliteLED is a factory specializing in the production of high-quality LED strip lights and LED tri-proof lights. Feel free to contact us if you need to obtain CE certification for your customized LED fixtures or if you are experiencing difficulties during the CE certification process.