LED strips are now one of the lamps we often use. This article mainly explains the main constituent materials of commonly used LED strips and how to identify high-quality LED strip products.

High voltage LED strip

Composition of high voltage LED strip

The so-called high-voltage LED strip is the led strip whose input is 220V mains power. Of course, it cannot be directly connected to AC 220V, and a power plug is also required, as shown in the figure below.

The structure inside this power head is extremely simple, it is a rectifier bridge stack, which rectifies the AC mains power into a non-standard DC power. LEDs are semiconductors and require direct current.

1. Flexible lamp bead board

The most important part is to paste an appropriate number of LED SMD lamp beads and current limiting resistors on the flexible circuit board.

We know that the voltage of a single LED lamp bead is between 3-5V; then, if more than 60 lamp beads are connected in series, the voltage can reach about 200V, which is close to the mains voltage of 220V, plus the resistor current limiting , so that the LED lamp bead board can work normally after being connected to the rectified AC.

More than 60 (of course, there are also 120, 240, nothing more than parallel connection) lamp beads are strung together, and the length is close to one meter. Therefore, high-voltage LED strips are generally cut at one meter.

The quality requirement of the flexible circuit board is to ensure the current load of a single string of lights within one meter. Because the current of a single string is generally at the milliampere level, the copper thickness requirements for high-voltage flexo plates do not need to be very high, and the use of single-layer single-sided panels will be more.

2. The wire

What connects each meter of LED strips is the wire. When the wire is running on high-voltage direct current, the voltage drop is very small compared to the 12V or 24V low-voltage lamp. This is why the high-voltage LED strip can be rolled 50 meters, or even 100 meters. The wires inlaid on both sides of the high-voltage LED strip transmit high-voltage electricity to each string of flexible lamp bead boards.

The quality of the wire is very important for the entire high-voltage lamp belt. Generally, the wires of high-quality high-voltage LED strips are made of copper wires, and the cross-sectional area will be relatively thick. Compared with the total power of high-voltage LED strips, they are more than enough.

But cheap and low-quality high-voltage LED strips will not use copper wires, but copper-clad aluminum wires, or directly aluminum wires, or even iron wires. The brightness and power of this kind of LED strip are naturally not very high, and the probability of the wire being burned out due to overload is quite high.

3. Potting glue

The wires of the high-voltage LED strip run high-voltage electricity, and it will be dangerous to encounter it, so the insulation must be done well. The general practice is to potting transparent PVC material plastic.

This kind of plastic has good light transmission, light weight, good plasticity, good insulation and heat insulation performance. With this layer of protection, the high-voltage LED strip can be used safely, even outdoors, even in wind and rain.

Here is a cold knowledge: because of the performance problem of transparent PVC plastic, it is not air after all, and there must be some attenuation of the brightness of the light strip. This is not the difficulty, the difficulty is that it also affects the correlated color temperature of the LED strip, which is the color temperature drift that is troublesome. Generally speaking, it will drift up to 200-300K. For example: if you use lamp beads with a color temperature of 2700K to make a lamp bead board, the color temperature after potting may reach 3000K. If you make it with a color temperature of 6500K, it will run to 6800K or 7000K after potting.

4. New constant current chip high voltage LED strip

With the rapid development of LED drivers and integrated circuits, the current high-voltage LED strips have used high-voltage constant-current IC.

What are IC? It means integrated circuit. Generally speaking, they are small rectangular black blocks with 4-8 pins on them.

With the help of these IC, the high voltage LED strip becomes much more stable. Even if the mains power is unstable, such as high peak voltage, grid pollution, etc., the normal operation of the LED strip can be guaranteed. Moreover, the emergence of high-voltage LED chips (SMD lamp beads with a voltage drop greater than 3-5V at both ends, in fact, is nothing more than multiple lamp bead chips connected in series on a lamp bead package), can also make high-voltage LED strips not limited to Cut one meter at a time. Now there are also 100mm cut high-pressure LED strips.

How to identify high-quality high-voltage LED strips?

Judging from the material:

1. Use high-quality lamp beads, resistors, and flexible boards with thick copper skin.

2. Use pure copper wire, and the cross-section of the wire is large. Try not to choose copper clad aluminum, or even aluminum, iron wire.

3. Look at the potting glue, which requires high transparency, good flexibility, uniform potting and no peculiar smell.

4. The power head with large chip bridge stack can make it less likely to burn out the lamp beads. Because the bridge stack has a current limit, for example, 4A, 6A. If a bridge stack with a small chip is used, it is easy to burn out the input head due to overcurrent.

5. When using, try not to fold the LED strip repeatedly. Folding the LED strip not only prevents the heat from the LED strip from dissipating, but also easily causes the deformation of the high-voltage line or the detachment of the lamp bead pad on the flex plate, which will cause the LED strip to not light up or burn out.

Judging from the optical parameters and power:

The larger the LED chip, the larger the margin when using the lamp bead, the better the light effect and the longer the service life.

For light parameters, a good LED strip needs to have the following items:

1. High luminous flux, the best light efficiency is also high. The luminous effect is the luminous flux from the unit power consumption. High luminous flux can be achieved by increasing the unit power of the lamp bead, but to ensure high luminous efficiency at the same time, the lamp bead chip must have a large chip.

2. It has accurate and stable correlated color temperature and low color tolerance. In this way, the LED strip looks very uniform in color and brightness.

3. Have a high color rendering index, such as 80 or more than 90. The color rendering index is the score to restore the original color of the object. 100 means that the color of the object under the sun is 100% restored. Of course, the light strips that are only used for backlight atmosphere effects do not require a high color rendering index, but as much luminous flux as possible. Because the color rendering index and luminous flux are generally inversely proportional.

Types of low-voltage LED strips

The low-voltage LED strip is mainly the flexible lamp bead board mentioned in the high-voltage LED strip, and it is equipped with different external materials, forming many different types, including the following:

Bare board

Generally, double-sided adhesive is pasted on the back of the lamp bead board to facilitate fixing on the surface of various installation materials.

Epoxy

Drop soft silicone on the front of the lamp bead board, and still put double-sided adhesive on the back. Compared with the bare board, this kind of epoxy lamp strip has slightly higher protection for the circuit and lamp beads.

Potting glue

Similar to the practice of high-voltage LED strips, the bare board of the lamp bead is potted with resin or transparent PVC plastic. This way can achieve a very good level of protection and can be used outdoors.

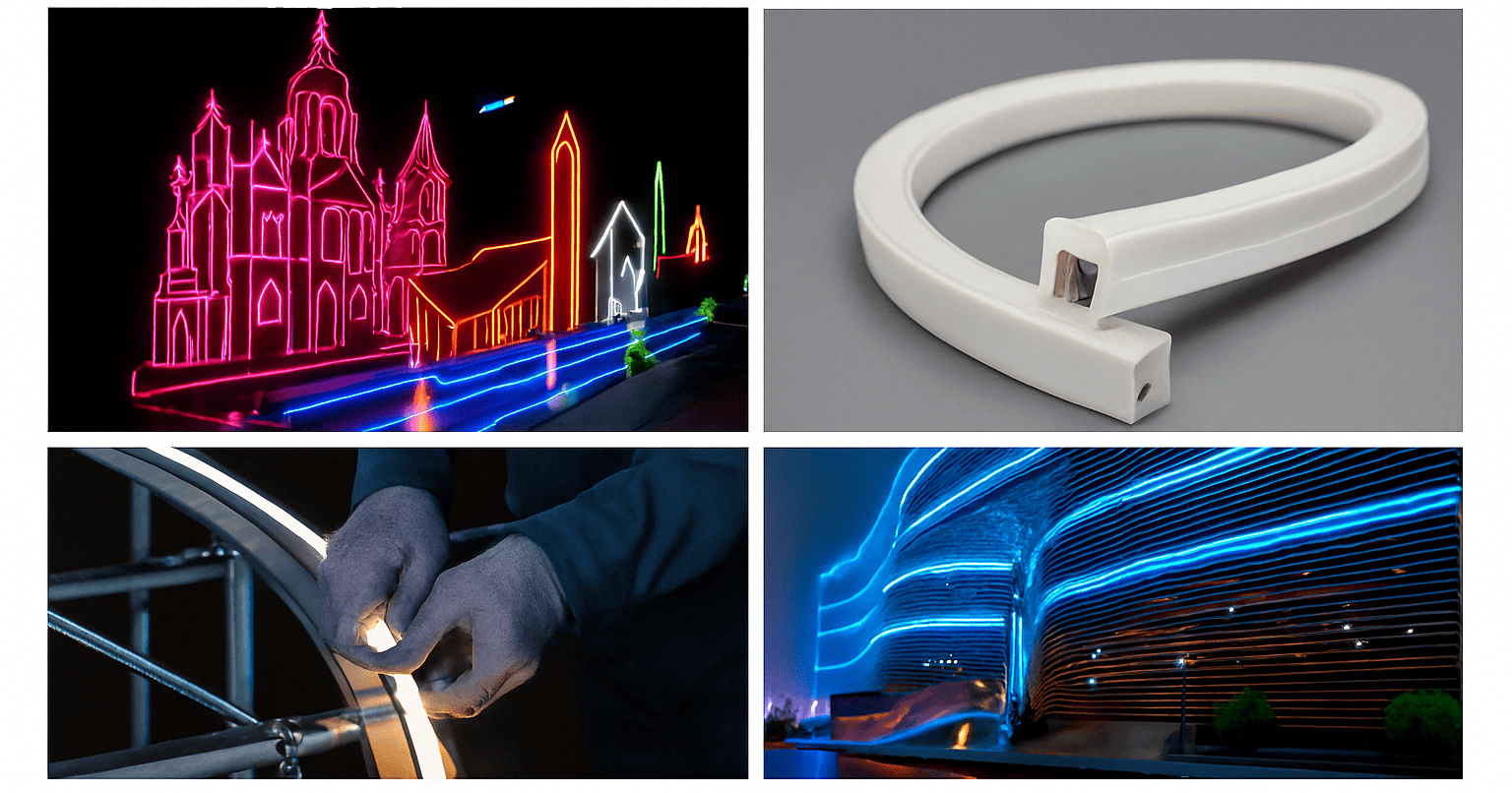

Casinge

Cover the bare board LED strip with a rectangular transparent silicone sleeve, and seal the plugs on both sides with silicone. Because silica gel has better performance than resin and PVC: more temperature resistance, more stability, excellent resilience, less deformation, high insulation, etc. Moreover, the sealed sleeve light strip can also be used in outdoor scenes, and even has an IP67 protection level.

Silicone

Similar to a sleeve, but wrapped in a thicker two-tone silicone. White silicone is used to cover the circuit board for a more aesthetic appearance. The milky white silica gel is used for light transmission. This kind of light transmission can soften the LED lights and form a coherent light strip. At the same time, it also has all the excellent characteristics of the sleeve light strip, so it is the best quality one of the LED strips.

Hard LED strip

Generally speaking, there are two kinds of hard LED strips, one is that the material itself is not a flexible board, but a glass fiber board or an aluminum substrate. Therefore, there is no free bending function of the flexible board, and it is generally used in straight line scenarios. The other is that the bare board of the flexible LED strip is pasted on the aluminum profile, and it is usually equipped with a soft light PC cover to achieve a more uniform and softer light effect.