LED strip lights are one of the best inventions in lighting. You can use them to decorate your artwork and home, illuminate kitchen countertops, and use them as stair lighting or holiday roof lighting. Since they come in long strips, you can cut them to the desired length or join them together for additional length. Especially when dealing with larger LED strip lighting projects, you often have to deal with multiple LED strip connections.

Connecting multiple LED strips together isn’t just for aesthetic purposes—the visual impact is truly remarkable. This unified power strategy allows for consistent control over the brightness and hue of the LEDs, creating a cohesive and dynamic lighting atmosphere. Whether the goal is to create ambient lighting, improve task efficiency, or simply introduce a splash of color, integrating multiple LED strips into a single power supply ensures a seamless blend of light.

When connecting multiple LED strips, you’ll face common problems such as loose connections, voltage drops, and inconsistent lighting. To avoid these problems, in this article we’ll cover the proper way to connect multiple LED strips and the factors that affect them.

Can I connect multiple LED strips together?

The answer is yes. However, there are some things you need to be aware of.

Firstly, if you have cut your LED strips before and want to reconnect them to the same strip, then you don’t need to worry about anything else. All you have to do is to continue using the extended LED strip in any of the ways we have mentioned in this article below.

Secondly, you can’t connect two different LED strips, i.e., one with single-color LEDs and the other with RGB LEDs. In this case, the LED strips are completely incompatible with each other, and you cannot connect them together. Furthermore, what if you have two strips of different brands? If they are compatible with each other, i.e., they have the same layout and both have the same voltage rating, then you can connect two LED strips of different brands.

Thirdly, the connection of multiple LED strips must have the same operating voltage, which is an important factor that needs to be emphasized. Because some LED strips have a working voltage of 5V DC, some LED strips have a working voltage of the more common 12V DC. and some LED strips have a higher working voltage, such as DC 24V, but 12V DC LED strips are very popular.

Why do I need to connect multiple LED strips?

Combining multiple strips is an excellent option for large LED strip installations. In addition to covering a wide area, this method offers several other advantages:

Extended coverage and full coverage: The main benefit of connecting multiple LED strips is that they can be extended in length as required. Typically, LED strips are supplied on 5-meter reels. You can connect multiple strips to fit a larger space to seamlessly cover the area. In addition, you can cut and join strips to fit corners and edges, ensuring sophisticated lighting even in curved or tricky spaces.

Increase brightness by connecting: Connect multiple LED strips for brighter, more impactful lighting. This method is great for illuminating dark areas and adding function and drama to your room.

Cost-effective solution: Using multiple LED strips is also a cost-effective option. You don’t need a lot of power adapters and outlets, which can reduce overall costs. In addition, by adding dimmers, you can adjust the brightness, reducing energy consumption and saving money.

Personalized lighting solutions: Connecting multiple LED strips gives you greater control over your lighting settings for a customized solution. For example, if you’re backlighting a mirror, you can cut the LED strip into four segments to match the size of the mirror. By powering all the strips from a single source, you can create a cohesive and customized lighting design. For a detailed guide to backlighting mirrors, check out our article A Guide for Mirror LED Strip.

Is it safe to connect multiple LED strips?

The answer is simple: it is safe. When connecting multiple LED strips, it is safe to connect multiple LED strips if certain precautions are taken to prevent overloading the LED power supply and to ensure compatibility between the LED strips and the power supply. However, if the LED power supply is overloaded, it can lead to dangerous situations, such as the risk of fire. In addition, problems with the LED strip itself can also pose a safety risk, such as low-quality LED strips.

One of the advantages of LED light strips is that they can be easily expanded by adding more light strips. To ensure safety when connecting multiple LED strips, consider the following key points:

Avoid overloading the power supply

Make sure that the total power consumption of the connected LED strips does not exceed 80% of the power consumption of the LED power supply. Overloading the power supply can lead to overheating and potential fire hazards.

Check voltage compatibility

Make sure that the power supply voltage is not lower than the voltage of the LED strip. If your LED strip is 24V, the power supply should also be 24V. If you use a 12V power supply for a 24V LED strip, it may cause a fire.

Use high-quality LED strips

Low-quality LED strips may contain inferior materials and construction, increasing the risk of operational problems and safety hazards. Choose high-quality LED strips from reputable LED strip manufacturers to ensure reliability and safety.

How to connect multiple LED strips together?

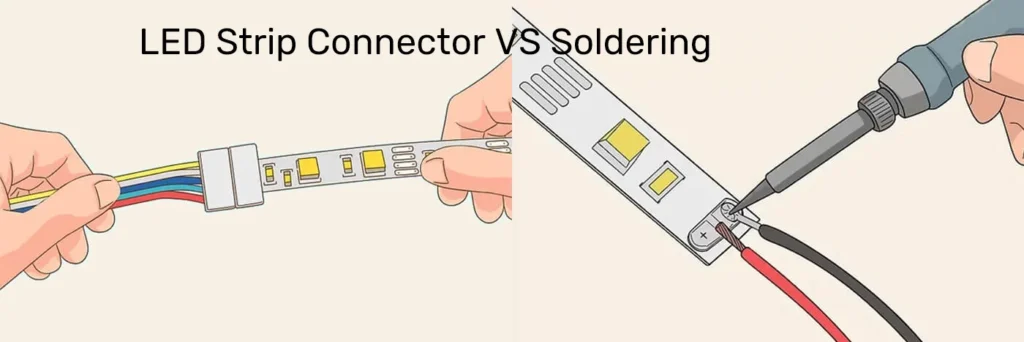

There are two main ways to connect multiple LED strips together: soldering or using LED strip connectors, which are easy to install. However, if you want a more permanent and secure connection, soldering is your best option. In addition, the wiring method you choose (whether series or parallel) is important, and the voltage rating and total run length of the LED strip are key factors to consider. In addition to this, the compatibility of the LED strip’s connectors is also important. If you use a connector that is not compatible with the LED strip model, the connection will fail.

Issues to consider when connecting multiple LED strips

When connecting multiple LED strips, there are a number of issues you must consider to ensure that the connection is effective and safe. For example, how many LED strips can be connected? Which connection method will be used? How do I make sure the LED strips are securely connected? Is there a voltage drop?

How many LED strips can be connected?

When connecting multiple LED strips, the first thing you should pay attention to is the maximum number of connections; in general, the number of connections is determined by the LED power supply, and the total power of the strip cannot exceed the power of the power supply. And it is better for the LED power supply to be 1.2 times the total power of the strip; follow the 80% rule to calculate the power you need, which can improve the service life of the LED driver and avoid burnout leading to a short circuit.

Here is the formula for determining the proper number of LED strips in an individual chain:

Number of strips = Power supply in watts / Power consumption per strip

So if the power supply is 500 watts and each LED strip consumes 100 watts, the number of LED strips required is:

Number of strips = 500 watts/100 watts = 5 strips

However, to ensure the longevity and efficiency of the power supply, please avoid loading the power supply to 100% and turn off 20% of the load to minimize the stress on the power supply. It is recommended to keep the load at about 80%. For example, if you want to connect 20 meters of RGB color-changing LED strips, generally LED strips are 5 meters per roll; that is to say, you need to connect 4 LED strips. If the total power of the 4 LED strips is 200W, then the power of the power supply and the controller needs 240W (200*1.2).

Which connection method is used?

There are two ways to connect multiple LED strips together: series connection and parallel connection.

Series Connection

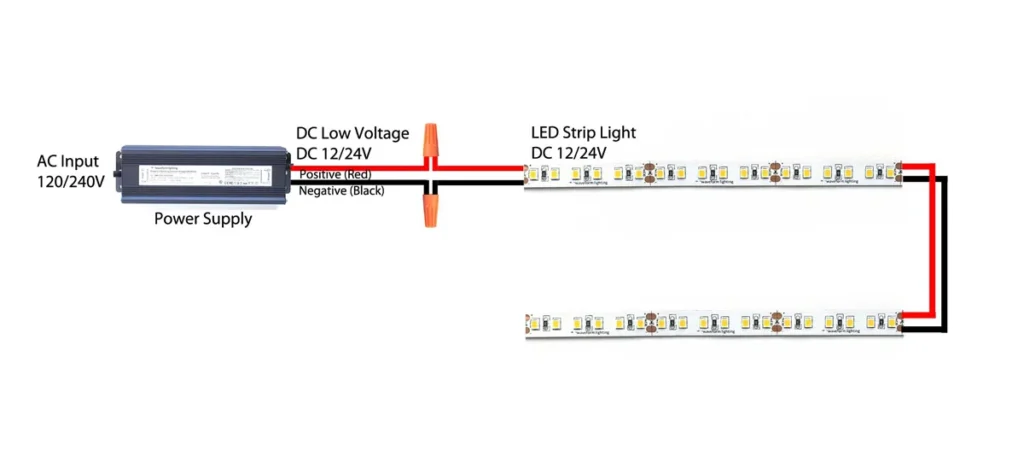

The easiest way to connect LED strips in series is to use LED strip connectors or solder to connect the end of one strip to the beginning of the next. This method does not require wiring each strip to a separate power source, making it easier for beginners and DIY projects. However, series connections are best suited for short-term installations because the voltage drops dramatically as the length of the strip increases. Since power is only supplied at one end, the voltage and brightness will decrease with distance, resulting in noticeable inconsistencies in brightness.

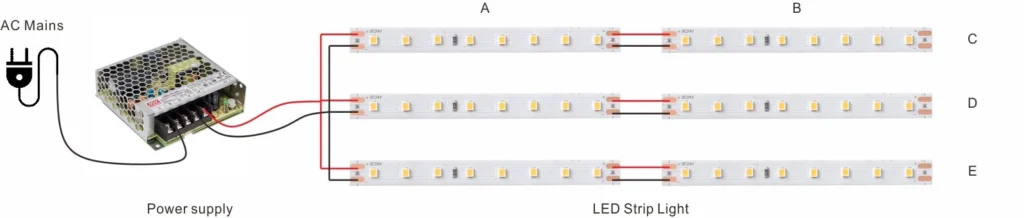

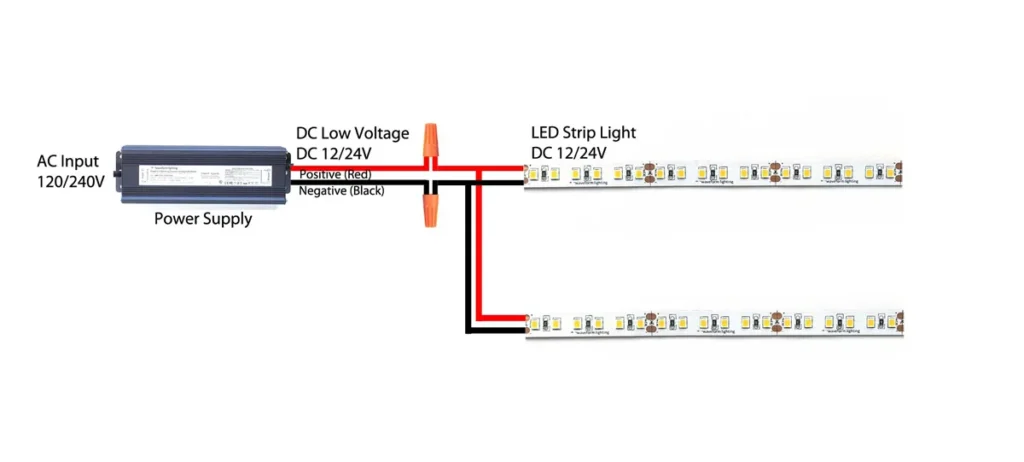

Parallel Connection

Parallel connection is the more specialized and recommended method of connecting multiple LED strips. In this setup, each strip is connected directly to the power supply, ensuring that each strip receives enough current to achieve consistent brightness. The main challenge with parallel connections is their complex wiring. You need to manage multiple wires from different points on the LED strip to the power supply. Most power supplies only have positive and negative output wires, so you have to split them into multiple connections. This can be tricky for beginners, and care needs to be taken to prevent voltage drops, especially when the strip is away from the power supply. Additionally, you may need to invest in thicker wires for longer runs, which makes this method more costly.

Which is better, series or parallel connection of multiple LED strips?

Whether series or parallel is better for connecting multiple LED strips depends on several factors. These include the voltage of the LED strip, the total run length, consistent brightness, and ease of installation.

If you have high-voltage LED strips, you can connect them in series. Even if you have low-voltage LED strips, you can still string multiple strips unless there is no serious voltage drop. However, if you run them for a long period of time, a voltage drop may occur. In this case, series connection is not recommended.

Connecting in parallel provides more even illumination and is ideal for larger installations. Therefore, even if too many LED strips are connected, all strips will receive the same voltage. This is because each LED strip is connected to the mains via a parallel circuit. While this provides consistent lighting from one end to the other, it can be difficult to install. You’ll need extra wiring, multiple power supplies, and professional help to make parallel connections. This makes parallel installations more costly than series connections.

How to ensure a solid connection of the LED strip?

Whether the LED strips are connected in series or in parallel, a solid connection is of utmost importance. If the connections are not strong enough, they will come loose, breaking the circuit and causing the LED strip to go out. Therefore, you should pay close attention to the firmness of the connections. It is easier and more convenient for newbies to use LED strip light connectors, but they are not as strong. And, over time, the connection may be lost. In addition, the heat generated by LED light strips may melt the plastic connectors and make them loose.

Therefore, if you want a stronger connection, solder it. Although this requires specialized skills, you will get a permanent solution. However, soldering requires heating the iron and pre-coloring, which makes the process tricky for beginners. However, it will provide a strong connection and minimize the chances of disconnections.

Voltage drops that have to be considered

When you connect multiple LED strips in series, you will notice that the brightness and color of the LEDs will dim as the length of the strip increases when using a single power supply because of the voltage drops that are present in the LED strip.

The length of the LED strip relates to the voltage of the fixture. Low-voltage LED strips support shorter lengths. For example, 12V LED strips can provide uniform illumination for up to 5 meters. As the length increases, they begin to face serious voltage drops. To ensure that the LED strips are equally bright, you can add another power supply or connect an LED amplifier at the end. The amplifier is placed between the two LED strips and should be connected to a separate power supply. You can check this article to learn about voltage drop on LED strips and its solutions: Voltage Drop on LED Strips: Causes and Solutions

How to connect?

There are two ways to connect LED strips: soldering or using LED strip connectors. Which one is better for you? You can choose according to their advantages and disadvantages.

Soldered

Soldering is a more stable method than using LED strip connectors. The performance of the LED strip is almost the same before and after soldering, and the operation of the LED strip is hardly affected. However, it requires you to have soldering tools and some soldering skills. With these, you can get a more permanent and durable connection than with ribbon connectors. Here is the procedure for this method:

Step 1: Keep your soldering iron tip clean. Rubbing the tip of the soldering iron on a sponge soaked in water will not only cool it down temporarily but also remove any excess tin from the tip of the soldering iron, being careful not to burn your hands.

Step 2: Hold the wire in your left hand and the soldering iron in your right hand. Remember to wear gloves when soldering. Do not inhale odors that are harmful to your health.

Step 3: Gently touch the tinned part of the wire to the soldering point of the LED strip. Tap gently with the soldering iron and be careful that the tip of the iron touches both objects at the same time.

Step 4: Leave it for a few seconds and then leave it at a 45° angle.

Step 5: After sticking firmly, connect the power and see if the strip can light up.

Using LED Strip Connectors

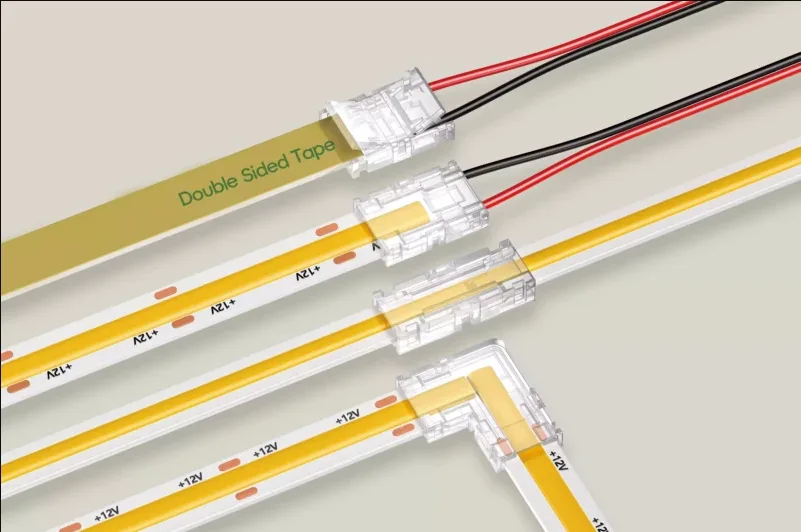

There are several types of LED strip connectors. To connect multiple LED strips, you need LED strip connectors for strip lights, strip wires, and strip power. Here’s how to effectively use the connectors to connect multiple LED strips:

Step 1: Selecting the Right LED Strip Connector

First, determine the type of LED strip you are using, as this determines the connector’s pinout. For example, a single-color LED strip requires a 2-pin connector, while an RGB LED strip requires a 4-pin connector. Also consider the width of the LED strip to ensure that the connector fits correctly. If your LED strip is waterproof, select an IP67 or IP68-rated connector to maintain a watertight seal.

Step 2: Prepare and Connect the LED Strip

LED strips usually come with an adhesive backing for ease of use. First remove the tape from the ends of the strip to be connected. Attach the connector to one end of the LED strip and then attach it to the other strip. During this process, make sure that the positive and negative markings on the LED strip are aligned with the markings on the connector to avoid any electrical mismatch.

Step 3: Protecting the Connection

After connecting the LED strip, snap the supplied plastic cover over the connector to secure the fitting. This cover helps protect and seal the connection. Press firmly on the cover to ensure it seals tightly. You are now ready to install the extended LED strip setup in the selected location.

Which is better, solder or LED connectors?

LED strip connectors and soldering are two methods of connecting LED strips together. They are both effective methods of connecting LED strips, and the choice depends on the needs of the installation project. Soldering is generally more durable and may be suitable for more complex installations, whereas LED strip connectors are easier to install and customize, making them ideal for simpler installations or projects that require frequent modifications. Here are some of the differences between them:

LED Strip Connector:

1. no soldering or special skills or tools required for installation

2. allows for easy and quick customization and modification of LED strips

3. can be quickly installed or removed without additional tools

4. Safe to use, avoiding the risk of burns or other injuries

5. Provides a safe and reliable connection when installed correctly

6. More suitable for simpler LED strip installations

Soldering:

1. requires soldering iron and soldering skills

2. Provides a permanent connection that is difficult to modify or undo

3. is time consuming and requires additional tools and materials

4. requires care to avoid burns or other injuries

5. can provide a strong and reliable connection if done correctly

6. suitable for more complex LED strip installations

Types of LED Strip Connectors

Connector type is a key consideration when using LED strip connectors to connect multiple LED strips. LED strip connectors are available in a variety of types and styles. Common types include solderless connectors that are easy to connect, such as snap-in and plug-in connectors; waterproof connectors for wet locations; and angle connectors for angled installations, each designed to meet specific needs and installation requirements. Each connector is designed to meet specific needs and installation requirements. They can be either gapless pin connectors or jumper connectors. Gapless pin connectors have pins that are inserted into the end points of the LED strip. In this way, they form a continuous strip flow connecting several LED strips.

Depending on the PIN, there are several types of LED strip connectors, and each of these PIN connectors is designed for a specific LED strip variant:

- 2-pin connectors: for single-color LED strips, white, red, green, etc.

- 3-pin connector: for bicolor LED strips, color-selectable strips, CCT-adjustable strips (CCT adjustable), and addressable RGB strips (SPI, e.g., WS2811, WS2812).

- 4-pin connector: for RGB LED strips.

- 5-pin connector: for RGBW LED strips, addressable RGB strips (DMX512).

- 6-pin connector: for RGBWW, RGBCW, and RGBCCT LED strips.

Furthermore, the LED Strip Connectors are available in different widths to match the corresponding LED Strip size, ensuring a secure fit and reliable connection, including:

- 5 mm width LED strip connectors.

- Connectors for 8mm-wide LED strips.

- Connectors for 10mm-wide LED strips.

- Connectors for 12mm-wide LED strips.

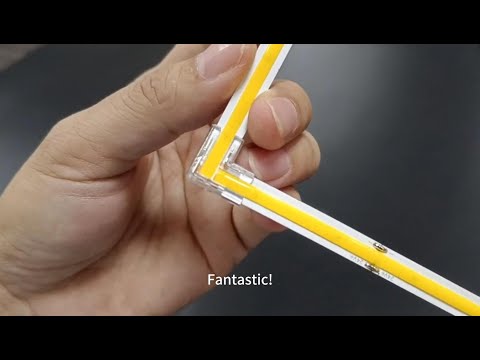

Besides, if you consider the shape and function of strip connectors, they can be COB LED strip connectors, LED strip 90-degree connectors, Hippo-M LED strip connectors, and so on. For more information about LED connectors, please check the article: How to Choose the Right LED Strip Connector

Connecting multiple LED strips to an LED power supply

You can connect multiple LED strips directly to the power supply using sockets, or you can use an LED strip distributor. If you choose to connect directly, there is nothing new to learn. But in this case, you may need more than one power supply. For this reason, LED splitters are a good option. LED splitters easily eliminate the complexity of connecting multiple LED lights, and these splitters are equipped with multiple outputs that make it easy to converge individual LED strips into an overall lighting package. This technology is especially beneficial for those looking for a quick and easy installation process.

LED splitters enable multiple strips to draw power from a unified source, ensuring consistent brightness and chromatic uniformity. It doesn’t require complex wiring or in-depth electrical knowledge; the process is as simple as taking the distributor wire at one end and connecting the LED strips. You can make this connection in series and parallel and then plug the other end of the LED dispenser into a power supply unit (PSU).

However, when connecting the LED strip to the power supply, make sure that the power consumption and voltage ratings are compatible. Also, keep the number of LED strips in the chain within 80% of the power requirement. To be on the safe side, always save 20% of the power load instead of putting in 100%.

Conclusion

The beauty of LED strips is that you can easily cut them to the desired length and add additional strips to increase the length. Connecting multiple LED strips requires careful consideration of wiring methods, voltage drop, and connection reliability. By choosing the right wiring methods, connectors, and power supplies, you can ensure that your lighting project is illuminated safely and efficiently.

So, after considering all these factors and connection methods, if you want constant brightness and more specialized wiring, choose parallel wiring, but if you are not an expert and want a simple installation, use series wiring. For connecting LED strip lights, LED strip connectors are a simple solution. Whether you choose strip connectors for convenience or solder for durability, following best practices will result in a reliable lighting setup.

SignliteLED offers LED strips in different types and widths and a variety of LED strip connectors, as well as LED drivers and LED controllers to enhance your lighting project. With our comprehensive line of high-quality LED products, we offer all the necessities to efficiently connect multiple LED strips.