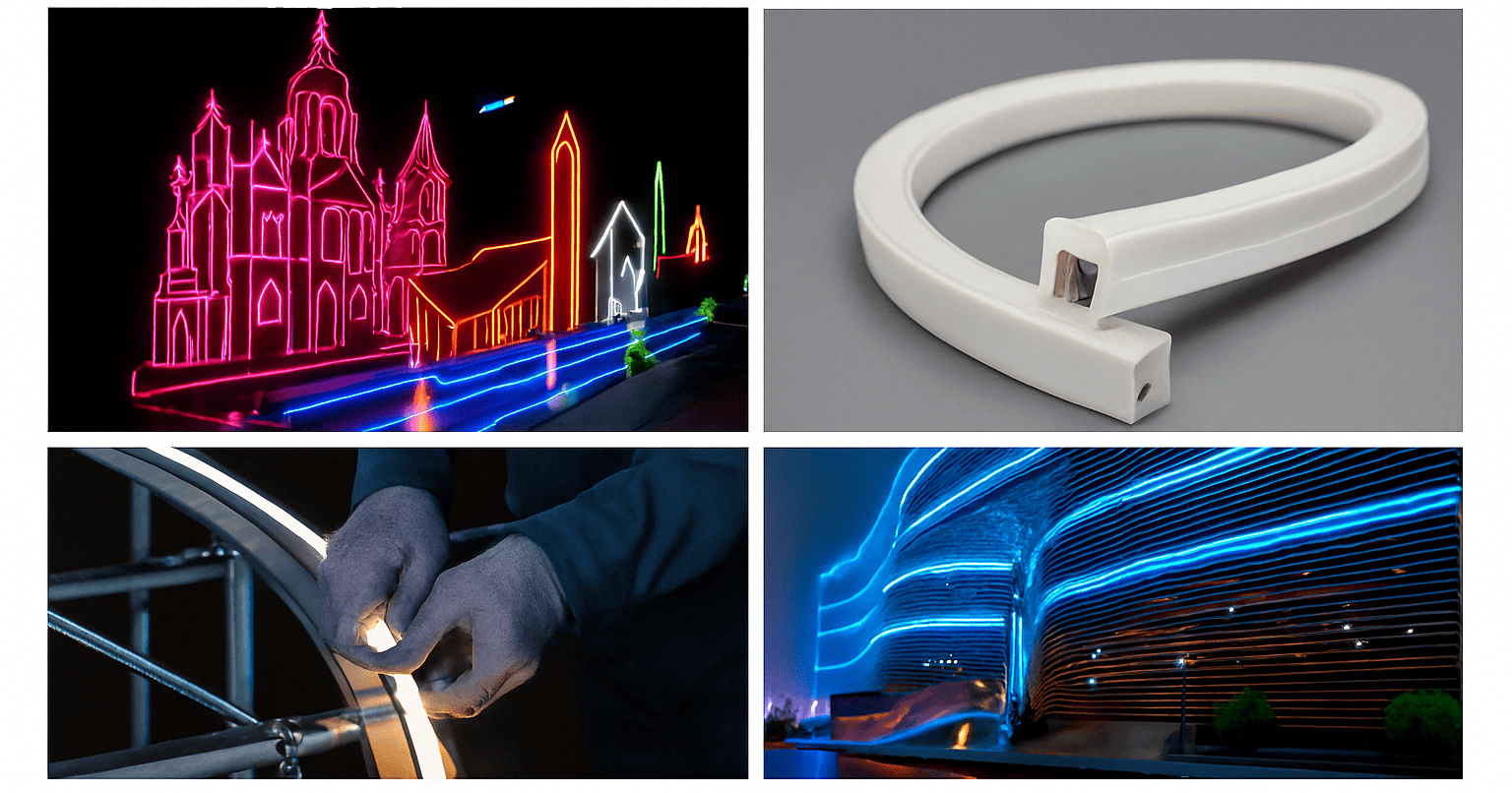

Twenty years ago, all cabinet signs and pylon signs were fluorescent, leaving many older signs without LED lighting, while newer illuminated signs like cabinet signs, pylon signs, and custom signs utilize LED lighting. Therefore, it was imperative to retrofit older signs, such as pylon signs, cabinet signs, and monuments, from fluorescent to LED. These large signs have been around for 20–40 years, and they require a variety of services, which is a challenge.

According to the U.S. Department of Energy (DOE), linear fluorescent lighting accounts for more than three-quarters of the energy used by commercial signs and commercial buildings. So you can imagine how much energy you could save by switching to energy-efficient lighting options like LEDs.

LEDs are an extremely energy-efficient source of lighting. According to the U.S. Department of Energy, LEDs (especially ENERGY-STAR certified LEDs) use at least 75 percent less energy than incandescent bulbs and last up to 25 times longer. By 2027, continued use of LEDs could save nearly 348 TWh of electricity. So, you should consider an LED retrofit to increase the market value and economics of your cabinet signs and improve energy efficiency.

What is LED Retrofit?

The word “retrofit” means “conversion,” and LED retrofit means upgrading your current lighting to low-cost, energy-efficient LED devices. So, in an LED retrofit, you’re converting outdated lighting technology (such as CFLs, fluorescent lights, and HIDs) to advanced lighting technology (such as LEDs).

While sign retrofitting is the process of upgrading or retrofitting an existing sign to improve its performance, energy efficiency, or functionality, LED sign retrofitting involves replacing traditional lighting fixtures with LEDs. This typically involves replacing outdated components, such as lighting fixtures, bulbs, or electrical systems, with newer, more efficient technology.LED lighting works differently than traditional incandescent lighting, which relies on thin metal filaments to emit light. Instead, LEDs use semiconductor diodes, through which an electric current is passed to produce light without wasting a lot of energy-generating heat. This unique design allows LED bulbs to emit the same amount of light as incandescent bulbs while consuming less energy.

LED retrofits can also include adding new features or upgrading cabinet signage to meet current standards or regulations. Overall, a signage LED retrofit can improve the effectiveness, longevity, and sustainability of your signage while minimizing cost and environmental impact.

LED Retrofit: What to Consider

There are many reasons to consider an LED retrofit for your cabinet signage. In addition, not every cabinet sign or other type of advertising sign needs an LED retrofit. Therefore, here are some questions you can consider to determine if your sign needs an LED retrofit:

- Do you want to reduce the energy costs of lighting your cabinet signs?

- How old is your sign’s lighting technology?

- Are you spending more money on maintenance of your cabinet sign’s existing lighting system than you originally anticipated?

- What is your daily lighting energy consumption?

- Are “sustainability” and “the environment” top priorities for your business?

- How old is your signage?

- Would you like to have better control over your lighting system?

- Do you receive any financial incentives from the government or local authorities?

Conversion of Fluorescent Lamps to LED Sign Tubes

Converting fluorescent lamps to LED cabinet signage will save you a lot of money. Electricity may be the first thing that comes to mind, but repairs and maintenance are a much bigger expense. Fluorescent lamps have a life expectancy of about 10,000 hours, which sounds like a long time, but running them 10 hours a day will require replacement in less than 3 years. Ballast and other damage can also occur, which also requires many repairs. These repairs can cost thousands of dollars each time, using a crane or other aerial vehicle. And to add to the problem, replacing one part usually leads to replacing another, which can be expensive.LEDs aren’t perfect, but they can greatly reduce repairs and extend the life of the sign.

The conversion from fluorescent to LED lights has dramatically improved the efficiency and sustainability of LED sign cabinets. Our 360 LED sign tubes offer many benefits and are the ideal LED retrofit kit solution for retrofitting T12HO and T8HO fluorescent lamps.

LED sign tubes offer a variety of benefits, including:

Multiple energy savings: The LED sign lamp is much more efficient, and with its ballast bypass design, you can replace 580W fluorescent tube with 280W sign tube for a 5’x10′ lighting box, saving over 60% energy.

Easy installation: We put an internal driver inside this LED sign bulb; no external driver is needed. For new sign installation, insert it in and turn it on; that’s it. For retrofits, still use the existing R17D sockets; just remove the ballast and connect it directly to the AC circuit.

360° beam angle: Unlike other LED solutions, this LED retrofit sign tube is specifically designed for cabinet signs. The use of an optical lens makes it cover wider illumination areas and eliminates hot spots, which presents better ADs to customers.

Last longer: Based on high standards, this cabinet retrofit led tube is built to last 50000 hours, or around 5 times as long as a fluorescent tube. Evaluated to UL 48 and UL 879A standards, with a 5-year warranty.

LED Retrofit Tubes Sized to Match Fluorescent Lamps

As fluorescent tubes are often fitted to cabinet or pylon signs and connected directly to the mains supply, and many cabinet or pylon signs are often very tall, they are relatively expensive and difficult to replace completely. Therefore, it is often most economical to replace fluorescent tubes with LED tubes of the same size.

For this reason, it is important to know the types and sizes of fluorescent tubes that have been developed so that the correct LED tube can be retrofitted in the proper location.

Over the years, fluorescent tube manufacturers have developed a wide range of sizes and types.

- T8HO Fluorescent Fixtures: 4-foot and 8-foot T8 fluorescent fixtures are by far the most common types used for cabinet lighting. They are available in lengths of 48 inches and 96 inches, with a lamp diameter of 1 inch.

- T12HO Fluorescent Lamps: T12 fluorescent lamps are less efficient than T8 lamps. They are the same length as T8 lamps but have a larger lamp diameter of 1.5 inches.

T8HO and T12HO fluorescent tubes are also available in other lengths, such as 8-foot tubes (F96T12DHO), but 4-foot lengths are still the most common type.LED retrofit tubes replicate the mechanical dimensions to ensure that they can be true retrofit replacements and use the same form factor designation (e.g., 4-foot T8 LED tubes).T8 and T12 fixtures are typically the same length and use the same pins, so T8 and T12 fixtures are usually the same length and use the same pins. T8 and T12 fixtures are typically the same length and use the same pins, so mechanically they are often cross-compatible.

Ballasts for Fluorescent Lamps and LED Retrofits

All fluorescent tubes use a device called a ballast to regulate the brightness of the lamp when it is warmed up, and these devices are required for fluorescent lamps.

Fluorescent light fixtures usually have the ballast mounted inside the signage, and the ballast cannot be accessed without opening the signage. Only personnel familiar with electrical work should retrofit fluorescent ballasts.

UL Type A: Ballast Compatible

Commonly known as “UL Type A” designs, these LED lamps are designed to be compatible with fluorescent ballasts. They are the most straightforward to implement, as they do not require rewiring of fluorescent fixtures. UL Type A LED tubes are essentially the same as fluorescent lamps and are simple to replace.

Ideal for: consumers who are uncomfortable with or do not want to avoid working with wires and lighting fixtures with high electrician labor costs.

Cons: Fluorescent ballasts can fail, requiring ongoing maintenance and eventual replacement or bypassing of the ballast; potential problems with fluorescent ballast compatibility; overall electrical efficiency is lower due to the ballast.

UL Type B: Ballast Bypass

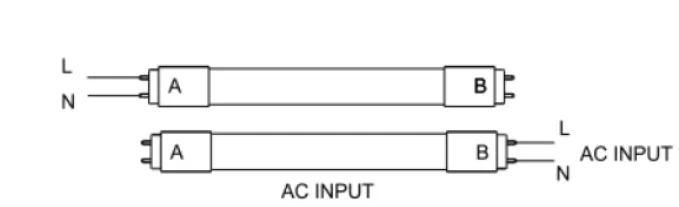

LED tubes with “UL Type B” specifications are not compatible with fluorescent ballasts. They cannot be used with fluorescent ballast and must be connected directly to the mains. However, the LED driver is integrated into the LED tube itself. UL Type B LED tubes can be further categorized as single-ended or double-ended.

In the single-ended configuration, only the two pins at one end of the lamp are used (one pin = Fire; one pin = Zero), while the two pins at the other end have no electrical function and are only used to hold the lamp in place. For single-ended configurations, the orientation in which the lamp is mounted is important; incorrect configurations may result in the lamp not lighting up, or there is a potential risk of fire. Single-ended configurations usually have a label on one end of the lamp that says “AC Input” or similar.

In a double-ended configuration, both pins on both sides of the lamp are of the same polarity. Therefore, the lamp holder on one end of the lamp must be connected to [neutral] and the other end must be connected to [live].

Ideal for: Installations where rewiring is an option; greater efficiency and lower maintenance costs.

Disadvantages: Requires familiarity and understanding of fixture wiring and electrical safety.

UL Type C: Remote Driver

UL Type C LED tubes are relatively rare but offer maximum flexibility and efficiency for lighting systems. Unlike UL Type B LED tubes, these tubes do not have an integrated LED driver, so a separate LED driver device needs to be connected between the LED tube and the mains supply.

Ideal: Minimal maintenance costs as the LED driver can be replaced without replacing the entire LED tube; more LED driver options such as 0-10V dimming and other IoT connectivity.

Cons: Requires the most electrical work as fluorescent ballasts need to be removed and replaced with LED drivers.

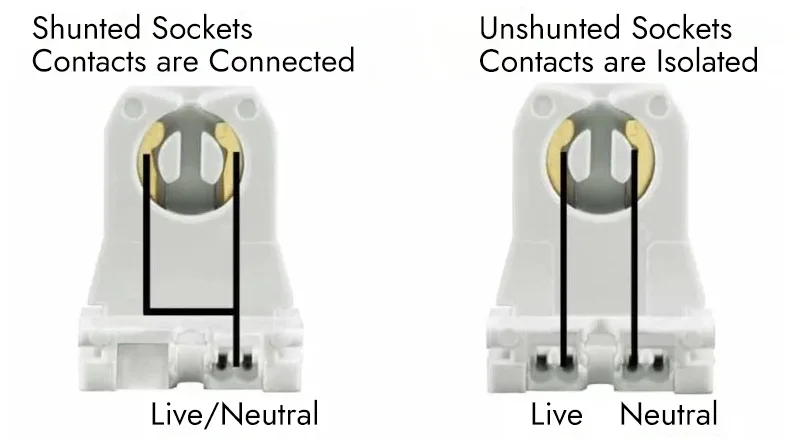

Shunted vs. Non-shunted Sockets

Sockets are lamp holders where LED tubes are mounted to provide mechanical support and current. Sockets have two electrical contacts that match two pins on the fluorescent/LED tube. The two electrical contacts can be:

1. not connected to any power source

2. One connected to the fire wire and the other to the zero wire

3. Both connected to either the fire or zero line

Scenario 2 is called a non-shunt, while Scenario 3 is called a shunt. A “shunt” is the combination of two separate circuits into one. The result of a shunt is that both socket contacts are connected to the same polarity.

Generally, fluorescent fixtures that have never been modified for LEDs or instant start ballasts have non-shunted sockets, while fluorescent fixtures that have been modified for LEDs or instant start ballasts may have shunted sockets.

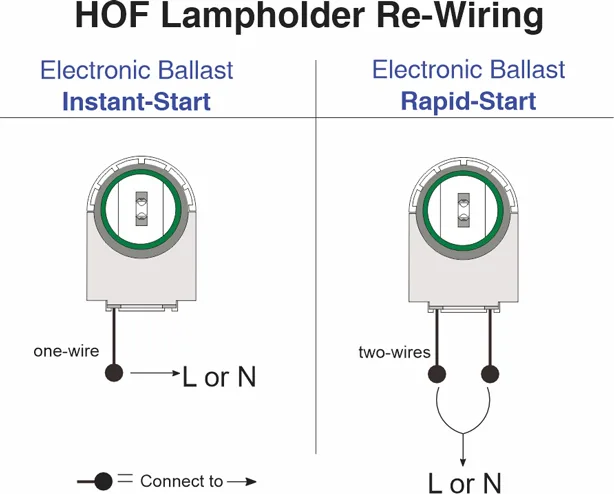

Sometimes the socket is externally shunted, as shown above, where the wire input is open on one side only. However, in some cases, the receptacle may be internally shunted, where the wire inputs on both sides are open but connected inside the receptacle.

Since some receptacles are internally shunted, visual inspection of the receptacle will not provide definitive results. We strongly recommend testing both receptacle contacts with a voltmeter to determine if a closed or open circuit exists. A closed circuit will indicate a shunted receptacle.

How to Convert Fluorescent Cabinet Signs to LED Tubes

Converting fluorescent cabinet signs to LED tubes is a very simple retrofit process that should follow local electrical codes and standards.

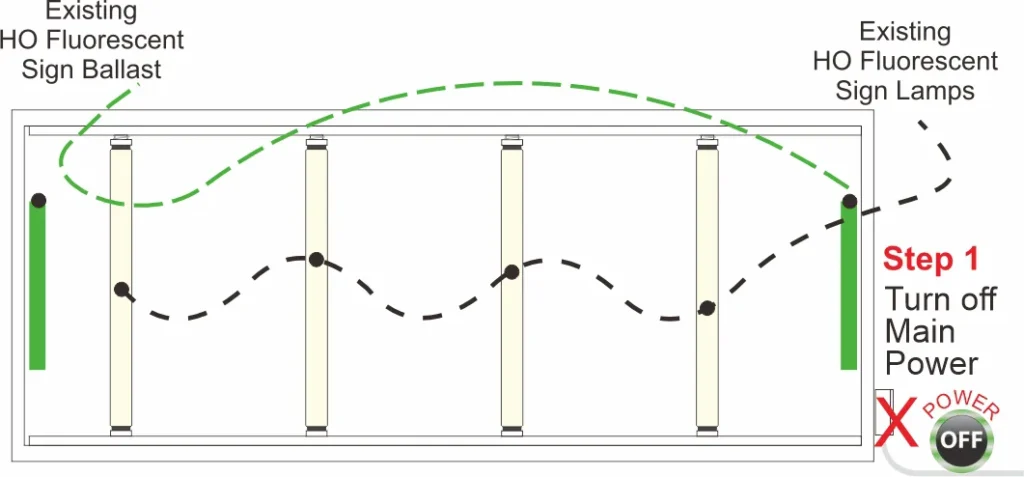

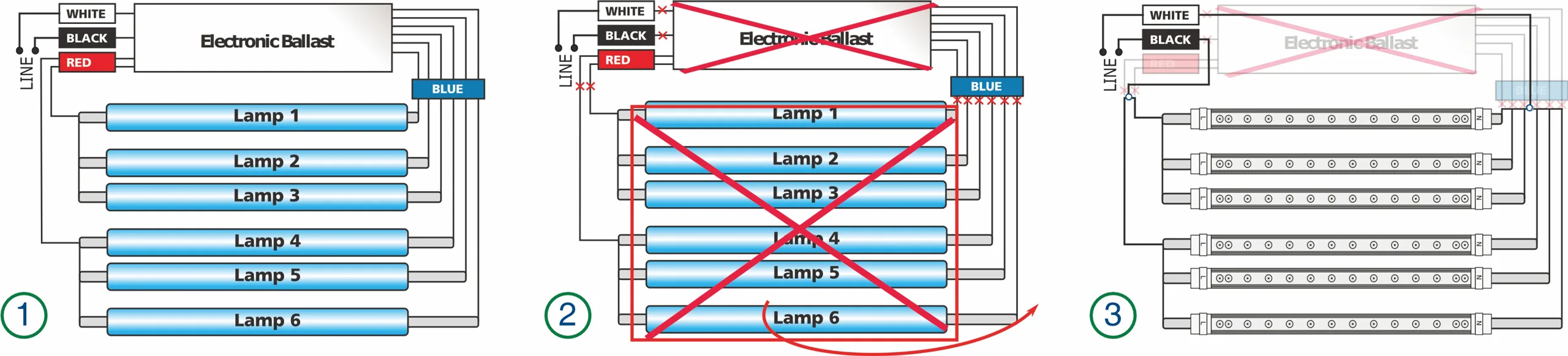

Step One: turn off main power to the sign or sign’s branch circuit. In the event that there is no Disconnect Switch one should be added to meet code. Ensure proper grounding is bonded to the sign enclosure.

Attention: There should be NO Power ever to the lampholders for any reason during installation!

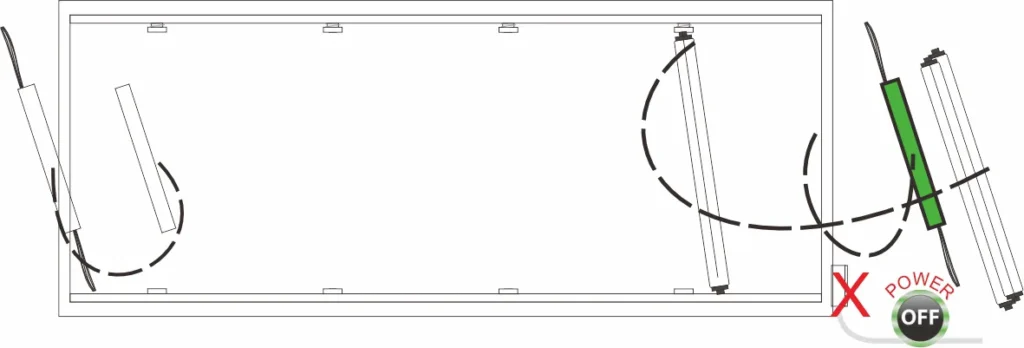

Step Two: remove all of the HO Lamps and Ballasts and dispose of them in accordance to local regulations. Do NOT disconnect existing wires from the lampholder terminals as you will need them again in step four.

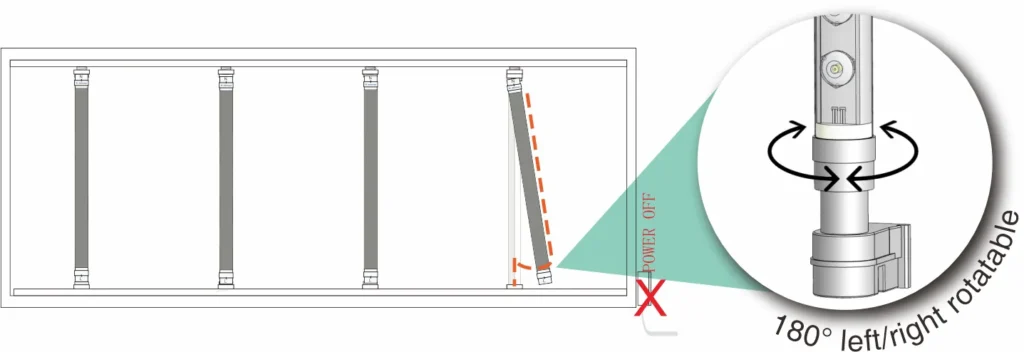

Step Three: install each LED sign tube into the lampholders by inserting one end into the “spring lampholder” then compressing the spring enough to swing the lamp to the opposite end and into the fixed lampholder.

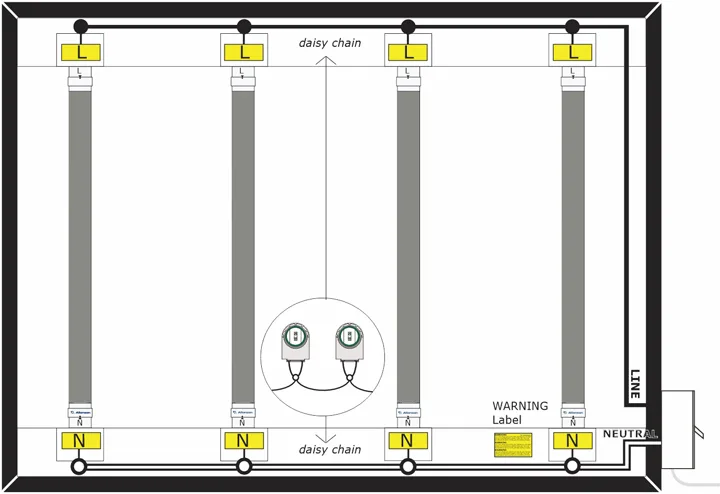

Step Four: re-wire the HOF lampholders. Ensure all lamps are oriented in a consistent manner, such that all sides of the lamp that are marked “LINE (L)” are connected into lampholders on the same side of the sign box and the “NEUTRAL (N)” sides are connected on the opposite side.

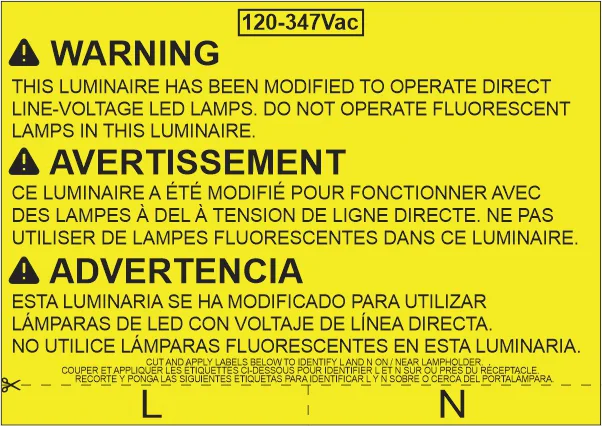

Step Five: Apply the yellow safety sticker, provided in the package, where directly visible (i.e. near the switch or on the raceway).

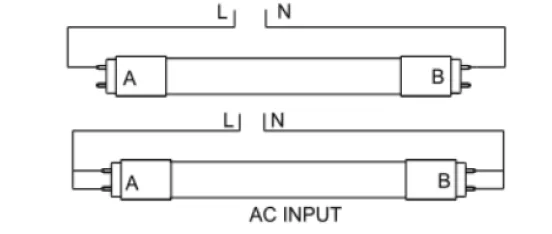

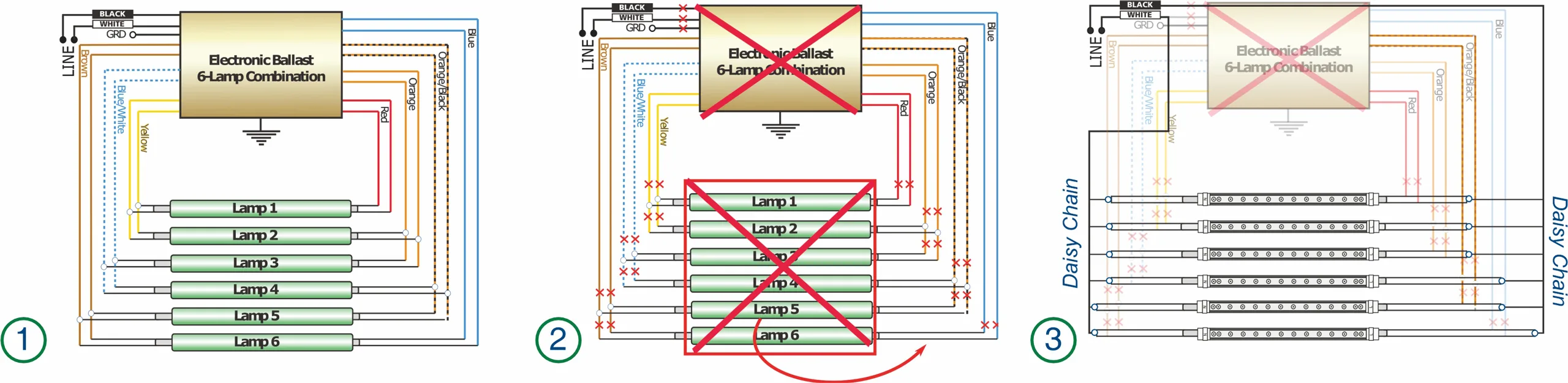

Parallel Connection Wiring Diagram(For retrofitting of signs with Instant-Start Ballast)

Series Connection Wiring Diagram (For retrofitting of signs with Rapid-Start Ballast)

Conclusion

LED signage retrofits offer numerous benefits to businesses looking to enhance their signage. By upgrading to LED technology, businesses can enjoy increased visibility, greater energy efficiency, and lower costs. LED signage offers brighter, more vivid displays, ensuring greater visibility during the day and night.

In short, if you are considering converting your existing signage to energy-efficient LED lights or if you are thinking of purchasing a new LED-illuminated signage cabinet, the decision is simple. The price is not much more expensive than converting your signage with HO T12 bulbs and ballasts. The relatively small additional cost is outweighed by the huge savings the sign will experience over the next five to ten years of operation. So if you are hesitant to make the switch or if you just need a complete professional quote to convert your illuminated signage to LED, SignliteLED can help you and your organization.

SignliteLED is a China LED linear lighting and LED signage lighting company specializing in LED strip lights and LED signage light sources. All of our products are tested and engineered for extreme weather and longevity. Contact us today for a free consultation.