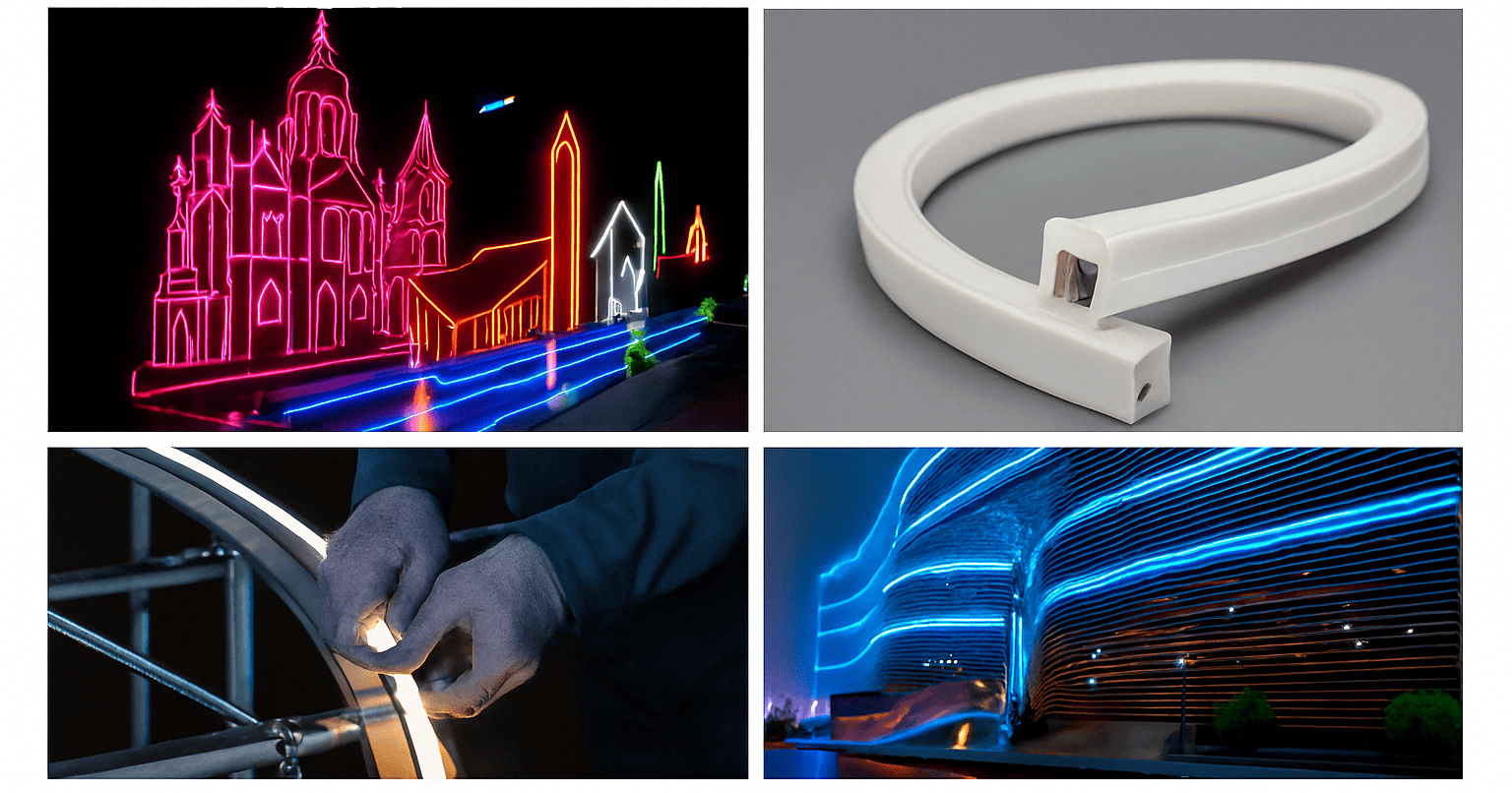

In the world of decorating and lighting, LED strips are a popular choice for modern homes and commercial locations due to their flexibility and versatility. However, choosing the right adhesive tape is vital to ensure that these strips can be securely installed and remain stable for long periods of time.

With so many adhesive tapes to choose from, the 3M VHB range stands out as the preferred choice for installing LED strip lights.

Why is 3M VHB the best choice for LED strip lights?

Strong adhesive properties

3M VHB adhesive tape (known as 3M Very High Bond Tape) has excellent adhesion to LED strip lights and can be applied to glass, metal, plastic, and other common substrates quickly and securely to hold the strip lights in place for a long period of time and is not prone to loosening or falling off.

Outstanding Weather Resistance

LED strips are often installed outdoors (such as on building facades and park landscape lighting) or in indoor variable environments (such as warehouses and workshops). 3M VHB adhesive tape is resistant to high and low temperatures; the summer sun does not soften the viscosity of the direct sun, cold winter temperatures do not make it brittle and hard, and a wet, rainy environment can maintain the sealing and bonding properties.

Convenient installation and aesthetics at the same time

Compared with the traditional screw fixing method, using 3M VHB tape for installation will not leave obvious holes in the substrate like screws, which will affect the overall aesthetics. It can make the whole LED strip light installation look neater and more beautiful and realize the non-marking and solid installation effect, which can be perfectly integrated into various decorative styles.

What is 3M VHB Tape?

3M VHB (Very High Bond) tape is a double-sided foam tape known for its superior adhesive properties and reliability. Developed by 3M and designed for applications that require a high strength bond, whether it is for industrial use or domestic decoration, VHB tape not only provides a long-lasting bond, but also adapts to a variety of surfaces and environments.

| Model No. | Specifications | Price(per meter) |

| 3M 9495 300LSE | Width 8mm, 110m/roll, thickness 0.17mm | USD $0.056 |

| Width 10mm, 110m/roll, thickness 0.17mm | USD $0.070 | |

| Width 12mm, 110m/roll, thickness 0.17mm | USD $0.084 | |

| 3M 9472 300LSE | Width 8mm, 55m/roll, thickness 0.13mm | USD $0.114 |

| Width 10mm, 55m/roll, thickness 0.13mm | USD $0.143 | |

| Width 12mm, 55m/roll, thickness 0.13mm | USD $0.171 | |

| 3M 9448A | Width 8mm, 100m/roll, thickness 0.14mm | USD $0.048 |

| Width 10mm, 100m/roll, thickness 0.14mm | USD $0.059 | |

| Width 12mm, 100m/roll, thickness 0.14mm | USD $0.071 | |

| 3M 9080A | Width 8mm, 50m/roll, thickness 0.16mm | USD $0.045 |

| Width 10mm, 50m/roll, thickness 0.16mm | USD $0.055 | |

| Width 12mm, 50m/roll, thickness 0.16mm | USD $0.066 | |

| 3M 93015 300LSE | Width 8mm, 55m/roll, thickness 0.15mm | USD $0.053 |

| Width 10mm, 55m/roll, thickness 0.15mm | USD $0.065 | |

| Width 12mm, 55m/roll, thickness 0.15mm | USD $0.078 | |

| 3M 5604A | Width 8mm, 33m/roll, thickness 0.4mm | USD $0.171 |

| Width 10mm, 33m/roll, thickness 0.4mm | USD $0.216 | |

| Width 12mm, 33m/roll, thickness 0.4mm | USD $0.259 | |

| 3M 5925 | Width 8mm, 33m/roll, thickness 0.64mm | USD $0.371 |

| Width 10mm, 33m/roll, thickness 0.64mm | USD $0.464 | |

| Width 12mm, 33m/roll, thickness 0.64mm | USD $0.559 |

Features

- Strong adhesive: Made from 3M VHB adhesive

- Waterproof & weatherproof: Adheres even in damp conditions

- Thick foam core: 0.025 inch thick foam adds cushioning and helps conform to uneven surfaces

- Flexible tape: Tape resists curling and conforms to curves and corners easily during application

- Multipurpose use: Suitable for mounting a wide variety of objects

- Easy to apply: Red liner for easy peel and application

The Importance of Choosing a Quality Adhesive Tape for LED Strip

LED strips are often mounted on irregular surfaces such as walls, ceilings, and the underside of furniture. These locations not only place high demands on the adhesion of the tape but may also be exposed to extreme conditions such as humidity, heat, or cold. If you use poor-quality tape, the strip light may fall off, which not only affects the aesthetics but also poses a safety hazard.

For more information on how to choose LED light strip adhesive tape, please read the post: How to judge and choose the quality of LED light strip adhesive tape?

3M VHB Adhesive Tape is particularly suitable in these situations, and its key benefits include:

1. Superior adhesion: VHB tape adheres tightly to a variety of surfaces, including metal, glass, plastic, and painted surfaces, ensuring that LED strips stay on for a long time.

2. Weather Resistance: VHB tape maintains its performance in both hot summers and cold winters and is suitable for both indoor and outdoor environments.

3. Shock Resistance and Flexibility: VHB tape has good flexibility and shock-absorbing ability, which can absorb vibration and shock and provide extra protection for LED strips.

3M VHB Tape Performance

3M VHB tape is suitable for LED strip lights of different sizes and shapes. To better understand the superior performance of 3M VHB tape, please review some of the common specifications below:

| Tape Model | Thickness (mm) | Width (mm) | Bonding Strength (N/cm) | Temperature Resistance Range (°C) | Color | Tensile Strength (MPa) | Elongation (%) |

| 3M VHB 5952 | 1.1 | 50 | 180 | -40 to 150 | Black | 3.4 | 500 |

| 3M VHB 4941 | 0.8 | 25 | 100 | -40 to 100 | Transparent | 2.7 | 400 |

| 3M VHB 5925 | 0.63 | 12 | 80 | -40 to 93 | Black | 2.1 | 300 |

You need to choose the right tape according to the size and weight of the LED strip and the installation environment to ensure a good adhesion and a perfect and hassle-free lighting arrangement. All in all, 3M VHB tape is the first choice for LED strip tape with many advantages, it is worth to try.

SignliteLED offers a wide range of LED strip lights that utilize 3M VHB tape, check out our products below:

IP20 RGBW SMD5050 LED Strip Light

- LED QTY per Meter Option: 60/72/84/96/120

- PCB Width Option: 10mm/12mm

- Color Option: RGBW

- CRI: >80

- Input Voltage: DC12V/DC24V

- Power per Meter: 12W/14W/16W/18W/19W/20W/22W

- IP Grade Option: IP20/IP65/IP67/IP68

- Warranty: 3 years

IP65 RGB Digital LED Strip Light

- LED QTY per Meter: 30/48/60/96/144

- PCB Width: 10mm/12mm/14mm

- Color: RGB

- IC Type: WS2811, External IC

- Pixel QTY per Meter: 10/16/20/32/48 pixel

- Data Type: SPI signal, Single data line

- Input Voltage: DC12V

- Power per Meter: 9W/14.4W/18W/28.8W/43.2W

- IP Grade: IP20/IP65/IP67/IP68

- Warranty: 3 years

IP67 RGBW COB LED Strip Light

- LED QTY per Meter Option: 784chips (Sanan)

- PCB Width Option: 12mm

- Color Option: RGB+W(2700K/3000K/4000K/6500K)

- CRI: >90

- Input Voltage: DC24V

- Power per Meter: 19W

- IP Grade Option: IP20/IP65/IP67/IP68

- Warranty: 3 years

IP68 110V 220V LED Strip Light

- LED QTY per Meter: 60/80/120

- PCB Width Option: 10mm/12mm

- Color Option: 2700K/3000K/4000K/5000K/6500K/RGB

- CRI Option: 80/90

- Input Voltage: AC110V/AC220V

- Power per Meter: 7W/10W

- IP Grade Option: IP67/IP68

- Warranty: 3 years

How do I use 3M VHB tape?

No matter where you need to mount, it’s important to know how to prepare the surface. Please keep the following instructions handy to ensure a smooth installation process:

1. Clean the surface: Before installing, you will need to wipe the mounting surface with alcohol or detergent to ensure it is free of dust, grease and contaminants.

2. Measure and cut the tape: Cut the appropriate amount of VHB tape according to the length of the LED strip and keep the edges straight.

3. Paste and apply pressure: Paste one side of the tape on the back of the strip and the other side on the mounting surface, and apply appropriate pressure to enhance the adhesion and eliminate all air bubbles.

4. Wait to bond: For best results, wait 24 hours after installation to allow the tape to fully bond to the mounting surface.

While VHB tapes can bond to many types of substrates, they are not suitable for all surfaces or applications. Be sure to read and follow the manufacturer’s guidelines and recommendations for the specific tape you are using, including recommended surface treatments, application techniques, and limitations.

Precautions for 3M VHB Tape

1. Storage conditions: Unused 3M VHB tape should be stored in a cool, dry, ventilated environment, out of direct sunlight and away from high temperatures and high humidity to prevent damage to the tape’s performance. It is recommended that the storage temperature be between 5℃ and 30℃, and relative humidity does not exceed 65%.

2. Applicable materials: Although 3M VHB tape has good adhesion to most common materials, the adhesive effect may not be ideal on the surface of some special materials, such as polytetrafluoroethylene (PTFE), which has extremely low surface tension. Before use, it is best to test on a small area to ensure reliable bonding.

3. Weight limit: Different specifications of the 3M VHB tape load-bearing capacity vary; in the installation of heavier LED strip components, based on the adhesive strength of the tape parameters, choose the appropriate model to avoid overweight tape failure caused by the strip falling off, resulting in potential safety hazards.

4. Avoid secondary paste: Once the tape is pasted with the mounting surface or LED strip, try not to reopen it and paste it again, which will seriously reduce the adhesion of the tape and affect the final fixing effect.

Not only does 3M VHB tape provide a stronger bond than ordinary double-sided tapes or inferior adhesive products, but it can also withstand a variety of extreme environments. This high-performance tape has been widely used in industries such as aerospace and automotive manufacturing for its proven reliability.

3M VHB tape is the best choice for those who want to create a long-lasting, reliable, and professional LED strip light installation. For more information on LED strip tape types, please read the post: What is the best double side adhesive tape for LED strip lights?

Conclusion

In short, among the many choices of LED strip tape, 3M VHB tape has become one of the best choices by virtue of its strong bonding performance, excellent weather resistance, convenient and beautiful installation characteristics, and wide applicability. If you are looking for a reliable adhesive tape for LED strip light installation, try 3M VHB tape; I believe it will bring you an unexpectedly good experience.

SignliteLED is a factory specializing in producing high-quality customized LED strip lights and LED neon strip lights. If you need to buy LED strip lights, please contact us.