Are you exploring LED aluminum profiles for your next lighting project? These specially designed casings protect and enhance LED strip lights, offering both functional and aesthetic benefits. But why choose aluminum over other materials, and what advantages does it offer? In this guide, we’ll answer these questions and more, diving into the role of LED aluminum profiles in modern lighting solutions.

What’s LED Aluminum Profile

An LED aluminum profile, also known as an LED channel, is an extruded aluminum housing designed to encase LED strip lights. It securely holds the strip and functions as a heat sink to dissipate excess heat, enhancing LED performance and lifespan. Available in various shapes and sizes, these profiles are ideal for applications such as under-cabinet, accent, and architectural lighting. Often paired with a diffuser cover, they soften light output, reducing glare while boosting visual appeal. Easy to install and highly durable, LED channels offer a sleek, modern aesthetic, providing an efficient and reliable lighting solution for diverse settings indeed.

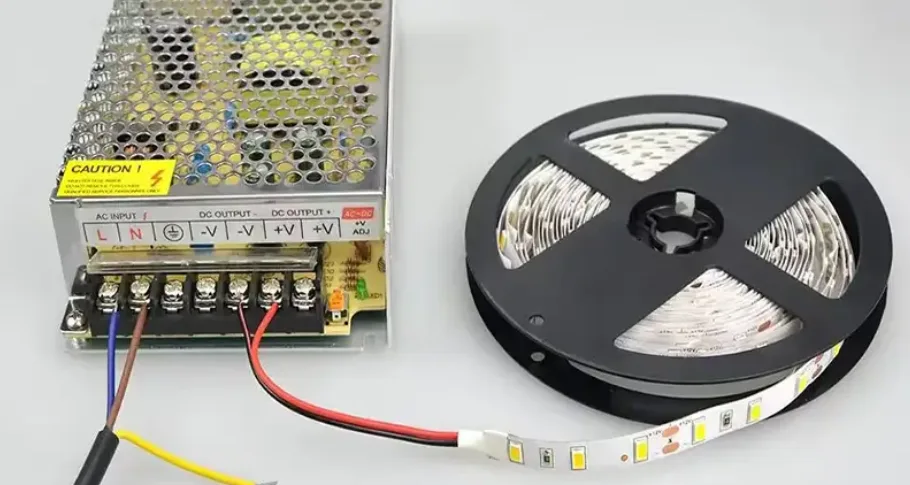

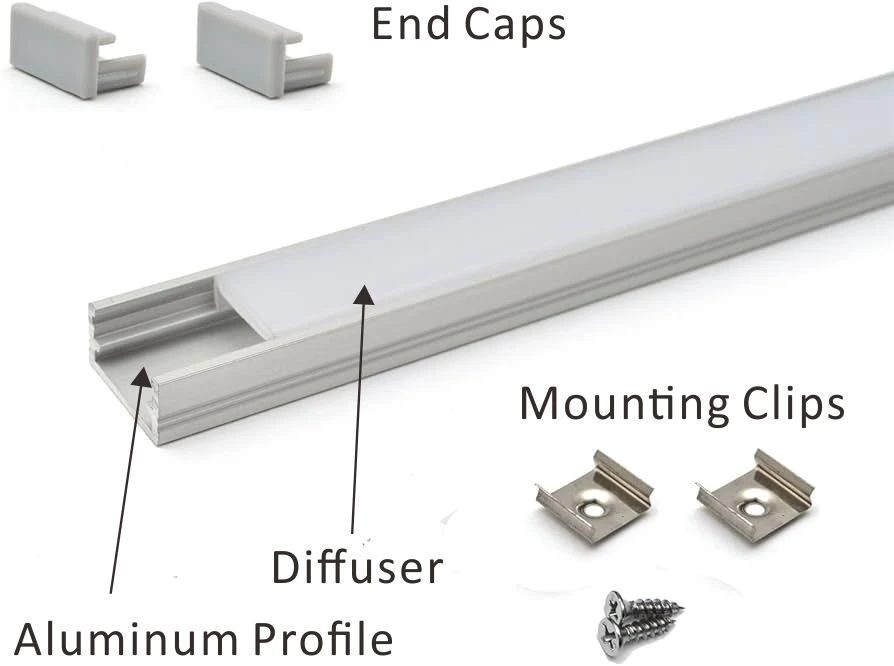

What’s A Complete LED Channel Lighting System

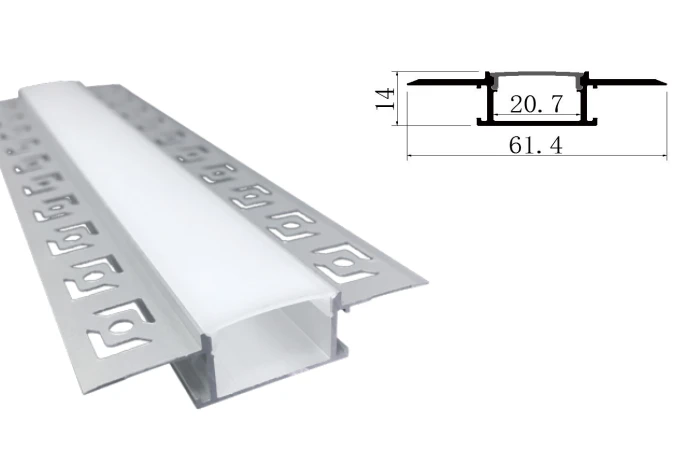

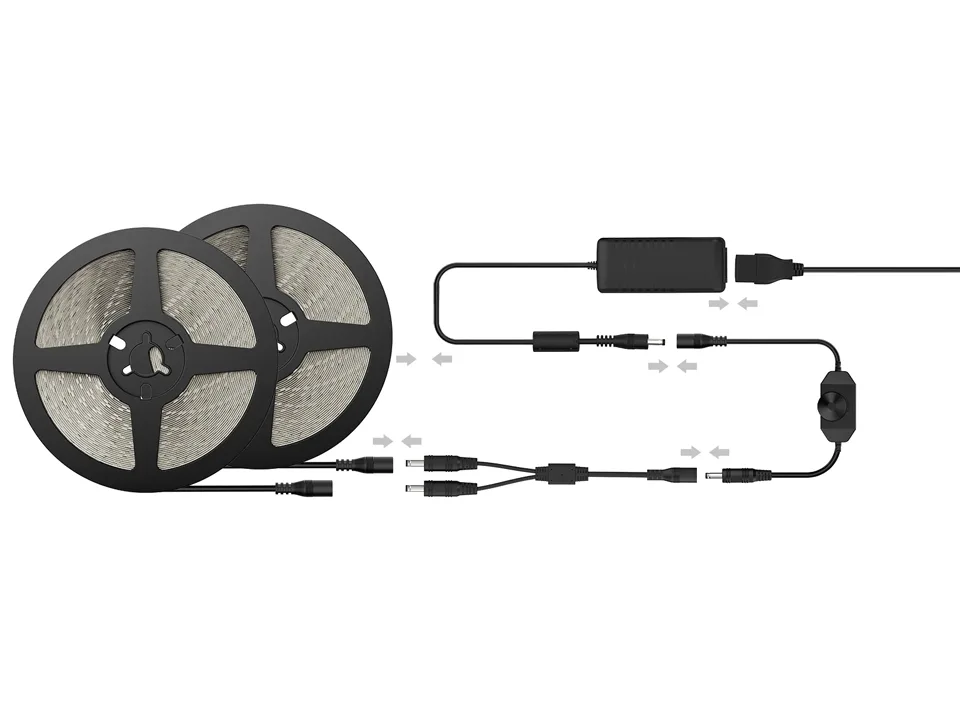

A full LED aluminum profile setup comprises aluminum channel itself, an LED light strip diffuser (cover), end caps, and mounting clips.

LED Aluminum Profile

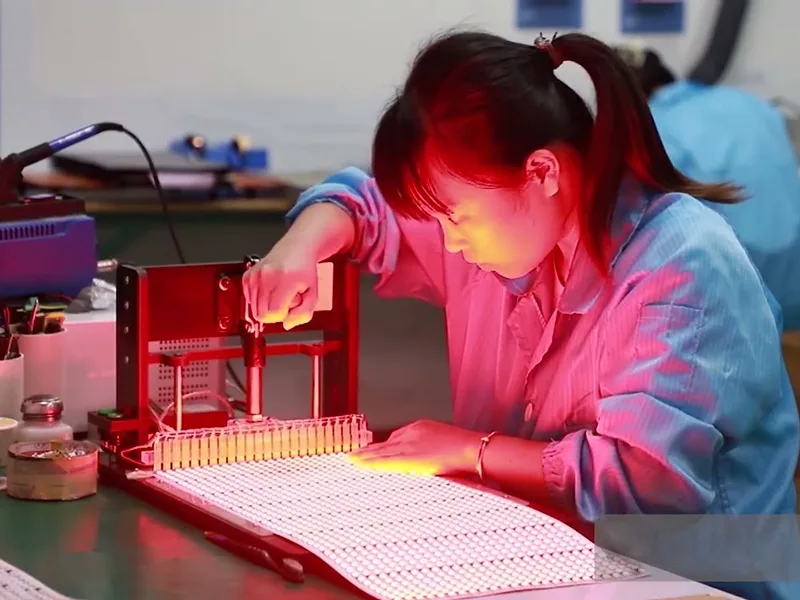

Aluminum Pofile Production Process

The aluminum profile is produced using an extrusion process. In this method, high-grade aluminum alloy is heated until molten and then forced through a precision-engineered die to form the desired cross-sectional shape. After extrusion, the profile is cooled and subjected to heat treatments such as annealing to ensure consistent structural strength and integrity.

Aluminum Pofile Material

Most of LED aluminum are made from 6063 aluminum, due to their lightweight, corrosion-resistant, and durable properties. This makes them an ideal choice for LED lighting applications, ensuring longevity and reliable performance.

Aluminum Pofile Color

The surface finish is achieved through anodizing or powder coating. Common colors include natural silver, black, and white, although custom finishes are also available to suit various design aesthetics.

Aluminum Pofile Shape

Aluminum profiles come in a variety of cross-sectional shapes, such as rectangular, square, or U-shaped designs. These shapes are engineered to accommodate LED strips securely while providing efficient heat dissipation.

Aluminum Pofile Sizes

Sizes vary to meet different application needs. Profiles are available in lengths typically ranging from 1 to 2 meters, with customizable widths and heights designed to match specific LED strip sizes and installation requirements.

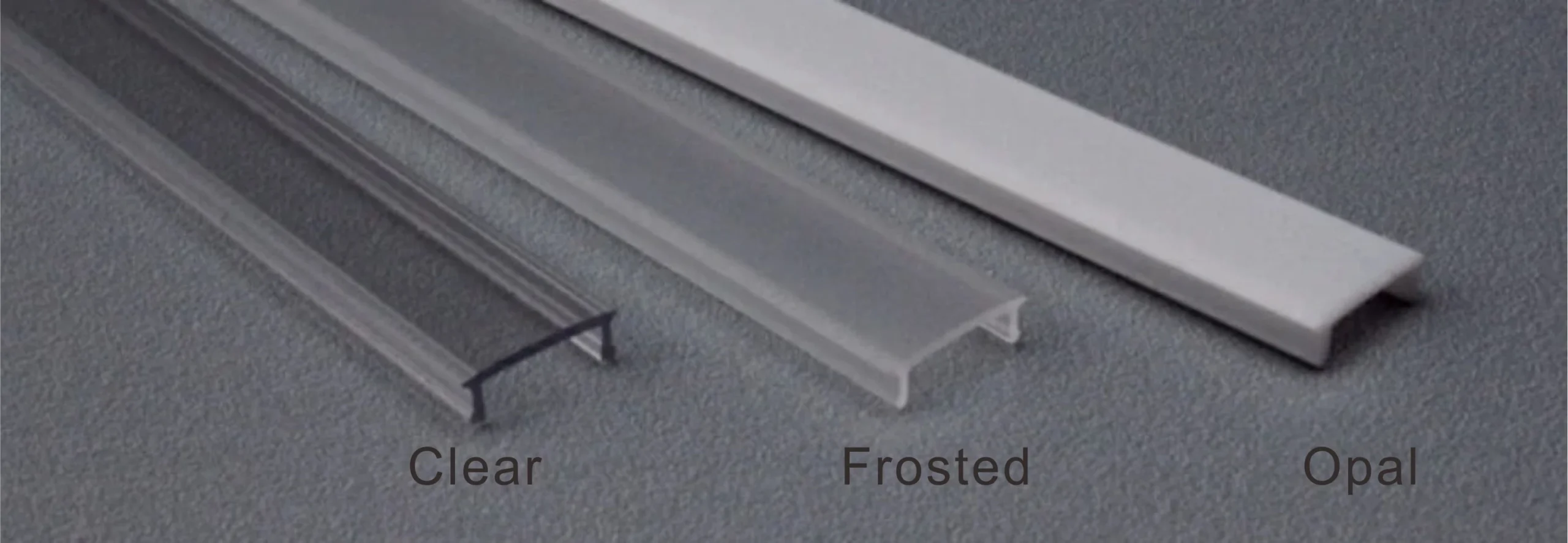

LED Channel Diffuser

Same as aluminum profile, diffuser is also extruded in machine. The LED channel diffuser enhances the lighting effect by evenly distributing LED light, preventing harsh glare and creating a more comfortable illumination.

LED Channel Diffuser Material

Diffusers are commonly made from high-quality, transparent or translucent plastics such as polycarbonate (PC) or acrylic (PMMA). PC is known for its high impact resistance and heat tolerance, making it ideal for robust lighting applications. PMMA offers excellent clarity and UV resistance, ensuring long-lasting performance without yellowing over time.LED Channel Diffuser

LED Channel Diffuser Transparency

Diffusers come in various transparency levels, including clear, frosted, and opal. Clear diffusers allow maximum light transmission with minimal diffusion. Frosted diffusers soften the light output, reducing glare and improving uniformity. Opal diffusers provide the highest level of diffusion, creating an even and smooth lighting effect with minimal visible LED dotsffects.

LED Channel End Caps

Production Process

End caps are typically manufactured using injection molding, where molten plastic or metal is injected into a mold to create precise shapes that fit LED aluminum profiles. This process ensures uniform quality, durability, and a secure fit. Some metal end caps may also undergo CNC machining for enhanced precision and strength.

LED Channel End Caps Material

End caps are commonly made from plastic (such as ABS or polycarbonate) or aluminum. Plastic end caps are lightweight, cost-effective, and available in various colors. Aluminum end caps provide greater durability, heat resistance, and a premium finish, making them suitable for high-end lighting applications.

LED Channel Mounting Clips

Securely mounting aluminum channels relies on mounting clips. Typically, two clips are provided for each meter of channel. A range of clip types are available, including stainless steel clips, PC buckles, spring clips, rotating brackets, and suspension or pendant kits.

Benifits of Using LED Channels

Protection

LED aluminum profiles provide essential protection for LED strip lights by shielding them from dust, moisture, and physical damage. This extends the lifespan of the LEDs and ensures consistent performance, especially in high-traffic or outdoor environments.

Aesthetics

With their sleek and modern design, aluminum profiles enhance the appearance of LED lighting installations. They help create a polished, professional look by concealing wiring and LED strips, ensuring a clean and seamless lighting effect in residential, commercial, and architectural applications.

Heat Dissipation

Aluminum has excellent thermal conductivity, allowing LED profiles to function as heat sinks. They effectively dissipate excess heat from LED strips, reducing the risk of overheating and maintaining optimal performance, which extends the lifespan of the LEDs.

Customization

LED aluminum profiles are available in various shapes, sizes, and finishes to accommodate different lighting needs. They can be cut to specific lengths, paired with different diffusers, and installed in various orientations, offering flexibility for tailored lighting solutions in diverse applications.

The Most of Popular LED Aluminum Profile

LED aluminum profiles come in various types, each designed to suit specific lighting needs and installation preferences.

Here are some popular LED aluminum profile which are widely used.

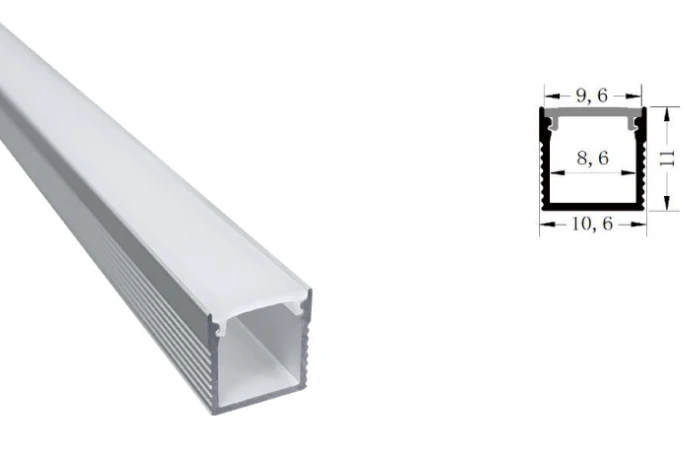

1. Surface-Mounted Channels

Surface-mounted aluminum profiles are designed to be installed on the surface of walls, ceilings, or furniture. They are ideal for applications where the profile needs to be visible and easily accessible.

Applications: Under-cabinet lighting, Accent lighting for walls and ceilings, Decorative lighting in residential and commercial spaces

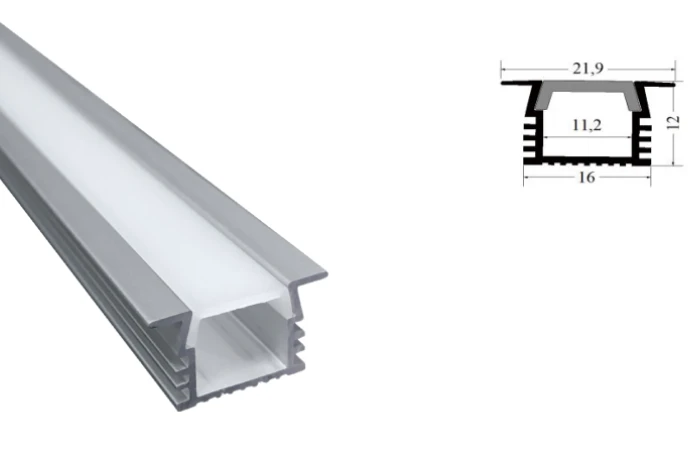

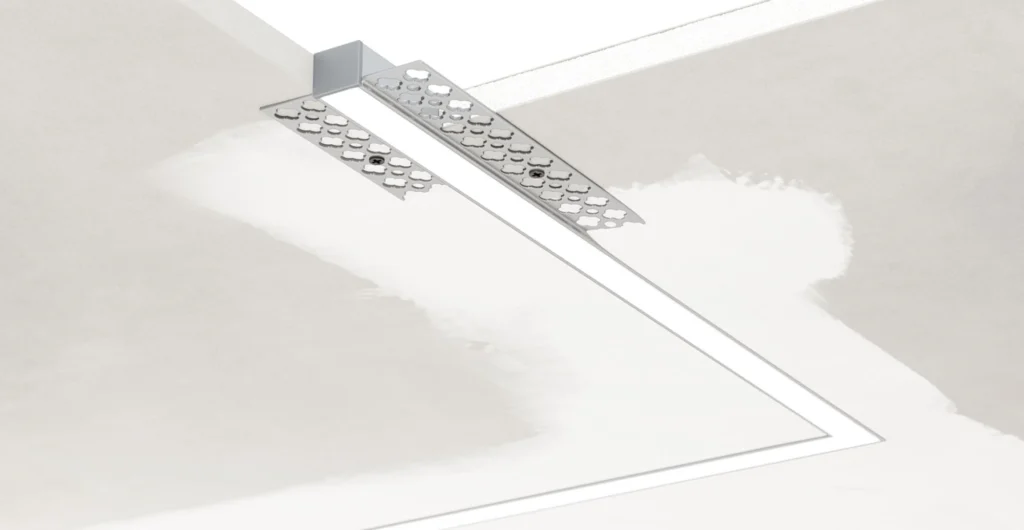

2. Recessed Channels

Recessed channels are installed into the surface, creating a flush, seamless look. They are often used in ceilings, walls, or floors for a hidden, minimalistic design.

Applications: Integrated lighting in ceilings or walls, Modern architectural designs, Underfloor lighting or floor-mounted fixtures

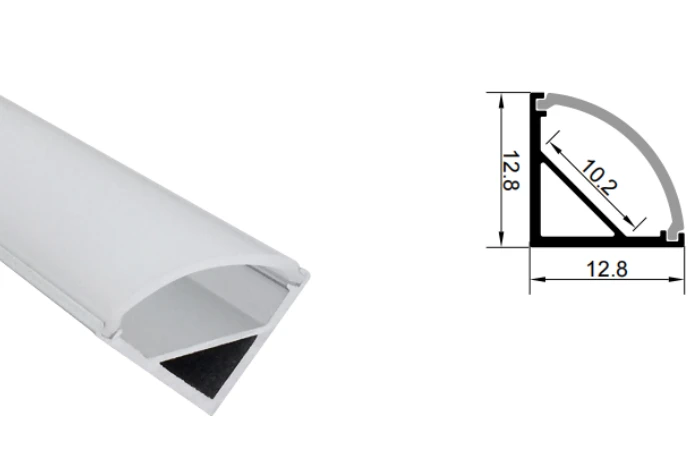

3. Corner Channels

Corner channels are specifically designed for installation in 90-degree angles, such as corners of rooms, cabinets, or furniture. These profiles enable uniform lighting around edges.

Applications: Corner lighting in living rooms, kitchens, or offices, Under-cabinet and countertop lighting, Decorative lighting along architectural edges

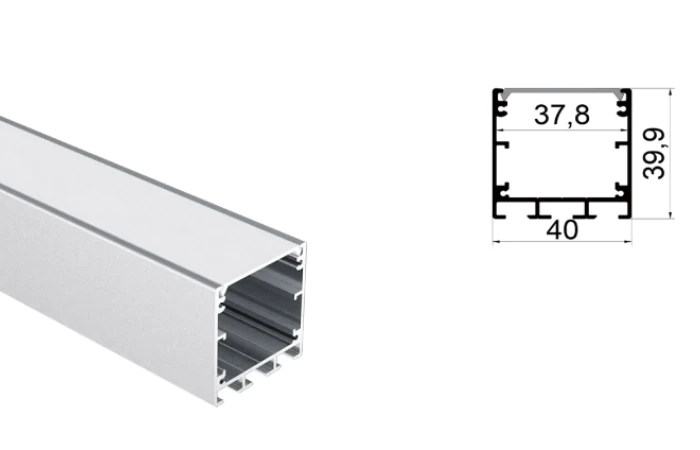

4. Pendant Channels

Pendant channels are designed for suspended installations, allowing the LED strip to hang at a certain height. These profiles are ideal for pendant-style or hanging lighting designs.

Applications: Commercial and office lighting, Suspended lighting in large spaces like lobbies or showrooms, Decorative pendant-style lighting for modern interiors

5. Drywall Channels

Drywall channels are made for installation within drywall, allowing LED strips to be recessed seamlessly into the wall. This provides a clean, hidden lighting effect.

Applications: Concealed lighting in residential or office walls, Hidden accent lighting in home theaters or art displays, Seamless integration into architectural designs

6. Wardrobe Closet Hanging LED Aluminum Profiles

These profiles are designed for wardrobe and closet applications, often allowing easy installation of LED strips along closet rods or shelving.

Applications: Closet lighting for easy visibility, Wardrobe lighting for better organization, Under-shelf lighting in retail display setups

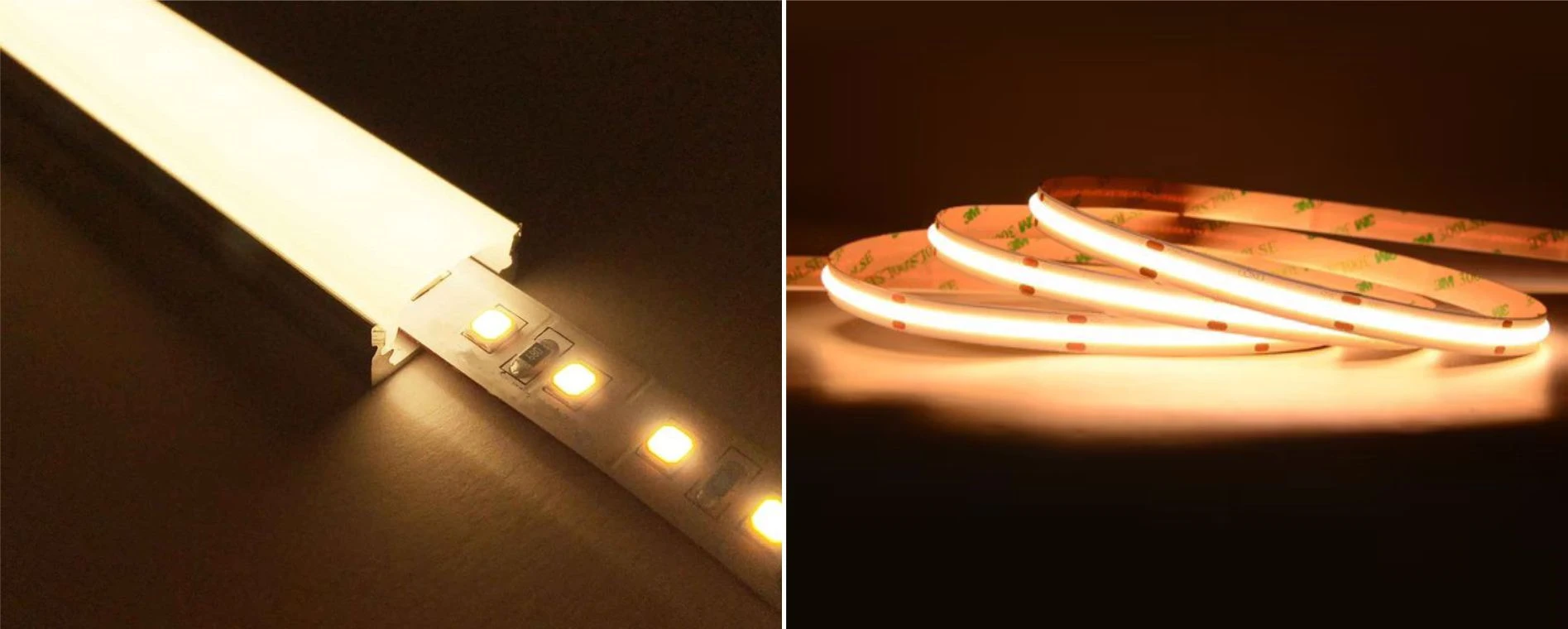

LED Channel Lighting VS COB Strip Light

Considering the consistency of lighting, COB light strips are often compared with LED channel lighting

Composition

LED channel lighting consist of an extruded aluminum channel, a diffuser, end caps, and mounting accessories. They house LED strips and provide structural support. COB (Chip-on-Board) LED strips integrate multiple LED chips closely packed on a single circuit board, eliminating the need for additional housing.

Light Uniformity

LED aluminum profiles with frosted or opal diffusers help soften the light, reducing glare and eliminating visible LED dots. COB LED strips naturally offer a seamless lighting effect with no visible LED points due to their high LED density, making them ideal for applications requiring continuous illumination.

Flexibility

COB LED strips are highly flexible, allowing them to bend and conform to curved surfaces, making them suitable for creative lighting designs. LED aluminum profiles, though more rigid, offer better installation stability and are ideal for linear lighting applications in straight lines or predefined angles.

Heat Dissipation

LED aluminum profiles act as heat sinks, effectively dissipating heat and extending the lifespan of LED strips. COB LED strips generate more heat due to their high LED density, and without proper heat management, they may have a shorter lifespan.

Protection

Aluminum profiles provide physical protection against dust, moisture, and impact, ensuring longer-lasting LED performance. COB LED strips, while often coated with a protective layer, are more exposed to environmental factors and require additional shielding for durability in harsh conditions.

LED Channel Lighting vs. LED Neon Light

Efficiency

LED channel lighting, typically used with LED strips, offers high energy efficiency. The use of diffusers in aluminum profiles ensures the light is evenly distributed, reducing wasted light. LED neon lights, while also energy-efficient, tend to consume slightly more power due to their continuous form factor and thicker construction but still provide excellent lighting output for various applications.

Flexibility

LED neon lights are highly flexible and can bend in all directions, making them ideal for curved and intricate installations, such as signs and decorative designs. In contrast, LED channel lighting is generally more rigid, as it’s housed in an aluminum profile, which limits its flexibility, making it more suitable for straight-line applications like under-cabinet or linear lighting.

Heat Dissipation

LED channel lighting benefits from aluminum profiles that act as heat sinks, helping to efficiently dissipate heat and extend the lifespan of the LEDs. LED neon lights, however, are typically encased in a rubber or silicone jacket, which can restrict heat dissipation, leading to higher operating temperatures and potentially shorter lifespan if not properly managed.

Waterproof

Both LED channel lighting and LED neon lights are available in waterproof versions. However, LED neon lights are more commonly designed for flexible outdoor use and often come fully sealed in a durable silicone tube, offering better protection against water and harsh environments. LED channel lighting can also be waterproof, but the profile itself must be sealed properly, and the type of diffuser used may affect water resistance.

How to Choose the Right LED Channel

Choosing the right LED channel depends on several key factors, including application, size, diffuser type, mounting options, and aesthetics. Here’s a guide to help you select the best LED aluminum profile for your needs:

1. Application

Determine where the LED channel will be used. Different applications require specific types of profiles:

Surface-mounted profiles – Ideal for under-cabinet, wall, and ceiling lighting.

Recessed profiles – Designed for flush installation in walls, ceilings, or furniture for a seamless look.

Corner profiles – Suitable for 90-degree installations, such as in cabinet corners or architectural edges.

Suspended profiles – Used for pendant lighting, often in commercial or office spaces.

Waterproof profiles – Essential for outdoor or damp environments.

2. Size and Compatibility

Ensure the LED channel is compatible with your LED strip. Consider:

Width – The profile should be wide enough to accommodate your LED strip.

Height – A deeper profile can help diffuse light better, reducing LED dot visibility.

Length – Standard lengths are 1m or 2m, but they can be cut to fit specific needs.

3. Diffuser Type

Diffusers impact the lighting effect and brightness:

Clear diffuser – Provides maximum brightness but may show LED dots.

Frosted diffuser – Softens light output and reduces glare.

Opal/milky diffuser – Offers the most even light distribution with no visible LED dots.

4. Mounting Options

Consider how you want to install the LED channel:

Screw-mounted clips – Secure and stable, ideal for permanent installations.

Adhesive backing – Quick and easy but less durable over time.

Recessed mounting – Requires a groove or cutout but provides a sleek, integrated look.

5. Aesthetic and Finish

Choose a finish that matches your design style:

Silver anodized aluminum – The most common and versatile option.

Black or white coated profiles – Blend well with modern interiors.

Custom colors – Available for unique design requirements