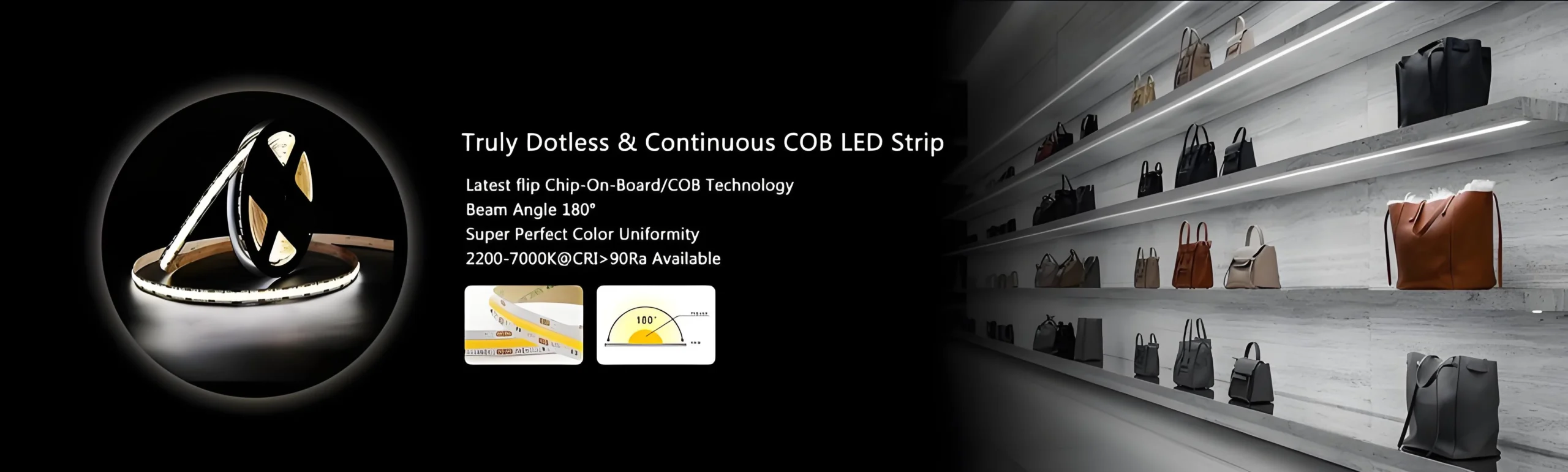

What is a COB LED strip?

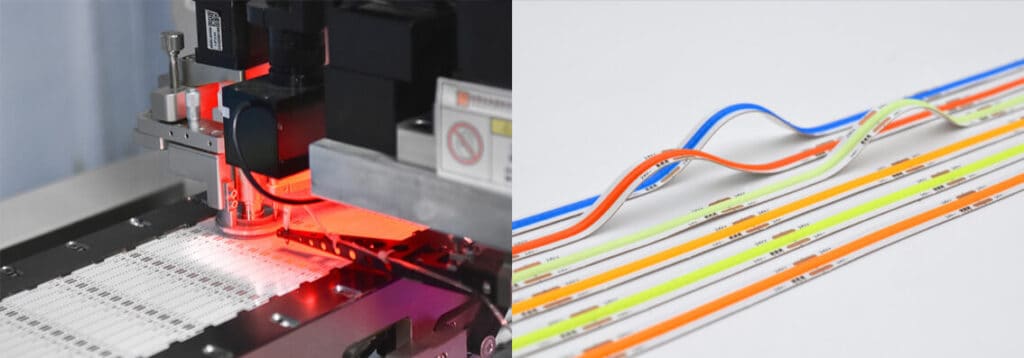

COB is Chips on Board, which means that the chip is directly packaged on the PCB board. The COB strip is a light strip with chips packaged on a flexible board. Chips are mostly flip chips, which are linearly bonded on the PCB, and then directly drop a layer of packaging glue mixed with phosphor powder on the surface of the chip. The light emitted by the chip is refracted, reflected, and interacted with phosphors in the packaging colloid, and the colloid uniformly emits light of different colors and color temperatures.

The difference between COB LED strip and lamp bead LED strip

①Due to the structural characteristics of the COB strip, the light emitting surface is a linear colloid; while the ordinary lamp bead type light strip, its structure is a light-emitting lamp bead, which is attached to the PCB board. Therefore, the light emitted by the COB strip should be much more uniform, linear, and without spots;

② Since the COB chip is directly bonded on the PCB, the heat of the chip can be quickly transferred to the PCB. Therefore, the chip heat dissipation speed of the COB strip is faster than that of the lamp bead type light strip, so that the light decay of the COB light strip is smaller and the service life is longer;

③The luminous angle of the light-emitting surface of the COB LED strip can reach 180°.

Application Scenario

① Home decoration (ladder lighting, hall aisle lighting, lighting decoration, edge hook decoration);

②Path indication and exterior wall outline decoration, billboard backlighting, advertising signs, etc.;

③ Contours of buildings, pavilions, bridges, parks, squares, etc., building lighting decoration, various indoor and outdoor lighting projects;

④Festival decoration, event venue scenery, exhibition venue decoration, exhibition hall decoration, showcase, window, props and other decorative lighting applications;

⑤ body decoration, interior decoration;

⑥ Decorative lighting in hotels, bars, KTV, nightclubs and other high-end entertainment venues.

Installation Precautions

①The COB packaging colloid is directly exposed outside, which is made of silica gel and has relatively soft hardness. Avoid contact with sharp objects during installation, so as not to scratch the luminous surface and affect the luminous effect;

②Colloidal material is easy to be contaminated with dust and difficult to handle, so when installing, pay attention to keep the light strip clean. If it is contaminated with dust, use a cotton swab to stick some alcohol and wipe it gently.

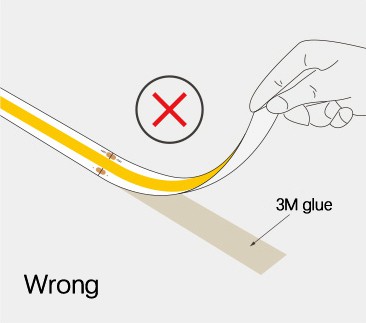

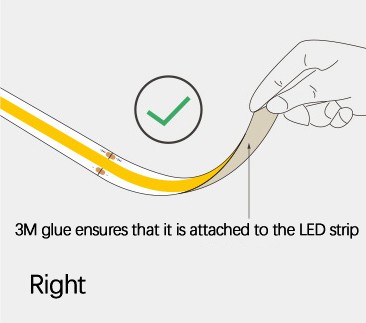

③In the installation process of the COB strip, try to install it in place at one time, and do not have too many repeated tearing and pasting operations. Because the COB strip chip is directly packaged on the PCB board, the chip size is very small, too much tearing action will cause the COB strip chip to be necrotic.

If you need to tear off and paste the LED strip again, the 3M glue must be attached to the LED strip, otherwise the LED strip will be damaged.