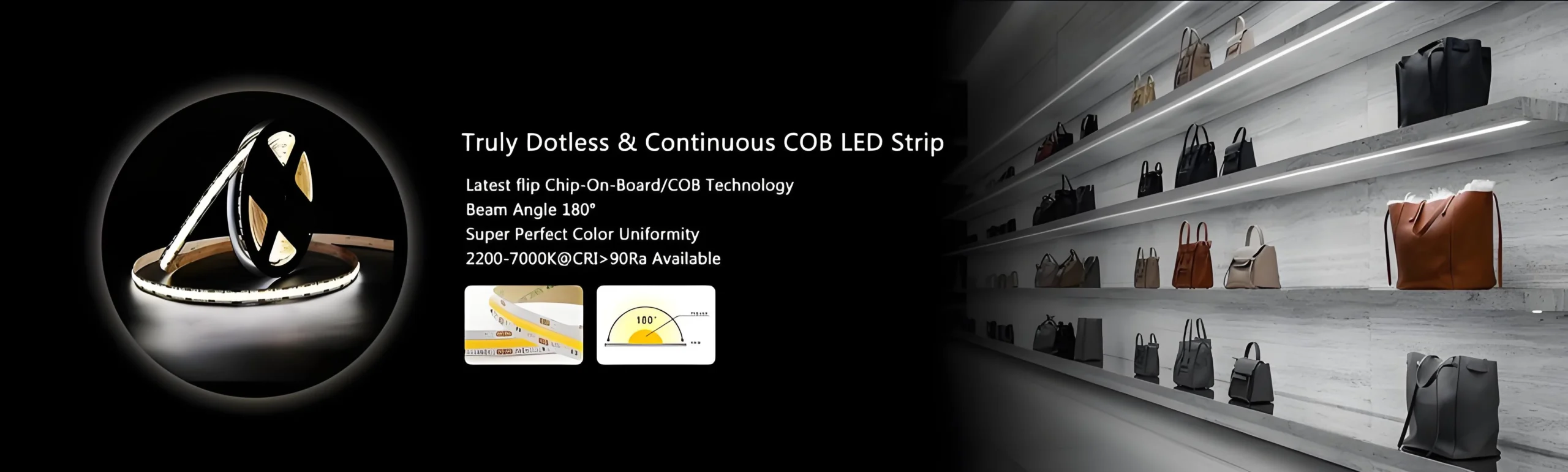

In the evolution of lighting technology, COB LED strips shine as a groundbreaking innovation. With superior performance and sleek design, they unlock transformative lighting solutions for homes, businesses, and industries. Whether enhancing ambiance in living spaces or meeting strict commercial lighting standards, COB LED strips are rapidly becoming the go-to choice for modern illumination.

Technical Core: Chip-on-Board (COB) Technology

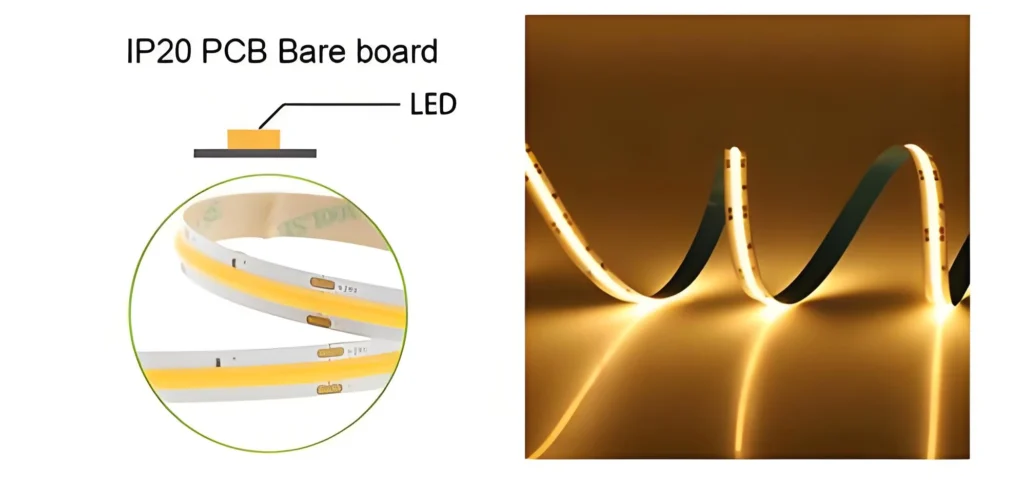

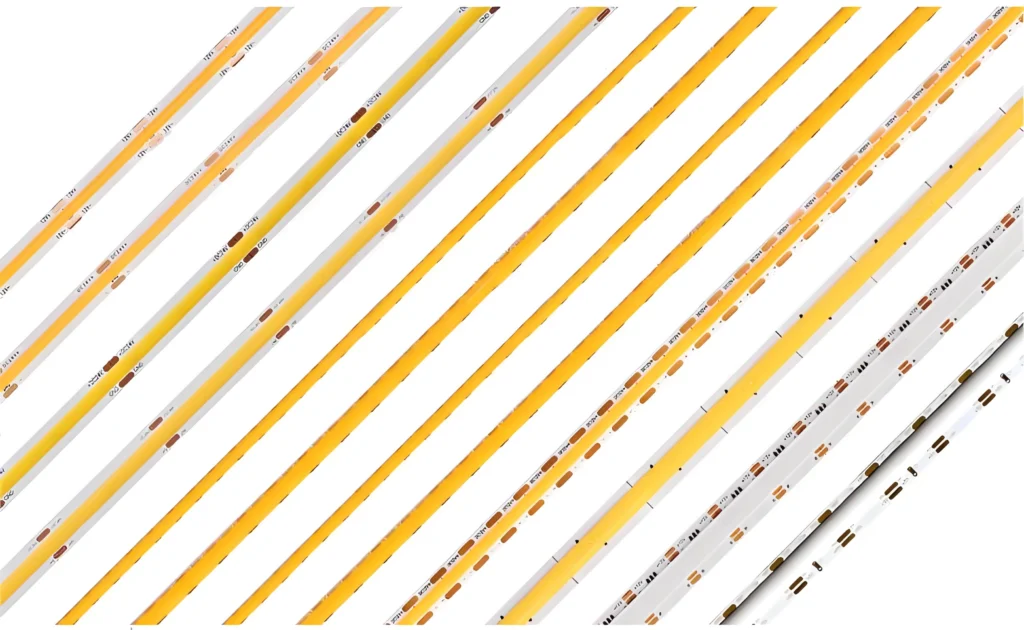

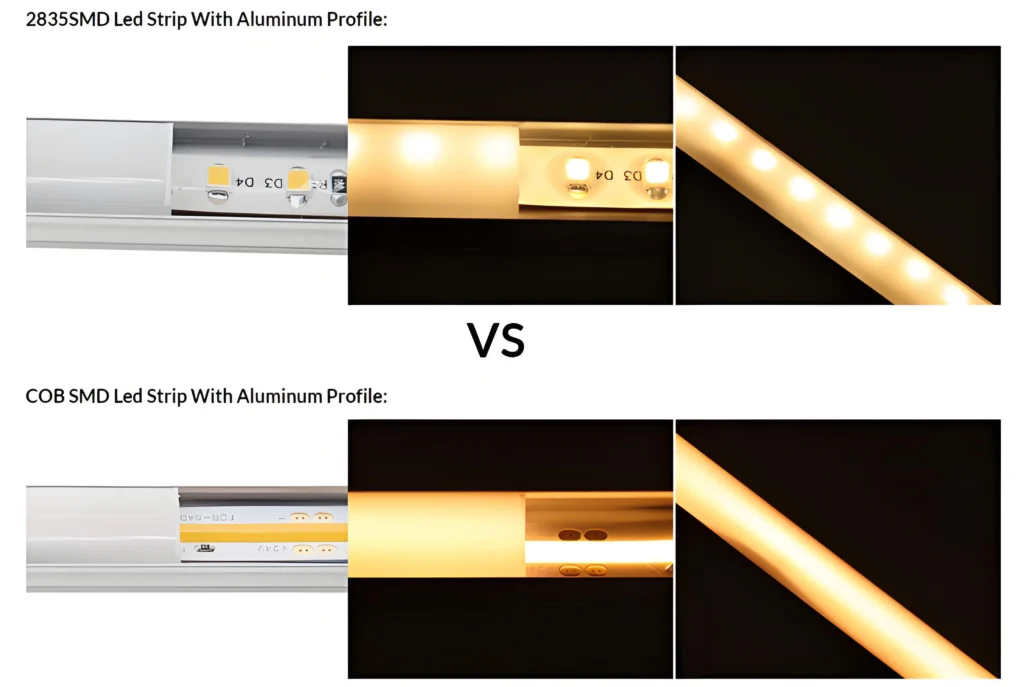

COB (Chip-on-Board) technology integrates hundreds of micro-LED chips directly onto a high-conductivity substrate (e.g., aluminum or ceramic PCB), replacing the discrete SMD beads in conventional strips. This eliminates gaps between light sources, achieving a seamless ‘glowing ribbon’ effect with 500-1000 chips per meter (vs. 60-120 in SMD). During production, multiple micro-LED chips are densely arranged on a flexible or rigid board, coated with a phosphor layer. This design creates seamless, spot-free lighting, unlike the “dotty” effect of conventional LEDs.

Key Advantages of COB Technology:

Smooth, Uniform Light: No visible gaps between light sources, resembling a glowing ribbon.

High-Density Chip Arrangement: Maximizes brightness and efficiency

Performance Advantages of COB LED Strips

(1) High Brightness & Efficiency: Powering Brighter, Greener Solutions

COB LED strips significantly outperform traditional LEDs. Third – party lab tests verify that, at the same power levels, they have a 20 – 30% higher brightness, thanks to their multi – chip integrated design. For instance, a 10W COB strip can reach 1,500 lumens, while a 10W standard SMD LED strip only outputs 1,000 – 1,200 lumens. This brightness advantage not only enhances lighting quality but also reduces the need for more light sources in some applications. Moreover, tests by the Lighting Research Center show that COB technology achieves 150 lm/W, exceeding Energy Star’s premium lighting benchmark, highlighting its energy – efficient nature.

Real-World Impact

- Retail Case Study: A well – known flagship apparel store in New York, decided to upgrade its lighting system. During the implementation process, they faced challenges such as the need to re – arrange the lighting layout to fully utilize the high – brightness and uniform light of COB strips. After careful planning and adjustment, they successfully replaced conventional LEDs with COB strips. As a result, the store reduced energy consumption by 25% while boosting in – store brightness by 35%, and sales increased by 12% due to enhanced product visibility.”

- Industrial Application: Warehouses using COB strips for high-bay lighting reported 40% fewer bulb replacements annually, translating to $50,000+ in maintenance savings per facility.

Technical Edge:

COB’s multi-chip integration minimizes energy loss through unified circuitry, unlike SMD LEDs where individual beads create resistance gaps. This design ensures 95%+ power utilization, aligning with global sustainability goals like the EU’s Ecodesign Directive 2025.

(2) Superior Heat Dissipation: Engineered for Longevity

COB technology revolutionizes thermal management, presenting a breakthrough approach that significantly enhances heat dissipation efficiency. It achieves this by eliminating the intermediary packaging layers, which is a crucial factor in enhancing heat dissipation efficiency. Chips are bonded directly to aluminum-core PCBs with thermal conductivity rates of 2-4 W/m·K, compared to 0.5-1 W/m·K for standard FR4 boards. This enables heat to dissipate 3x faster, reducing junction temperatures to <60°C (vs. 80°C+ in SMD LEDs).

Data-Backed Reliability:

- Accelerated Aging Tests: COB strips maintained 90% initial brightness after 30,000 hours of continuous operation, while SMD LEDs degraded to 70% under the same conditions.

- Thermal Imaging Analysis: A side-by comparison in an automotive factory showed COB strips operating at 45°C versus SMD strips at 68°C, significantly lowering risks of overheating failures.

Material Innovation:

Advanced ceramic substrates and graphene-enhanced thermal pads are now integrated into premium COB designs, pushing lifespan limits to 70,000+ hours—ideal for 24/7 environments like hospitals and data centers.

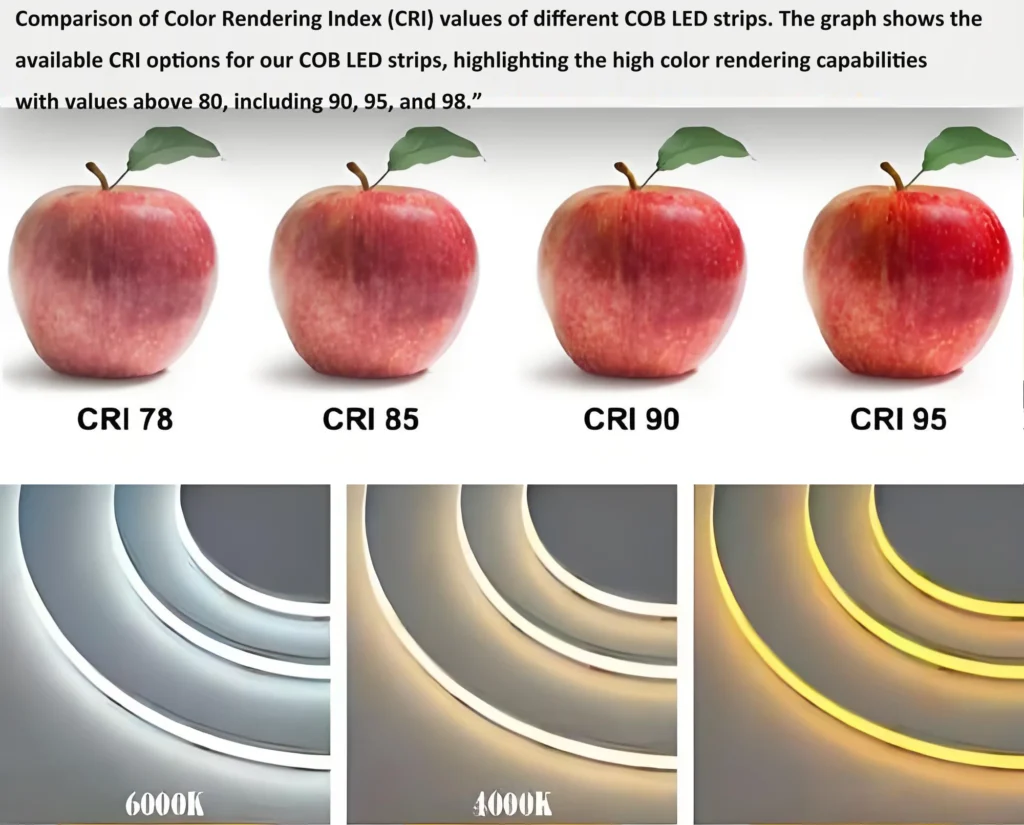

(3) High Color Rendering Index (CRI):

COB strips achieve CRI 90-97, rivaling natural daylight (CRI 100). This precision is quantified using TM-30-18 metrics, where COB LEDs score Rf (Fidelity) >90 and Rg (Gamut) >100, ensuring colors appear vivid yet accurate.

Industry-Specific Applications:

- Museums & Heritage Sites: The Louvre’s recent upgrade to COB lighting reduced UV/IR emissions by 99%, protecting delicate artifacts while achieving CRI 95 for true-color restoration.

- Medical Facilities: Operating rooms using COB strips reported 20% fewer diagnostic errors due to improved tissue differentiation under high-CRI light.

- Film Production: Netflix-approved studios now mandate COB strips with TLCI (Television Lighting Consistency Index) >90 to ensure on-camera color accuracy.

Beyond CRI: Advanced Metrics

- TM-30-18: Evaluates color saturation and fidelity across 99 color samples.

- SSI (Spectral Similarity Index): COB LEDs score SSI >80, outperforming most SMD LEDs (SSI 60-75).

In the market, there are various styles of COB light strips that can meet the needs of different scenarios. In terms of voltage types, there are low-voltage and high-voltage light strips. The common voltages of low-voltage COB light strips are 12V and 24V. They have high safety, and it is not easy to get an electric shock even if the human body accidentally touches them. In areas with high safety requirements, such as home bedrooms and children’s rooms, it is more appropriate to use low-voltage light strips. For example, 24V low-voltage COB light strip has a large number of lamp beads per meter, emits light evenly and has no stroboscopic effect. When used for home lighting, it can create a comfortable and soft lighting environment. High-voltage COB light strips are generally 220V and can be directly connected to the regular household circuit without an additional transformer, and the installation is relatively simple. They are often used in some commercial places or outdoor landscape lighting that have requirements for installation space and wiring convenience, such as the sign lighting of some small shops and the linear lighting of outdoor garden paths.

Market Common COB Light Strips

According to the color effects, there are single-color, two-color temperature, RGB, and RGBW light strips. Single-color COB light strips provide light of a single fixed color, such as the common warm white light, neutral white light, and cool white light. Warm white light creates a warm and comfortable atmosphere and is suitable for home living rooms and dining rooms. Neutral white light is clear and bright and is often used in areas with high requirements for light brightness, such as kitchens and bathrooms. Cool white light has a bluish-white tone and can make the space look more open and bright, which is more common in some modern and simple commercial spaces. Two-color temperature COB light strips can switch between two color temperatures. For example, they can be switched between warm light and white light as needed to meet the lighting needs in different scenarios. For example, two-color temperature COB light strip can control the color temperature change through a remote control or a switch. Whether it is to create a warm atmosphere at night or to have bright light for activities during the day, it can be easily achieved. RGB COB strips leverage additive color mixing (Red/Green/Blue) with 16.7 million color options, controllable via DMX512 or Bluetooth apps. For studios, RGBW variants add a dedicated white diode (CRI 95+) for natural tones alongside vibrant hues and can be used to create dynamic and colorful lighting effects. They are often used in entertainment venues, themed restaurants, etc., adding fun and vitality to the space. RGBW light strips add a white light source on this basis, which can not only achieve richer colors but also simulate white light of different color temperatures, making the lighting effect more natural and real. They are widely used in places with extremely high requirements for lighting effects, such as high-end hotels and art exhibition halls.

In terms of waterproof performance, there are waterproof and non-waterproof styles. Non-waterproof COB light strips are suitable for dry and indoor environments, such as home indoor decoration and the internal display lighting of shopping malls. Since they have no additional waterproof design, the cost is relatively low, and the installation is more convenient. Waterproof COB light strips have undergone special waterproof treatment and can be used in humid or outdoor environments. Different waterproof grades also have different application scenarios. For example, IP65-grade waterproof light strips can prevent water jets and can be used for outdoor landscape lighting and the lighting in front of bathroom mirrors. IP67-grade waterproof light strips can be immersed in water for a short time, and they are suitable for scenarios such as the lighting around fountains and the underwater lighting of outdoor swimming pools.

Spotless, CRI90, High Lumen COB Strip Light

Model No.: FYX08T480X

Input Voltage: DC12V/24V

Power: 11W/m

LED QTY: 480LEDs/m

CCT: 2700K, 3000K, 4000K, 6500K

CRI: >90

Efficiency: 105lm/W

Beam Angle: 180°

Cut Section: 25mm/50mm

IP Rating: IP20/IP65/IP67/IP68

Warranty: 3years

Price: 0.8-0.9USD/m

The Wide Application Fields of COB Light Strips

(1) Home Lighting

In the home environment, COB light strips can be flexibly applied to multiple scenarios, adding charm to the creation of the home atmosphere. Installed under the kitchen cabinets, it can provide sufficient and uniform light for the kitchen countertops, making the cooking and meal preparation processes more convenient. At the same time, the soft light can also add a warm feeling to the kitchen. Installed along the edge of the ceiling or on the steps of the stairs, the COB light strip can outline the spatial contours, creating a unique light and shadow effect and enhancing the sense of hierarchy and beauty of the home space. In the bedroom, arranging the COB light strip on the headboard background wall or under the bed can serve as auxiliary lighting, creating a comfortable and relaxing sleeping environment.

(2) Commercial Lighting

Commercial spaces have strict requirements for lighting effects, and COB light strips have become the favorite of commercial lighting due to their own advantages. In clothing stores, COB light strips can accurately illuminate the clothes, highlighting the fabric, texture, and color of the clothes, making the clothing display more attractive and stimulating customers’ purchasing desire. In restaurants, COB light strips can be used to create different dining atmospheres. The warm-toned light brings a warm and comfortable dining experience to diners. In some characteristic themed restaurants, by cleverly designing the installation position and light color of the COB light strips, the theme style of the restaurant can be strengthened. For areas such as the passages and display shelves in shopping malls, the high brightness and uniform lighting effect of COB light strips can not only ensure the safety of customers walking but also highlight the displayed products, improving the overall image and shopping environment of the shopping mall.

(3) Industrial Lighting

In the industrial field, COB light strips also play an important role. In factory workshops, large-area, high-brightness, and stable lighting are required to ensure the smooth progress of production operations. The high brightness output of COB light strips can meet the workshop’s demand for sufficient light, enabling workers to clearly see the production equipment and operation details, improving work efficiency and production safety. Its excellent heat dissipation performance and long lifespan characteristics meet the requirements of long-term continuous lighting in the industrial environment, reducing the replacement frequency of lamps and lowering maintenance costs. In some industrial inspection, fine processing and other links with high requirements for light uniformity, the characteristics of COB light strips, such as no light spots and uniform lighting, are indispensable.

What are the advantages and disadvantages of COB light strips compared with other types of light strips?

Compared with other types of light strips, COB light strips have advantages in aspects such as light emission effect and heat dissipation performance, but they also have some disadvantages in terms of cost, flexibility, etc. The details are as follows:

Advantages

• Good light emission uniformity: COB light strips adopt the on-board chip technology, directly fixing the LED chips on the circuit board. The chips are arranged closely with a small spacing, enabling a continuous and uniform light emission effect. Unlike traditional light bead type light strips, there will be no obvious light spots or dark areas due to the spacing between the light beads. In places with high requirements for light uniformity, such as museum display cases and the shelf lighting in high-end shopping malls, COB light strips can provide a better lighting environment.

• High brightness and high luminous efficacy: COB light strips usually adopt a multi-chip integrated design, and the brightness can be increased by adding the number of chips and optimizing the packaging process. At the same time, their luminous efficacy is also relatively high, which can more effectively convert electrical energy into light energy. Under the same power, the brightness of COB light strips is often higher than that of other types of light strips, making them suitable for occasions that require high-brightness lighting, such as industrial plants and parking lots.

• Excellent heat dissipation performance: The chips are directly connected to the circuit board, resulting in a short heat dissipation path. The heat can be quickly conducted from the chips to the circuit board and the heat dissipation device. Compared with traditional light strips, the temperature of the chips of COB light strips is lower during long-term use, which helps to reduce light decay and extend the service life. In some places that require long-term continuous lighting, such as hospitals and schools, the stability and durability of COB light strips are more advantageous.

• High color rendering degree: The color rendering index of COB light strips is usually relatively high, which can reach above 90, and some high-end products can even reach above 95. They can accurately restore the true colors of objects. For places with harsh requirements for colors, such as art galleries and photography studios, COB light strips can provide more accurate color lighting, showing the true color and details of objects.

Installation and Maintenance Key Points of COB Light Strips

(1) Installation Key Points

• Preparation of Installation Environment: Before installing the COB light strip, ensure that the installation surface is flat, dry, and clean, free of dust, oil stains, and other impurities to guarantee the adhesion or fixing effect of the light strip. If installing in an outdoor or humid environment, select a COB light strip with waterproof function, and make sure the installation location has good drainage conditions to prevent the light strip from being damaged by water accumulation.

• Determination of Installation Location and Length: Plan the installation location of the COB light strip accurately according to actual lighting needs. Measure the required length of the light strip, and use tools like scissors to cut it according to the cutting marks on the light strip. Be careful during cutting to avoid damaging the chips. If multiple sections of light strips need to be connected, use the matching connection accessories to ensure a firm connection and unobstructed circuit.

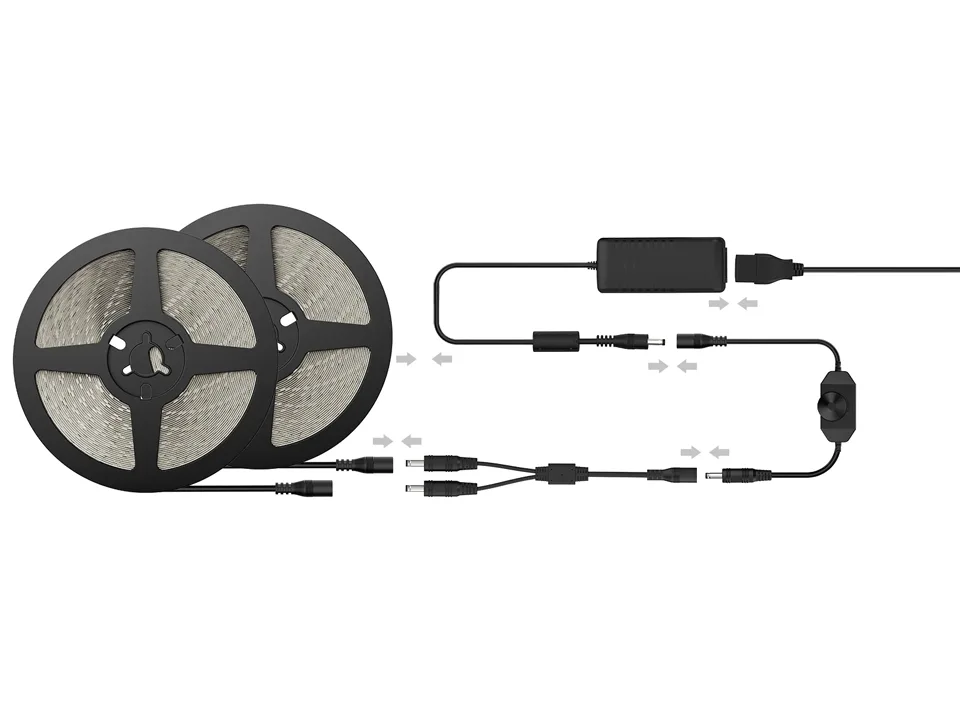

• Fixing and Wiring: Flexible COB light strips usually come with adhesive backing and can be directly pasted onto the installation surface. However, before pasting, conduct a power – on test on the light strip to ensure it emits light normally. When pasting, start from one end and press slowly to avoid air bubbles or wrinkles. Rigid COB light strips need to be installed using fasteners such as screws and clips. In terms of wiring, strictly follow the product instructions, correctly connect the positive and negative poles of the power supply to ensure safety and reliability. For those unfamiliar with circuit connection, it is recommended to have a professional electrician perform the operation.

(2) Maintenance Key Points

• Regular Cleaning: During the use of COB light strips, the surface is prone to adsorbing dust, which affects the lighting effect. Regularly wipe the surface of the light strip gently with a clean, soft damp cloth to remove dust and stains. But note that do not clean when the light strip is powered on to prevent the risk of electric shock. For stubborn stains, a small amount of mild cleaner can be used, but ensure that the cleaner will not corrode the light strip.

• Inspection of Connection and Fixing Conditions: Periodically check whether the connection parts of the COB light strip are loose and whether the fasteners are stable. If a loose connection is found, reconnect and reinforce it in time. For damaged or loose fasteners, replace or adjust them in time to ensure that the light strip will not be damaged by shaking or falling during use.

• Monitoring of Lighting Effect Changes: In daily use, pay attention to whether the lighting effect of the COB light strip is abnormal, such as a significant decrease in brightness, flickering, or some areas not lighting up. Once a problem is detected, promptly investigate the cause. If the problem is relatively simple, such as an individual lamp bead being damaged, try replacing the lamp bead. If it involves complex problems such as circuit failures, it is recommended to contact professional maintenance personnel for inspection and repair to avoid causing greater damage due to self – disassembly.

With its innovative technology, excellent performance, and wide application range, COB light strips are profoundly changing the landscape of the lighting industry. With the continuous advancement of technology and the gradual reduction of costs, it is believed that COB light strips will play an even more important role in the future of the lighting field, bringing people a higher – quality, more efficient, and more aesthetically pleasing lighting experience, illuminating every corner of life.

Why Choose COB LED Strips?

COB technology redefines lighting with uniformity, efficiency, and durability. As costs decline and adoption grows, COB strips will dominate 2025’s lighting trends, offering smarter, sustainable solutions for every space.

Upgrade to Professional COB Lighting Today!

Explore Signlite’s premium COB LED strips:

- CRI 95+, RGB/RGBW, waterproof options

- Flexible, cuttable, and seamless designs

- Free shipping & 5-year warranty